Ball bearing screw pump

A technology of ball screw and ball, which is applied in the direction of pumps, rotary piston pumps, liquid fuel engines, etc., can solve the problems of reducing the service life of the driving screw and the driven screw, the cooperation effect cannot be guaranteed, and the efficiency of the conveying medium is reduced. The effect of medium conveying efficiency, saving driving energy, and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

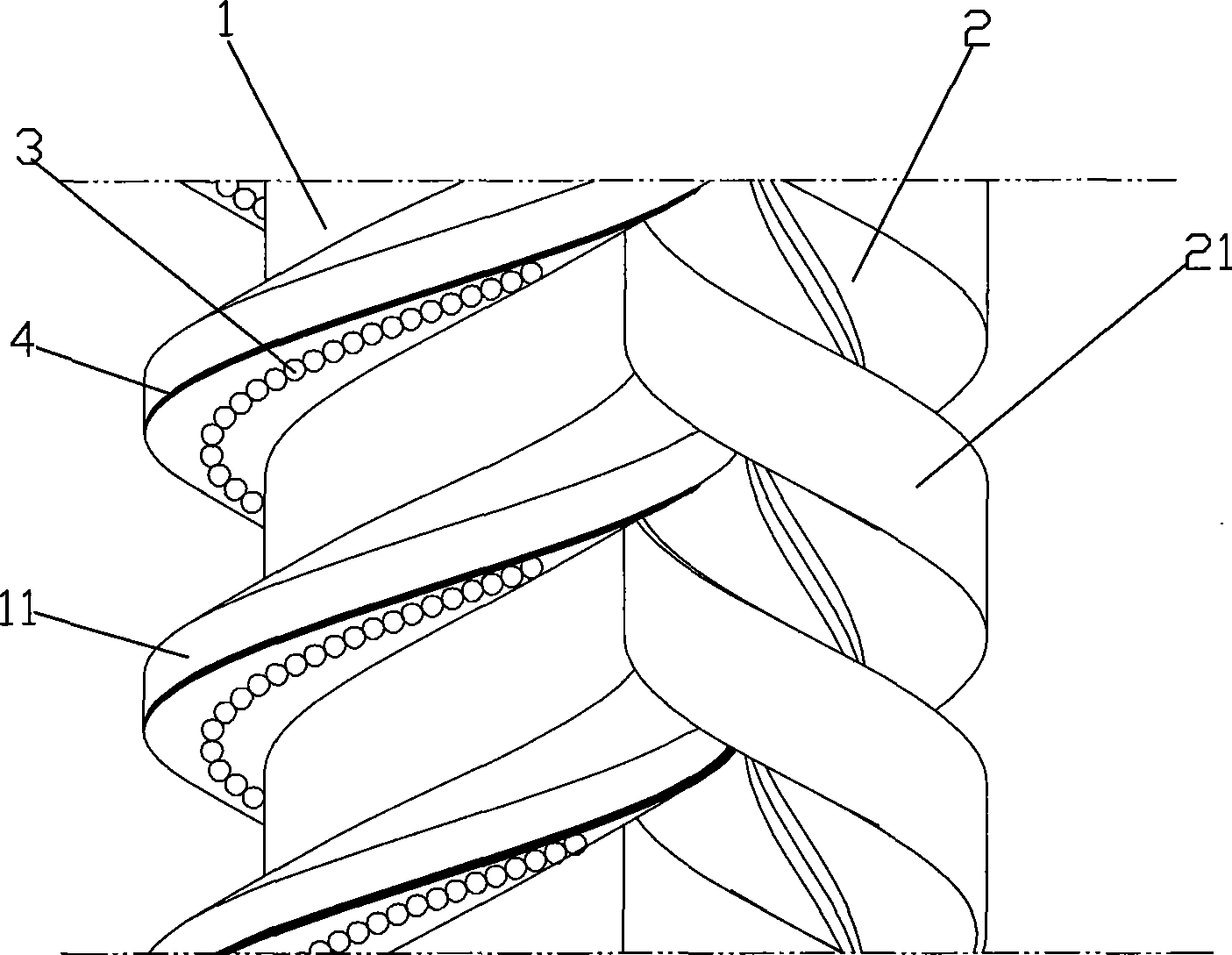

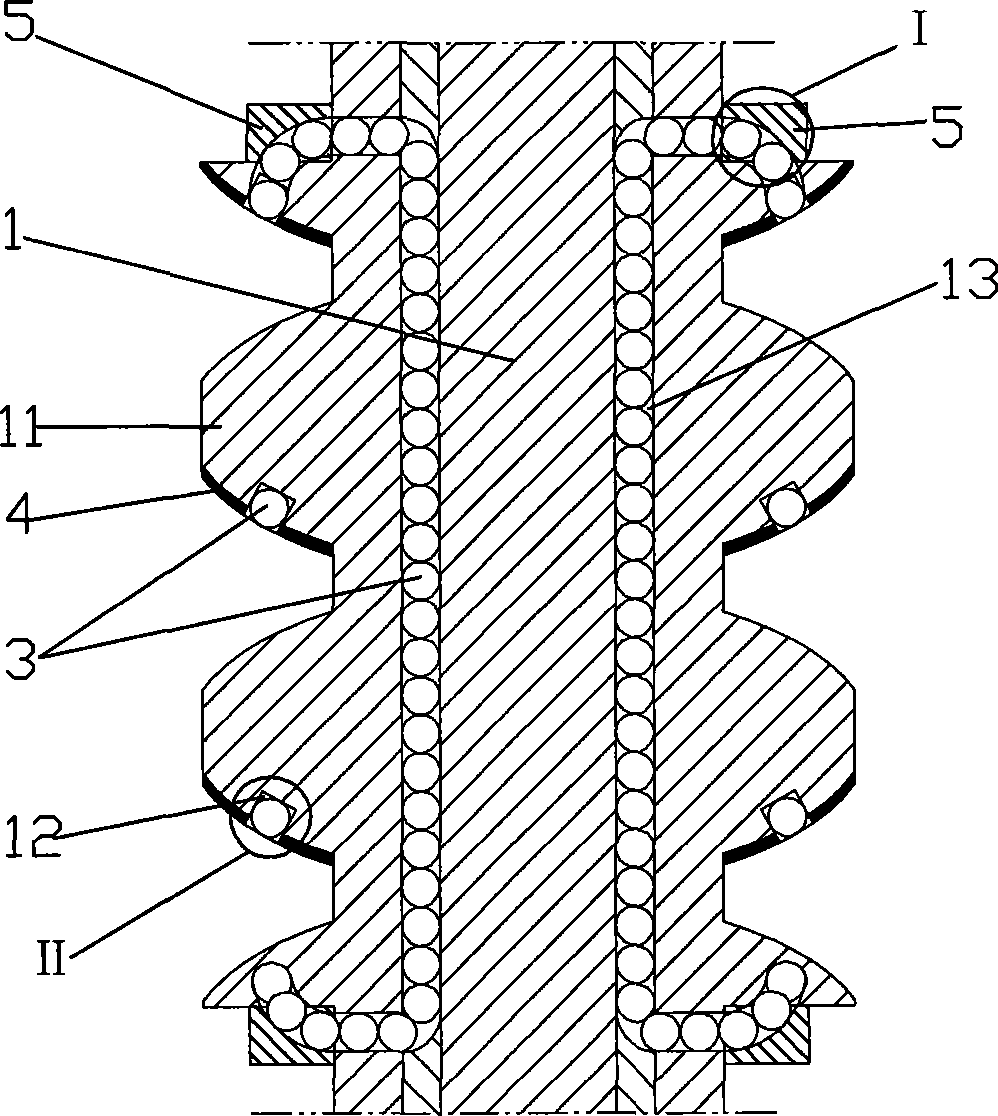

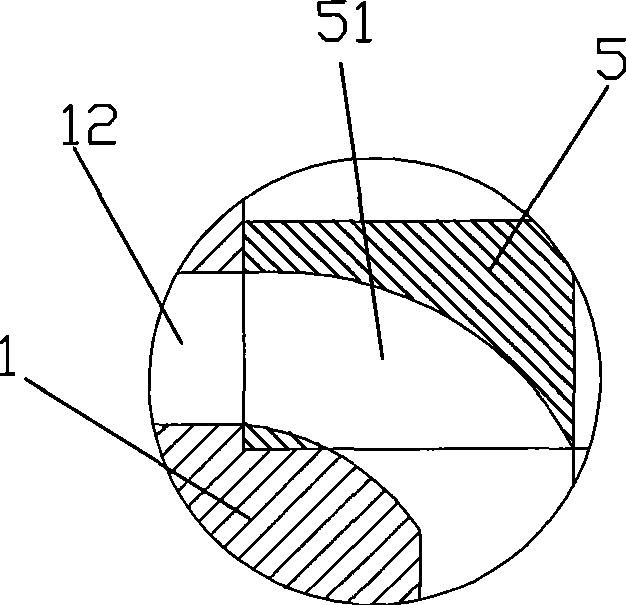

[0021] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 Set up a structural cutaway view for the ball, image 3 for figure 2 Enlarged view at I, Figure 4 for figure 2 The enlarged view at II, as shown in the figure: the ball screw pump of this embodiment includes a driving screw 1 and a driven screw 2 that are engaged with each other. Engaging, the intermeshing helical surfaces are provided with ball grooves 12 along the helix 11 of the active screw 1, and balls 3 are arranged side by side along the ball grooves 12. The diameter of the balls 3 is larger than the depth of the ball grooves 12; The ball return track 13, the number of the ball return track 13 is the same as the number of heads of the driving screw 1, so as to communicate with the ball groove 12 on each helix 11; the two ends of the ball return track 13 respectively transition smoothly with the two ends of the ball groove 12 Connected, balls 3 are filled in the ball re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com