Wood-plastic composite board/rubber sheet laminated seismic isolation bearing for low-rise buildings in villages and towns and its manufacturing method

A technology of seismic isolation bearing and manufacturing method, which is applied in the directions of buildings, building components, building structures, etc., can solve the problems of difficult popularization and application of steel plate/rubber laminated seismic isolation bearings, low seismic design standards, and complicated manufacturing process. , to achieve good application prospects, avoid poor bonding, and the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

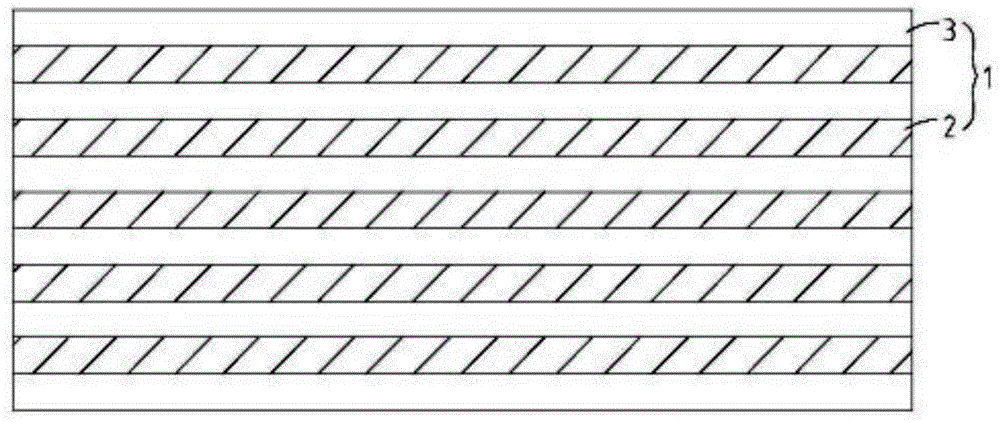

[0035] like figure 1 As shown, the wood-plastic composite board / rubber sheet laminated seismic isolation bearing for low-rise buildings in villages and towns of the present invention comprises a bearing body 1, and the bearing body includes a rubber sheet 3 and a wood-plastic composite board 2, and the rubber sheet 3 and the The wood-plastic composite boards 2 are alternately stacked, and the two outer layers of the support body 1 are rubber sheets 3 , and the support body 1 includes 5-10 layers of wood-plastic composite boards 2 . Preferably, the low-rise building is a 1-5 storey building. Preferably, the thickness of the wood-plastic composite board 2 is 2-8 mm, and the thickness of the rubber sheet 3 is 2-8 mm. Further preferably, the horizontal section of the support body 1 is rectangular or circular.

Embodiment 2

[0037] The manufacturing method of the wood-plastic composite board / rubber sheet laminated seismic isolation bearing for low-rise buildings in villages and towns of the present invention comprises the following steps:

[0038] S1. Production of wood-plastic composite panels:

[0039] The wood flour with a particle size of 40 meshes was placed in a high-speed mixer, vacuum-dried at 90°C for 12 hours, and set aside for use;

[0040] S101, put 65 parts by mass of isotactic polypropylene, 25 parts by mass of wood powder and 5 parts by mass of acicular wollastonite with a particle size of 40 μm into a high-speed mixer, after dispersing at 200 r / min for 1 h, the temperature is raised to 105 ℃, then add 2 parts by mass of maleic anhydride grafted polypropylene and 0.5 part by mass of A-171 silane coupling agent, disperse at 300 r / min for 3 minutes, put it into a cold mixing pot to cool, and wait until the temperature drops to 50 ℃ When the material is discharged, the initial mixtu...

Embodiment 3

[0048] In the present embodiment, the manufacturing method of the wood-plastic composite board / rubber sheet laminated seismic isolation bearing for low-rise buildings in villages and towns includes the following steps:

[0049] S1. Production of wood-plastic composite panels:

[0050] The wood flour with a particle size of 80 meshes was placed in a high-speed mixer, vacuum-dried at 95°C for 12 hours, and set aside for use;

[0051] S101, put 60 parts by mass of poly-1-butene, 30 parts by mass of wood powder and 15 parts by mass of talc powder with a particle size of 20 μm into a high-speed mixer, disperse at 260r / min rotating speed for 2h, then heat up to 110°C, Then add 4 parts by mass of maleic anhydride grafted polypropylene and 0.9 parts by mass of A-151 silane coupling agent, disperse at 350r / min for 5min, put it into a cold mixing pot to cool, and put it when the temperature drops to 50°C. material to obtain the initial mixture;

[0052] S102, placing the initial mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com