Rubber concave-convex inner tooth guiding type synchronous polyester conveying belt

A tooth-guided conveyor belt technology, which is applied in the field of rubber concave-convex internal tooth-guided synchronous polyester conveyor belt, can solve the problems of unstable operation, easy slipping, and low operational reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

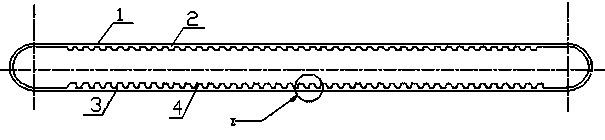

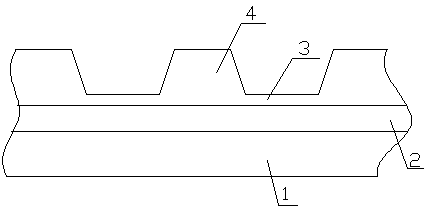

[0009] A rubber concave-convex internal tooth-guided synchronous polyester conveyor belt, comprising an upper cover rubber 1, a skeleton layer 2, and a lower cover rubber 3 that are sequentially pasted, and is characterized in that: the outer side of the lower cover rubber 3 is evenly arranged with irregularities in the lateral direction Internal tooth guide strip 4; the length of the concave-convex internal tooth guide strip 4 is the same as the width of the conveyor belt body; the cross-sectional shape of the concave-convex internal tooth guide strip 4 is an isosceles trapezoid, and its wide bottom surface is compounded with the lower cover rubber 3; The tooth height of the concave-convex inner tooth guide bar 4 is 10.4~10.6mm; the thickness of the upper cover rubber 1 is 10.0±0.2mm; the thickness of the skeleton layer 2 is 4.4±0.2mm; the lower cover rubber 3 The thickness of the conveyor belt is 1.0±0.2mm; the total thickness of the conveyor belt body (not including the conca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com