Thick-painted cement-based waterproof coating

A waterproof coating, cement-based technology, applied in the field of cement-based waterproof coatings, can solve problems such as easy cracking, increase construction costs, time-consuming and labor-intensive, etc., and achieve the effect of large contact area, cost saving, and good elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

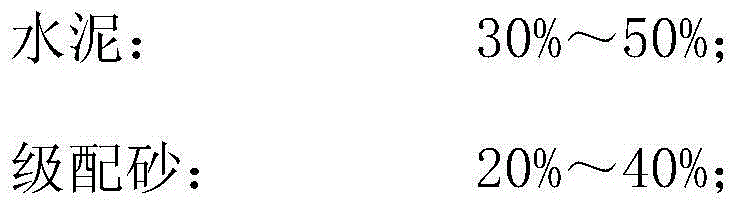

Method used

Image

Examples

Embodiment 1

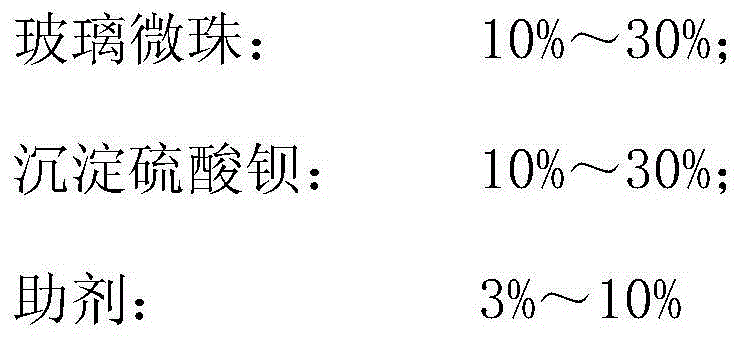

[0025] 1. Proportion the various raw materials according to Table 1 (weight ratio, the same below):

[0026]

[0027] 2. The preparation process is as follows:

[0028] Acrylic cationic high polymer emulsion, water, additives (defoamer, bactericide, plasticizer, propylene glycol, etc.) are weighed and added to the stirring tank, and the stirring tank is turned on for 15 minutes to disperse evenly to obtain the liquid material. Filling and packaging for use;

[0029] 32.5 white cement, river sand within the range of 40 mesh to 80 mesh + mountain sand within the range of 80 mesh to 120 mesh, glass beads with a particle size of 10 micron to 250 micron, and precipitated barium sulfate particles within the range of 200 mesh to 1250 mesh , naphthalene-based water reducer, etc., weighed and added to the mortar mixer, with a stirring speed of 300 rpm, started mixing and stirring for 5 minutes to disperse evenly, and then the powder was obtained, which was packaged for use.

[003...

Embodiment 2

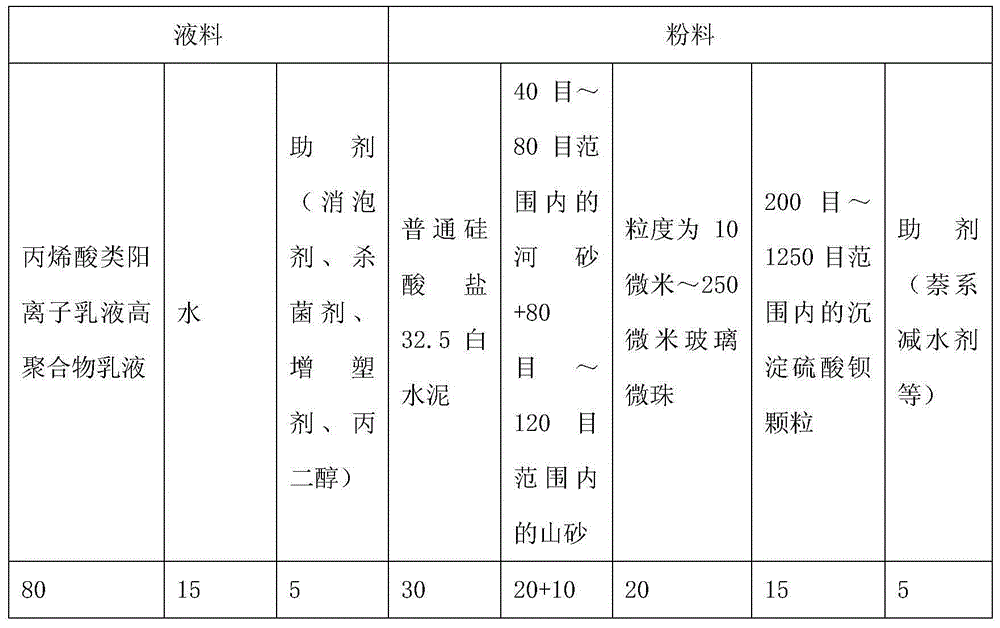

[0034] 1. Proportion the various raw materials according to Table 2 (weight ratio, the same below):

[0035]

[0036] 2. The difference between the preparation process and Example 1 is that the raw material composition ratio is in accordance with Table 2, and the others are the same as in Example 1.

[0037] 3. The method of using the thick-coated cement-based waterproof coating is as follows:

[0038] Put the liquid material into the bucket, turn on the electric mixer, stir the liquid material, add the powder material into the bucket, wherein the mass ratio of the liquid material to the powder material is 1:2, and mix and stir at a speed of 500 rpm for 3 minute. Roller coating plane and facade construction, the thickness of one construction can reach 1.5mm ~ 2.0mm, no cracking, no sagging, no slippage and other adverse phenomena.

[0039] The measured bonding strength is ≥2.8MPa; the elongation at break is ≥80%.

Embodiment 3

[0041] 1. Proportion the various raw materials according to Table 3 (weight ratio, the same below):

[0042]

[0043] 2. The difference between the preparation process and Example 1 is that the composition ratio of the raw materials is in accordance with Table 3, and the others are the same as in Example 1.

[0044] 3. The method of using the thick-coated cement-based waterproof coating is as follows:

[0045] Add the liquid material into the bucket, turn on the electric mixer, stir the liquid material, add the powder material into the bucket, wherein the mass ratio of the liquid material to the powder material is 1:2.5, and mix and stir at a speed of 500 rpm for 3 minute. Roller coating plane and facade construction, the thickness of one construction can reach 1.5mm ~ 2.0mm, no cracking, no sagging, no slippage and other adverse phenomena.

[0046] The measured bonding strength is ≥3.0MPa; the elongation at break is ≥50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com