Portable power tool

A hand-held machine tool and transmission mechanism technology, which is applied in the directions of manufacturing tools, power tools, portable mobile devices, etc., can solve the problems such as the incompetence of the twister, and achieve the effect of compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

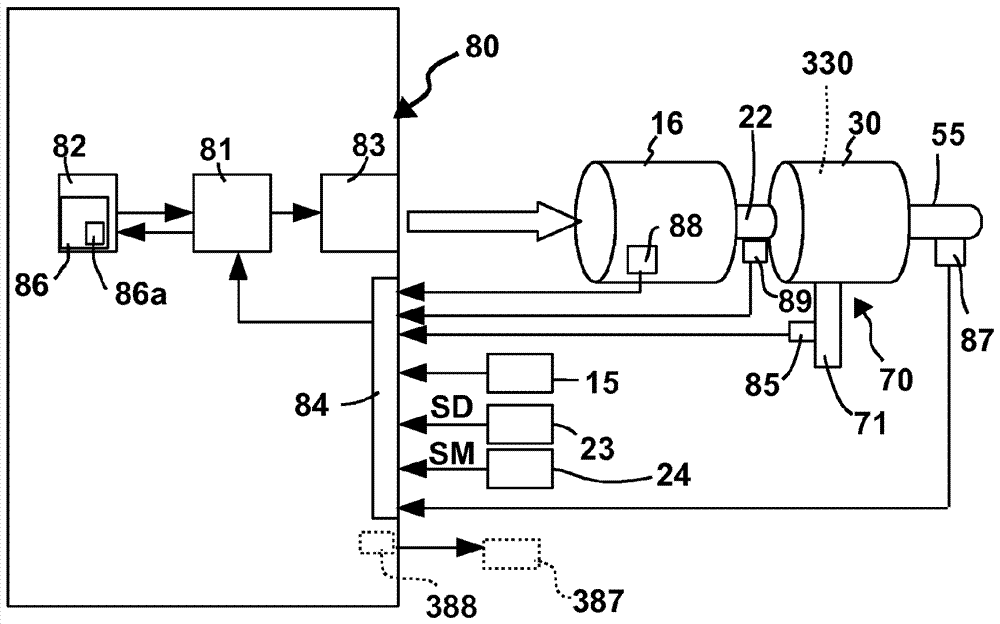

[0074] The hand-held power tool 10 has a housing 11 , in the interior of which a drive train 20 is arranged. Hand-held power tool 10 is, for example, a screwing instrument, a drilling instrument or both. The housing 11 can be comfortably gripped by an operator at a grip section 12 . The drive train 20 is accommodated in an upper housing section 13 that extends at an angle relative to the handle section 12 in the form of a pistol.

[0075] The front housing section 14 extends in front of a grip section 12 , which can be grasped, for example, by hand, wherein the grip section 12 and the housing section 14 are connected to one another via a lower housing section.

[0076]Connections, for example for grid cables 17 , are located on the lower housing section. It is also possible to arrange an accumulator or another mobile energy store on the housing section or, as shown in the exemplary embodiment, in the region of the front housing section 14 .

[0077] In each case it is poss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com