Modular PE pipe water activity platform

A movable platform, modular technology, applied in the direction of floating buildings, etc., can solve the problems of easy rust or brittle water leakage, lack of rigidity, serious safety hazards, etc., to reduce labor and maintenance costs, no electric shock hazard, and maintenance costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

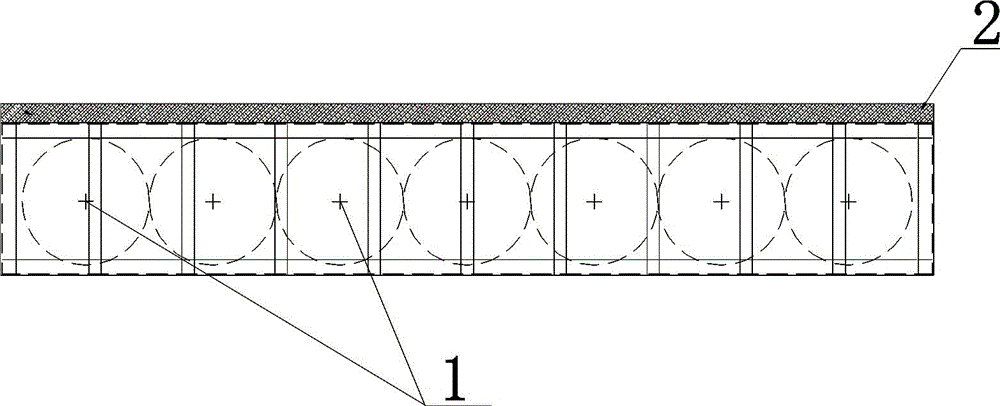

[0028] PE pipe floating body 1: 7 dn400PE pipes with a fixed length of 12m are used, and the ends of the pipes are sealed by hot-melt welding with PE pipe caps. Because the density of PE pipes is 0.95g / m3, which is less than that of water, and because it is a hollow pipe, Therefore, greater buoyancy will be generated.

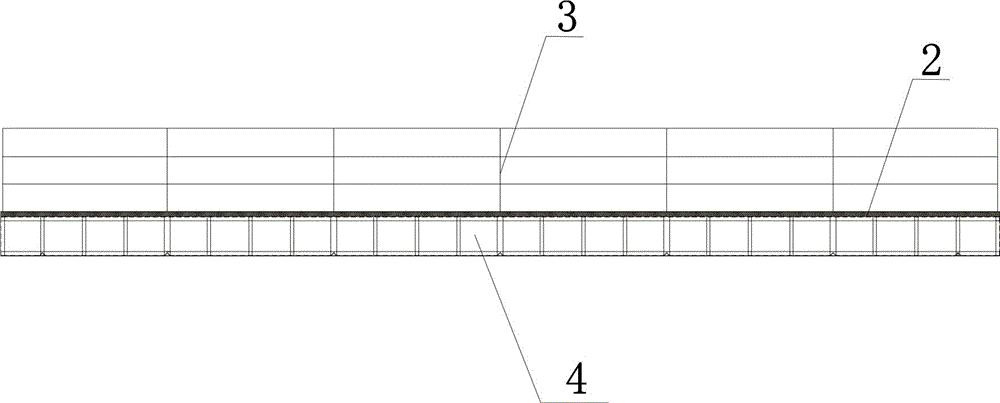

[0029] Single-section floating raft platform 2: The single-section floating raft platform 2 is a reinforced concrete structure with a length of 12m, a width of 3m, and a thickness of 40mm, with anti-skid stripes on the surface and wood grain paint. The single-section floating raft platform 2 is connected as a whole by the galvanized angle steel frame and the PE pipe floating body 1 .

[0030] Floating raft guardrail 3: adopt special plastic steel guardrail, its color is consistent with the color of the wood grain paint of the single-section floating raft platform 2, the guardrail is 1.1m high, a horizontal bar at the bottom, 0.11m away from the platform, and tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com