Laminated support for seismic isolation of low-rise buildings and manufacturing method thereof

A manufacturing method and construction technology, applied to buildings, building components, building structures, etc., can solve the problems of difficult popularization and application of steel plate/rubber laminated seismic isolation bearings, low seismic design standards, complicated manufacturing process, etc., to avoid Effects of poor adhesion, light weight, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

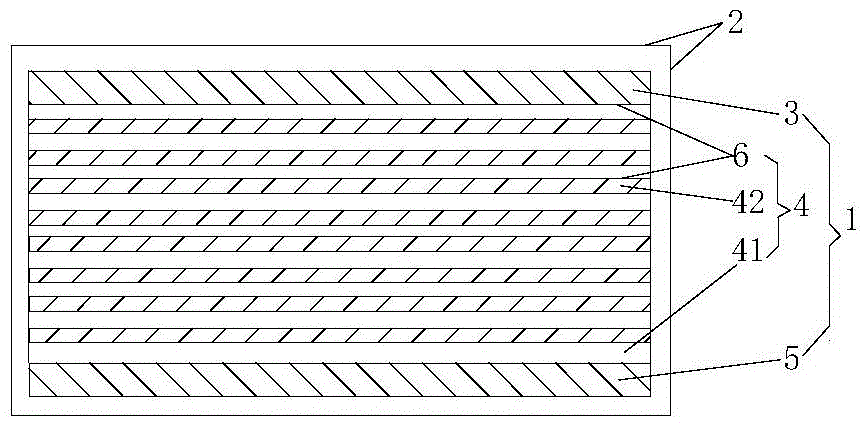

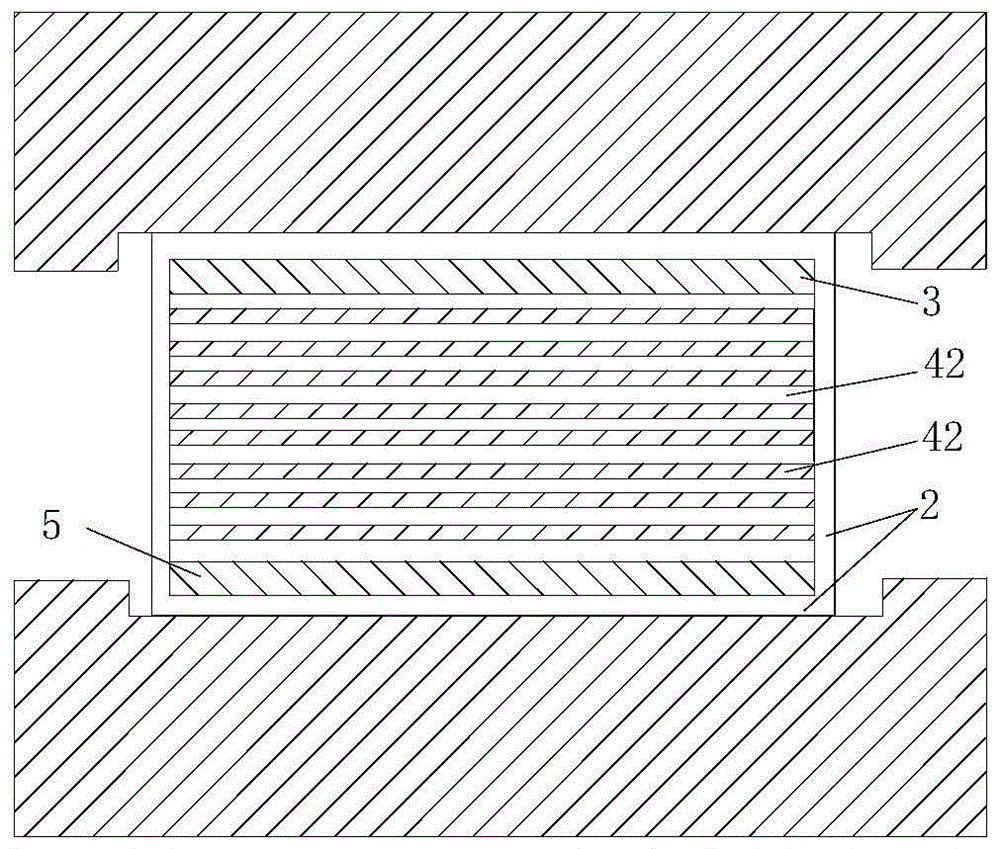

Embodiment 1

[0042] Such as Figure 1~4 The structure shown is one of the embodiments of a laminated support for low-rise building seismic isolation of the present invention, which includes a support main body 1, an outer protective layer 2 wrapping the support main body, wherein the support main body includes an upper Sealing layer 3, intermediate layer 4, and lower sealing layer 5; the intermediate layer 4 includes rubber layers 41 and bamboo-plastic composite board layers 42 that are alternately superimposed and fixed by adhesive layers 6, with a horizontal section that is square and of the same size. The thickness of the upper sealing layer 3 and the lower sealing layer 5 is greater than the thickness of the rubber layer 41 and the bamboo-plastic composite layer 42; the upper end surface of the upper sealing layer 3 and the middle layer 4 passes through the adhesive layer 6 are superimposed and fixed, and the lower end surface of the lower sealing plate layer 5 and the middle layer 4 i...

Embodiment 2

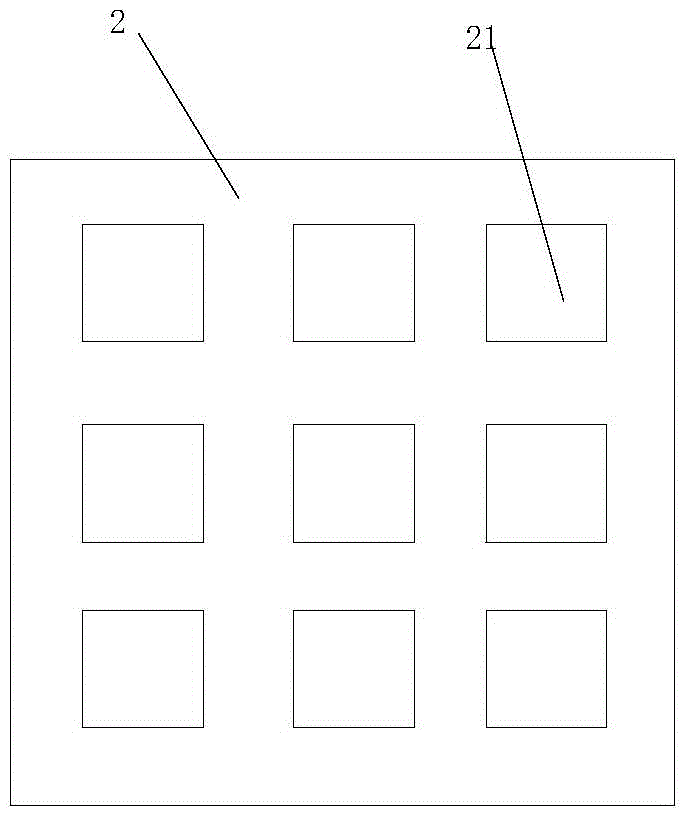

[0048] Such as Figure 5 The structure shown is the second embodiment of the present invention. It differs from Embodiment 1 in that: the horizontal section of the middle layer is circular, and the bamboo-plastic composite board layer has nine layers in total, and the thickness of each layer is 10mm; The above-mentioned rubber layer has ten layers in total, the thickness of each layer of rubber layer is 8mm, and the thickness of the upper sealing plate layer is 15mm.

Embodiment 3

[0050] Such as Image 6 The structure shown is the third embodiment of the present invention, and it differs from Embodiment 1 in that: the horizontal section of the middle layer is rectangular, and the bamboo-plastic composite board layer has ten layers in total, and the thickness of each layer is 2mm; The rubber layer has eleven layers in total, the thickness of each rubber layer is 2mm, and the thickness of the upper sealing plate layer is 4mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com