Fracturing type rock tensile strength test apparatus and method

A technology of tensile strength and testing equipment, which is applied in the direction of measuring equipment, strength characteristics, and the use of stable tension/pressure to test material strength, etc. It can solve the problem of eccentric compression of samples, difficulty in unifying fracturing effects, complicated and cumbersome operations, etc. problem, to achieve the effect of reducing mass and volume, reliable test results, and uniform damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

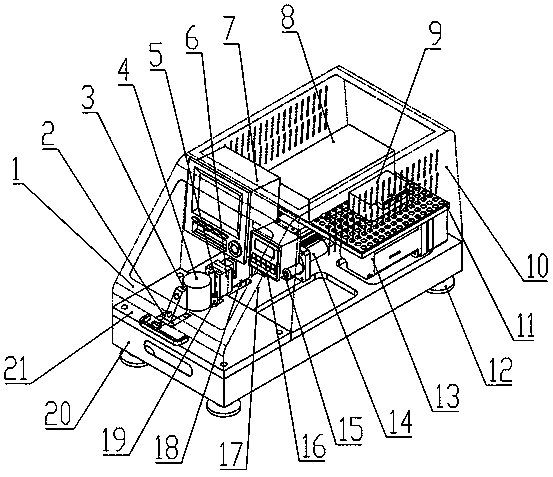

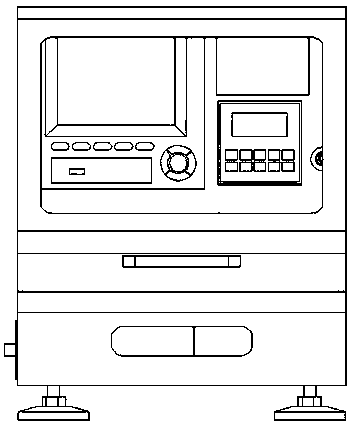

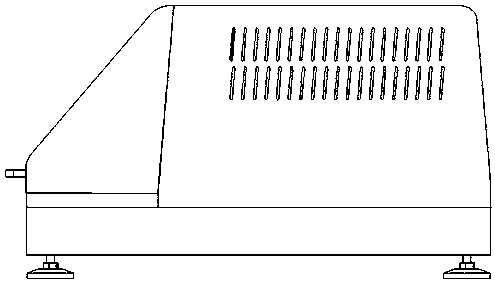

[0062] Such as Figure 1~4 As shown, a fracturing type geotechnical tensile strength testing device includes two parts, a mechanical structure and a control device. The mechanical structure includes a front cover 1 and a machine cover 10, and the front cover 1 and the machine cover 10 are fixed on the frame platform On the top 20, the front part of the frame platform 20 is fixed with a passive fracturing rod 3 and an active fracturing rod 5, the fracturing rod is in a columnar shape, the passive fracturing rod 3 is in a fixed state, and the active fracturing rod 5 is controlled by the electric cylinder 14 Drive the passive fracturing rod 3 to move, and place the sample 4 between the passive fracturing rod 3 and the active fracturing rod 5;

[0063] The control device includes a data processor 7, a power module 8, a stepping driver 9, a stepping motor 13, an electric cylinder 14, a power switch 15, a rate controller 16, a displacement sensor 17, and a pressure sensor 18. Mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com