Pole piece fly-cutting mechanism and pole piece fly-cutting method

A pole piece and flying cutting technology, which is applied in the field of lithium battery automation equipment, can solve the problem of low cutting efficiency of the pole piece, and achieve the effect of simple and ingenious structure, guaranteed work efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific drawings.

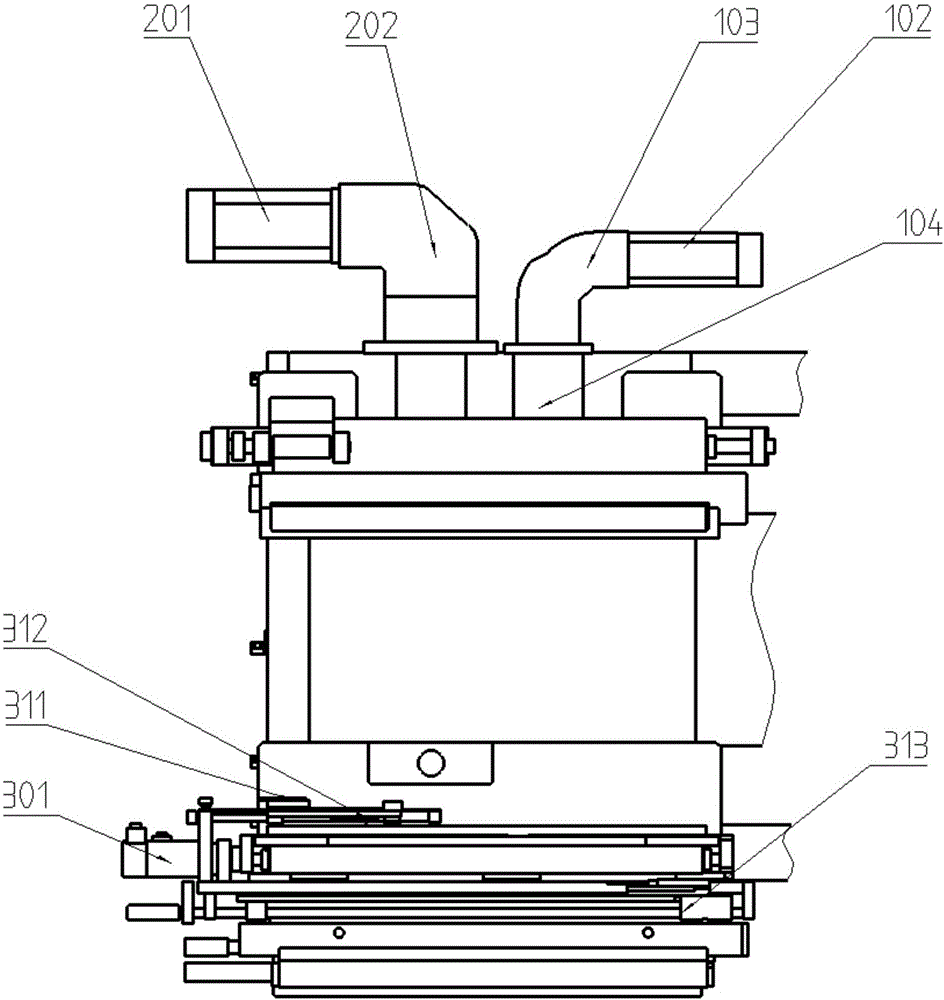

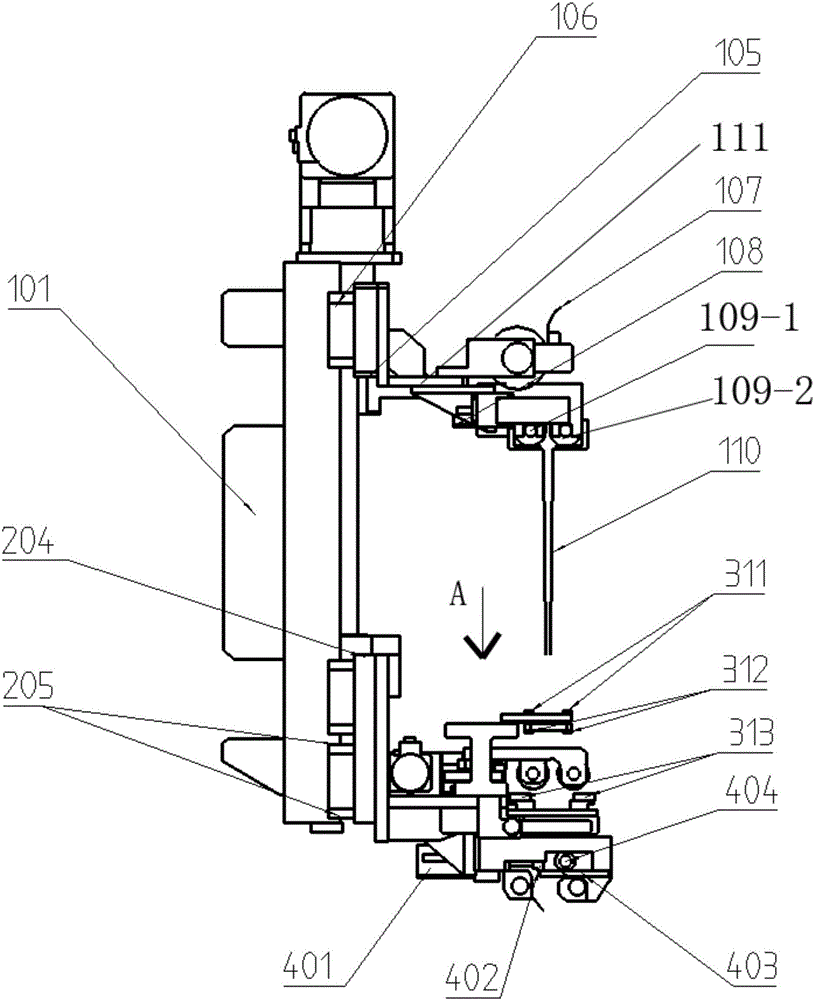

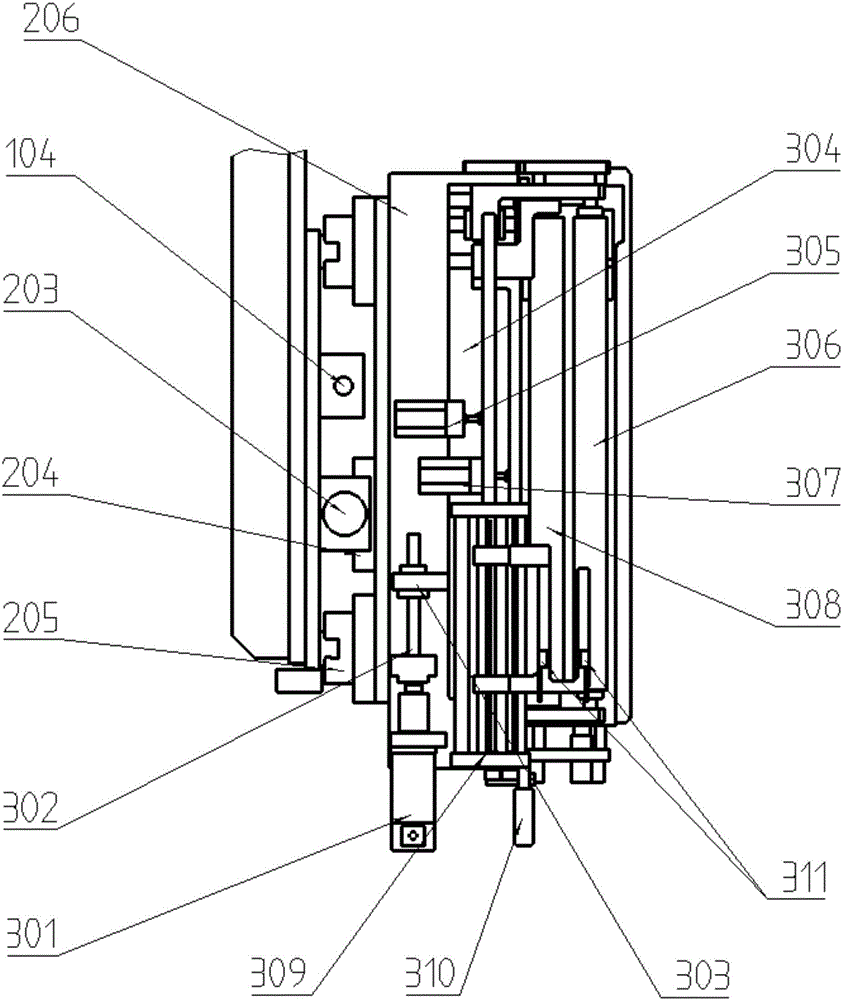

[0027] Such as Figure 1 ~ Figure 3 As shown: the pole piece flying cutting mechanism includes a bottom plate 101, a first servo motor 102, a first reducer 103, a first screw rod 104, a first connecting block 105, a first slider 106, a baffle 107, a first Clamping cylinder 108, first clamping roller 109-1, frame roller 109-2, clip 110, first connecting plate 111, second servo motor 201, second reducer 202, second screw mandrel 203, the second Two connecting block 204, the second slider 205, the second connecting plate 206, the third servo motor 301, the third screw mandrel 302, the third connecting block 303, the third connecting plate 304, the second clamping cylinder 305, the second Clamp roller 306, third clamp cylinder 307, third clamp roller 308, sensor bracket 309, adjustment knob 310, first sensor 311, second sensor 312, third sensor 313, cutter cylinder 401, moving kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com