Calibration and detection equipment of vehicle main girder

A technology for testing equipment and automobiles, used in vehicle maintenance, measuring devices, vehicle maintenance/repair, etc., can solve the problems of non-calibration, labor-intensive, scrapped main beams, etc., to achieve easy production, high efficiency, time saving and effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

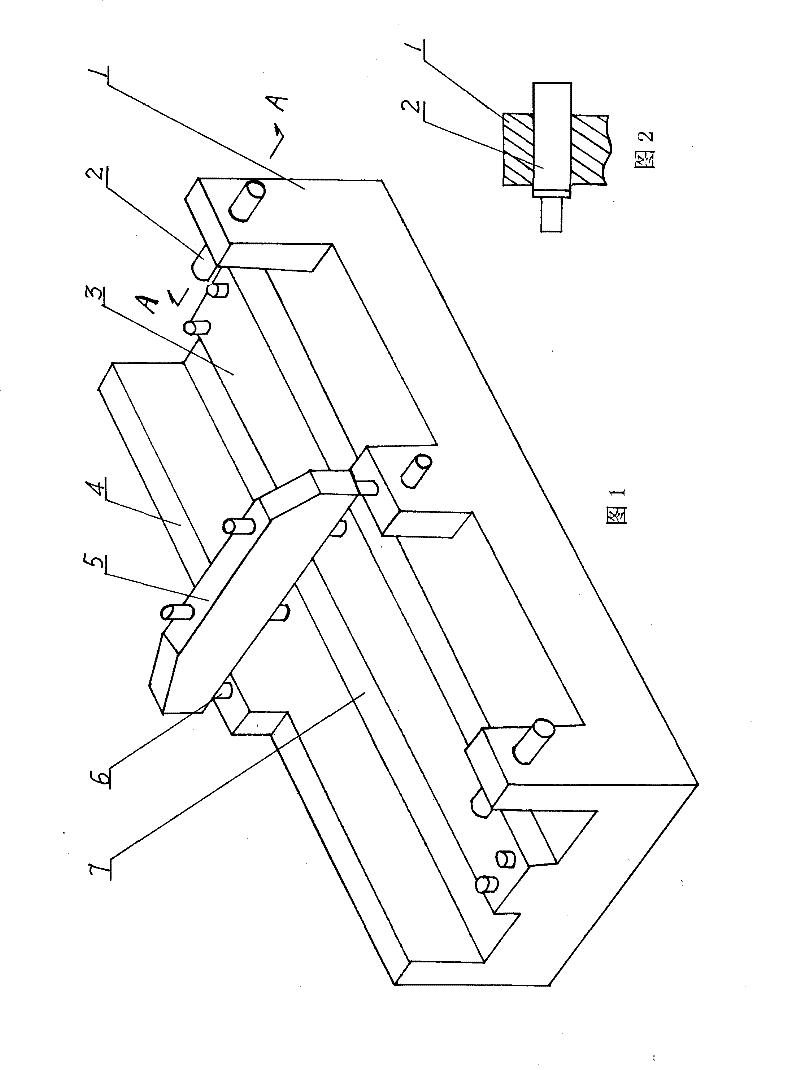

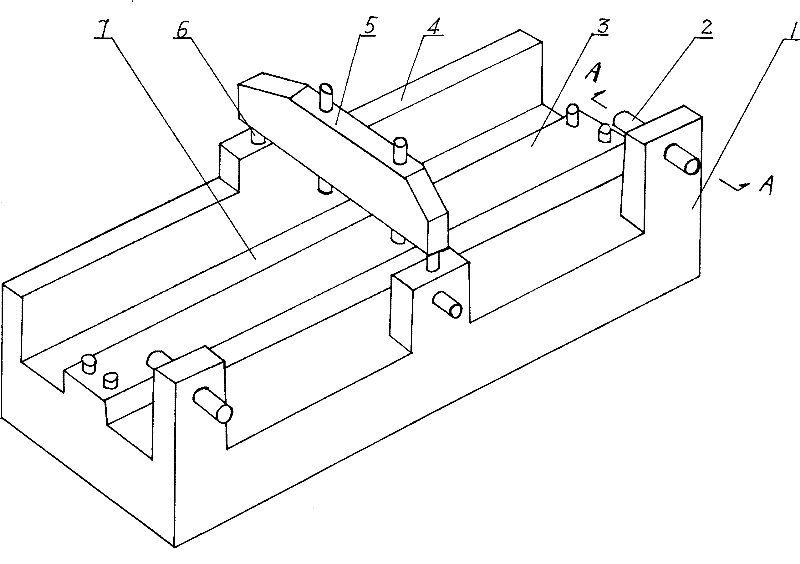

[0014] The present invention comprises a platform 7, the rear of the platform 7 is a baffle 4, the front of the platform 7 is a column 1, a beam 5 is arranged between the column 1 and the baffle 4, and a roof is arranged on the column 1, the platform 7, and the beam 5 respectively. The oil inlet cylinder 2; the vertical column 1 and the baffle plate 4 on both sides of the beam 5 are respectively provided with a lifting oil cylinder 6.

[0015] Columns 1 can be arranged in the middle and both sides of the platform 7;

[0016] A boss 3 may be arranged in the middle of the platform 7; in order to adapt to the correction and detection of the main girder of a large truck.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com