Pendulum shaft gyroscope coupled stepless speed changer

A continuously variable transmission, gyro technology, applied in the direction of friction transmission, belt/chain/gear, mechanical equipment, etc., can solve problems such as low efficiency, and achieve the effect of saving shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

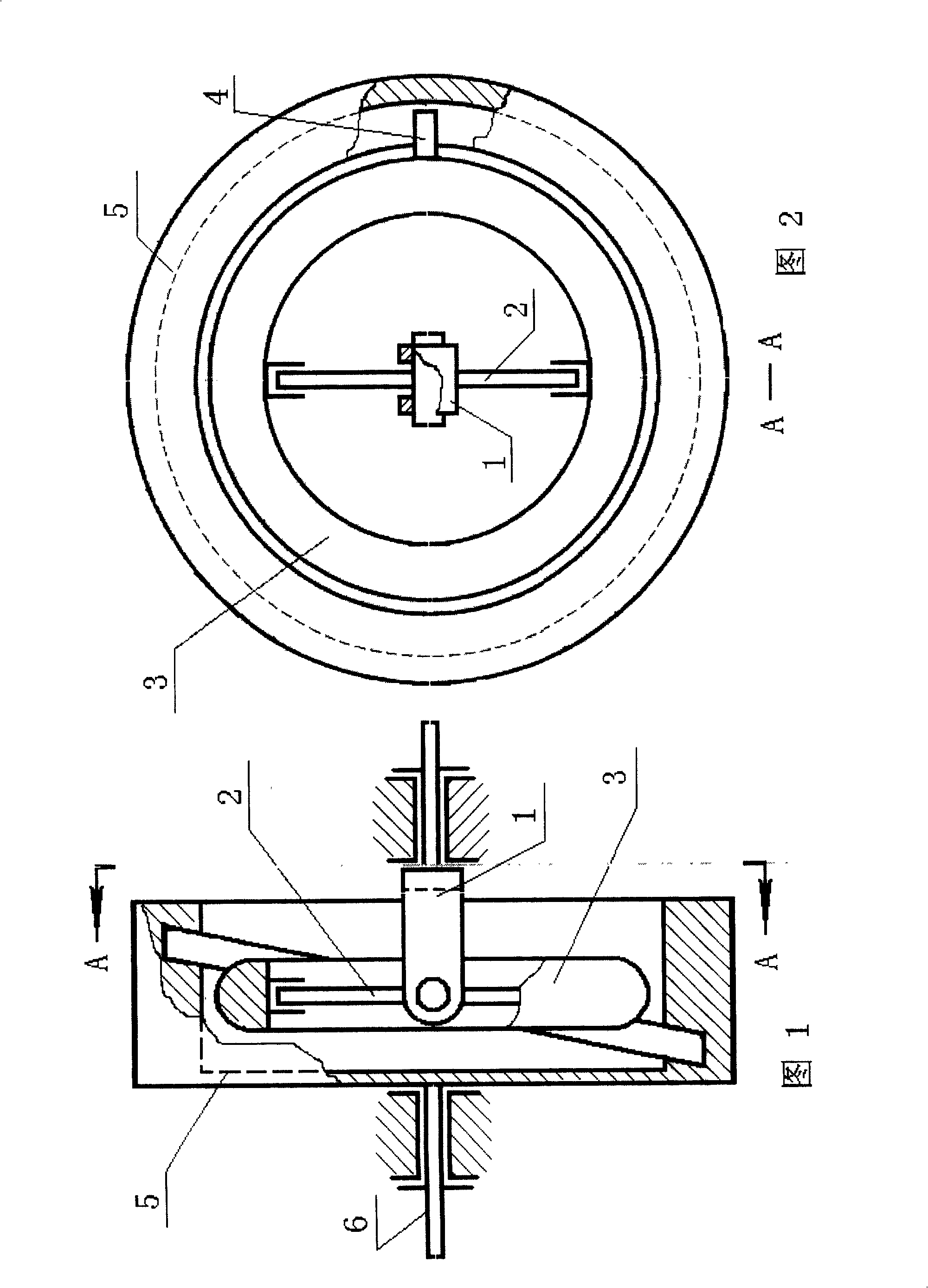

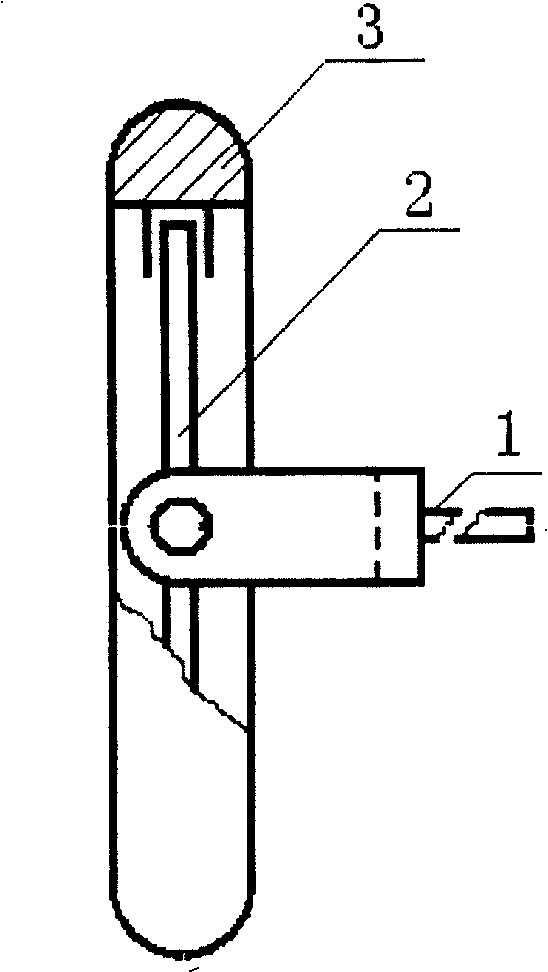

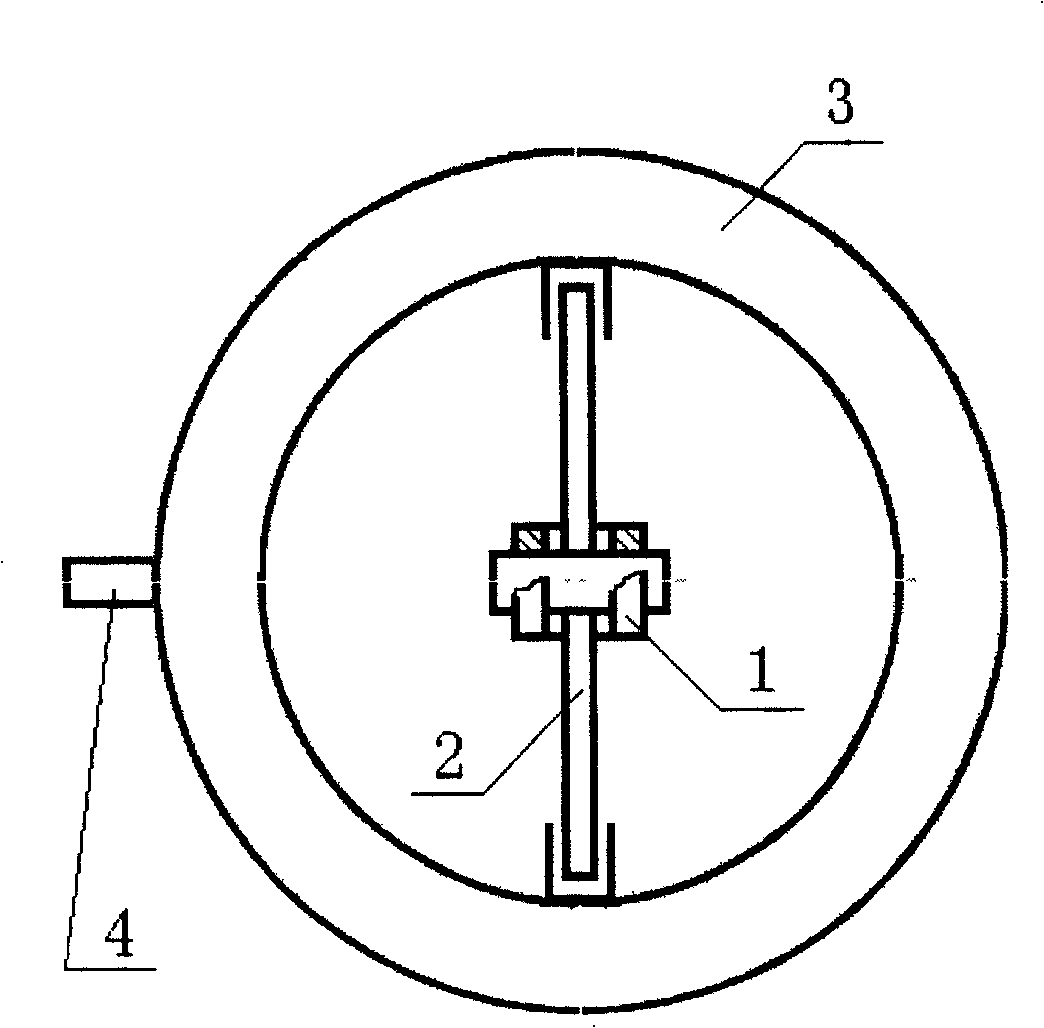

[0016] Embodiments of the present invention are shown in the accompanying drawings, in which 1 is an input shaft, 2 is a cross shaft, 3 is a top, 4 is a top balance shaft, 5 is a cam, and 6 is an output shaft. The input shaft 1 forms a universal connection with the top 3 through the cross shaft 2, and then connects with the cam 5 integrated with the output shaft 6 through the swing shaft 4 of the top. The rotational power input from the input shaft 1 makes the gyro 3 obtain kinetic energy and rotate through the universal connection, and the gyro effect is generated due to the restriction of the steering of the gyro 3 by the cam 5 through the gyro pendulum shaft 4, so that the gyro 3 generates self-rotation and corresponding Precession and nutation, due to the gyro effect through the dynamic action of the gyro pendulum shaft 4 on the cam 5, the power coupling between the gyro 3 and the cam 5 is realized, and then the output shaft 6 connected to the cam 5 generates a rotational t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com