Patents

Literature

139 results about "Beam hardening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

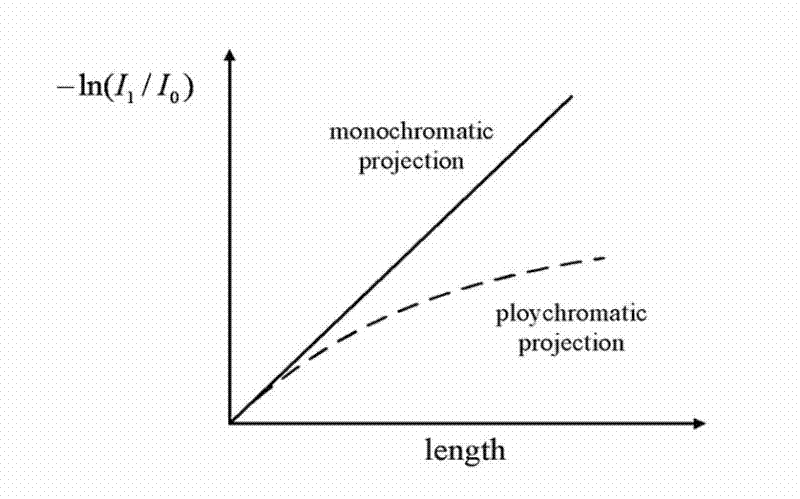

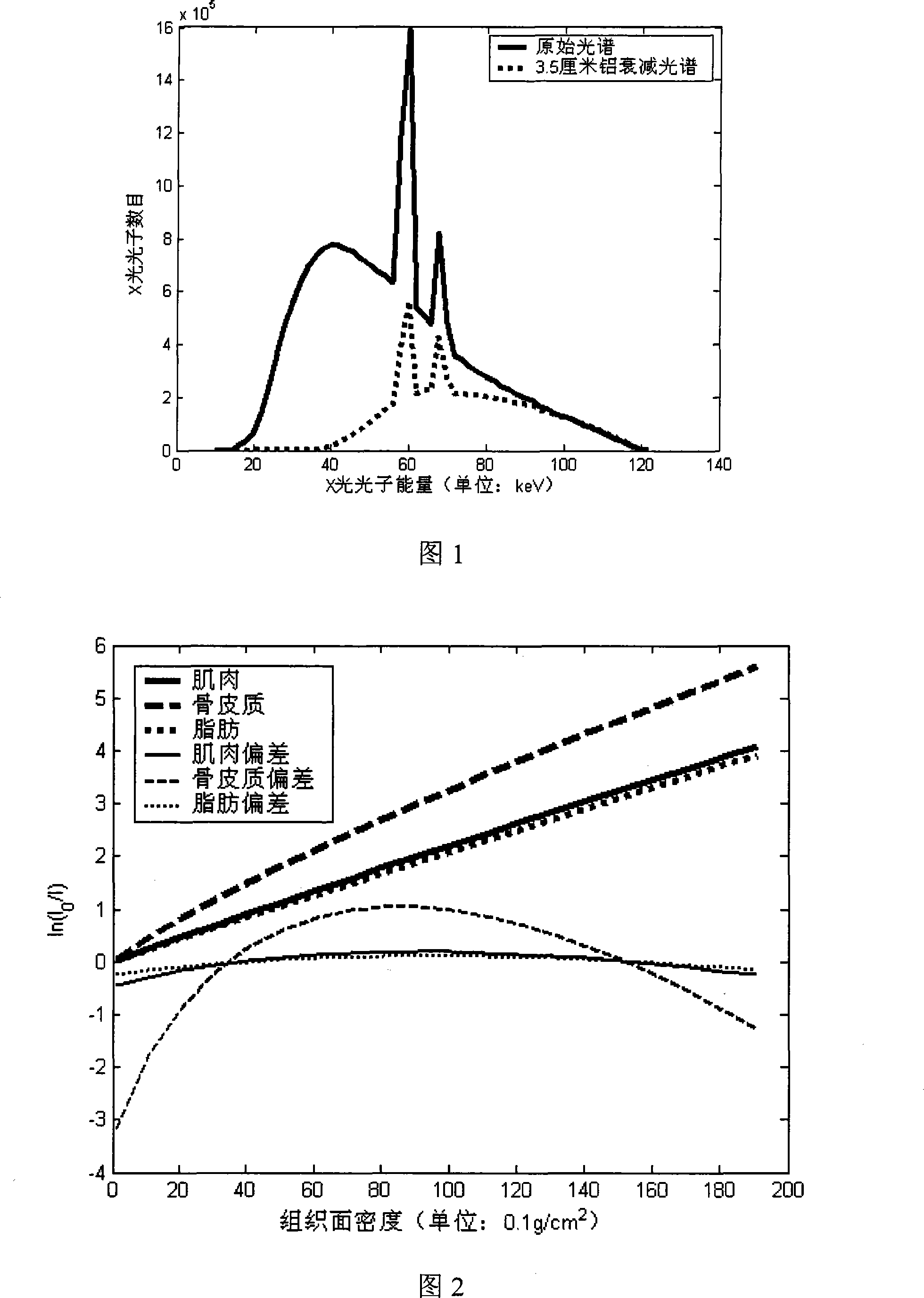

Beam hardening is the phenomenon occurring when an x-ray beam comprised of polychromatic energies passes through an object, resulting in selective attenuation of lower energy photons. The effect is conceptually similar to a high-pass filter, in that only higher energy photons are left to contribute to the beam...

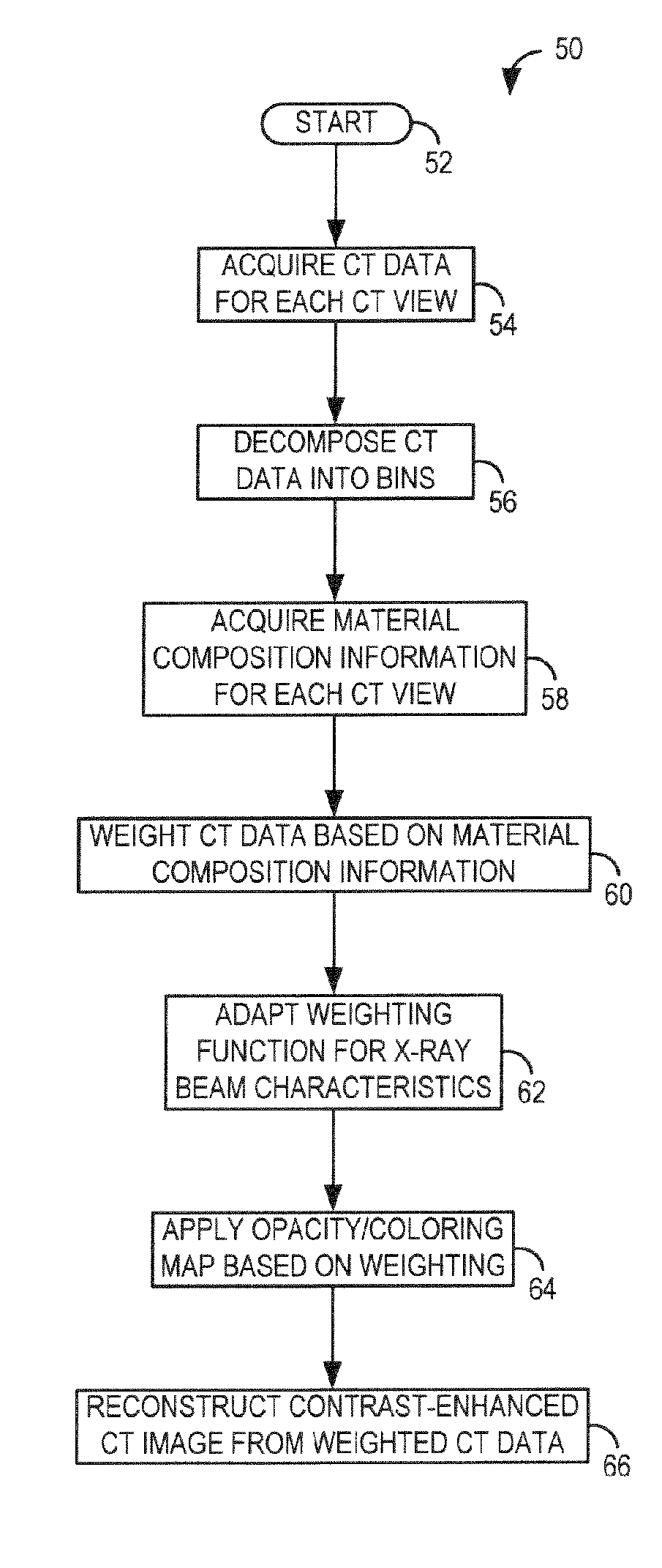

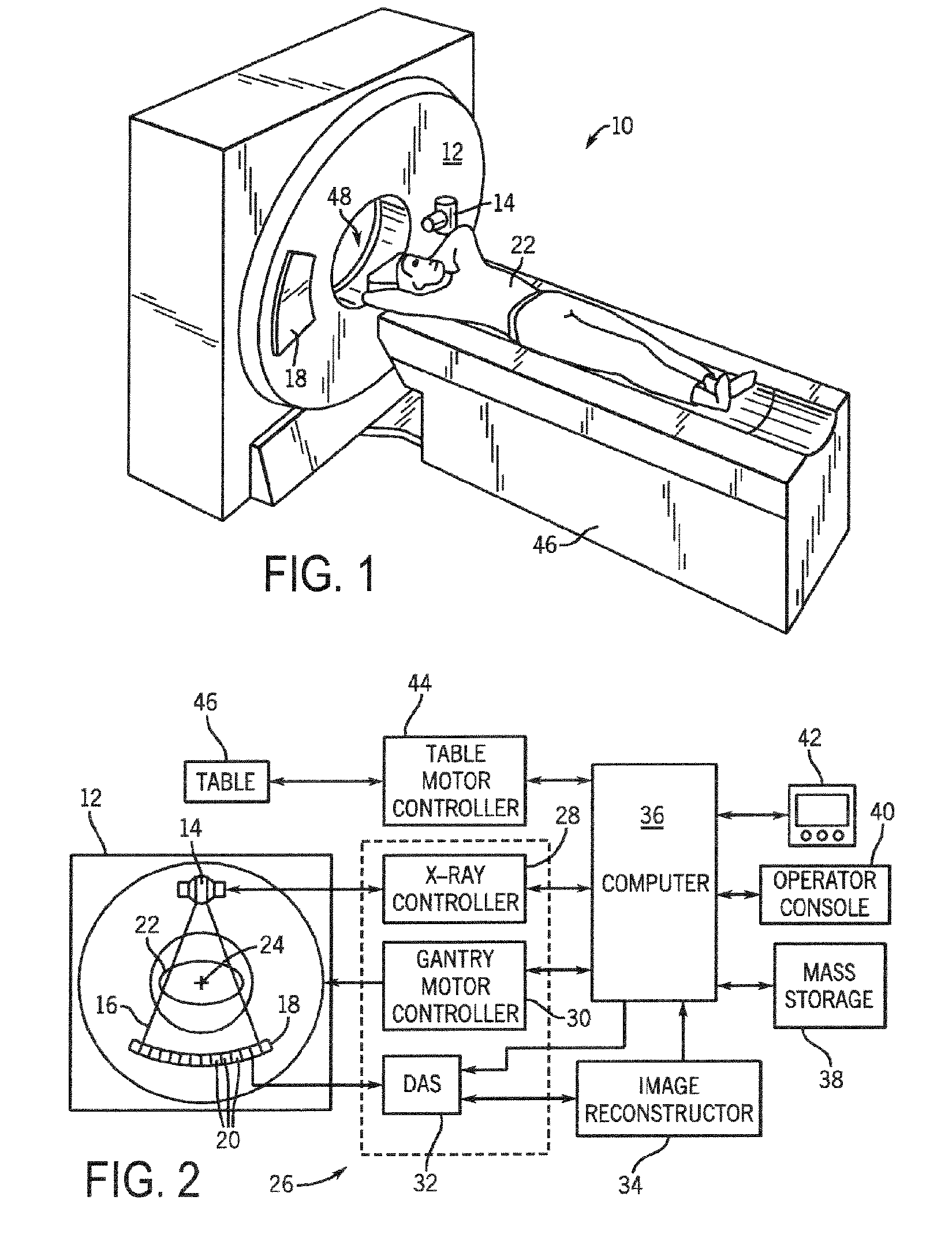

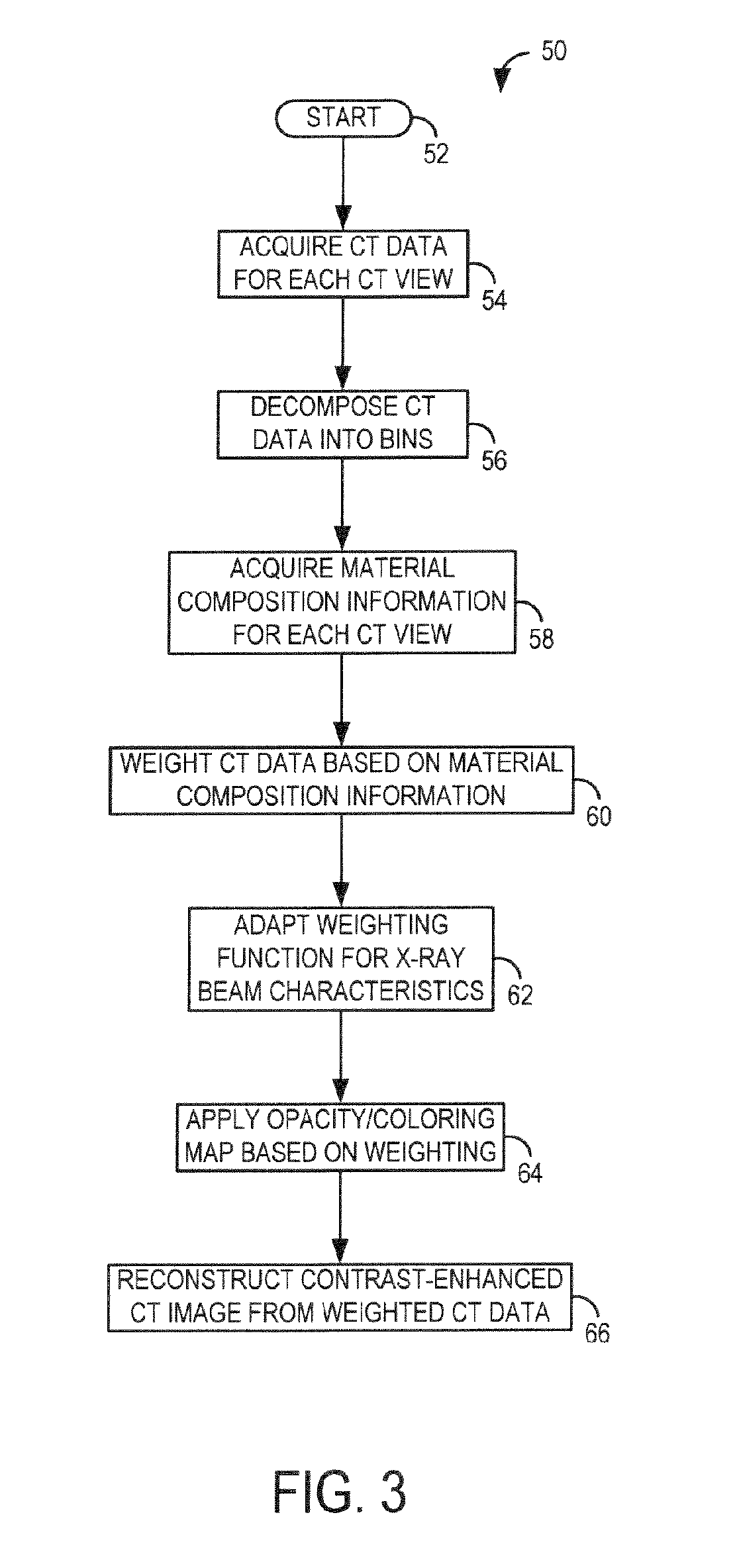

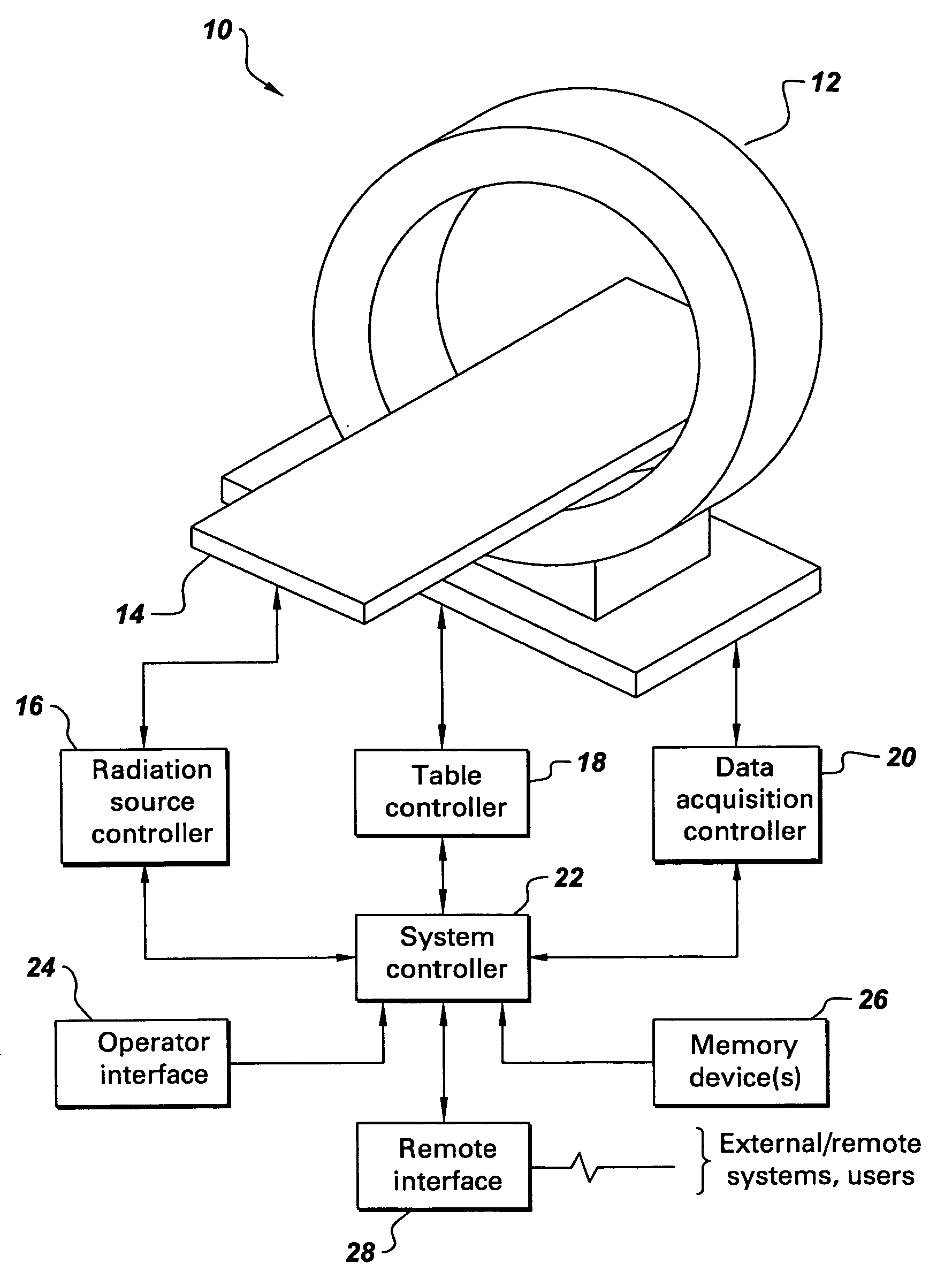

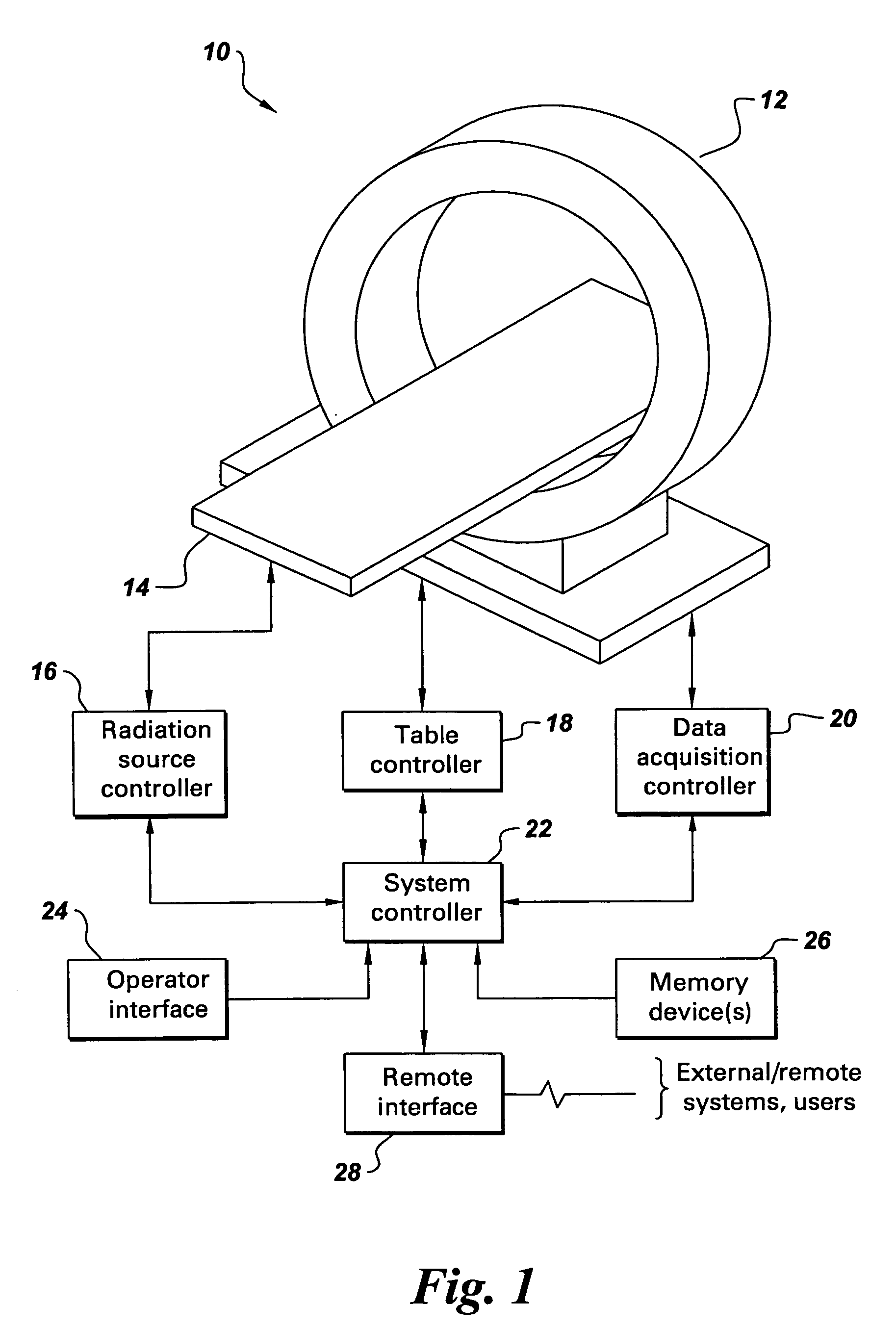

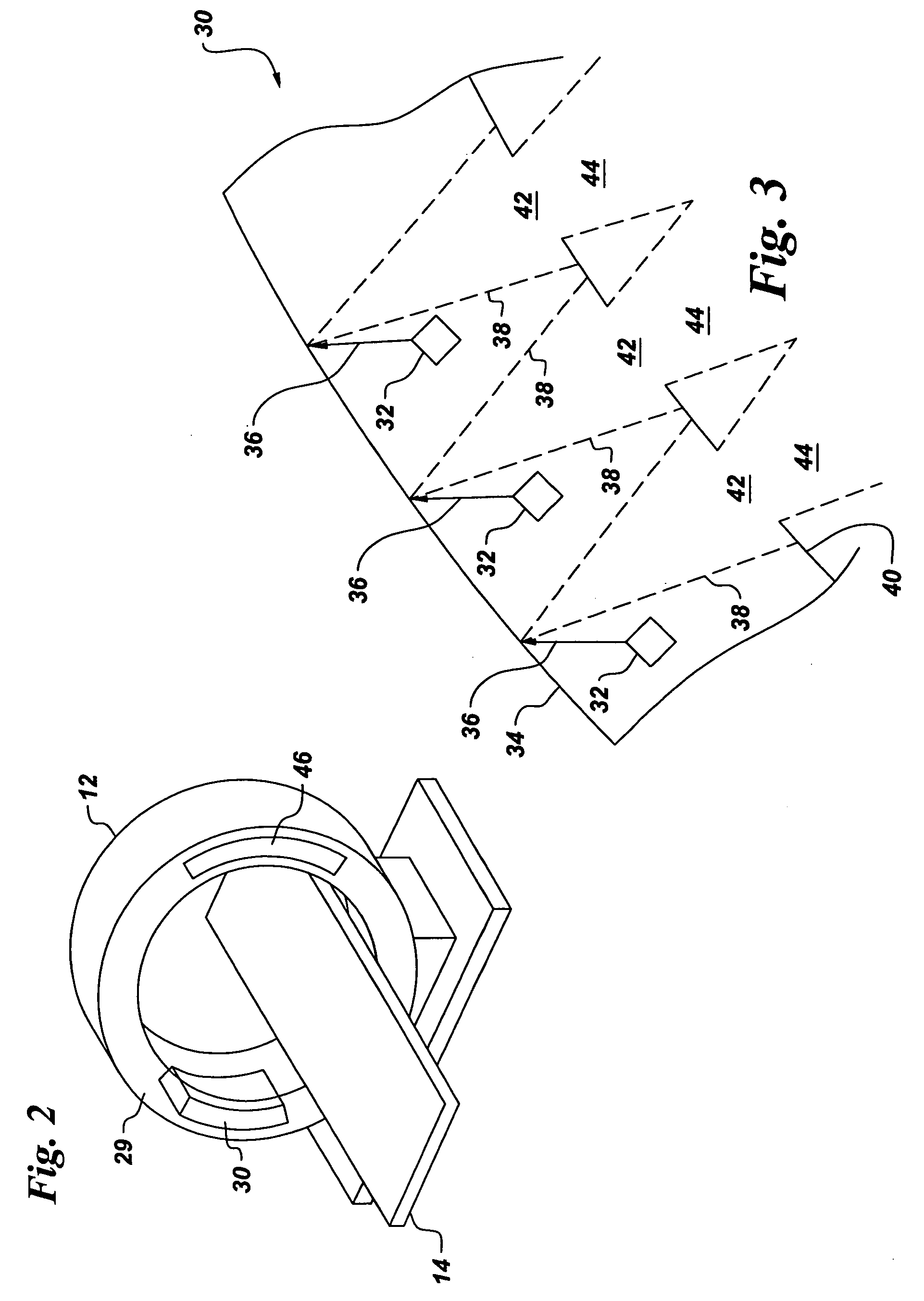

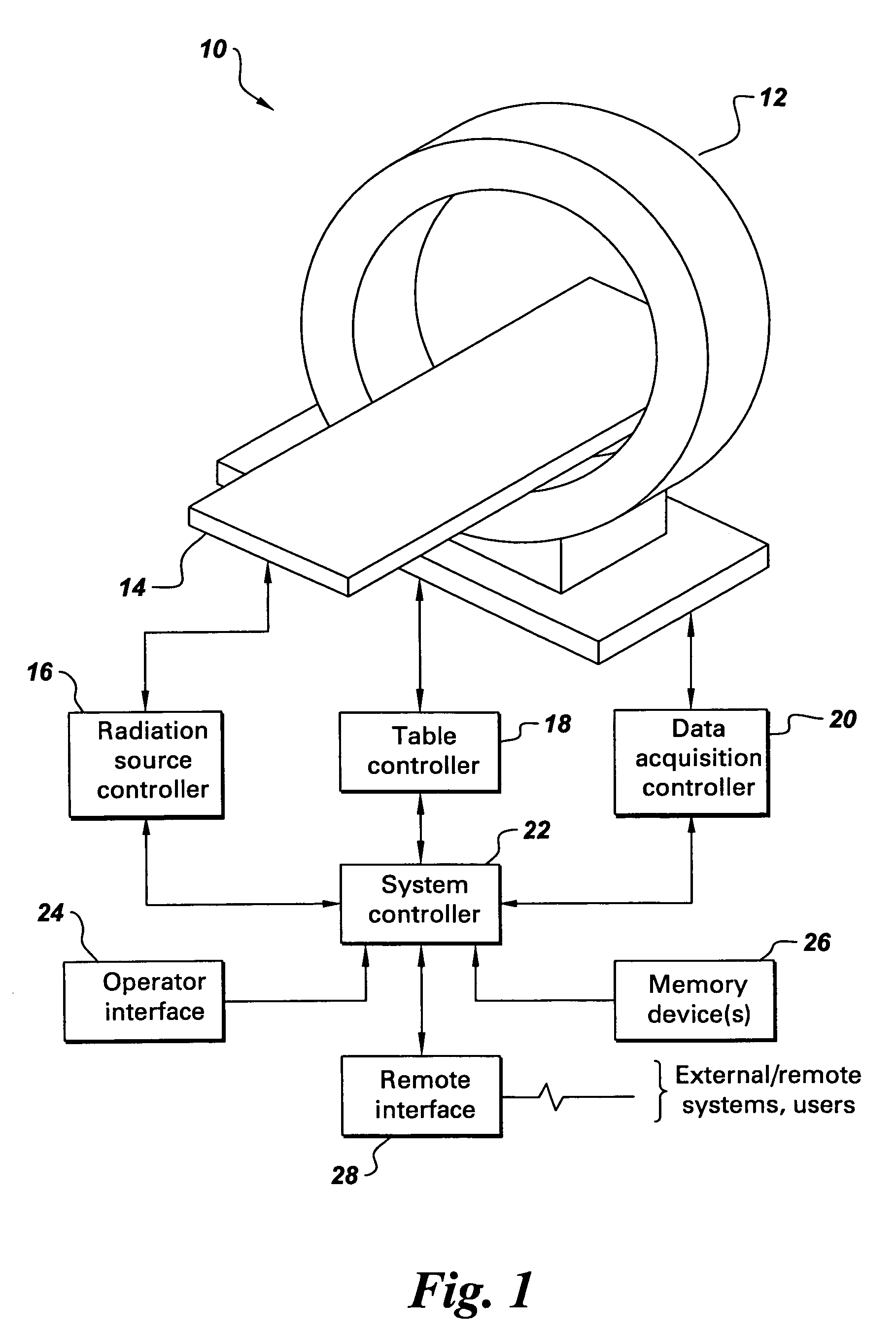

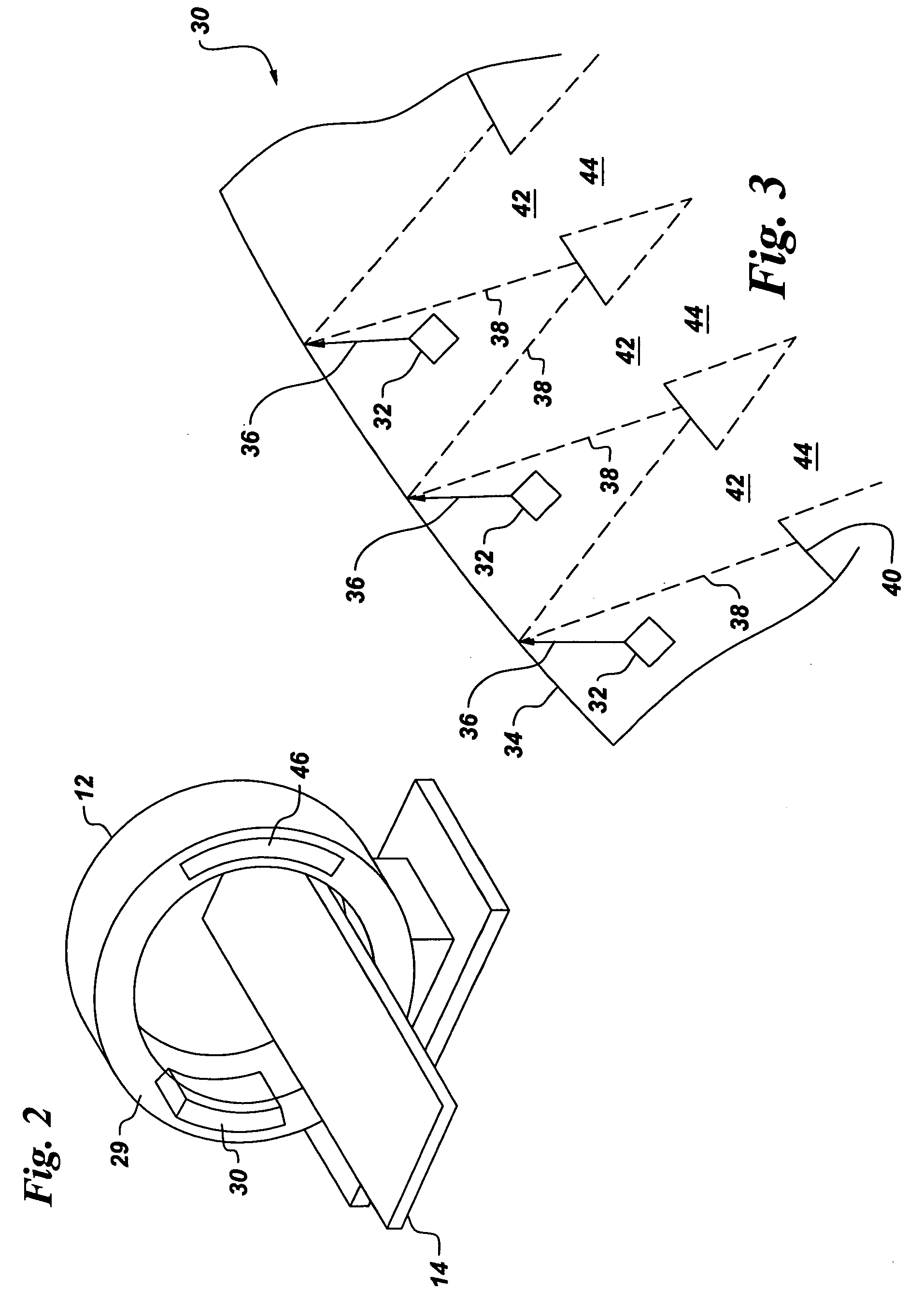

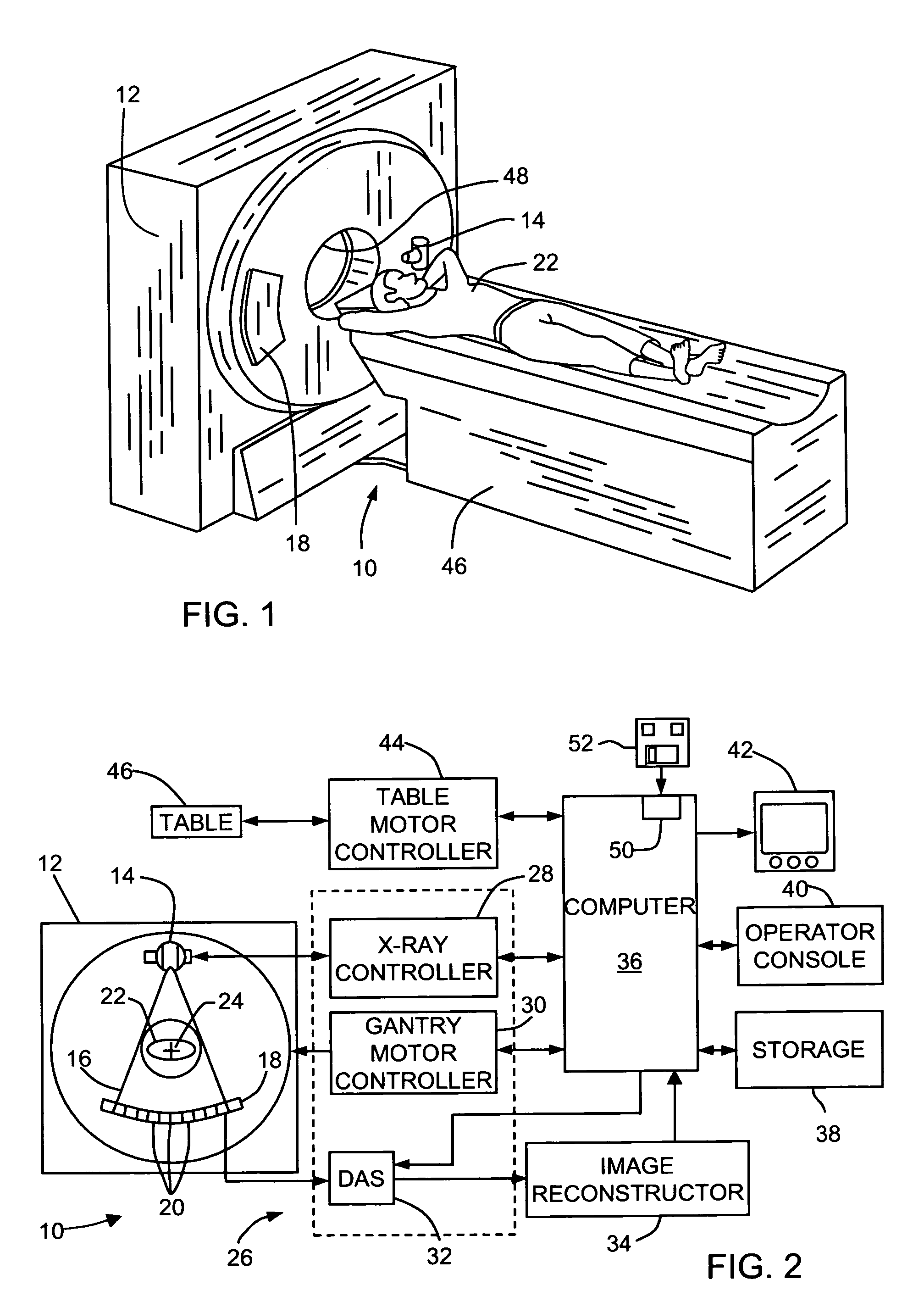

System and method for acquisition and reconstruction of contrast-enhanced, artifact-reduced CT images

ActiveUS20060109949A1Reconstruction from projectionMaterial analysis using wave/particle radiationView basedPhoton

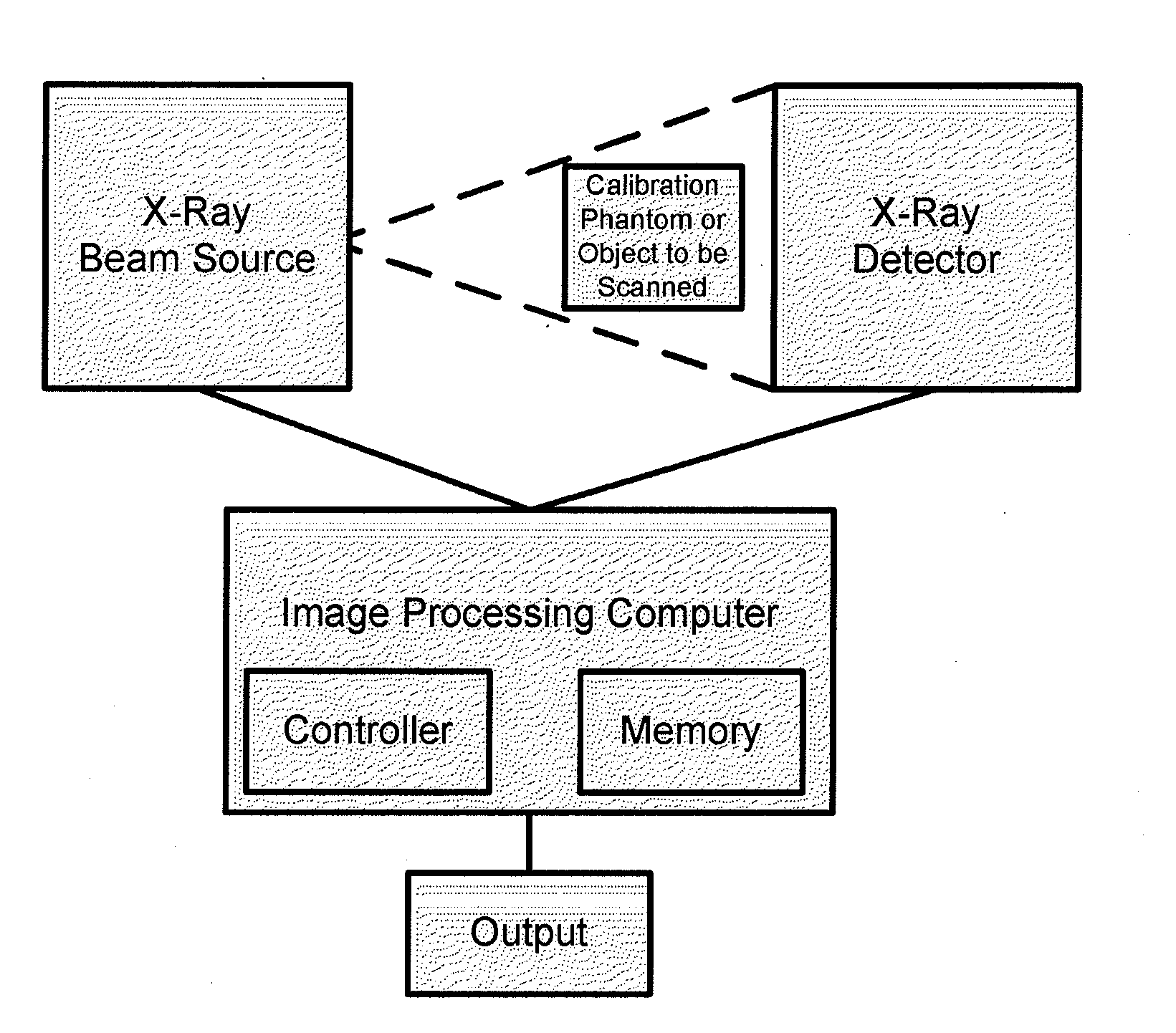

A system and method are disclosed for reconstructing contrast-enhanced CT images that are substantially free of beam-hardening artifacts. An imaging system includes a radiation source configured to project radiation toward an object to be scanned and an energy discriminating detector assembly having a plurality of detector elements and configured to detect radiation emitted by the radiation source and attenuated by the object to be scanned. The imaging system also includes computer programmed to count a number of photons detected by each detector element and associate an energy value to each counted photon and determine a material composition of a CT view from the number of photons counted and the energy value associated with each counted photon. The computer is also programmed to apply a weighting to the CT view based on the material composition of the CT view and reconstruct an image with differential weighting based on the weighting of the CT view.

Owner:GENERAL ELECTRIC CO

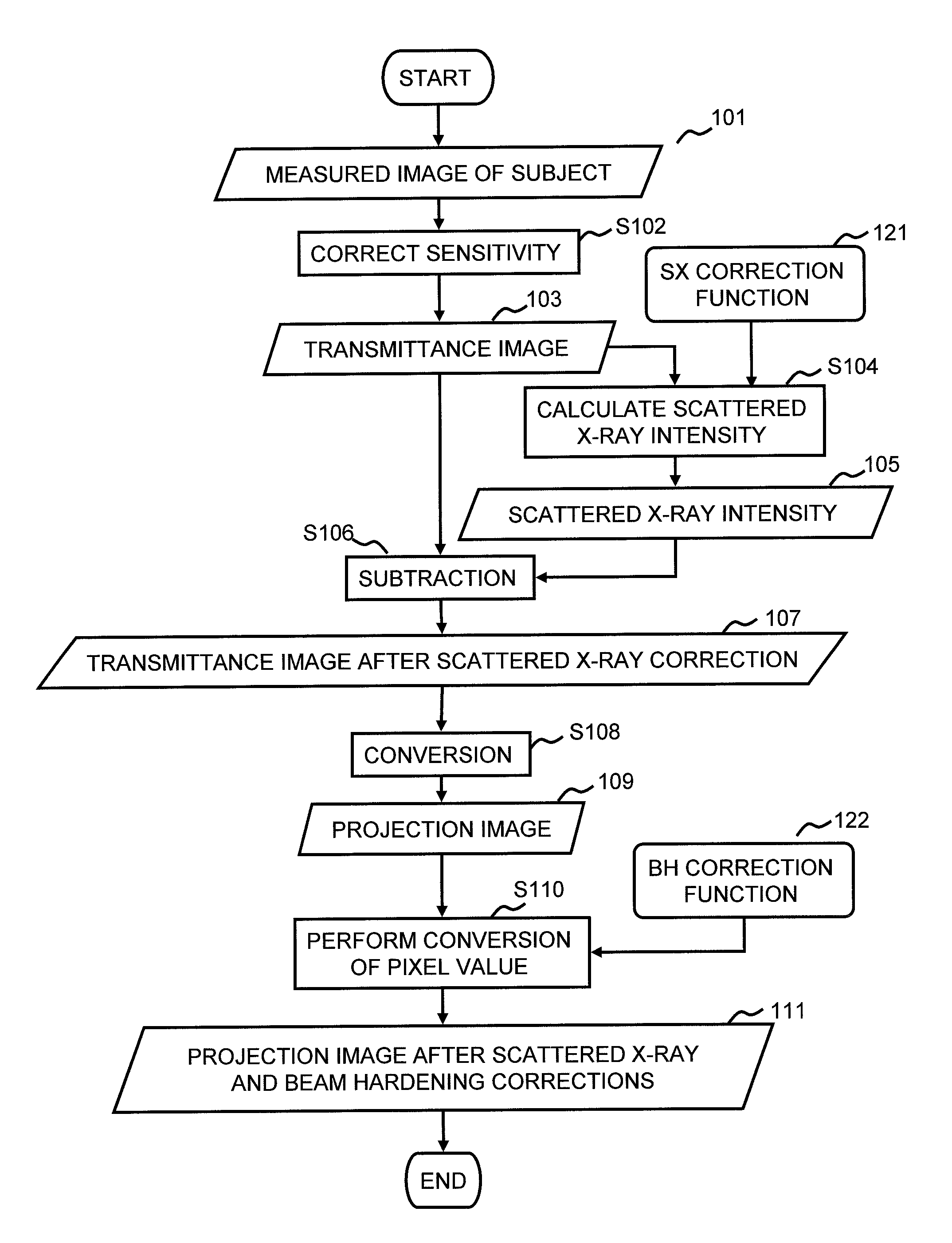

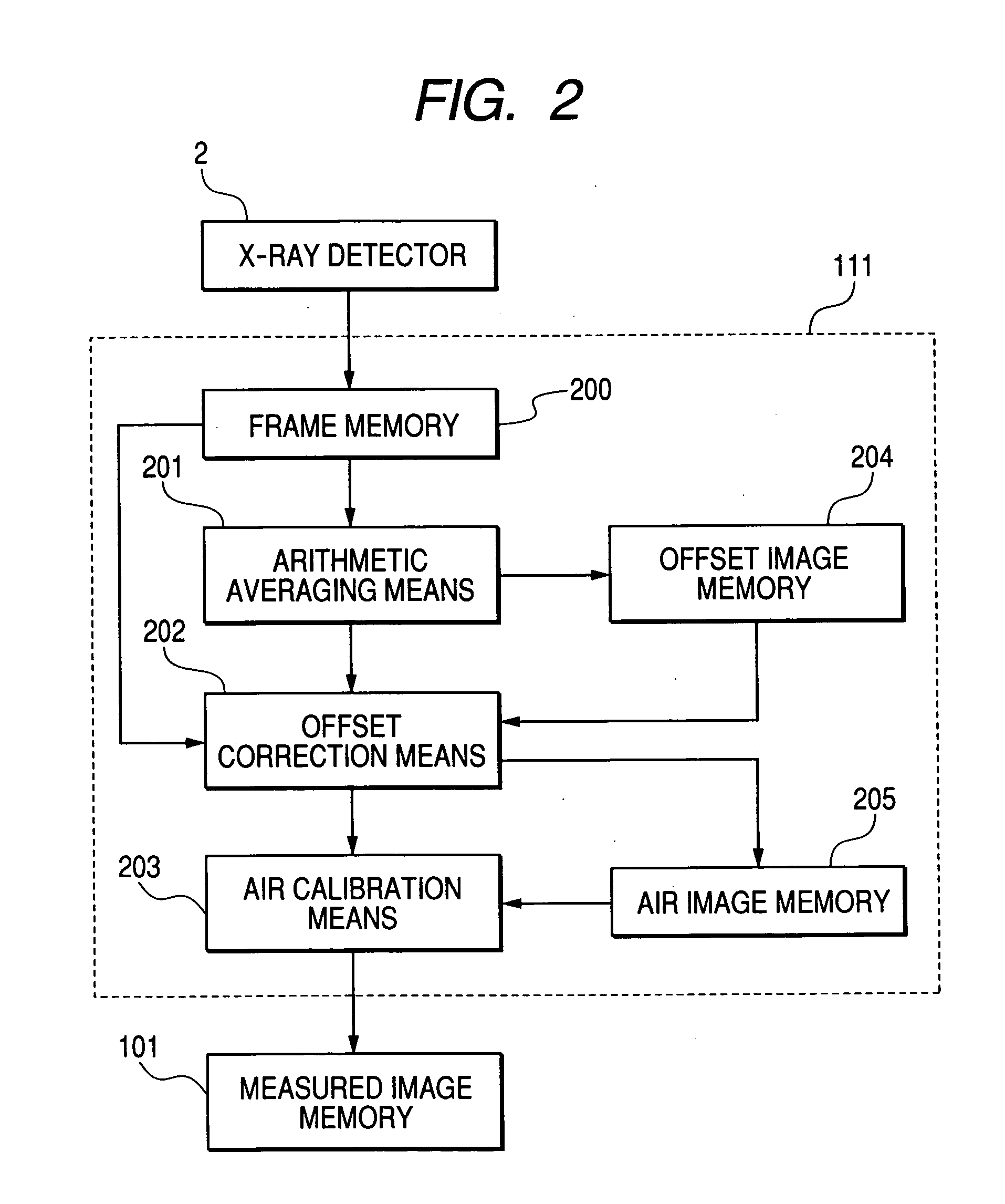

Radiation imaging device

InactiveUS8787520B2Promote generationHigh degreeReconstruction from projectionMaterial analysis using wave/particle radiationSoft x rayImaging quality

Owner:HITACHI LTD

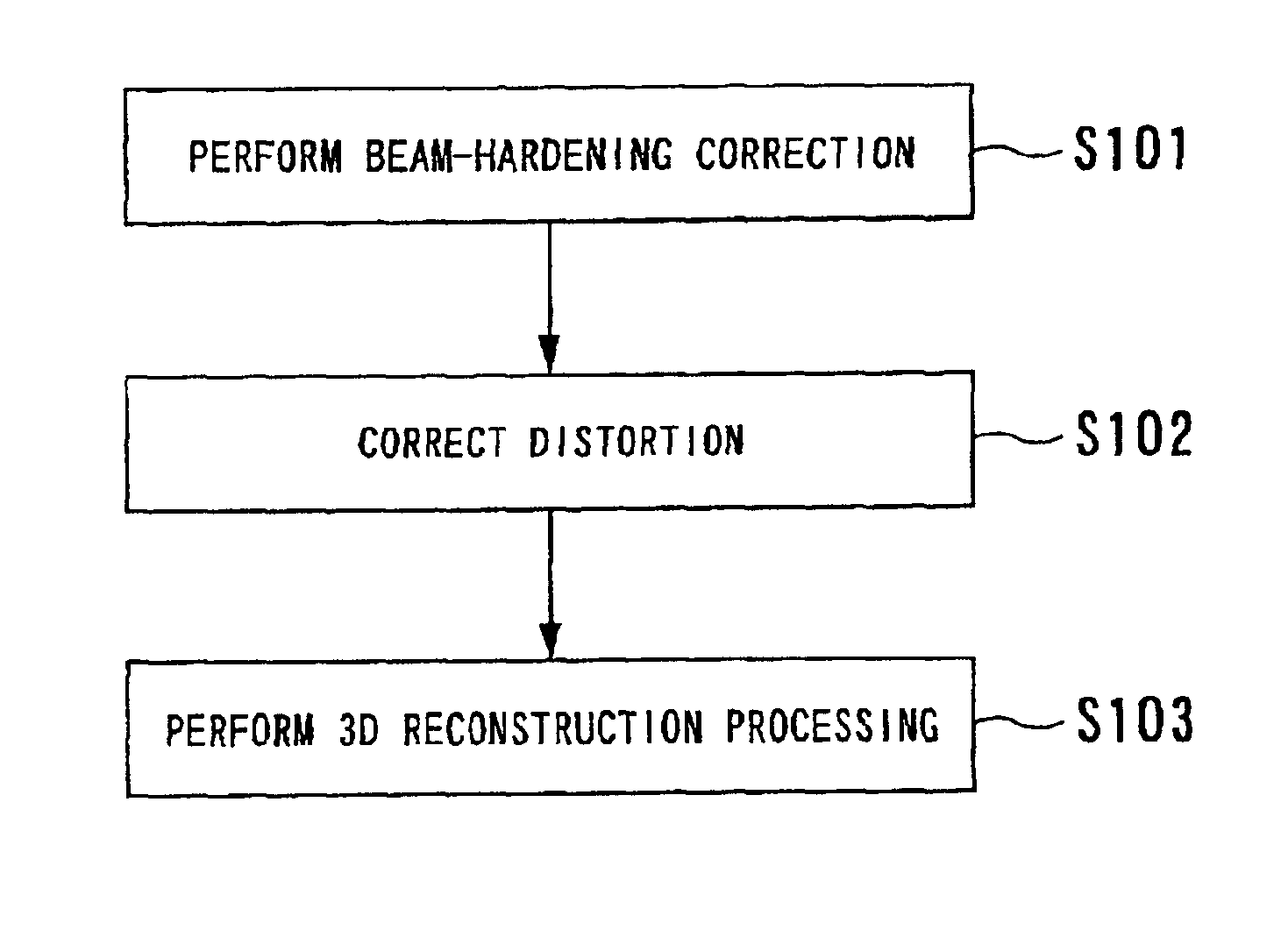

Image processing involving correction of beam hardening

InactiveUS6845142B2Avoid artifactsImage enhancementReconstruction from projectionSoft x rayImaging processing

An image processing apparatus is provided for processing a plurality of sets of projection data acquired by radiating an X-ray onto an object in a multitude of directions. The apparatus has a correcting unit and a reconstructing unit. The correcting unit corrects the projection data with regard to beam hardening of the projection data. The beam hardening is caused due to a contrast agent injected into the object. For example, the correcting unit includes a correction table defining a correcting value to a change in densities of a region in which the contrast agent is present and corrects the projection data on the basis of the correcting value obtained from the correction table. The reconstructing unit reconstructs the corrected projection data into an image of the object. Thus, artifacts due to beam hardening resultant from use of the contrast agent can be avoided.

Owner:TOSHIBA MEDICAL SYST CORP

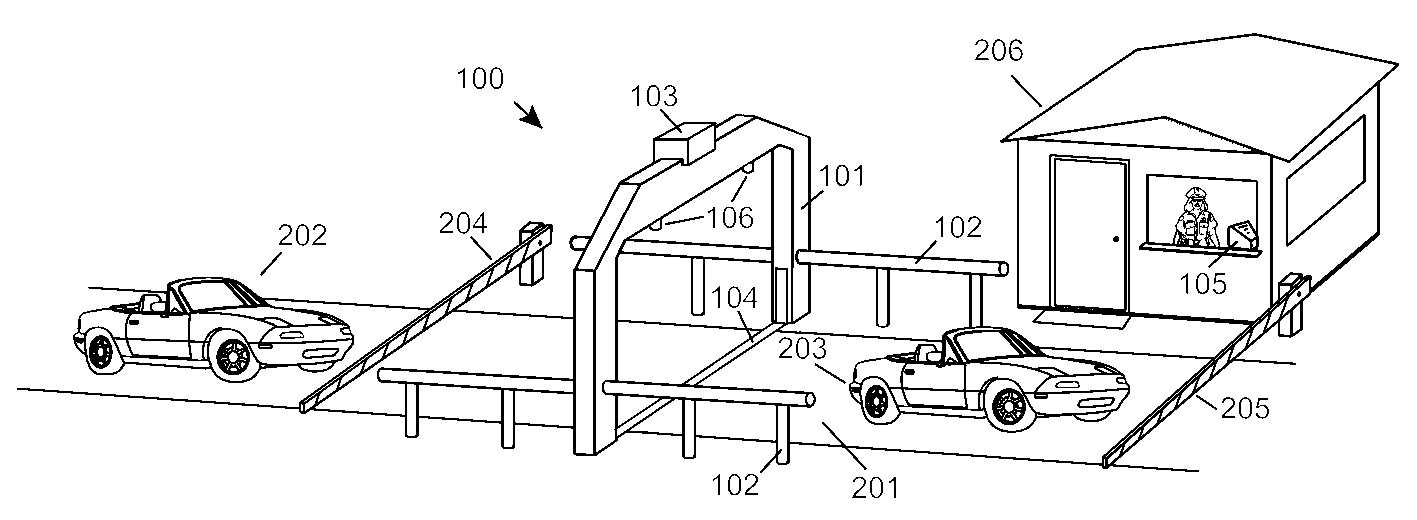

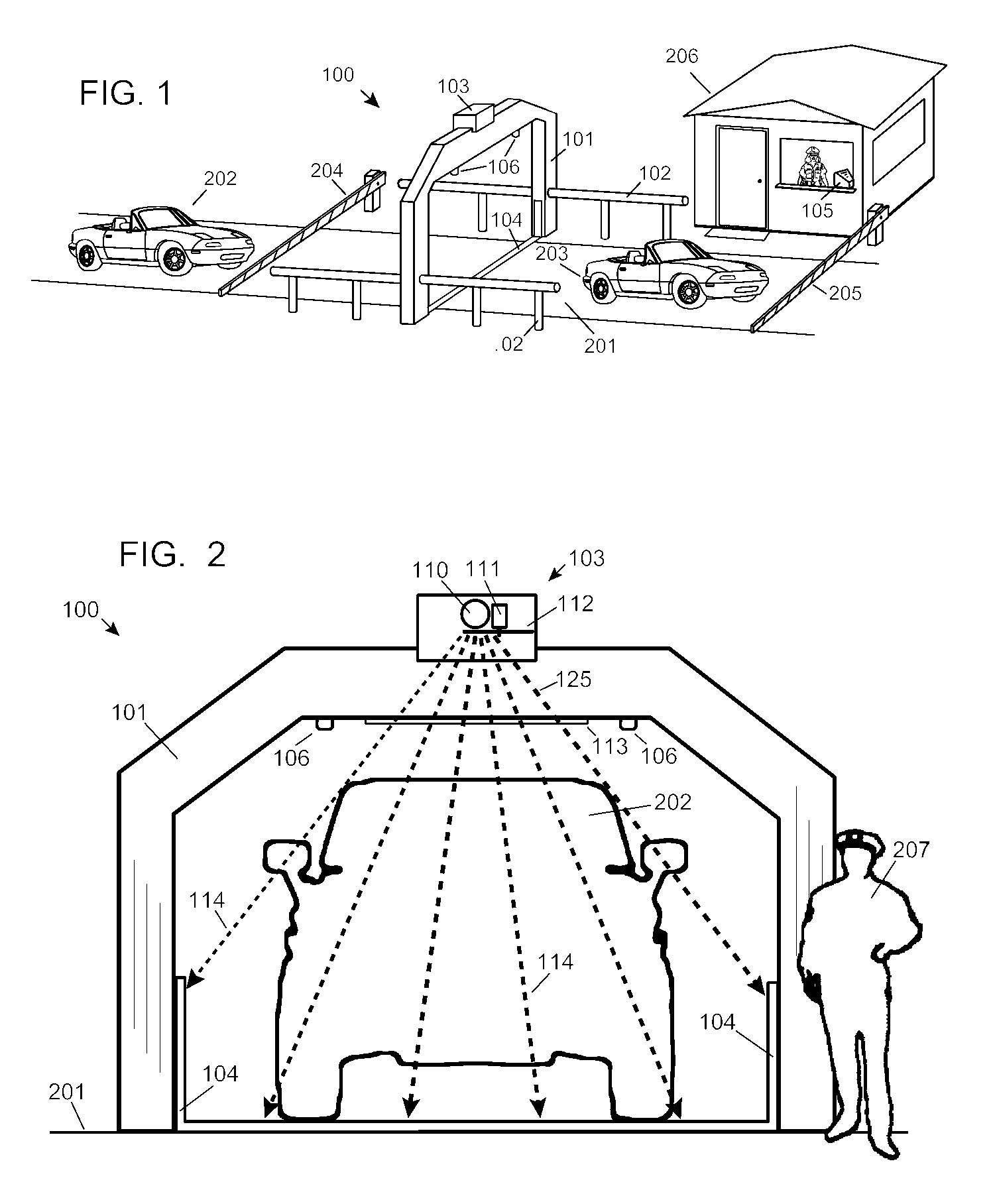

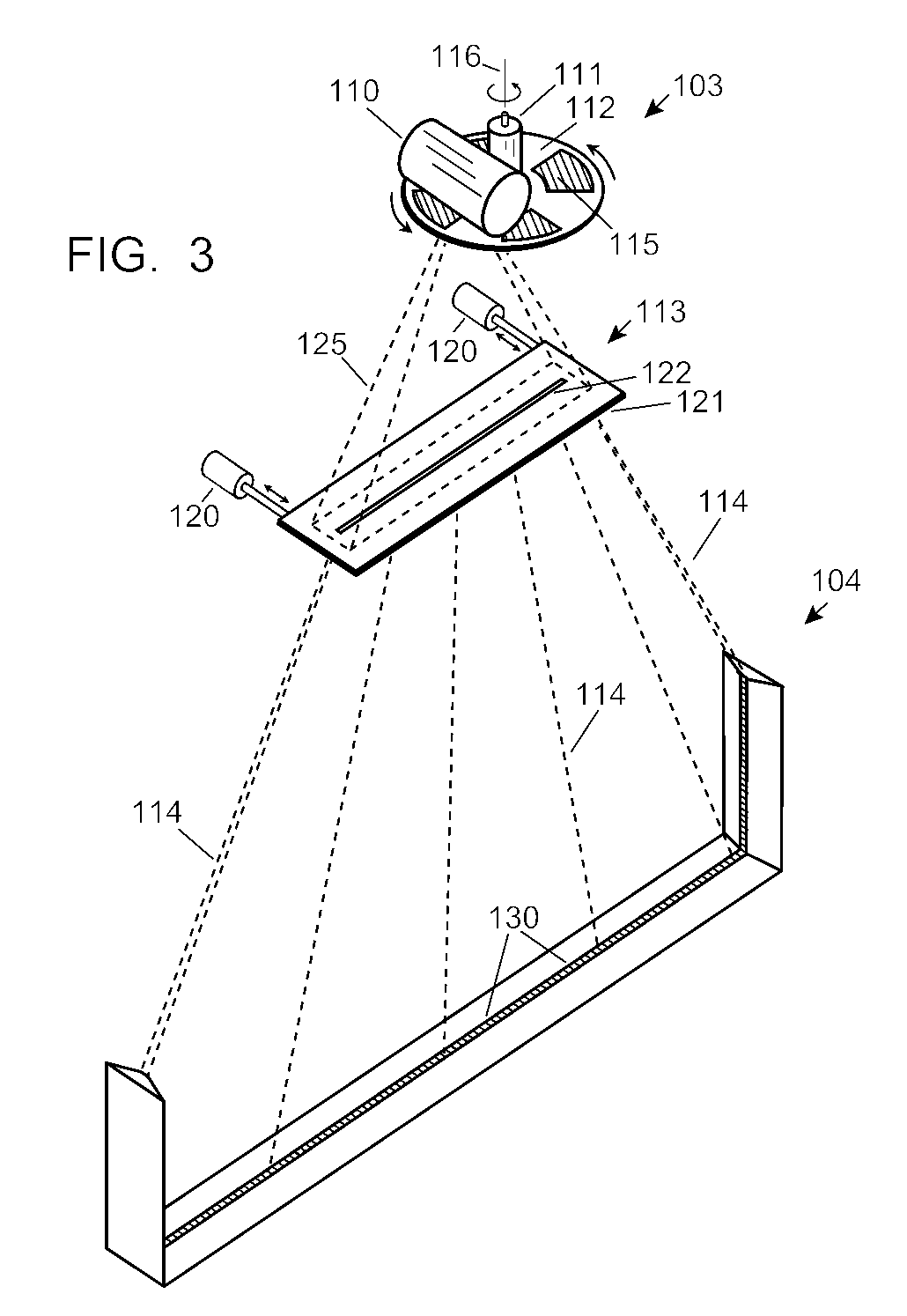

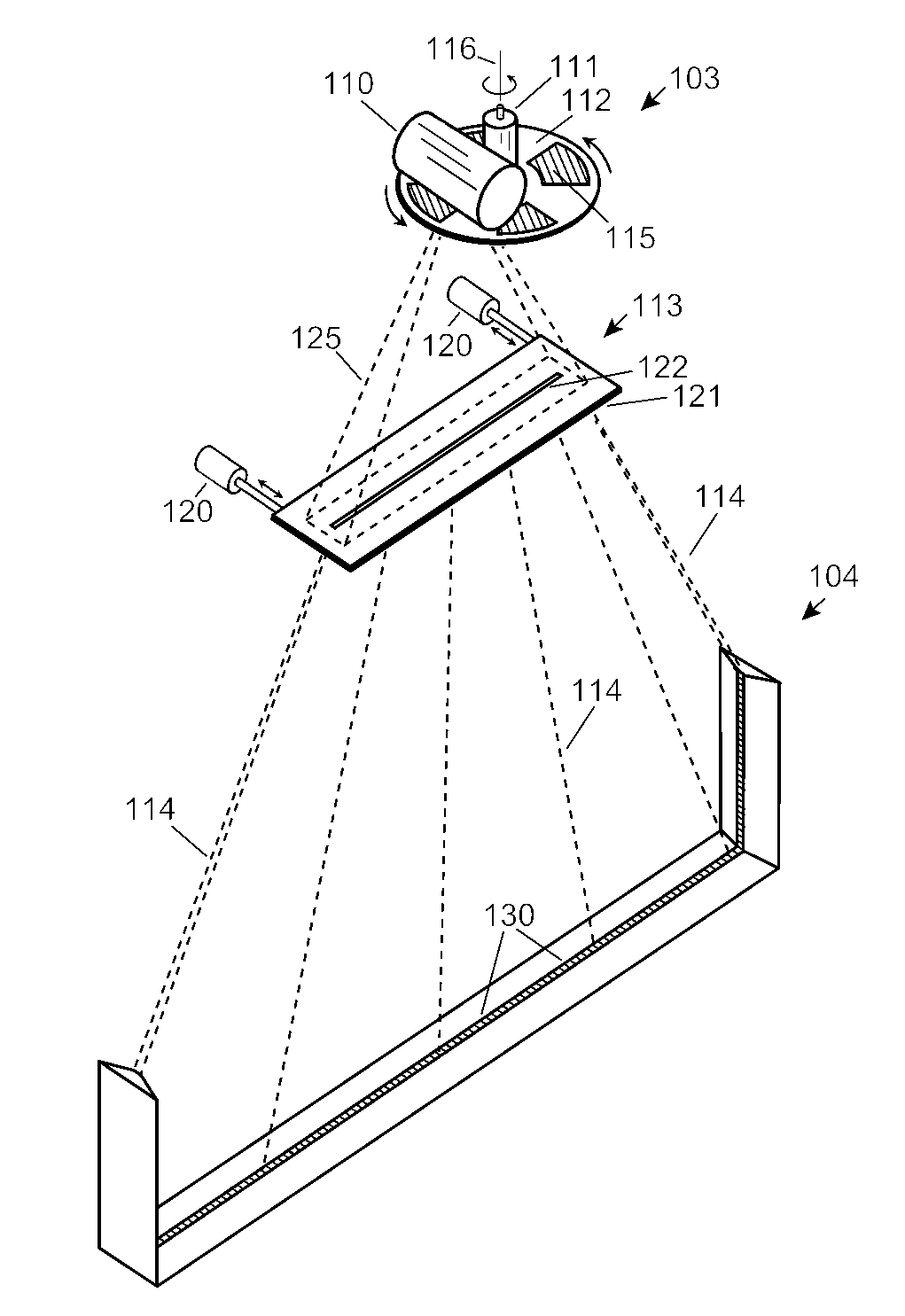

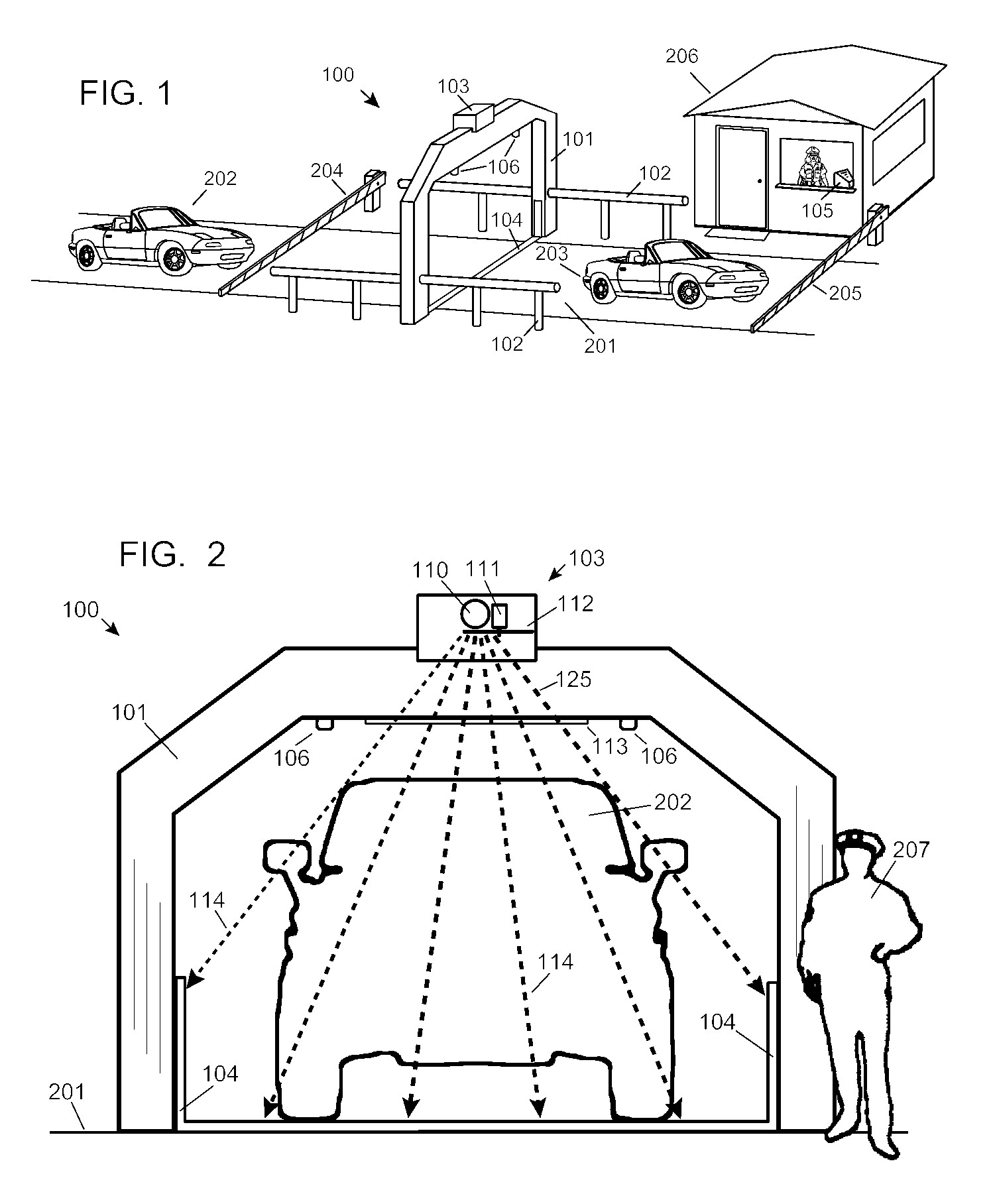

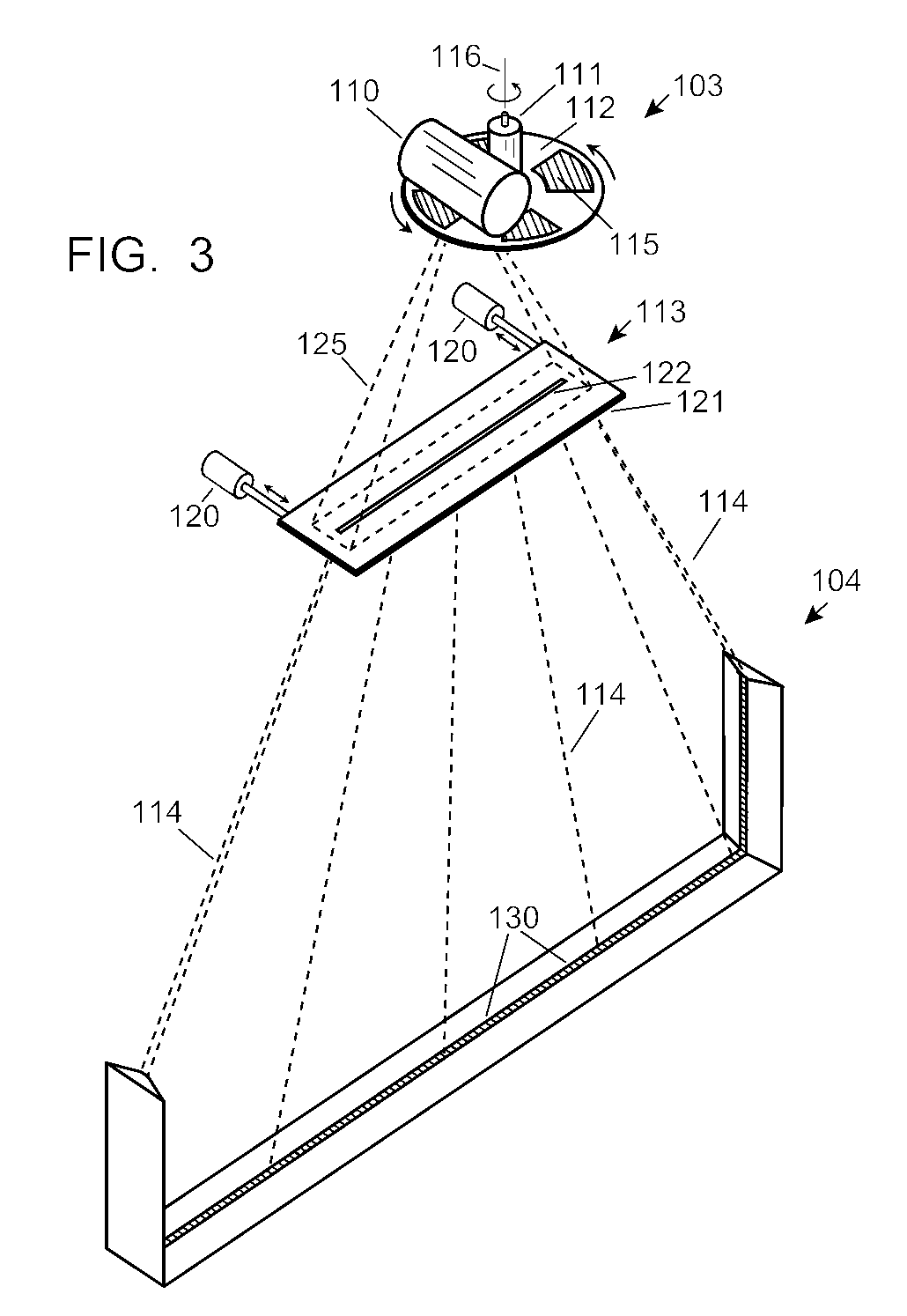

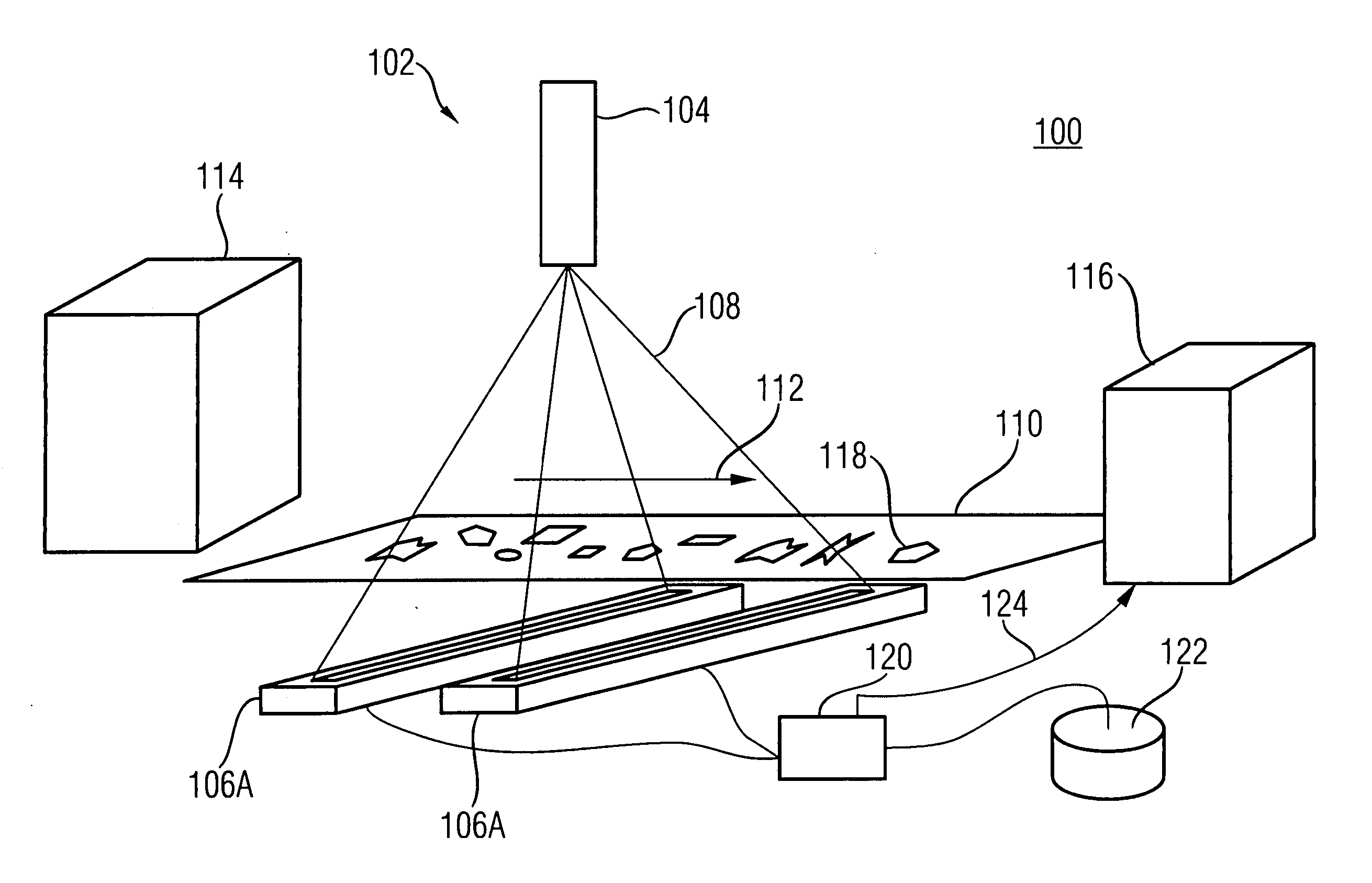

Automobile scanning system

ActiveUS7742568B2Easy to checkUniform exposureX-ray apparatusMaterial analysis by transmitting radiationAtomic elementHigh energy

A dual-energy x-ray imaging system searches a moving automobile for concealed objects. Dual energy operation is achieved by operating an x-ray source at a constant potential of 100 KV to 150 KV, and alternately switching between two beam filters. The first filter is an atomic element having a high k-edge energy, such as platinum, gold, mercury, thallium, lead, bismuth, and thorium, thereby providing a low-energy spectrum. The second filter provides a high-energy spectrum through beam hardening. The low and high energy beams passing through the automobile are received by an x-ray detector. These detected signals are processed by a digital computer to create a steel suppressed image through logarithmic subtraction. The intensity of the x-ray beam is adjusted as the reciprocal of the measured automobile speed, thereby achieving a consistent radiation level regardless of the automobile motion. Accordingly, this invention provides images of organic objects concealed within moving automobiles without the detritus effects of overlying steel and automobile movement.

Owner:LEIDOS

Automobile Scanning System

ActiveUS20090086907A1Easy to checkUniform radiation exposureX-ray apparatusMaterial analysis by transmitting radiationAtomic elementHigh energy

A dual-energy x-ray imaging system searches a moving automobile for concealed objects. Dual energy operation is achieved by operating an x-ray source at a constant potential of 100 KV to 150 KV, and alternately switching between two beam filters. The first filter is an atomic element having a high k-edge energy, such as platinum, gold, mercury, thallium, lead, bismuth, and thorium, thereby providing a low-energy spectrum. The second filter provides a high-energy spectrum through beam hardening. The low and high energy beams passing through the automobile are received by an x-ray detector. These detected signals are processed by a digital computer to create a steel suppressed image through logarithmic subtraction. The intensity of the x-ray beam is adjusted as the reciprocal of the measured automobile speed, thereby achieving a consistent radiation level regardless of the automobile motion. Accordingly, this invention provides images of organic objects concealed within moving automobiles without the detritus effects of overlying steel and automobile movement.

Owner:LEIDOS

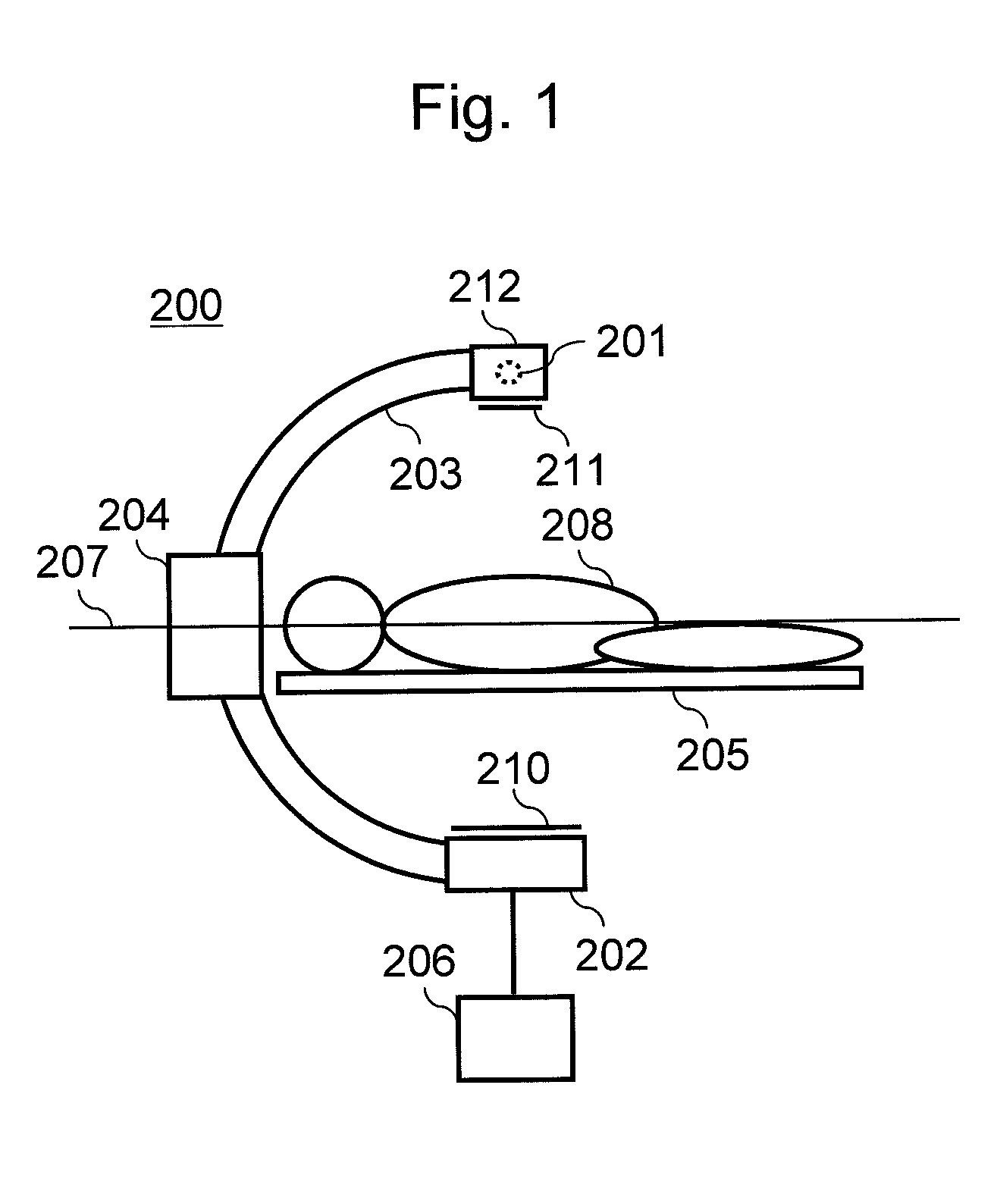

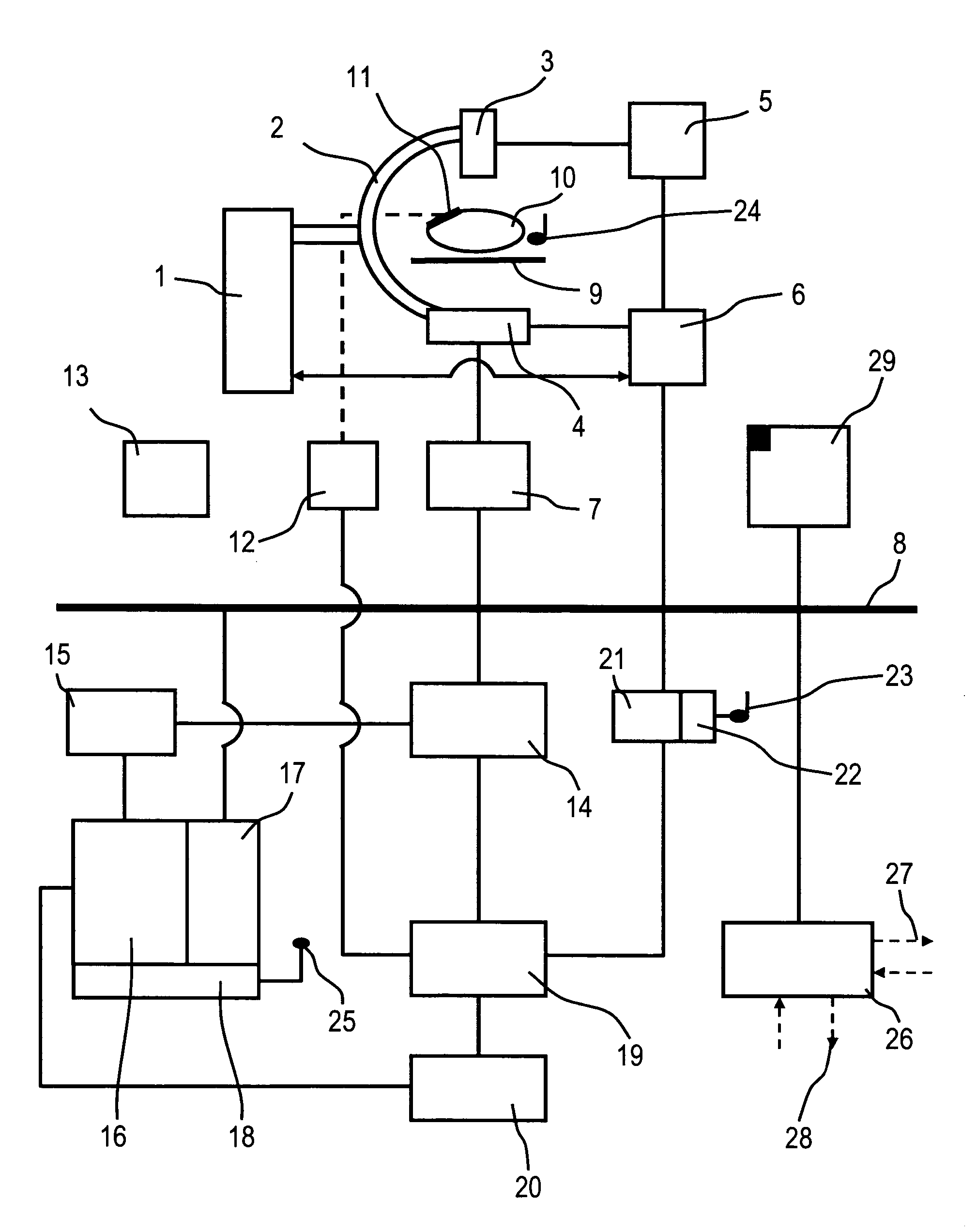

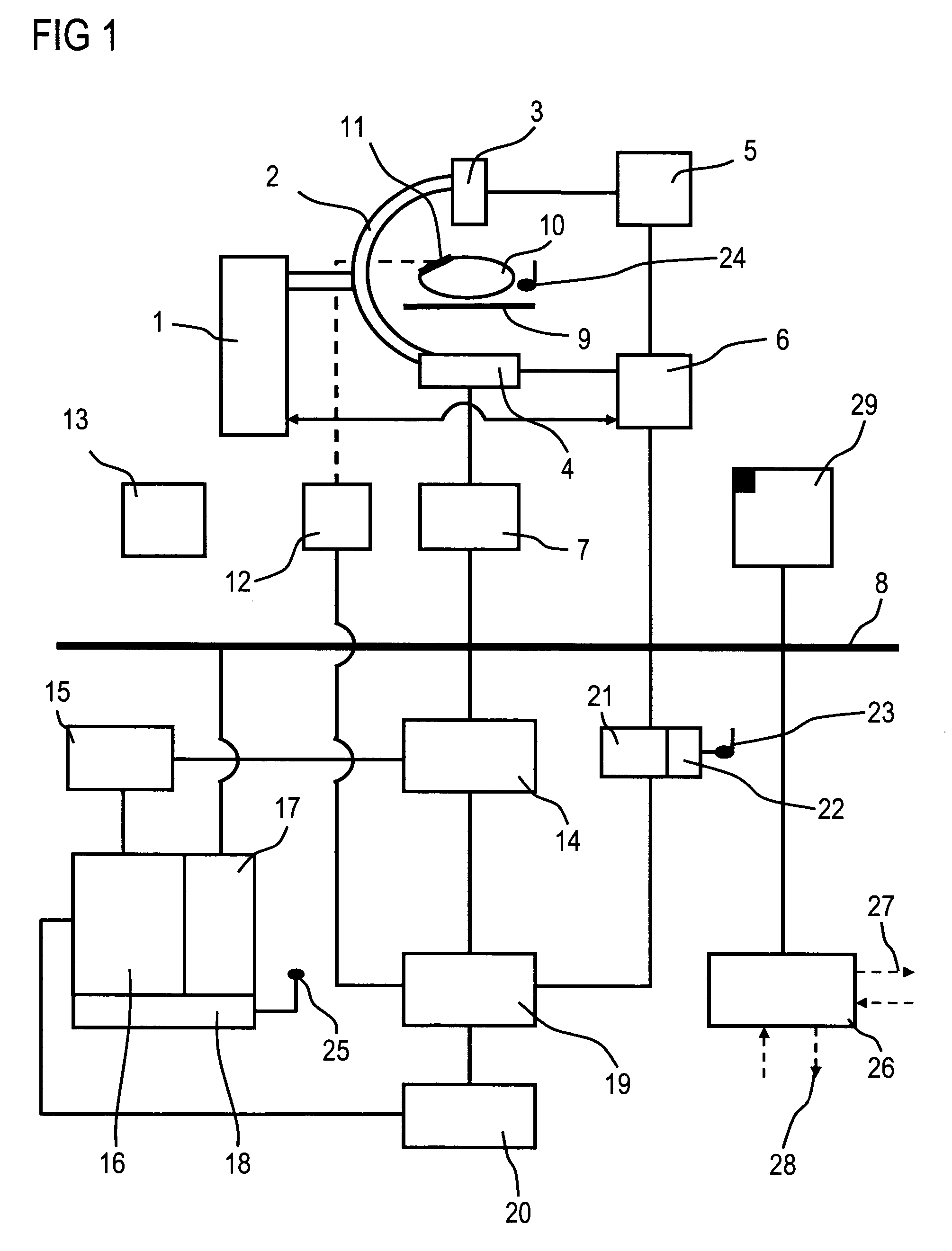

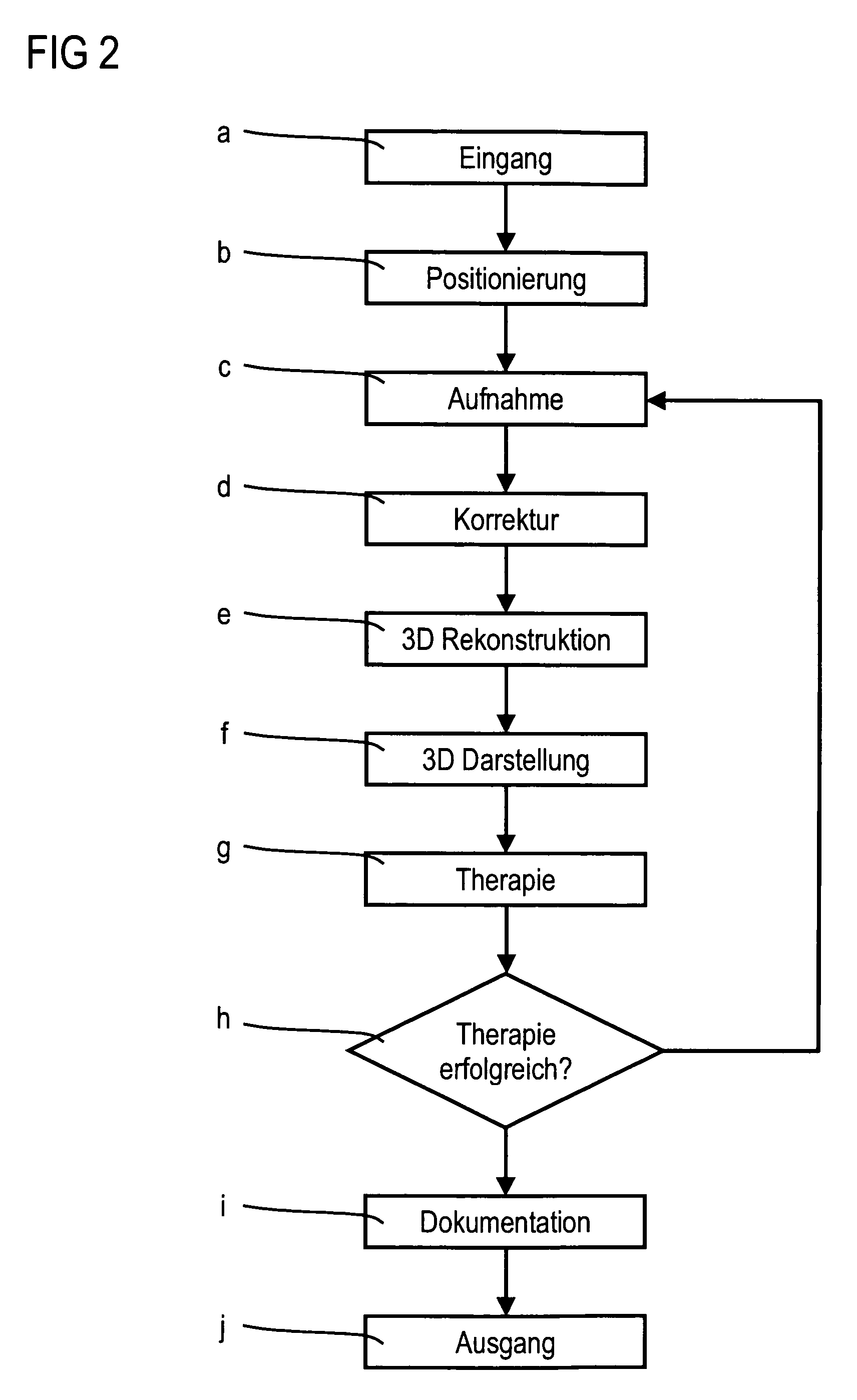

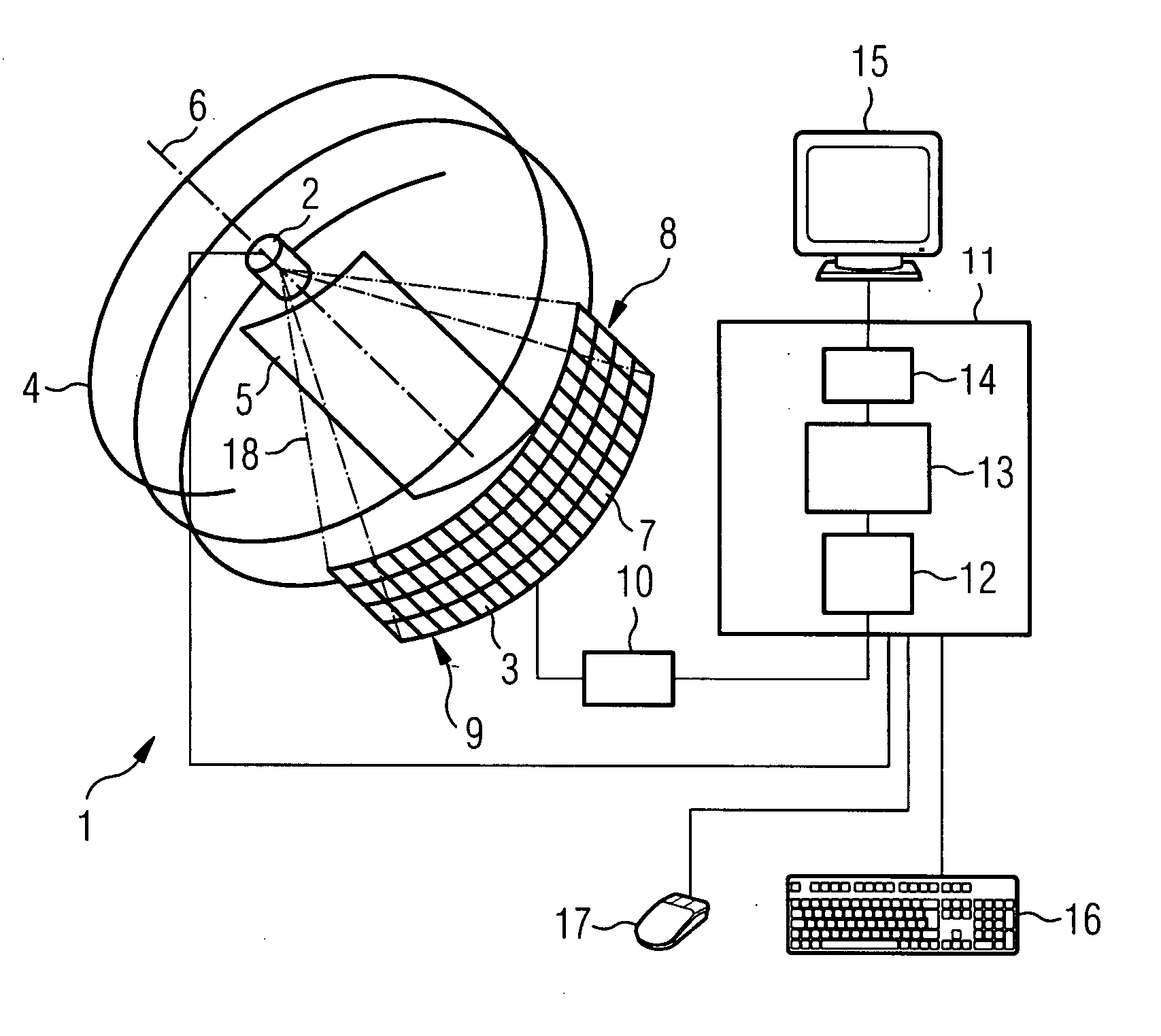

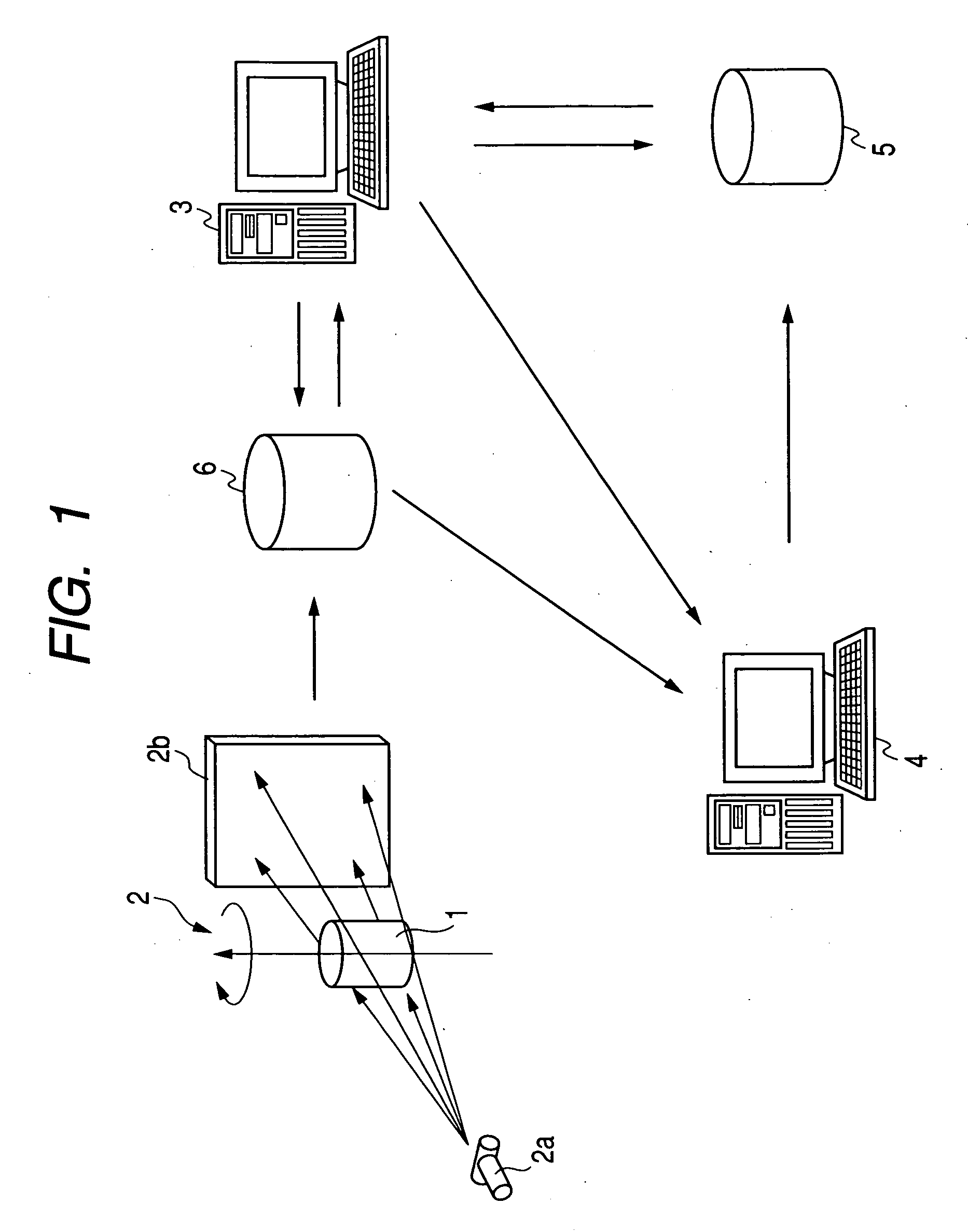

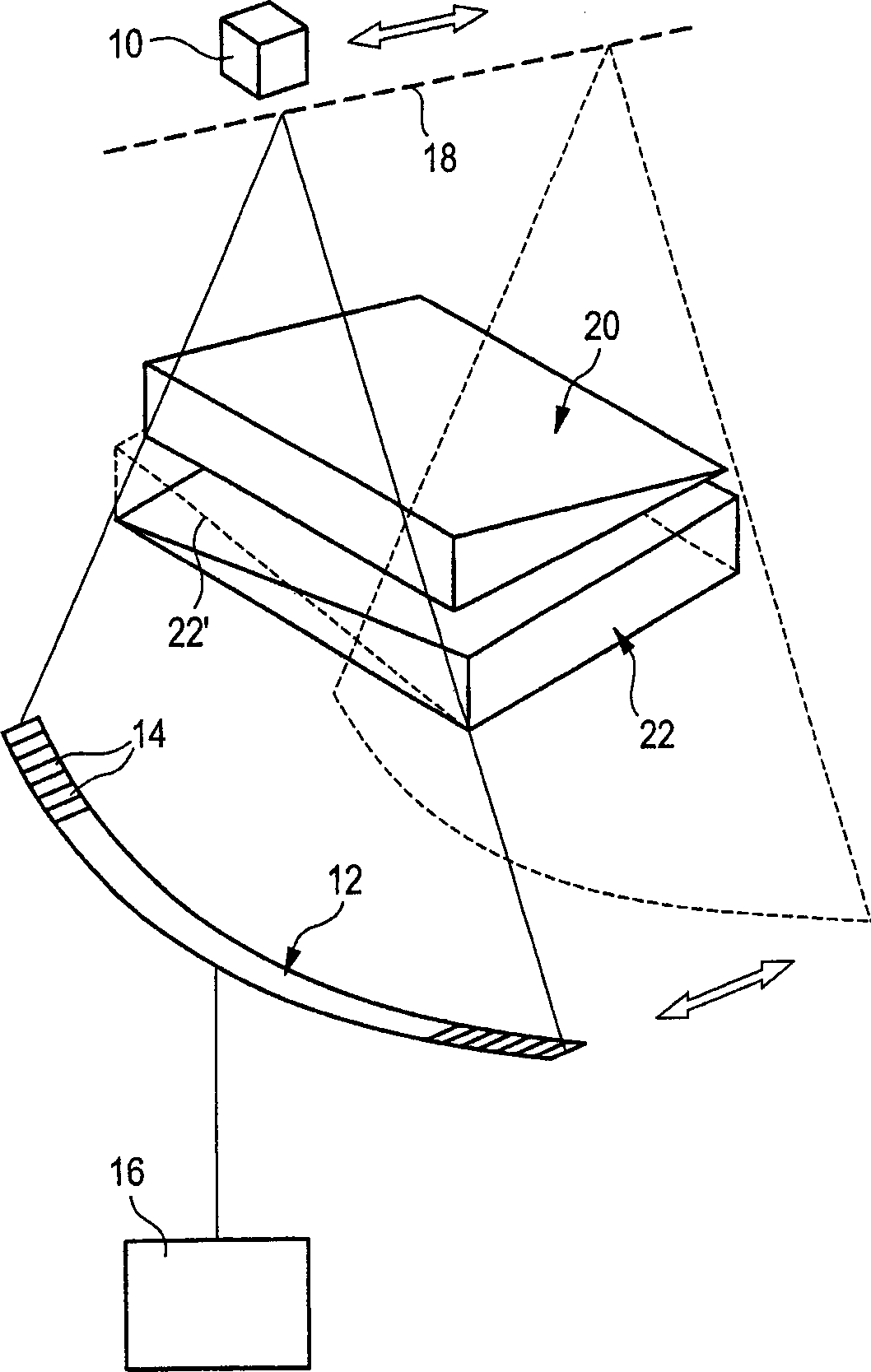

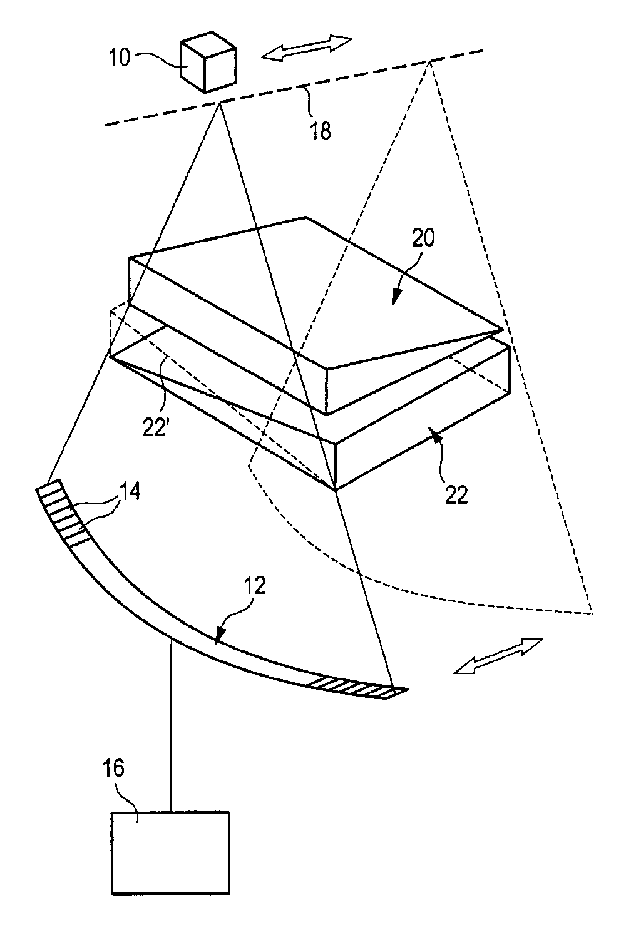

Angiographic x-ray diagnostic device for rotation angiography

ActiveUS7734009B2Improve the display effectReconstruction from projectionRadiation/particle handlingImage detectionX-ray

The invention relates to an angiographic x-ray diagnostic device for rotation angiography with an x-ray emitter which can be moved on a circular path about a patient located on a patient support table, with an image detector unit which can moved on the circular path facing the x-ray emitter, with a digital image system for recording a plurality of projection images by means of rotation angiography, with a device for image processing, by means of which the projection images are reconstructed into a 3D volume image, and with a device for correcting physical effects and / or inadequacies in the recording system such as truncation correction, scatter correction, ring artifact correction, correction of the beam hardening and / or of the low frequency drop for the soft tissue display of projection images and the 3D volume images resulting therefrom.

Owner:SIEMENS HEALTHCARE GMBH

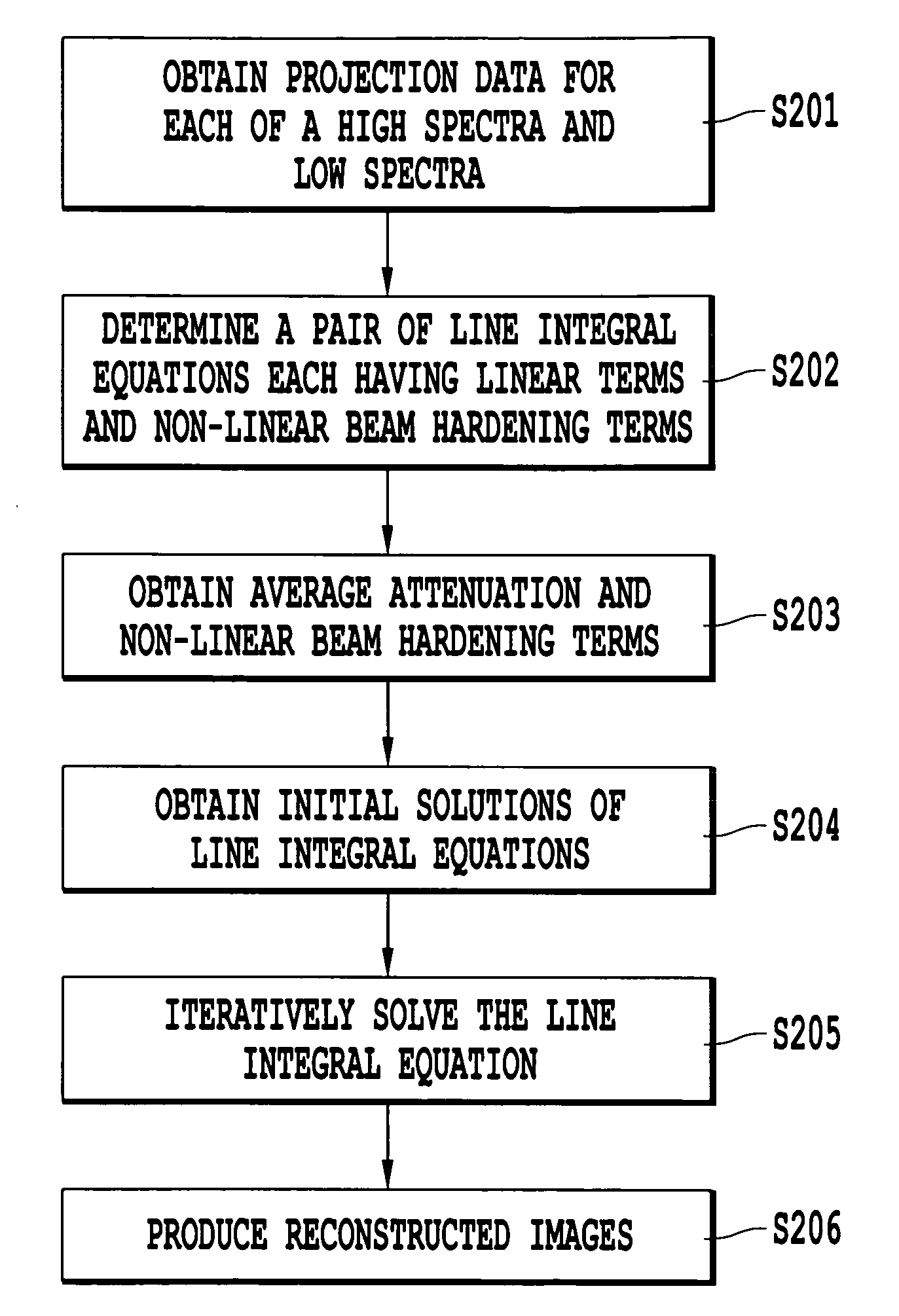

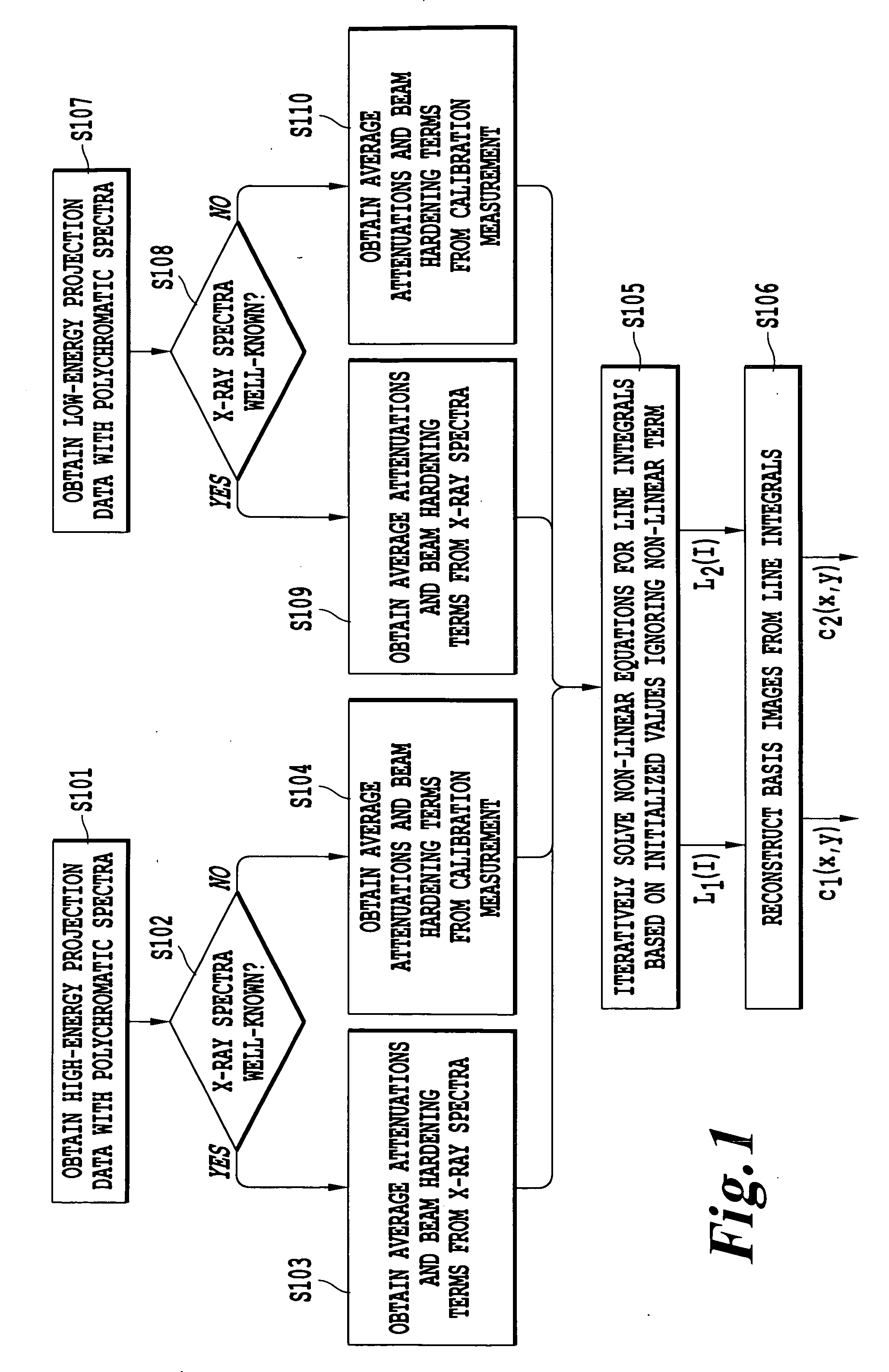

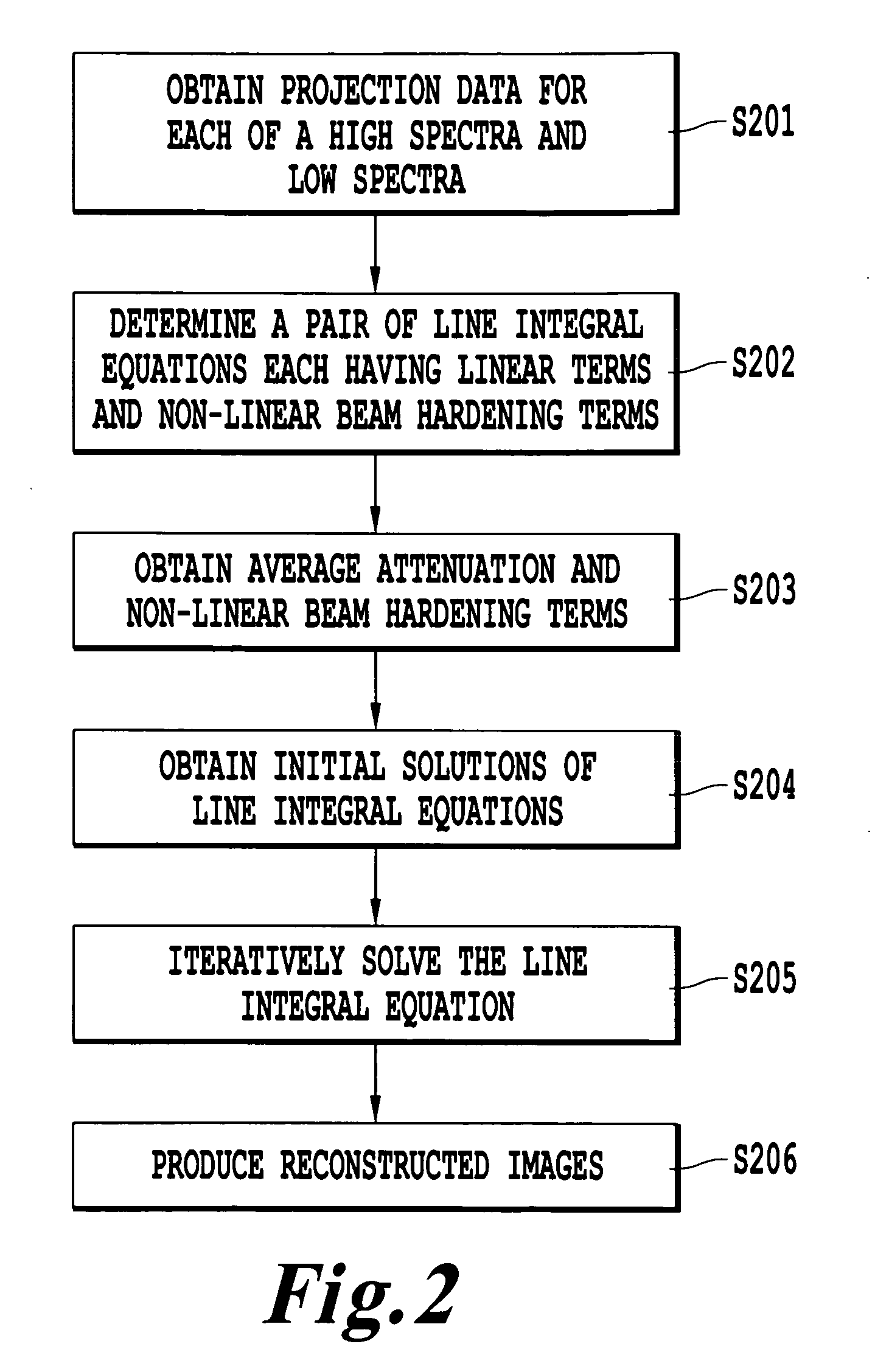

Method, apparatus, and computer-readable medium for pre-reconstruction decomposition and calibration in dual energy computed tomography

ActiveUS20090262997A1Easy to handleReconstruction from projectionMaterial analysis using wave/particle radiationDecompositionDual energy

A method of obtaining a computed tomography image of an object includes determining linear terms and non-linear beam hardening terms in a pair of line integral equations for dual-energy projection data from inserting average and difference from average attenuation terms, obtaining an initial solution of the line integral equation by setting the non-linear beam hardening terms to zero, and iteratively solving the line integral equations to obtain one line integral equations for each basis material. Attenuation by the first basis material corresponds to a photoelectric attenuation process, and attenuation by the second basis material corresponds to a Compton attenuation process. The line integral equations can be inverted by an inverse Radon procedure such as filtered backprojection to give images of each basis material. The images of each basis material can then be optionally combined to give monochromatic images, density and effective atomic number images, or photoelectric and Compton processes images.

Owner:TOSHIBA MEDICAL SYST CORP

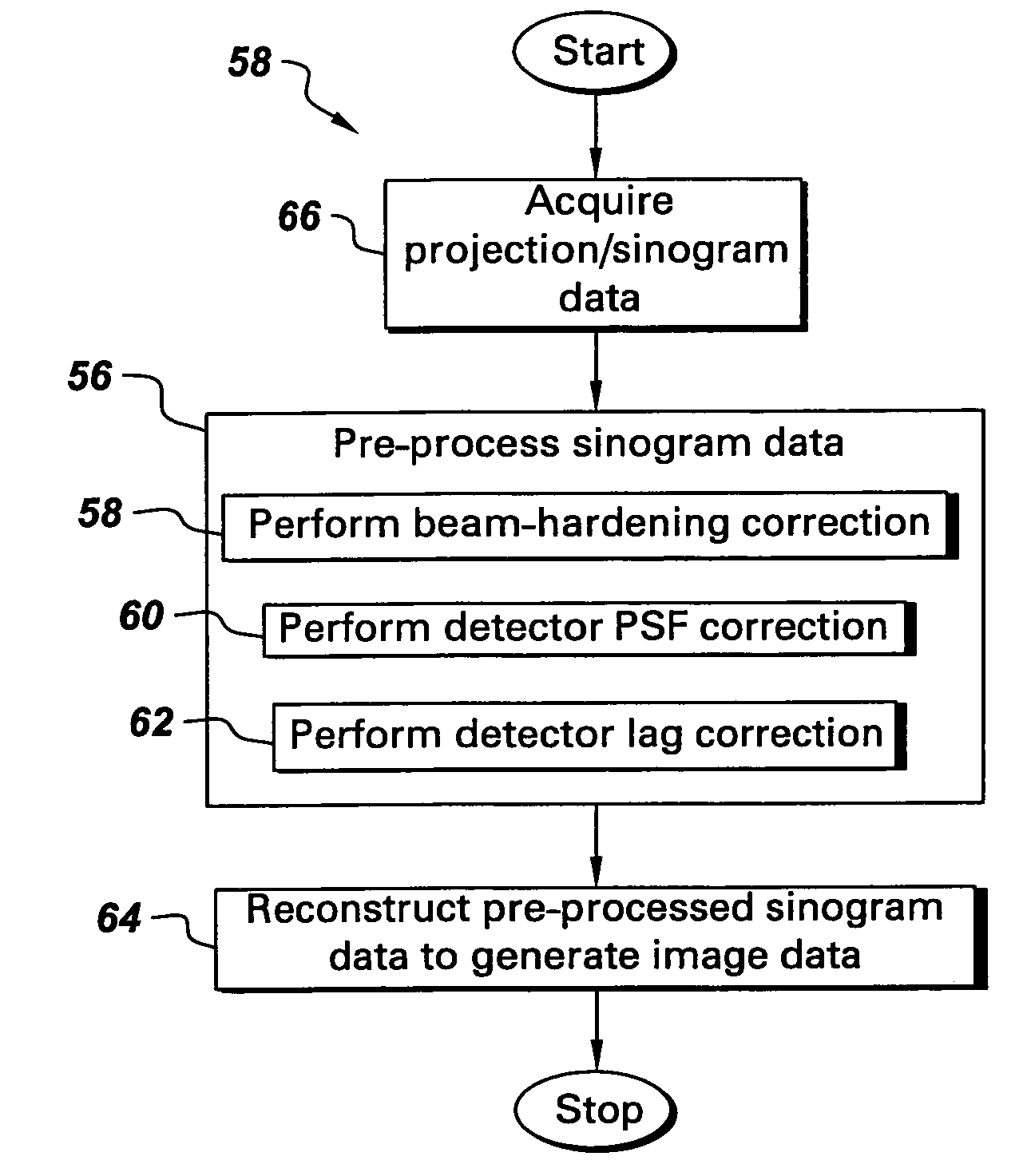

Method and system for CT reconstruction with pre-correction

InactiveUS20060067461A1Image enhancementReconstruction from projectionPoint spread functionBeam hardening

A method for reconstructing image data from measured sinogram data acquired from a CT system is provided. The CT system is configured for industrial imaging. The method includes pre-processing the measured sinogram data. The pre-processing includes performing a beam hardening correction on the measured sinogram data and performing a detector point spread function (PSF) correction and a detector lag correction on the measured sinogram data. The pre-processed sinogram data is reconstructed to generate the image data.

Owner:GENERAL ELECTRIC CO

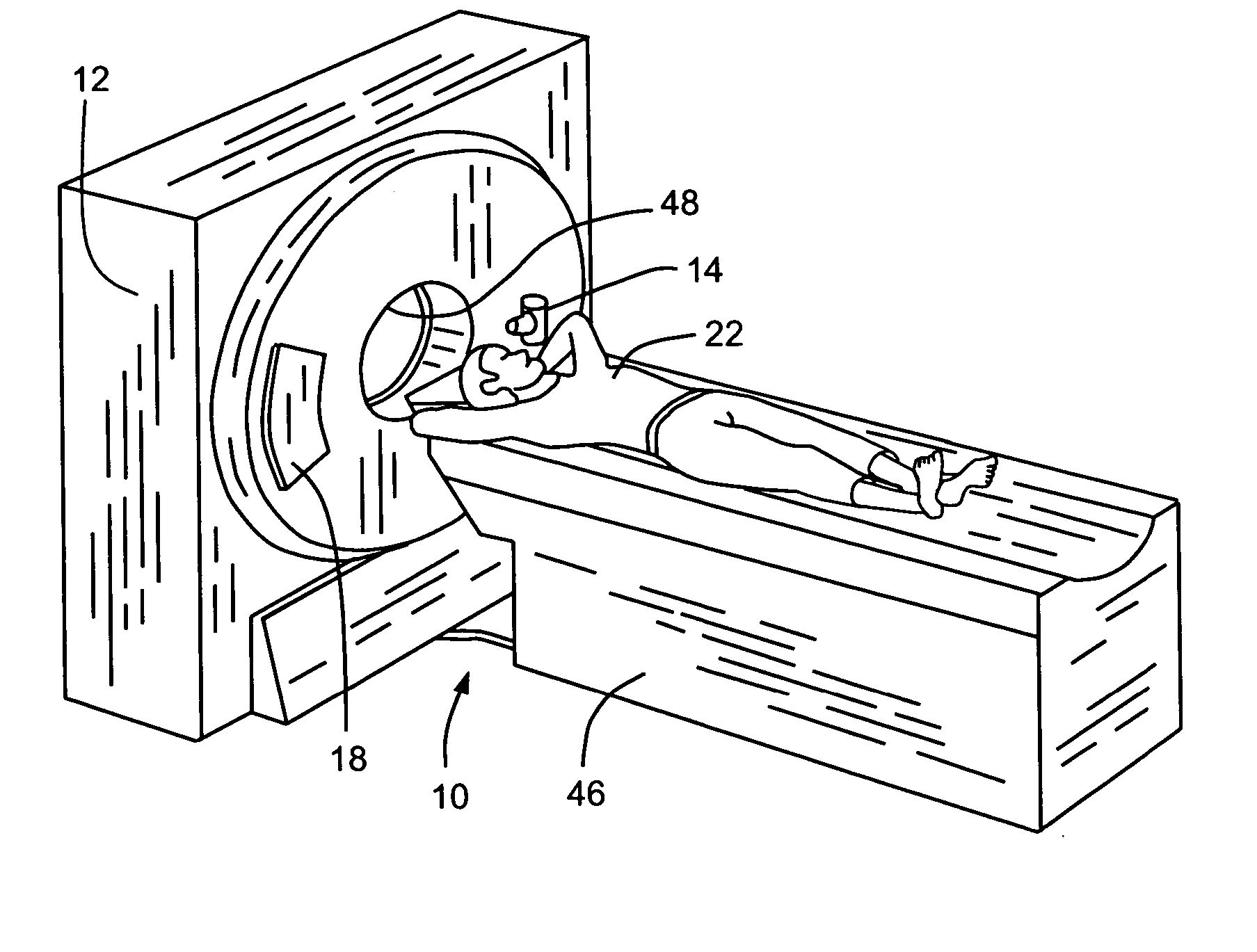

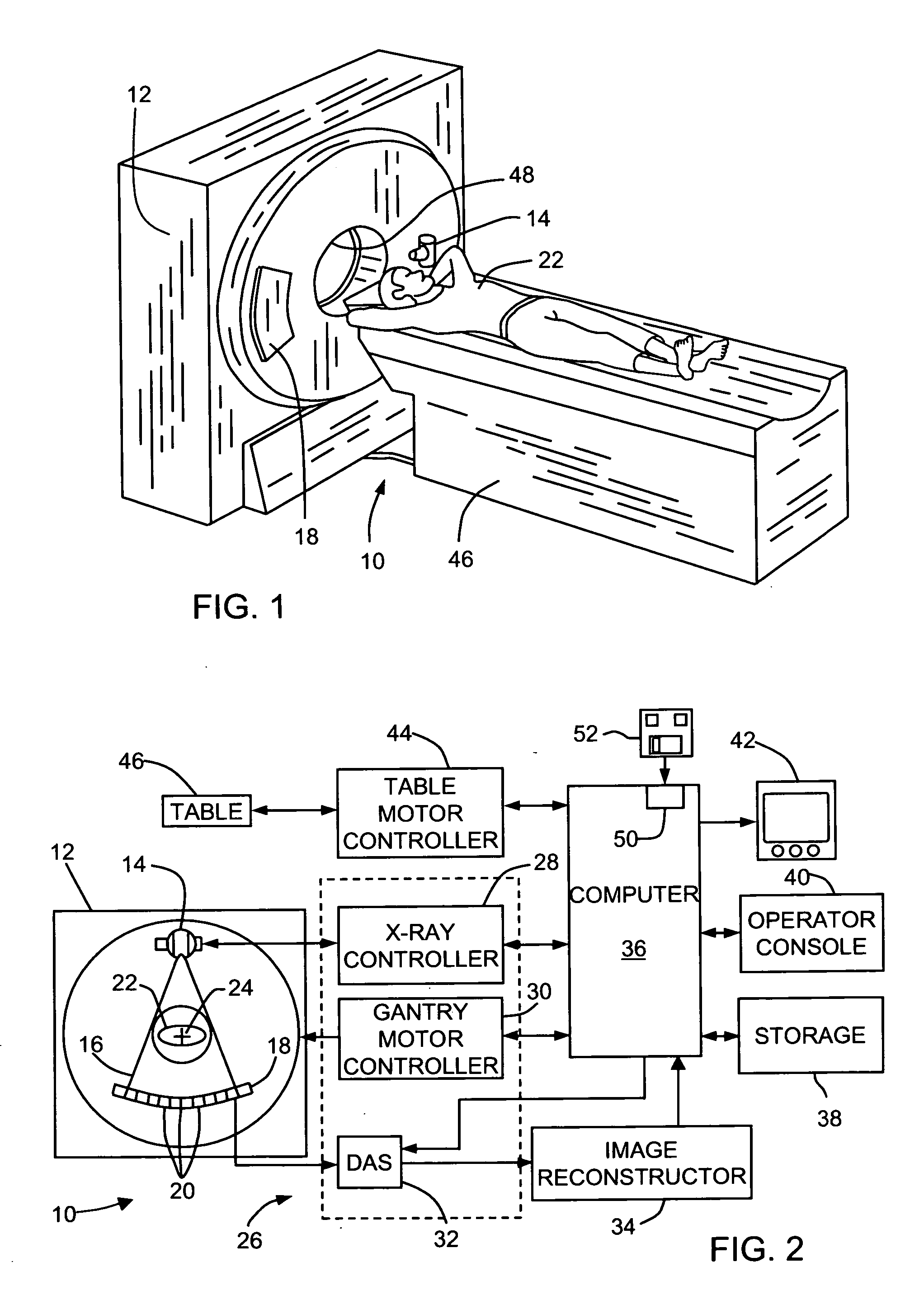

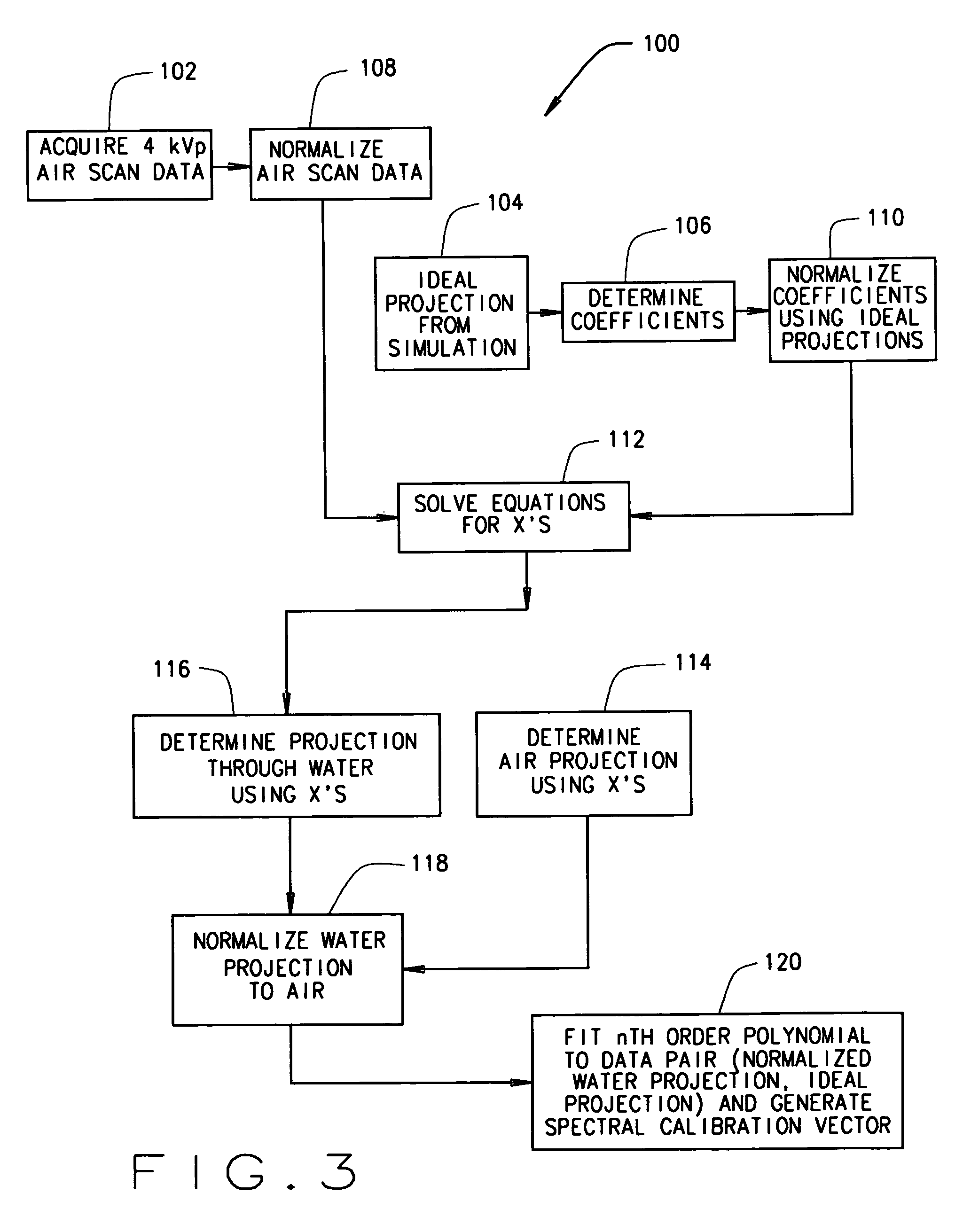

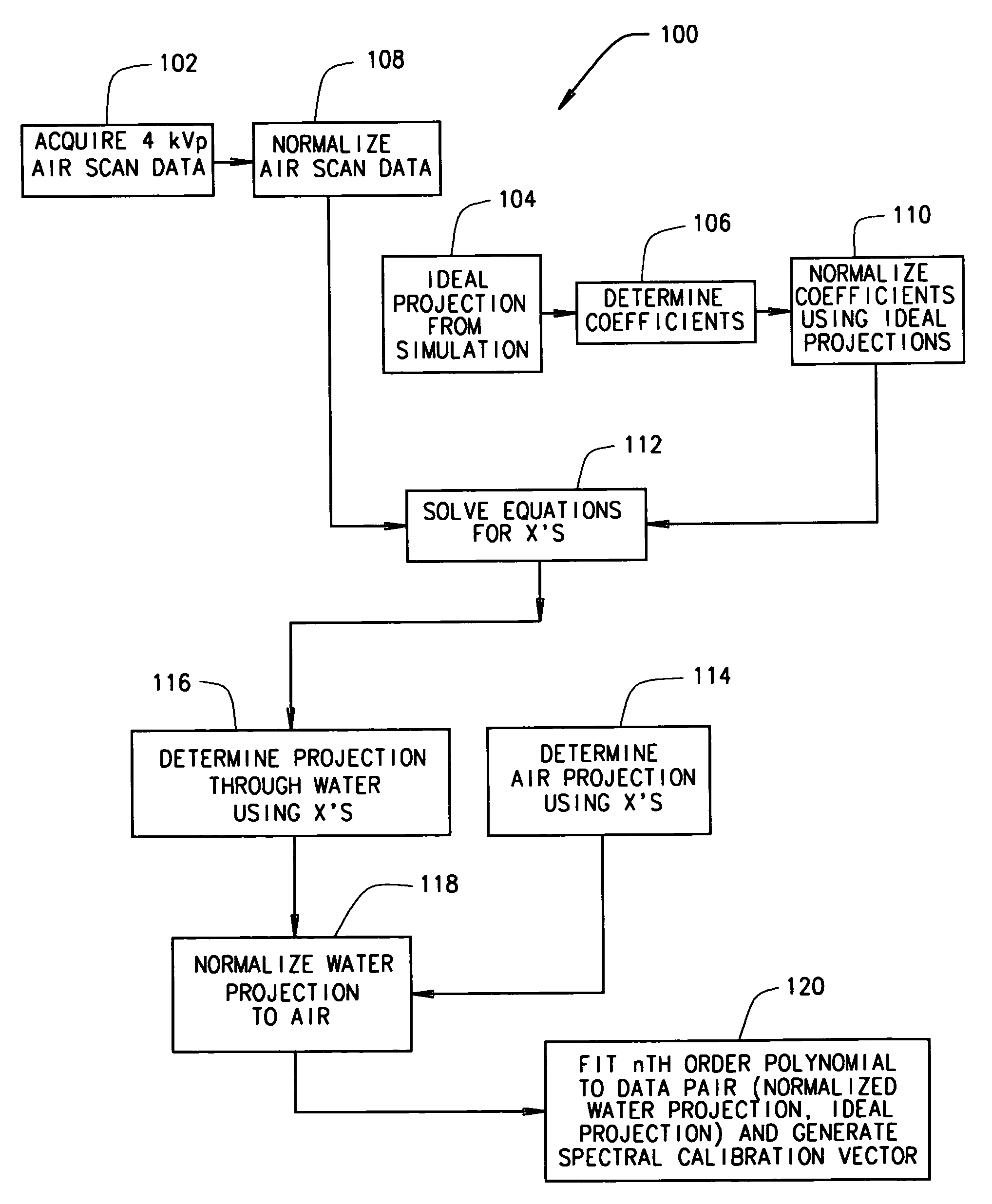

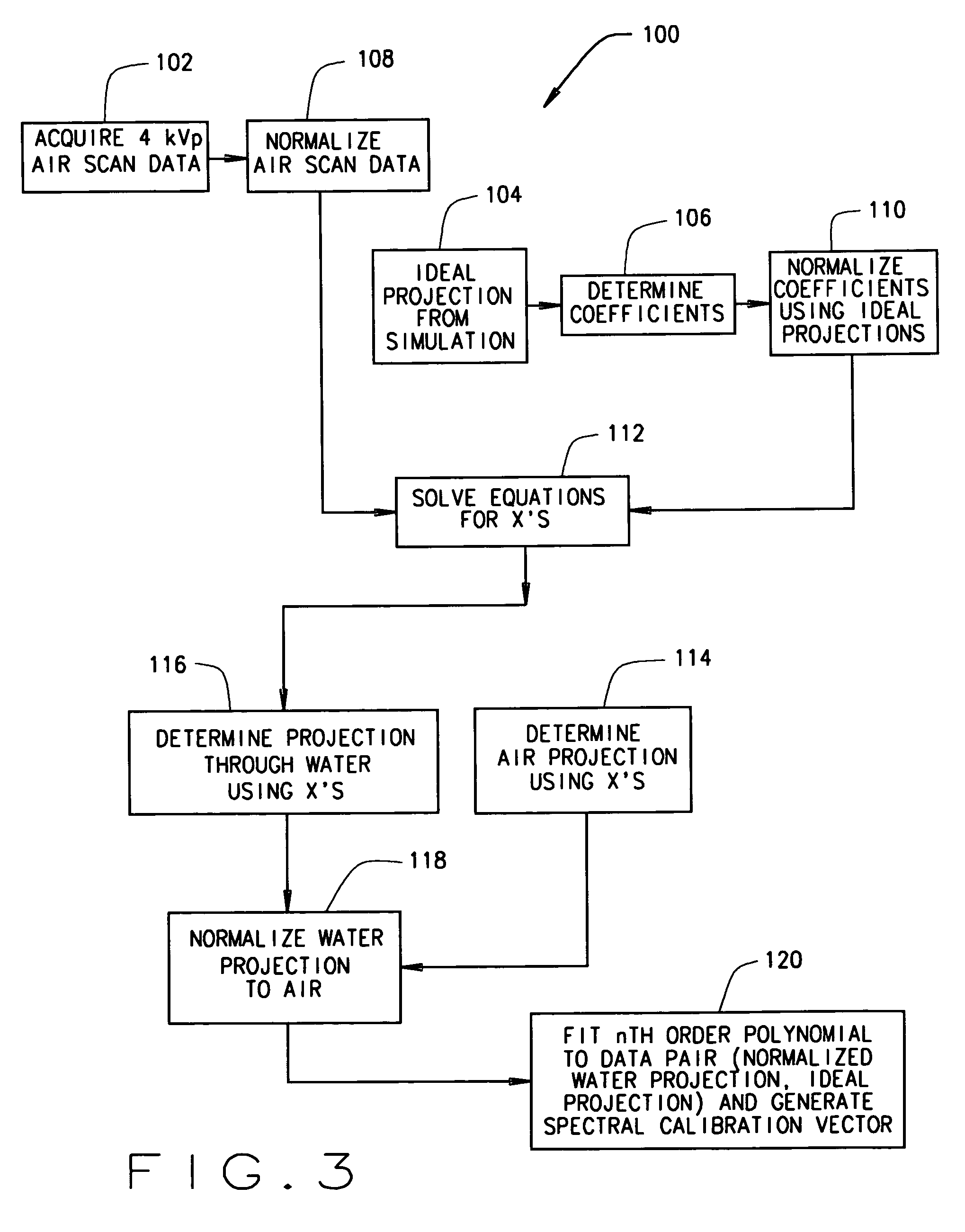

Method and apparatus for correcting for beam hardening in CT images

InactiveUS20060159223A1Material analysis using wave/particle radiationRadiation/particle handlingRadiologyBeam hardening

A method for determining a correction for beam hardening in CT images includes obtaining air scans at a plurality of kVp's, determining detection efficiencies for detector elements of the CT imaging apparatus, and estimating projection values through a combination of at least two different materials of different thicknesses. The method further includes determining a transfer function that translates the estimated projection values into ideal projection values for at least two of the different materials and storing the transfer function as the beam hardening correction for images of the CT imaging apparatus.

Owner:GENERAL ELECTRIC CO

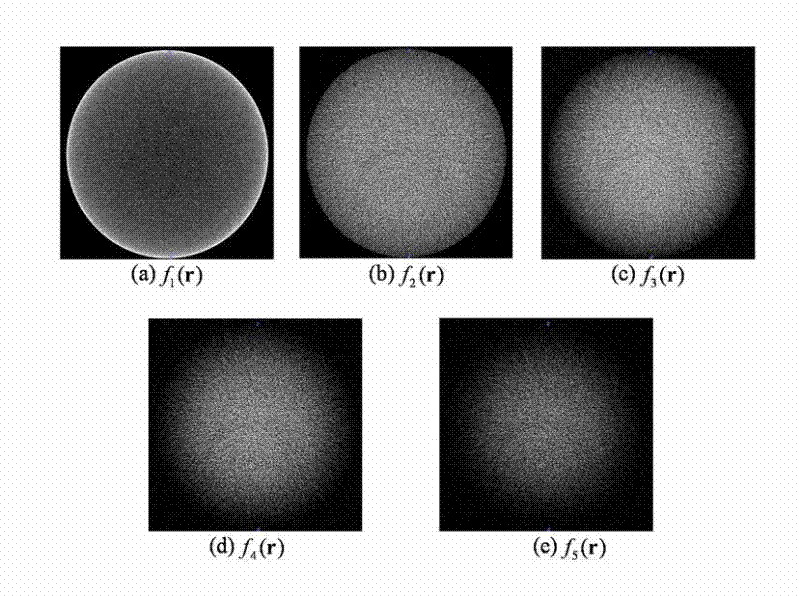

Base image TV model based CT (Computed Tomography) beam hardening correcting method

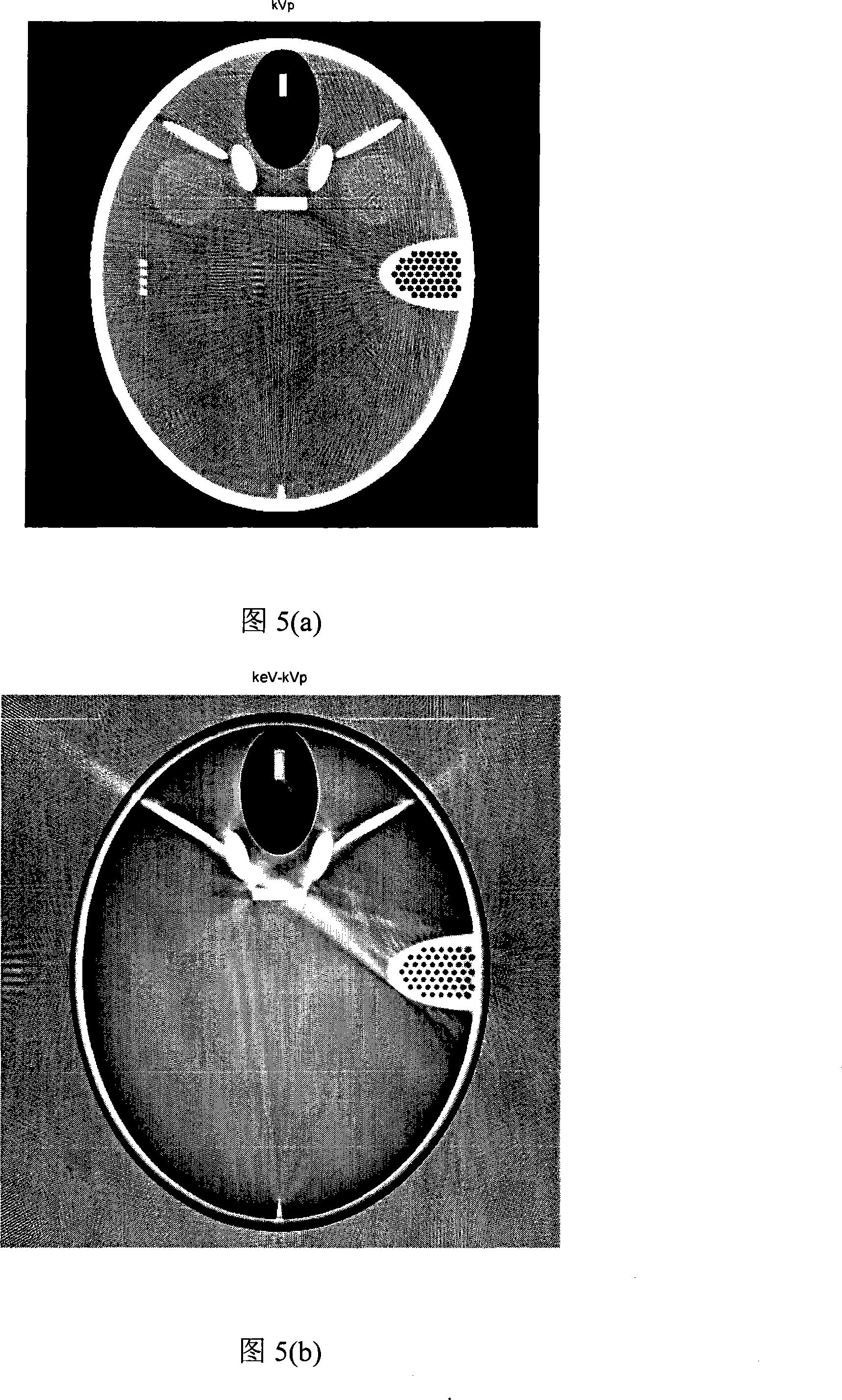

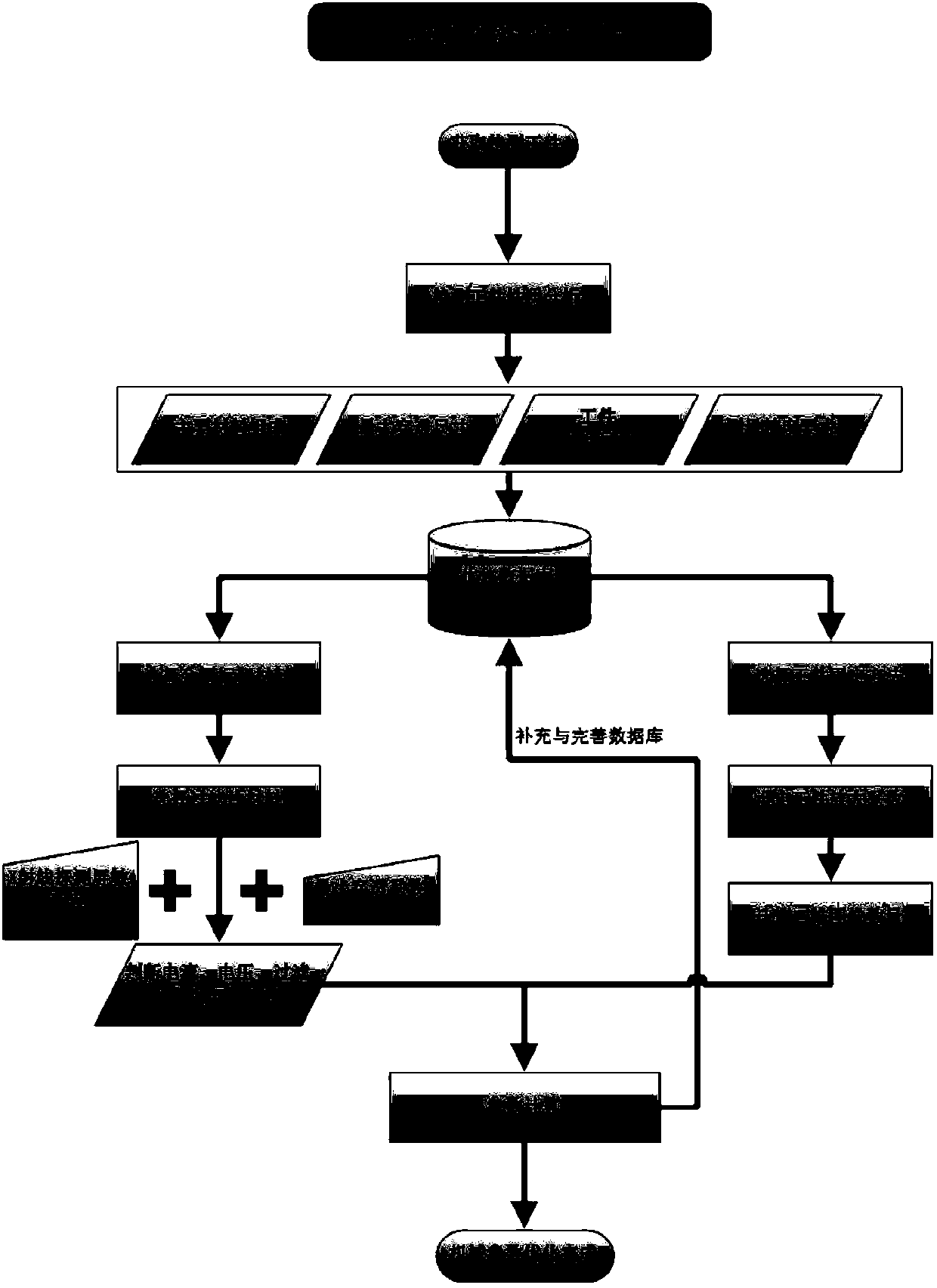

ActiveCN102609908ASuppress artifactsImprove general performanceImage enhancement2D-image generationComputation complexityBeam hardening

The invention relates to a CT (Computed Tomography) transmission imaging beam hardening correcting method and particularly relates to a base image TV minimized model based CT beam hardening correcting method. On the basis of establishing a beam hardening correcting model with an adjustable parameter, the base image TV model based CT beam hardening correcting method comprises the following steps: firstly, converting an original projection data through the model pretreatment so as to obtain sets of pretreated projection sequences under different adjustable parameter conditions; respectively reconstructing the pretreated projection sequences, thereby obtaining a series of corrected base images; taking a full-variation function of a target image as a cost function and obtaining an optimal solution of a weighting coefficient according to an iterative method; and lastly, summing the weights of the obtained series of base images, thereby forming a final reconstructed image. Compared with the traditional method, the method provided by the invention has the advantages that the priori knowledge, such as scanning copy material, radiation source condition, and the like, is unnecessary, the method is unlimited by external conditions and is strong in universality, and the linear combination is solved when a weighting coefficient is confirmed, so that the method has the advantages of small computation complexity and short operation time.

Owner:THE PLA INFORMATION ENG UNIV

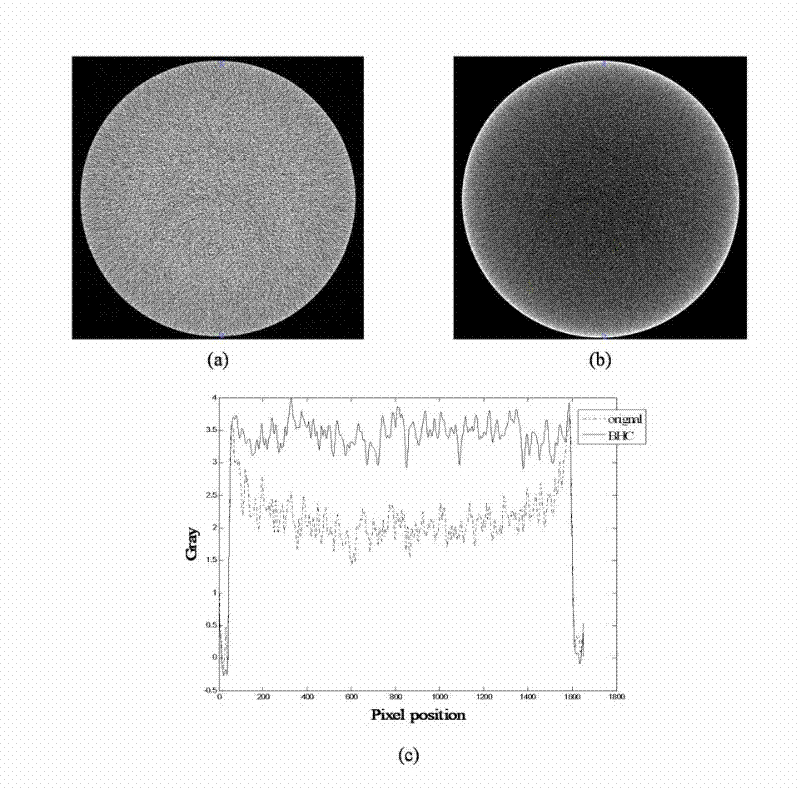

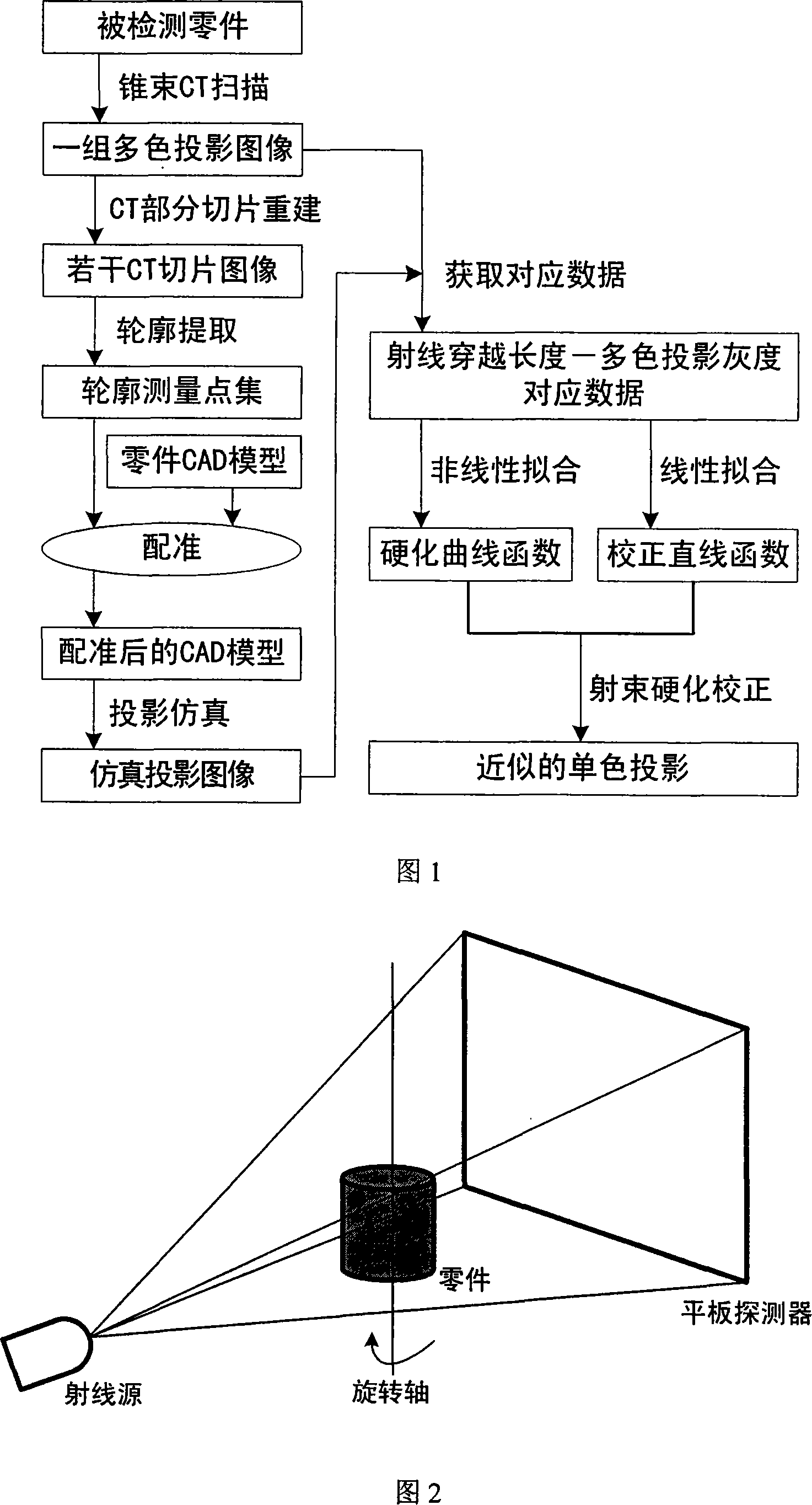

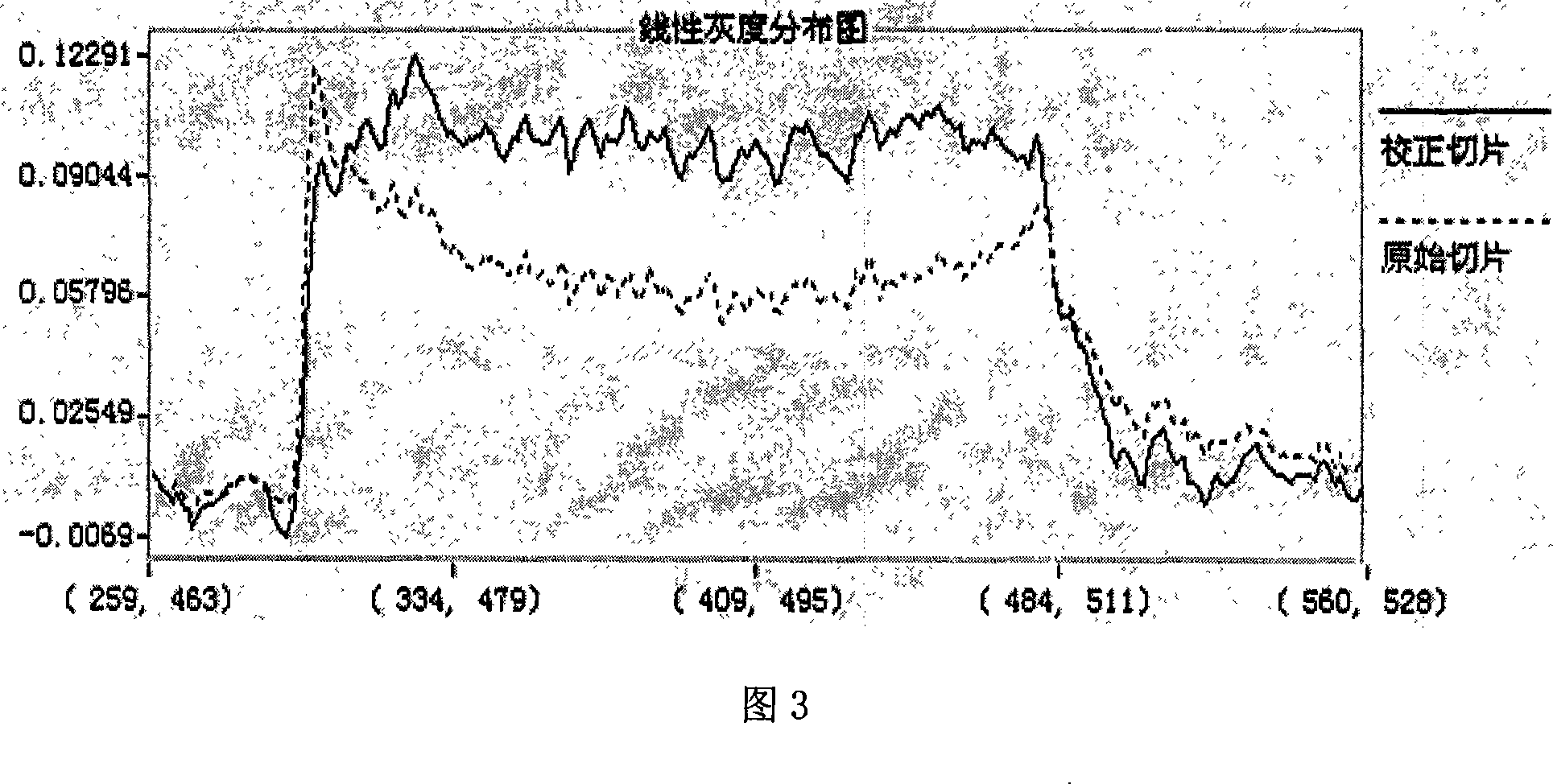

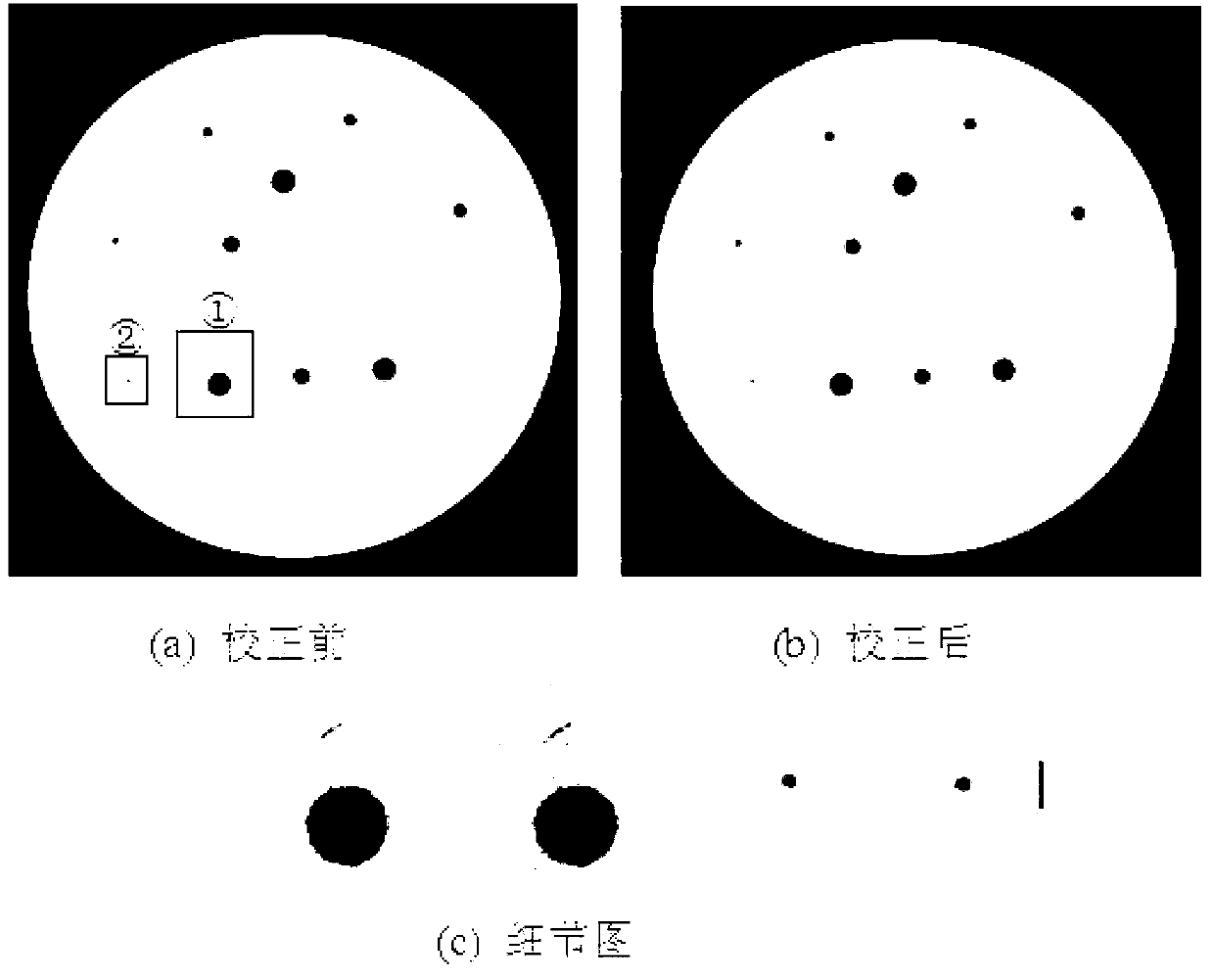

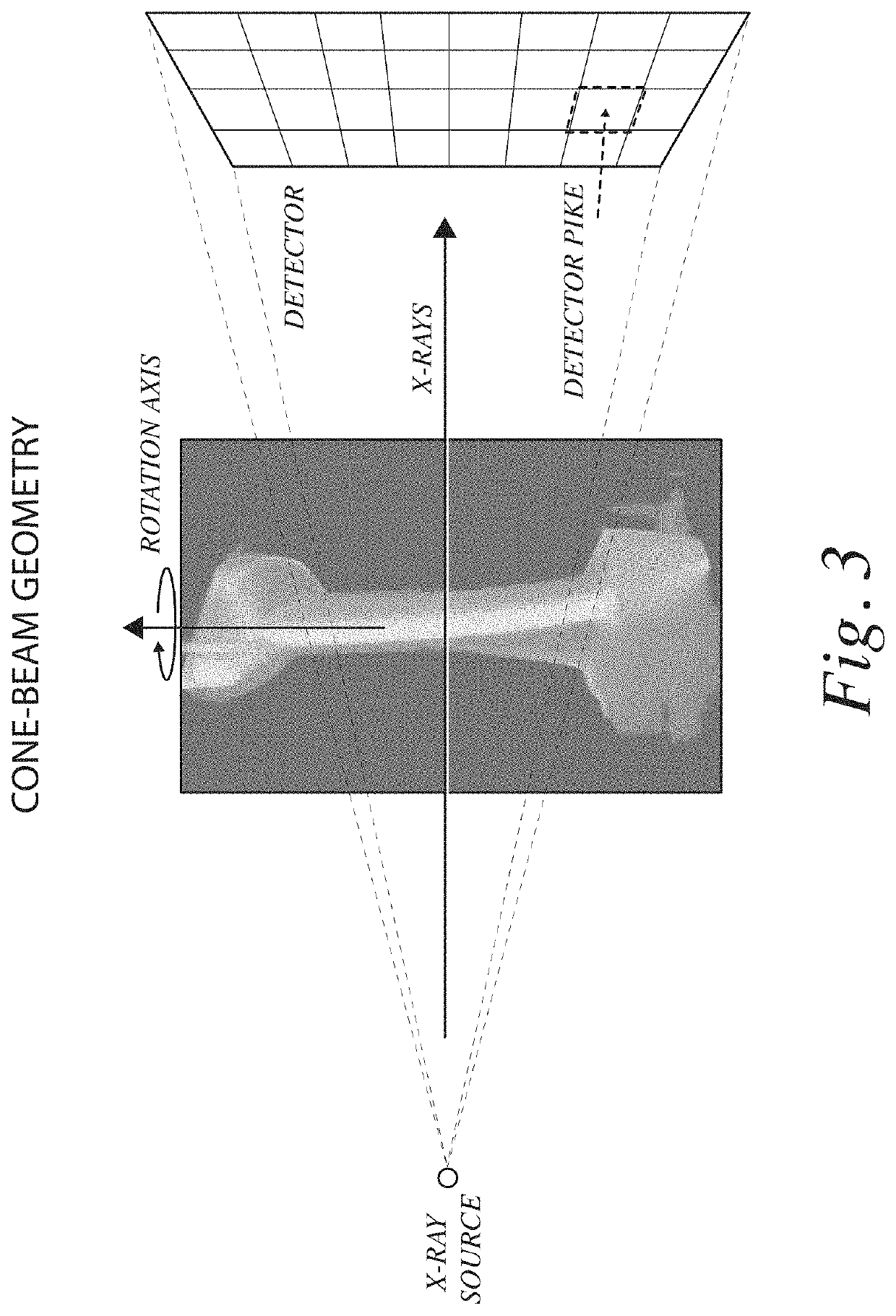

Cone-beam CT beam hardening calibration method based on registration model emulation

InactiveCN101126722AFlexibleReduced beam hardening artifactsImage enhancementImage data processing detailsMeasurement pointBeam hardening

The utility model discloses a beam hardening correction method of cone beam CT based on registration model simulation, which acquires multi-color projection data through circle locus cone beam CT scanning to a spare part. After acquiring CT images of sequence slices by cone beam CT reconstitution to the multi-color projection, the contour of certain pieces of the images are extracted so that a measurement point formed a plurality of closed contour lines is acquired. Projection simulation is processed after the registration of the measurement point and the CAD model of the part, and then the length of the part passing through the part at every imaging point is acquired. A hardening curve that passes through the original point is acquired by nonlinear fitting and a straight line that passes through the original point is acquired by linear fitting. The beam hardening constructed defect of the cone beam CT is corrected according to the hardening curve and the rectifying straight line. The utility model is flexible in application, and can approximately corrected through multi-color projection to unique color projection, and the beam hardening artifacts is reduced obviously after correction.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

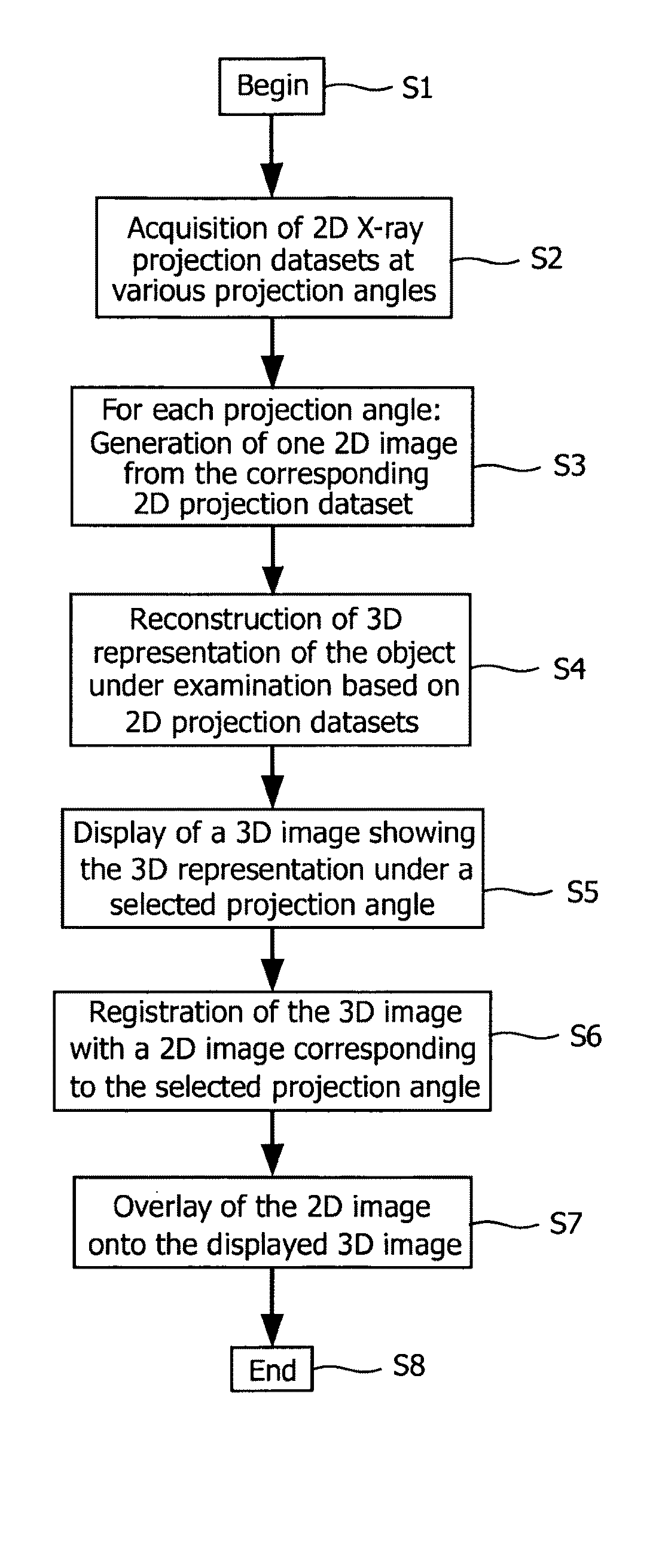

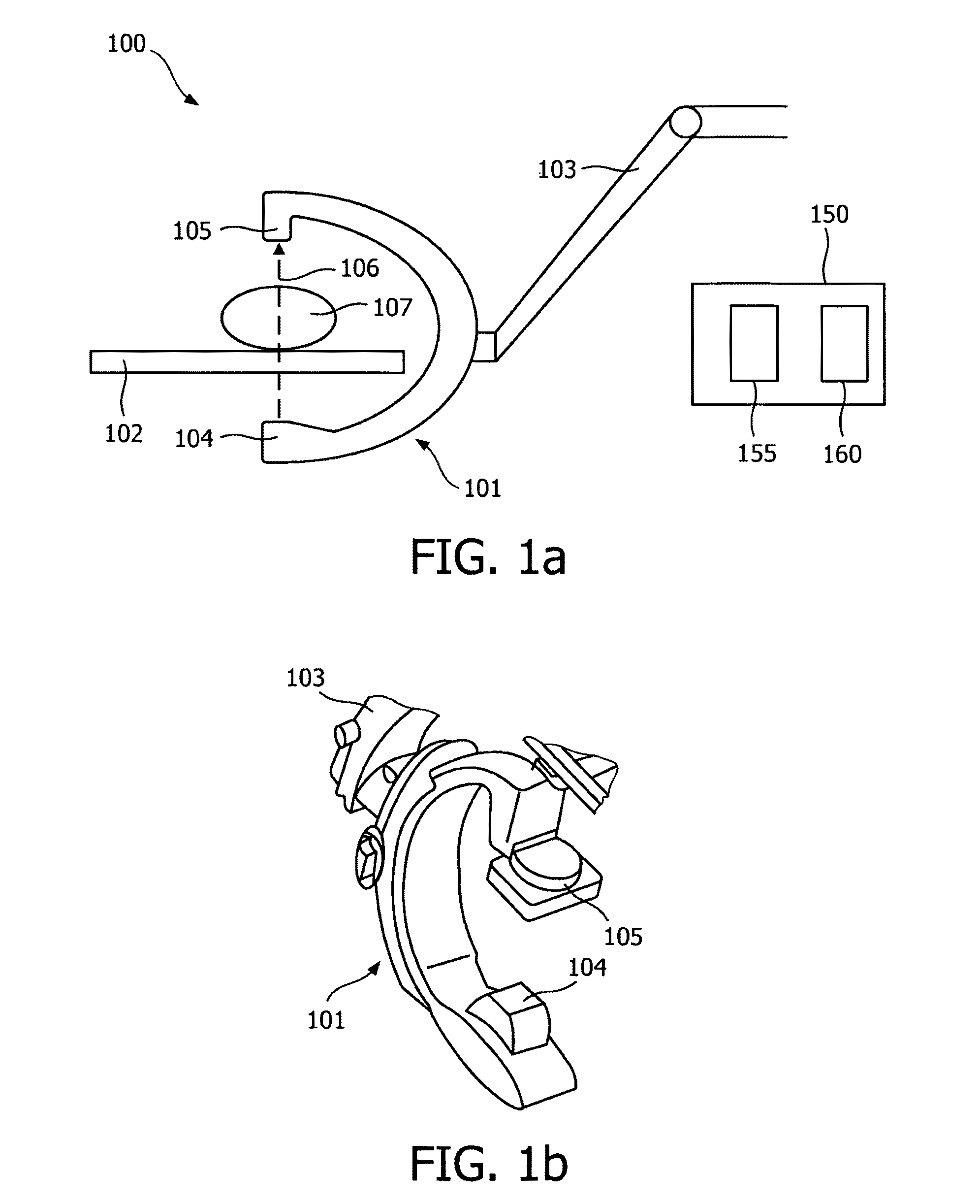

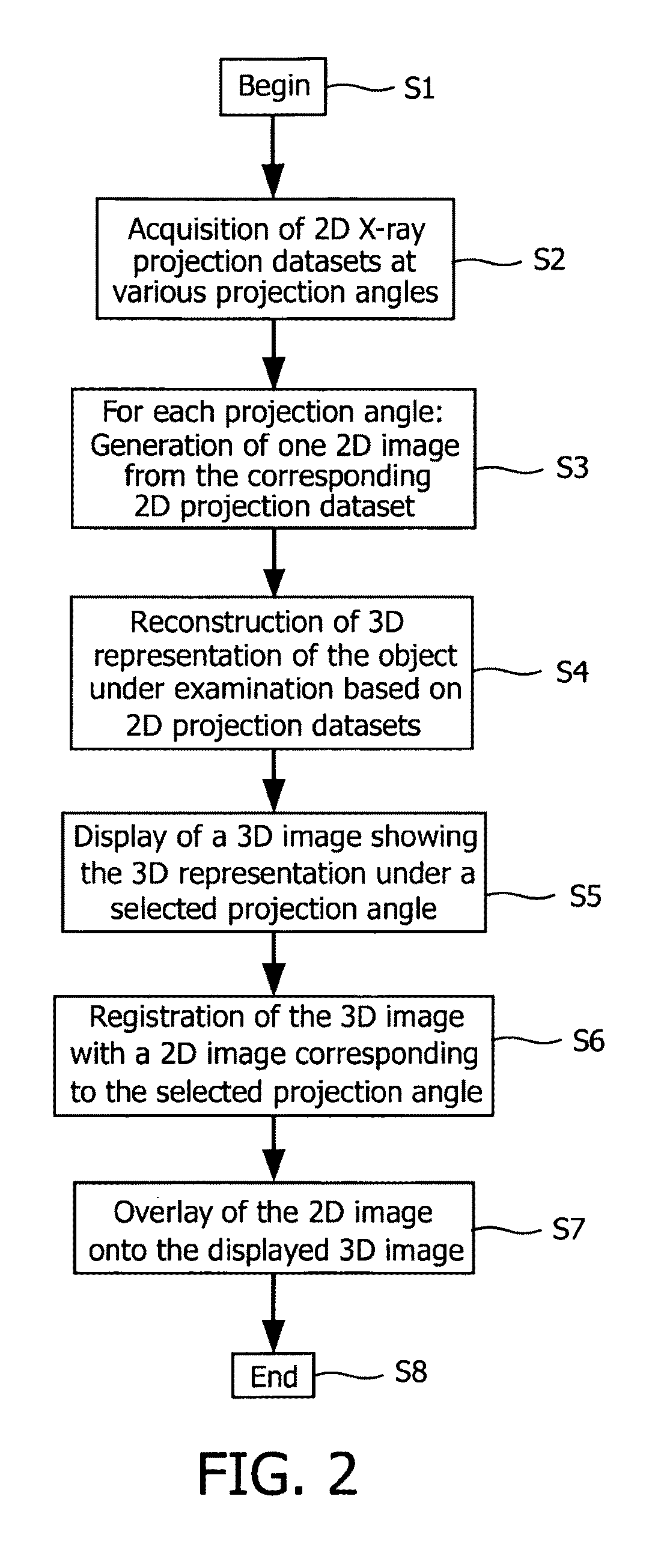

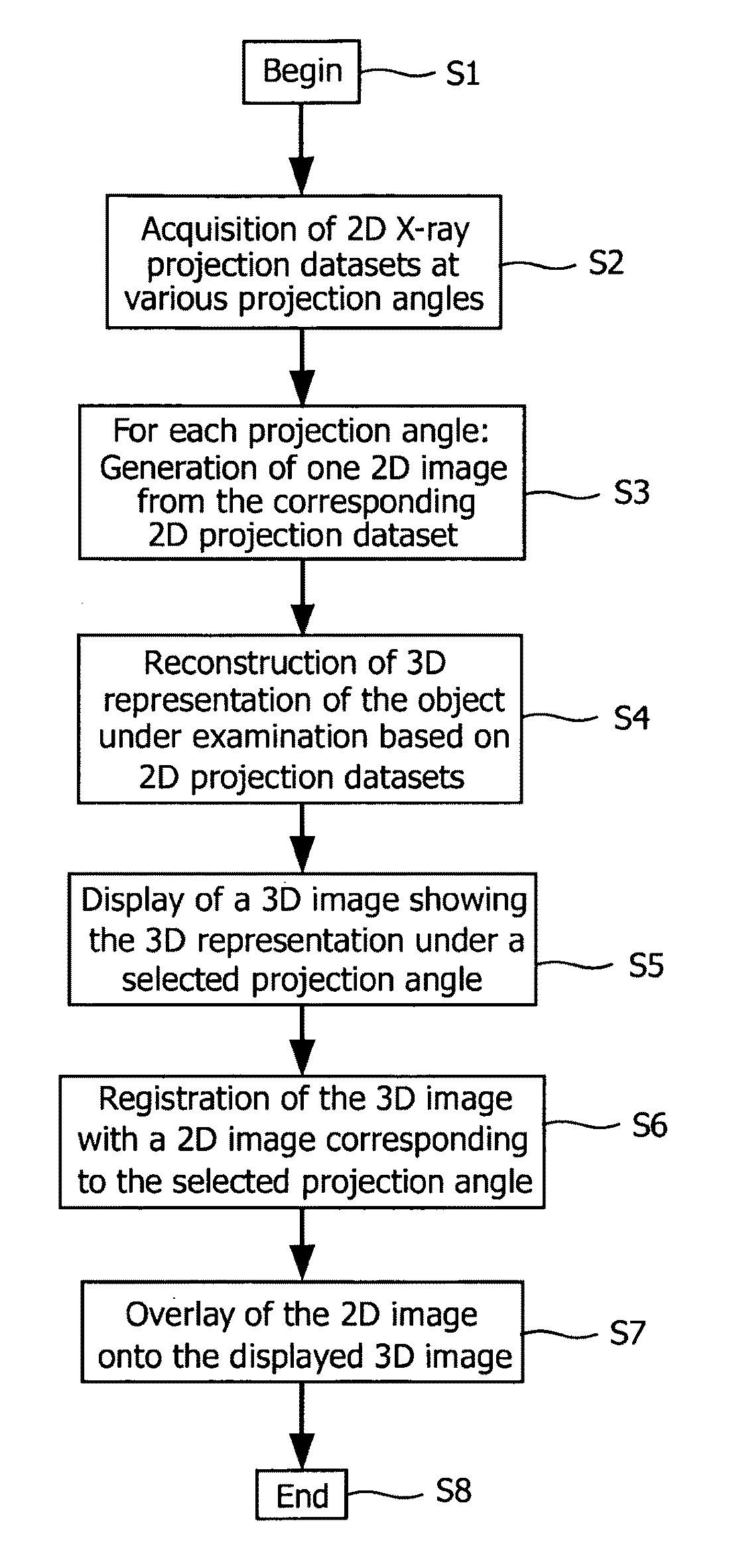

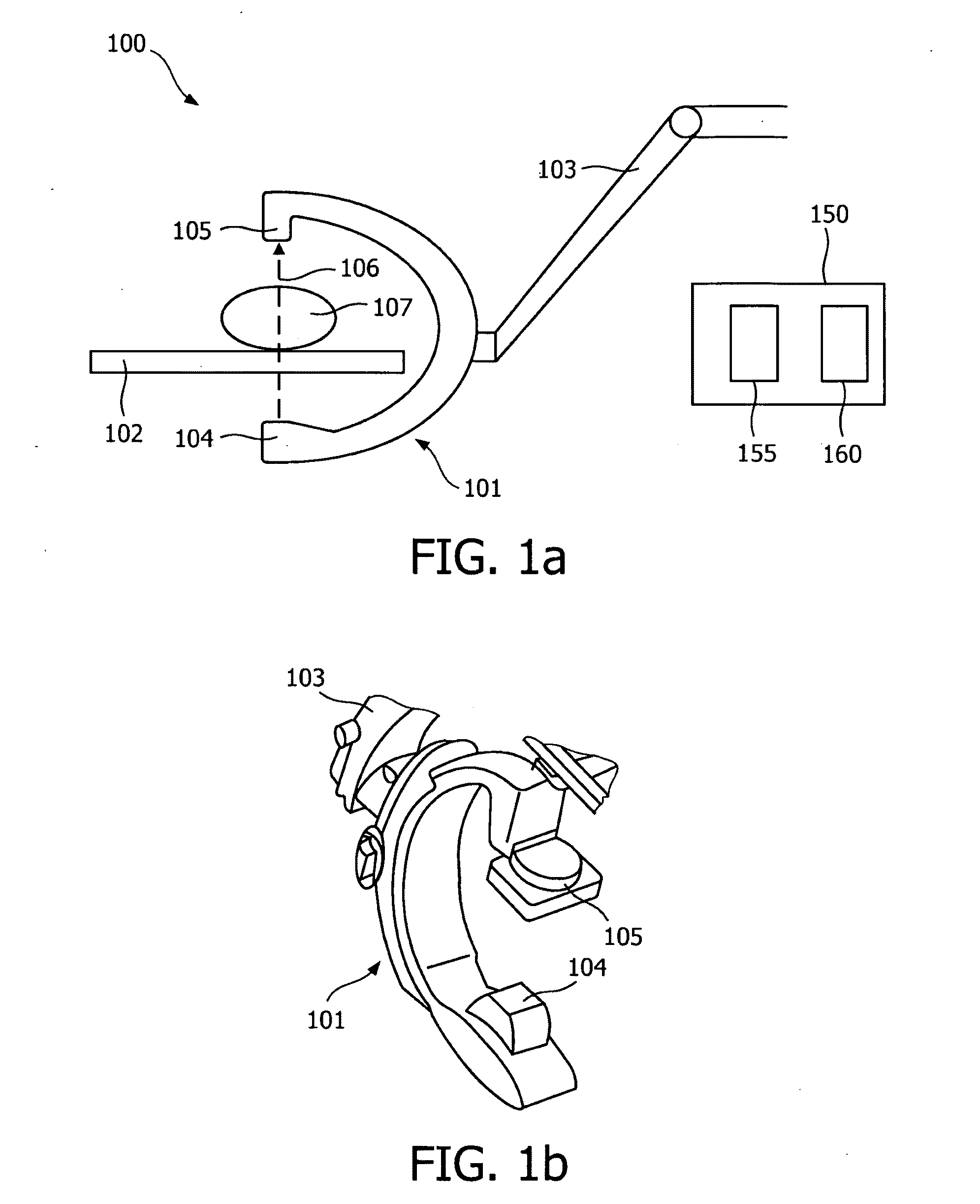

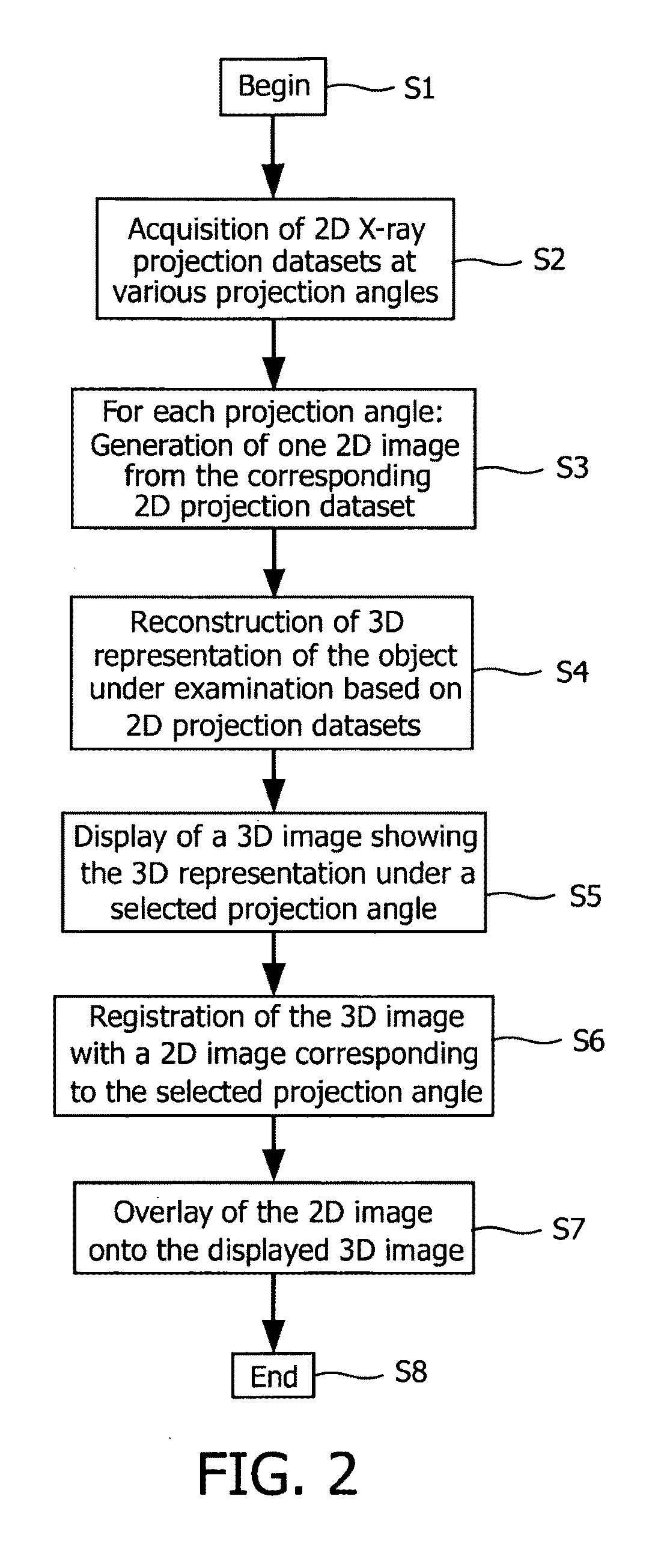

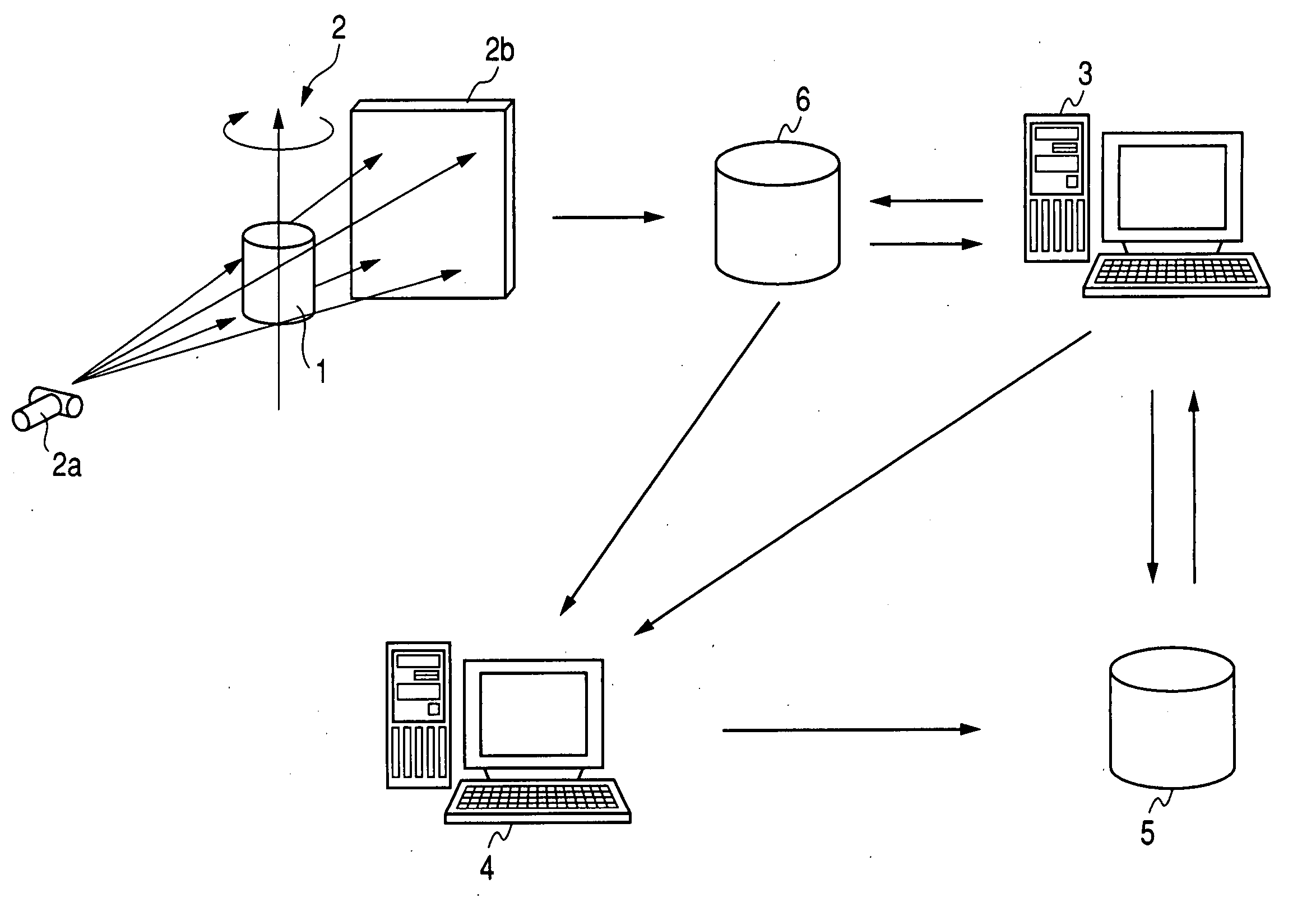

Visualization of 3D images in combination with 2D projection images

InactiveUS7991105B2Quality improvementIncrease awarenessReconstruction from projectionMaterial analysis using wave/particle radiationProjection image3d image

Original 2D rotational projections are combined preferably in an overlaying manner with corresponding viewings of a 3D reconstruction. By showing the 2D rotational projections in combination with the 3D reconstruction, 3D vessel information can be compared with the original 2D rotational image information over different rotational angles. In a clinical setup the combined visualization will allow for an easy check if findings in the 3D RA volume such as stenosis or aneurysms are not overestimated or underestimated due to e.g. an incomplete filling with contrast agent and / or a spectral beam hardening during the rotational scan.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Visualization of 3D images in combination with 2d projection images

InactiveUS20100296623A1Increase awarenessQuality improvementReconstruction from projectionMaterial analysis using wave/particle radiation3d imageProjection image

It is described an improved visualization of an object under examination (107). Thereby, original 2D rotational projections are combined preferably in an overlaying manner with corresponding viewings of a 3D reconstruction. By showing the 2D rotational projections in combination with the 3D reconstruction, 3D vessel information can be compared with the original 2D rotational image information over different rotational angles. In a clinical setup the combined visualization will allow for an easy check if findings in the 3D RA volume such as stenosis or aneurysms are not overestimated or underestimated due to e.g. an incomplete filling with contrast agent and / or a spectral beam hardening during the rotational scan.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Method for hardening correction in medical imaging

InactiveUS20080095302A1Eliminate the influence of noiseReduce the effects of noiseReconstruction from projectionRadiation/particle handlingProjection imageLight beam

The invention relates to a method for beam hardening correction in medical image. Beam hardening within the context of medical imaging projection image profiles are split up into a basic profile which is assigned to a homogeneous object area and into a detailed profile which is assigned to an inhomogeneous object area. On the basis of the basic profile and of the difference profile the mass occupancy of the different components in the object to be examined can be approximately determined. On the basis of the approximately determined mass occupancy the correction of the beam hardening can then be performed directly on the projection data.

Owner:SIEMENS HEALTHCARE GMBH

Method for three-dimensional representation of stratified structure micrometer CT imaging of turbine blade heat barrier coating

InactiveCN104897698AImprove reconstructed image qualityRealize 3D structural analysisMaterial analysis by transmitting radiationPorosityProcess quality

The invention discloses a method for three-dimensional representation of stratified structure micrometer CT imaging of a turbine blade heat barrier coating. The method comprises the following steps: preparing a double-layer-structure heat barrier coating micrometer CT scanning sample; firstly, carrying out micrometer CT scanning on the heat barrier coating sample, carrying out ring artifact and beam hardening correction on projection data, then carrying out three-dimensional reconstruction to obtain three-dimensional stratified structure information, establishing a three-dimensional structure analysis model, and carrying out characteristic segmentation and extraction on three components, namely a ceramic heat insulating layer, a bonding layer and matrix alloy; then, analyzing the thickness of the coating, extracting the distribution of holes in the coating, calculating the porosity, extracting the interface topography of the coating, and analyzing structure characteristics such as internal defects; and finally, estimating the preparation process quality of the heat barrier coating by integrating the composition, thickness, porosity distribution, interface topography and the like. The method for three-dimensional representation of the stratified structure of the heat barrier coating provided by the invention is suitable for estimation and optimization of the spraying process quality of the heat barrier coating, so that the quality of the heat barrier coating can be well controlled.

Owner:NANCHANG HANGKONG UNIVERSITY

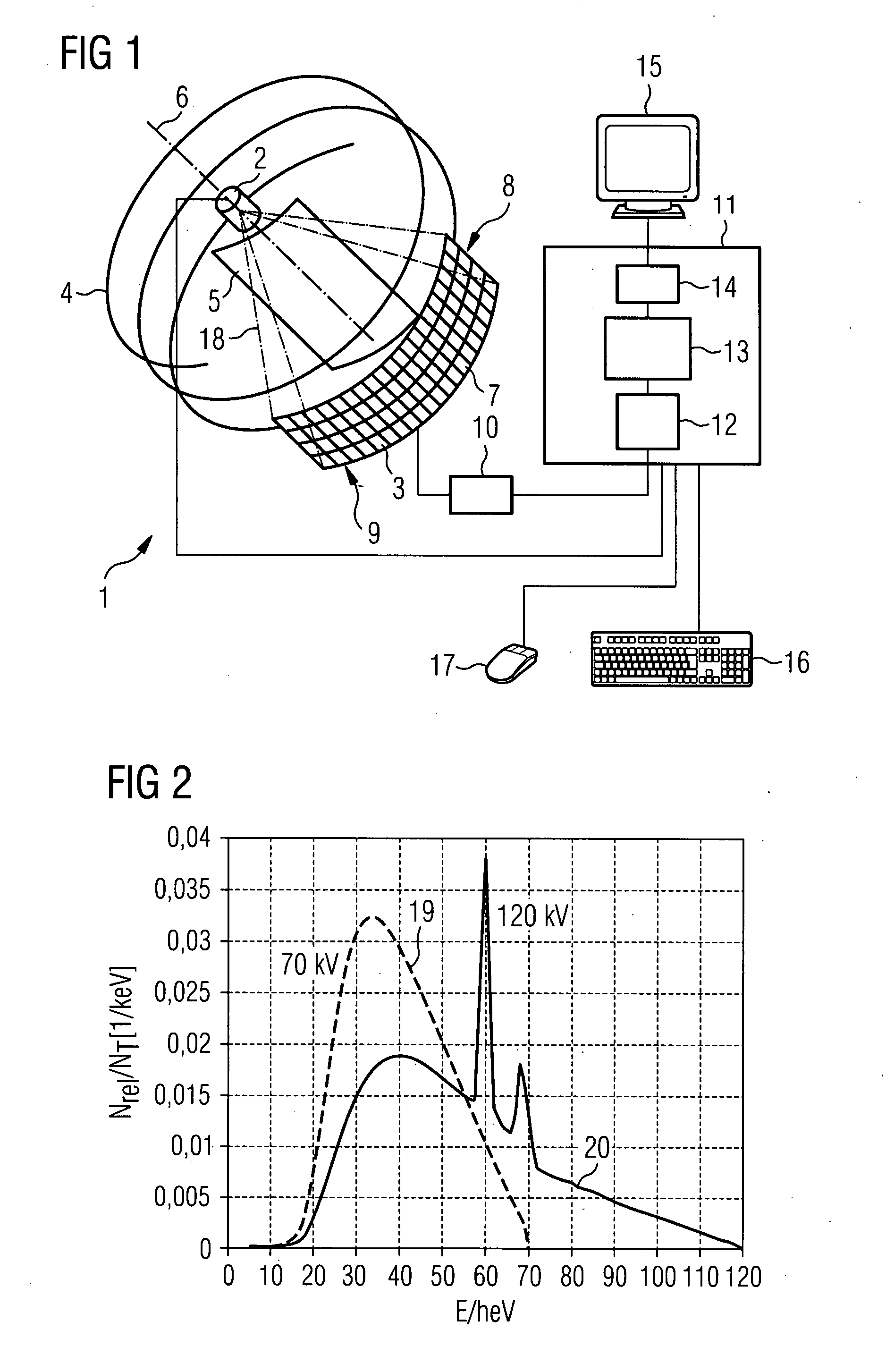

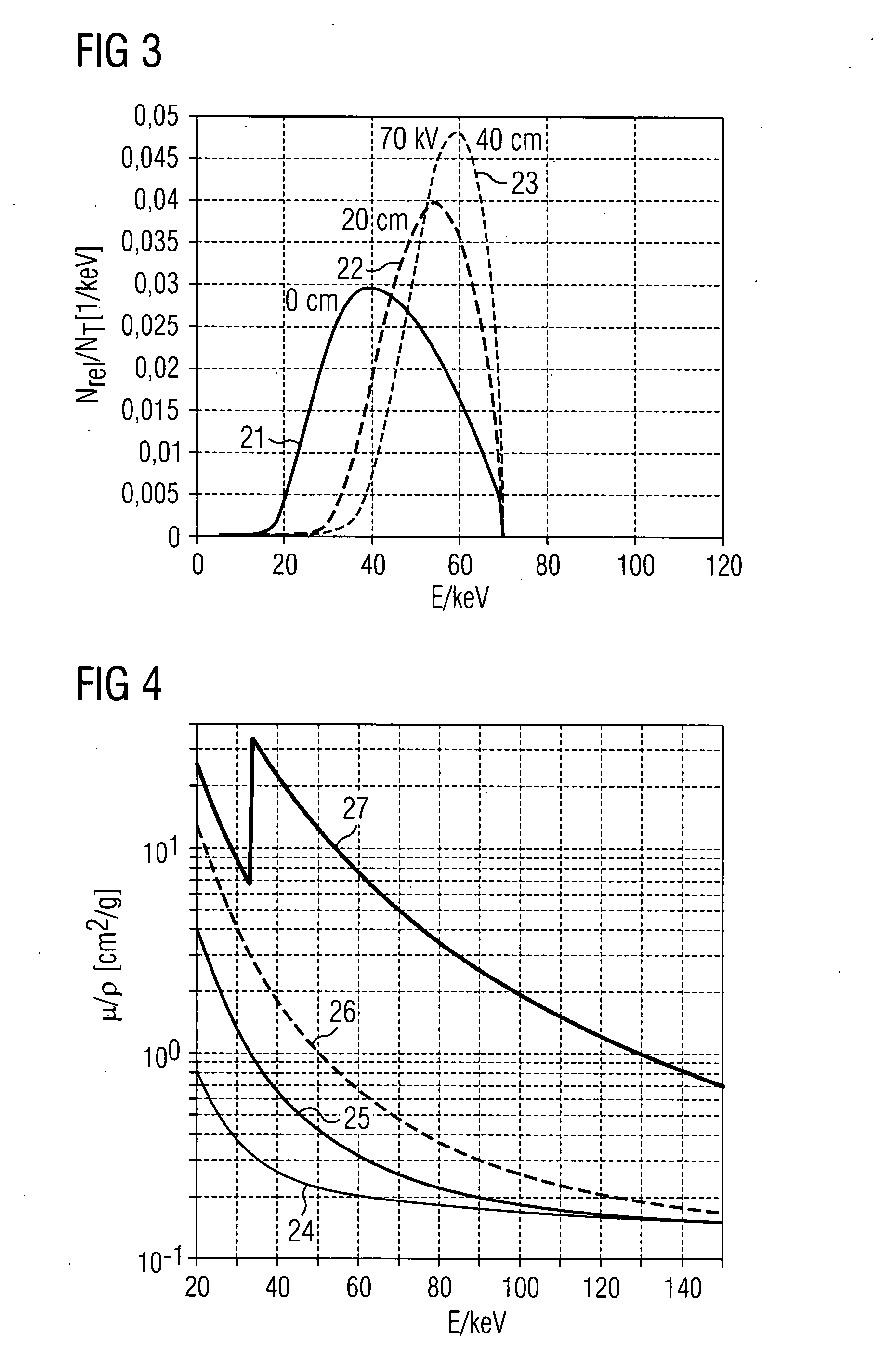

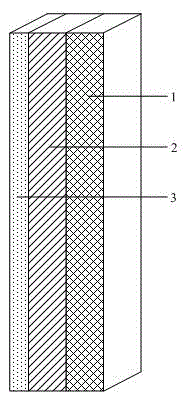

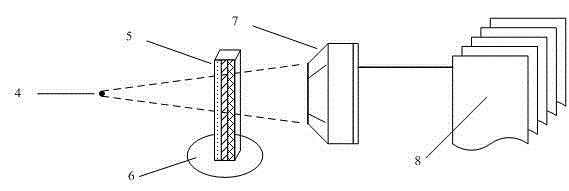

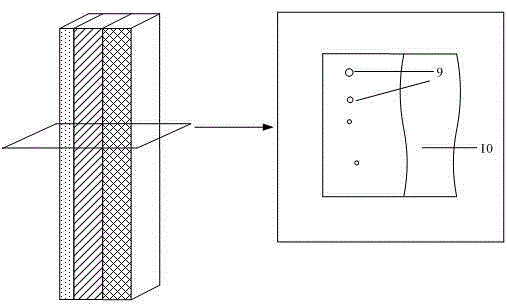

Method and apparatus for empirical determination of a correction function for correcting beam hardening and stray beam effects in projection radiography and computed tomography

Methods for empirical determination of a correction function for correcting beam hardening and stray beam effects of water-equivalent tissue in projection radiography or computed tomography using an imaging detector, and apparatuses for implementing the same are disclosed. The projection values obtained from the logarithmic values of the detector signals are corrected, the corrected projection values being represented by a correction function dependent on the tube voltage applied during the X-ray projection recording, the coefficients of which function are determined from a single calibration scan on an object-like calibration phantom made of water-like material.

Owner:ZIEHM IMAGING

Method and apparatus for determining an object material

ActiveUS20070064868A1Short integration timeImprove spatial resolutionMaterial analysis by optical meansMachines/enginesAttenuation coefficientLight beam

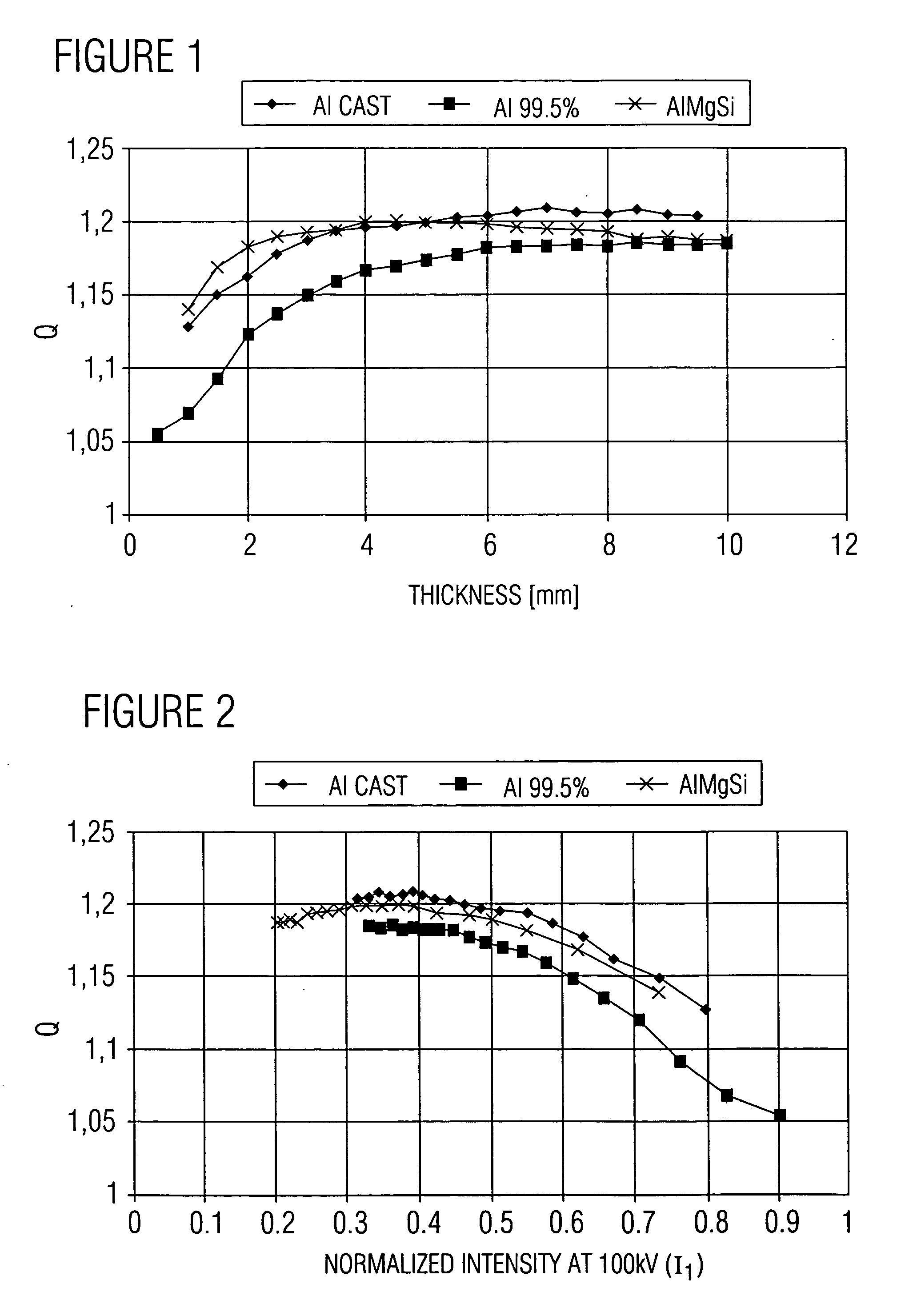

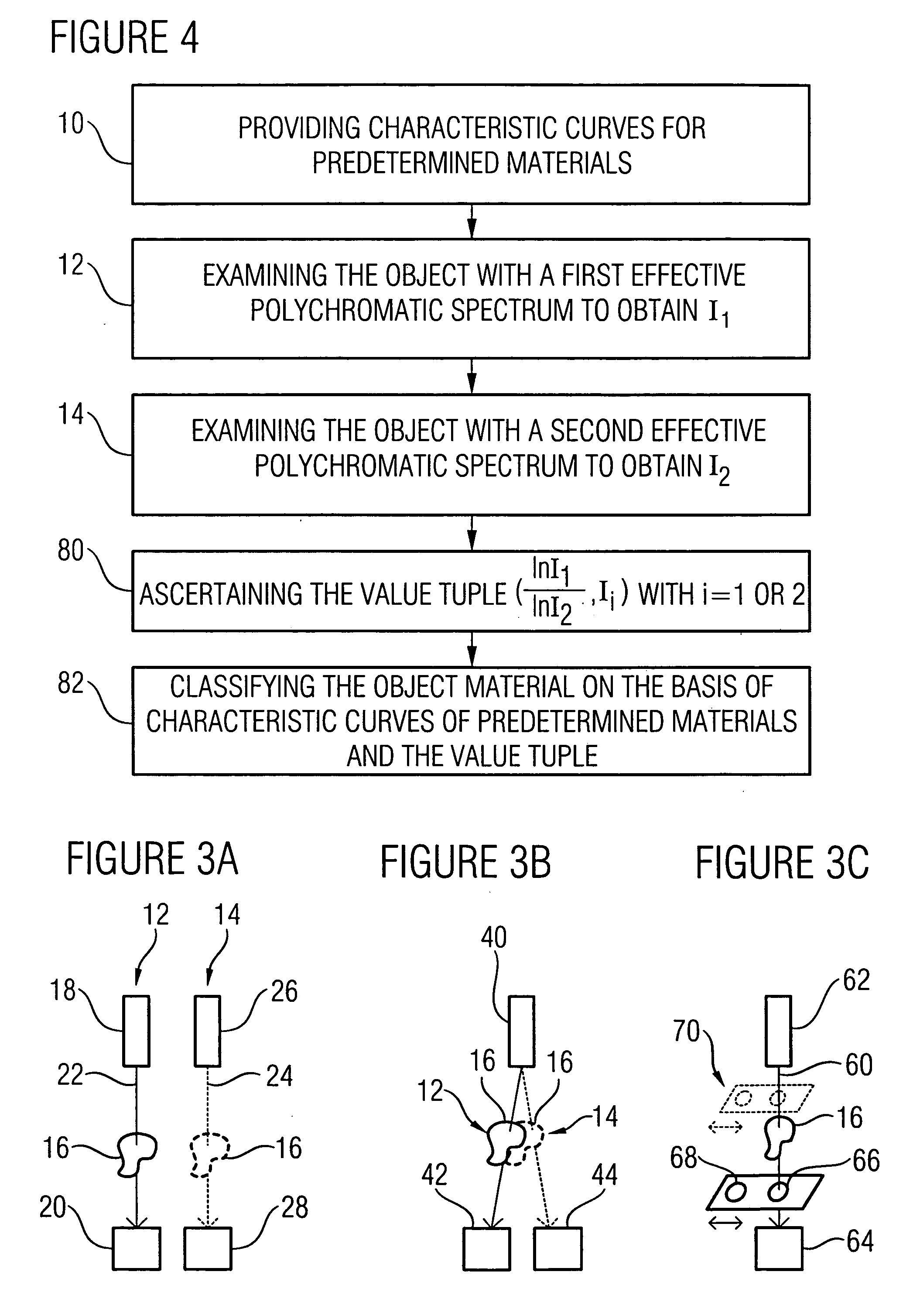

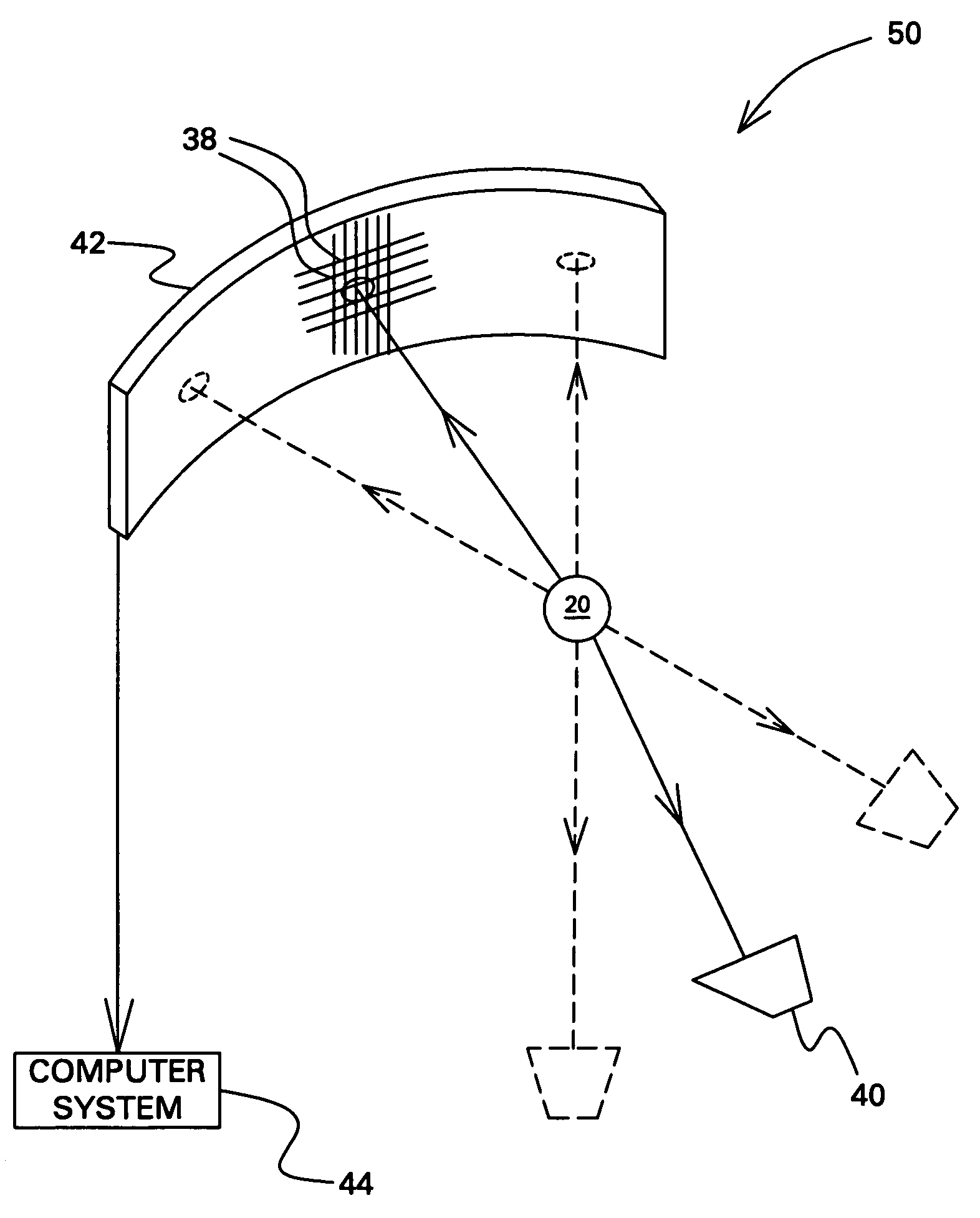

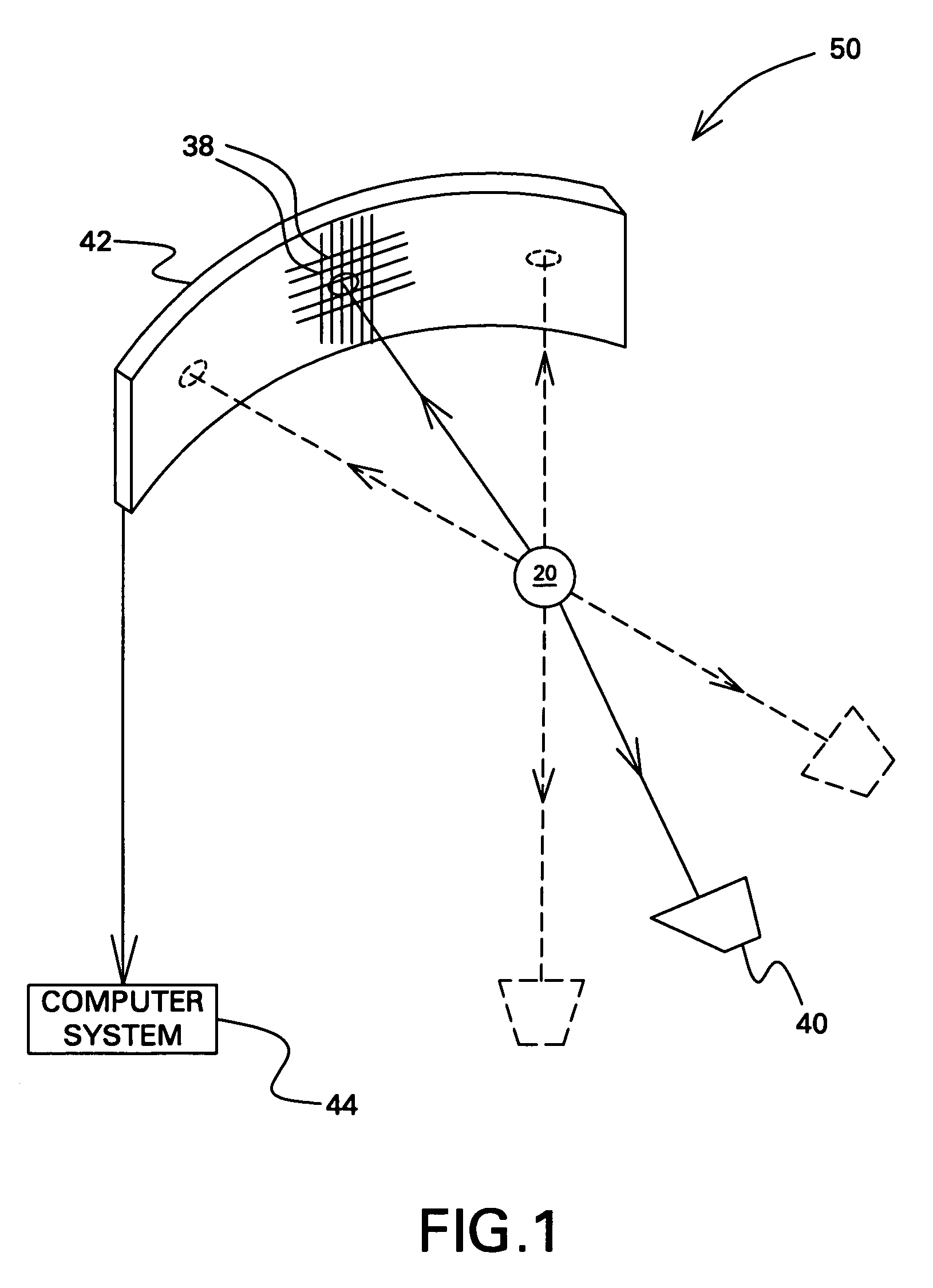

One finding of the present invention is that, by use of radiation with a polyfrequent effective spectrum for the examination of the object, beam hardening or shift of the spectrum's center of gravity does indeed lead to the fact that the effectively operative absorption coefficient or attenuation coefficient and / or the effective operative reflection coefficient of the object material, and thus particularly also the ratio of two coefficients to different radiation spectrums, no longer is solely specific for the material, but also depends on the thickness, but that this may be accepted, and nevertheless exact classification of the object material can still be done by using, in addition to the ratio of the absorption and / or reflection coefficients, one of the intensity values resulting during irradiations, in order to perform an association with one of a plurality of predetermined materials on the basis of reference data.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

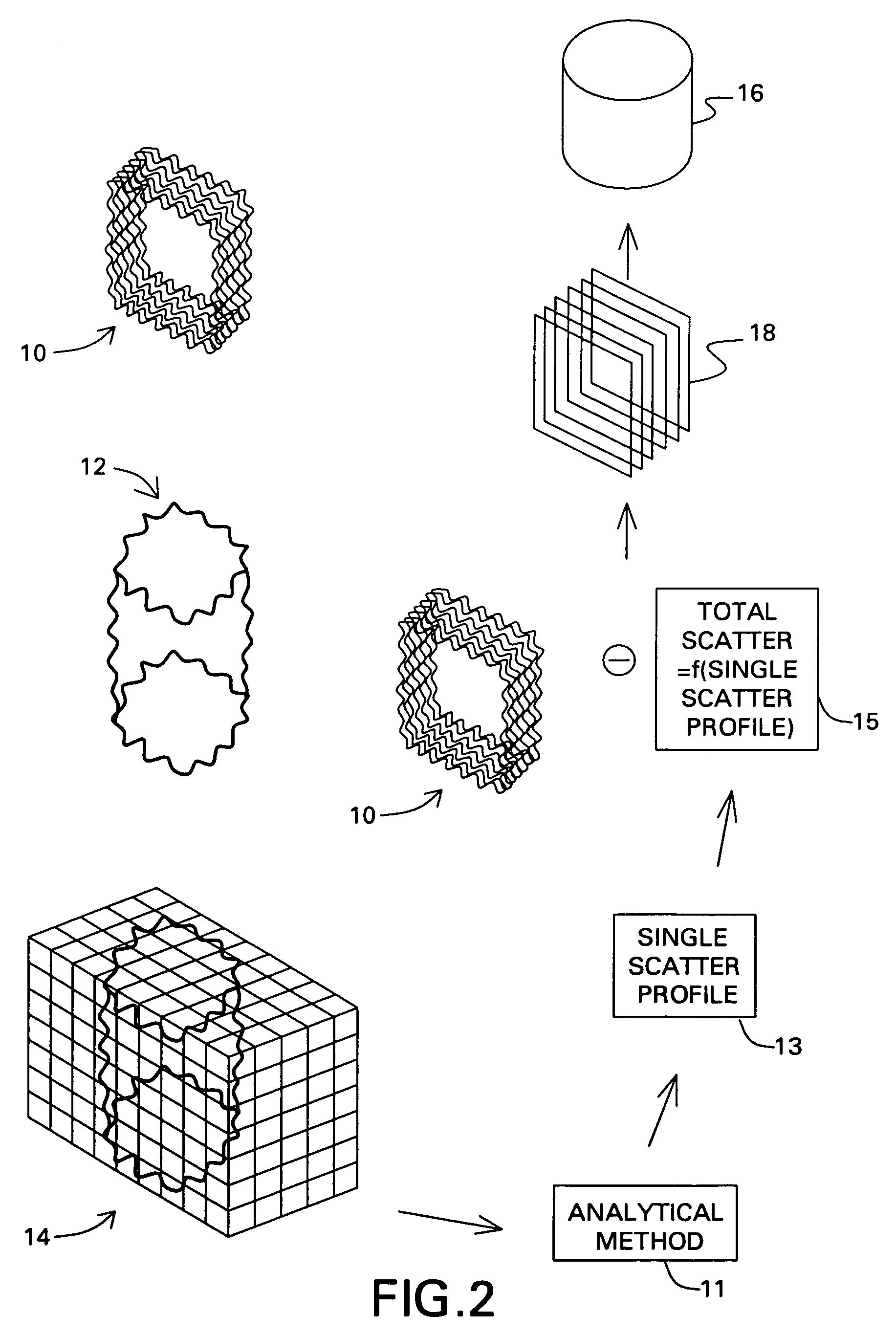

Scatter and beam hardening correction in computed tomography applications

InactiveUS7065234B2Reconstruction from projectionRadiation/particle handlingSpectral response3d image

A method of correcting scatter includes obtaining a voxellized representation of a 3D image of an object from a plurality of projection data. A single scatter profile for the object is calculated using the voxellized representation of the 3D image of the object. A total scatter profile for the object is determined using the single scatter profile and an adjustment factor and the projection data is corrected using the total scatter profile to obtain a scatter corrected projection data. A beam hardening correction method includes simulating a number of attenuation data for an x-ray spectrum, at least one object material, and a detector spectral response. A function is fitted to the attenuation data to obtain an attenuation curve. A number of projection data for an object are corrected using the attenuation curve to obtain a number of beam hardening corrected projection data. A corrected image of the object is reconstructed from the beam hardening corrected image data.

Owner:GENERAL ELECTRIC CO

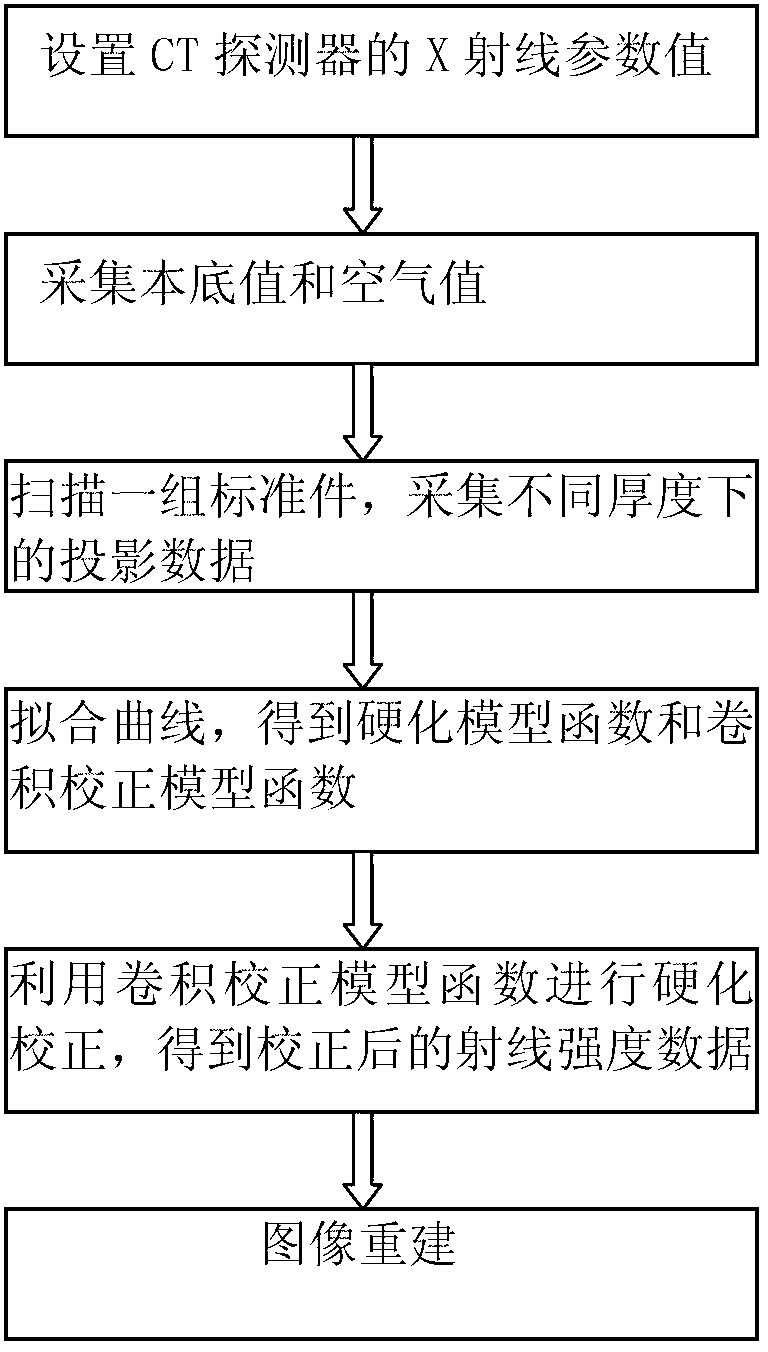

Convolution-based X-ray CT system beam hardening correction method

InactiveCN103134823ANo lossSignificant beam hardening correctionMaterial analysis by transmitting radiationBeam hardeningAluminum foil

The invention discloses a convolution-based X-ray CT system beam hardening correction method, belonging to the applying field of industrial CT systems. The method comprises the following steps of: I. conducting scattering correction by clinging an aluminum foil filter plate to a rear collimator; II. setting the scanning parameter of a CT system; III. collecting the background value of the system with a ray source not opening; IV. opening the ray source, and scanning the air in the current laboratory to obtain the ray strength of the current air; V. scanning a group of standard parts, and collecting the projection data under different thicknesses; VI. fitting a curve to obtain a hardening model and a convolution correction model; VII. conducting hardening correction by utilizing the function of the convolution correction model to obtain the corrected ray strength data; and VIII. conducting image reconstruction by using the corrected ray strength data. With the correction method, the beam hardening correction effect is obvious, the edge of a detected object can be well maintained, the detail part of the detected object can be saved, and the high-precision detection need can be met.

Owner:CHONGQING UNIV

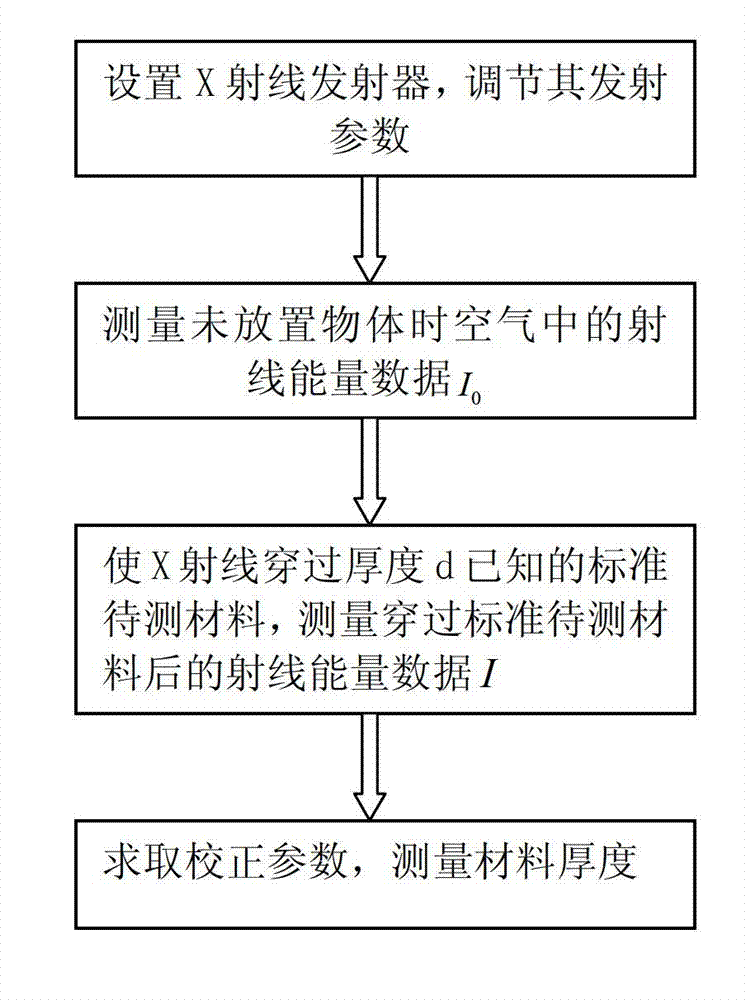

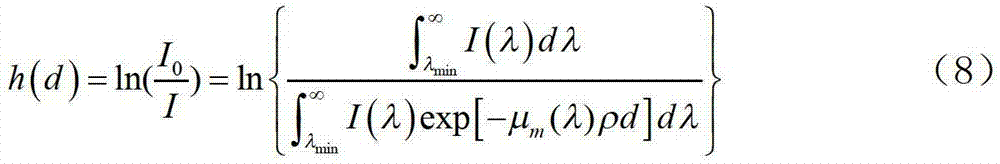

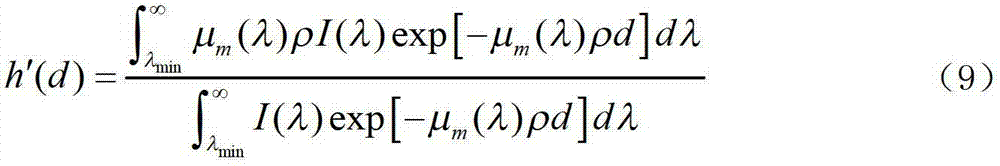

Method and device for measuring X-ray thickness

InactiveCN103206931AWith correction functionThe problem of inaccurate customer service measurementUsing wave/particle radiation meansSoft x rayUltrasound attenuation

The invention discloses a method and device for measuring X-ray thickness and belongs to the field of ray measurement. The method for measuring the X-ray thickness comprises the steps of (1) arranging an X-ray emitter and adjusting emitting parameters; (2) starting up the X-ray emitter and measuring energy data I0 of rays in the air where an object is not placed; (3) starting up the X-ray emitter, enabling X-rays to penetrate through a standard to-be-measured material with known thickness d and measuring the ray energy data I after the rays penetrates through the to-be-measured material; and (4) calculating correction parameters by means of the following methods for obtaining corresponding attenuation coefficients mu according to a formula, performing least-squares curve fitting calibration to obtain the correction parameters A, alpha and beta according to a formula mu(d)=A(e-alphad+beta) and performing thickness measurement of the to-be-measured material according to a formula. By means of the method, the problem of mismeasurement caused by 'beam hardening' of the X-rays is solved. The method has a correction function. The method and device for measuring the X-ray thickness is simple and easy to operate, high in accuracy and strong in reliability.

Owner:CHONGQING UNIV

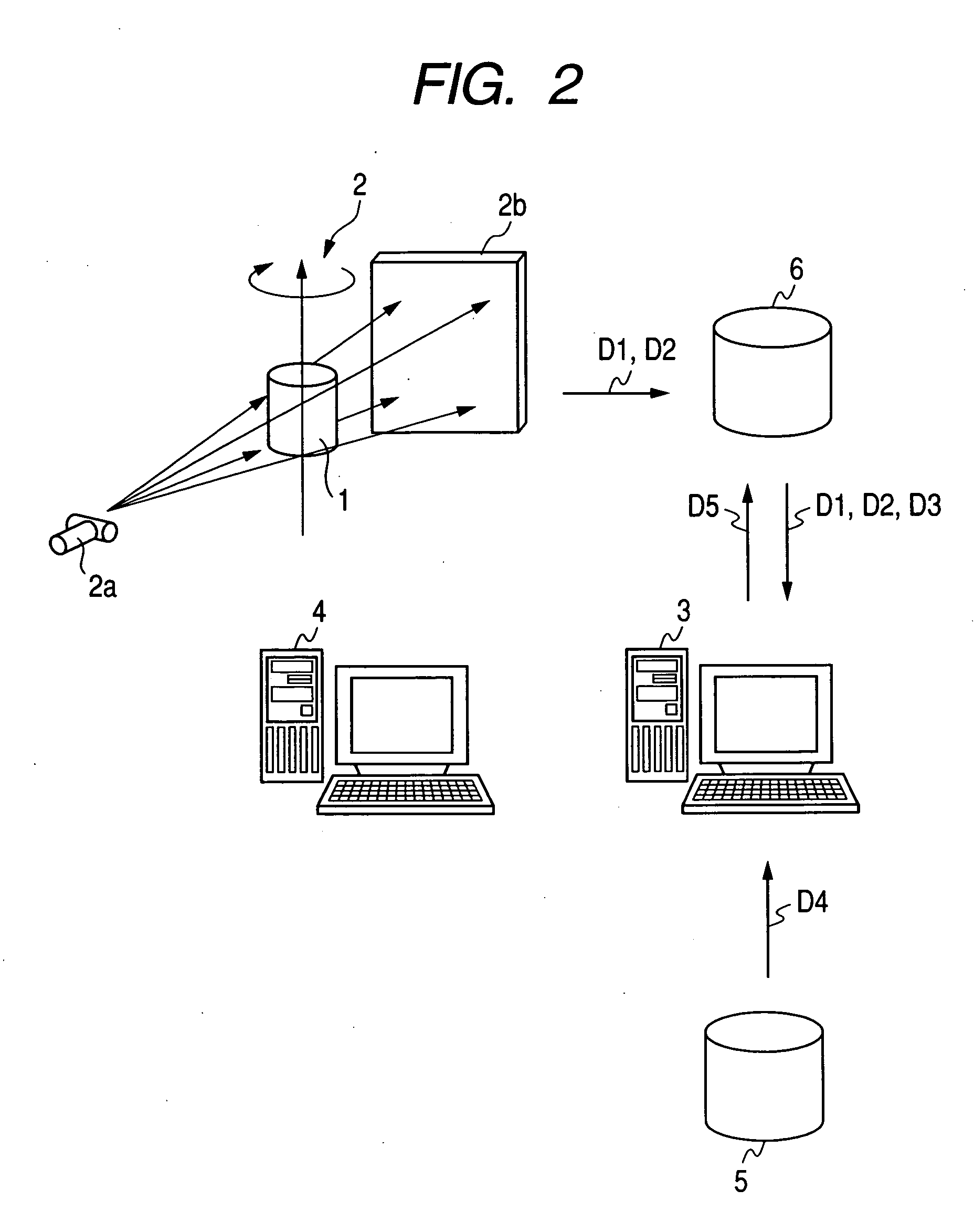

Medical information processor, image photographing system, and absorption coefficient calibration method

ActiveUS20060049358A1Easily obtain dataReconstruction from projectionPhotometryUltrasound attenuationX-ray

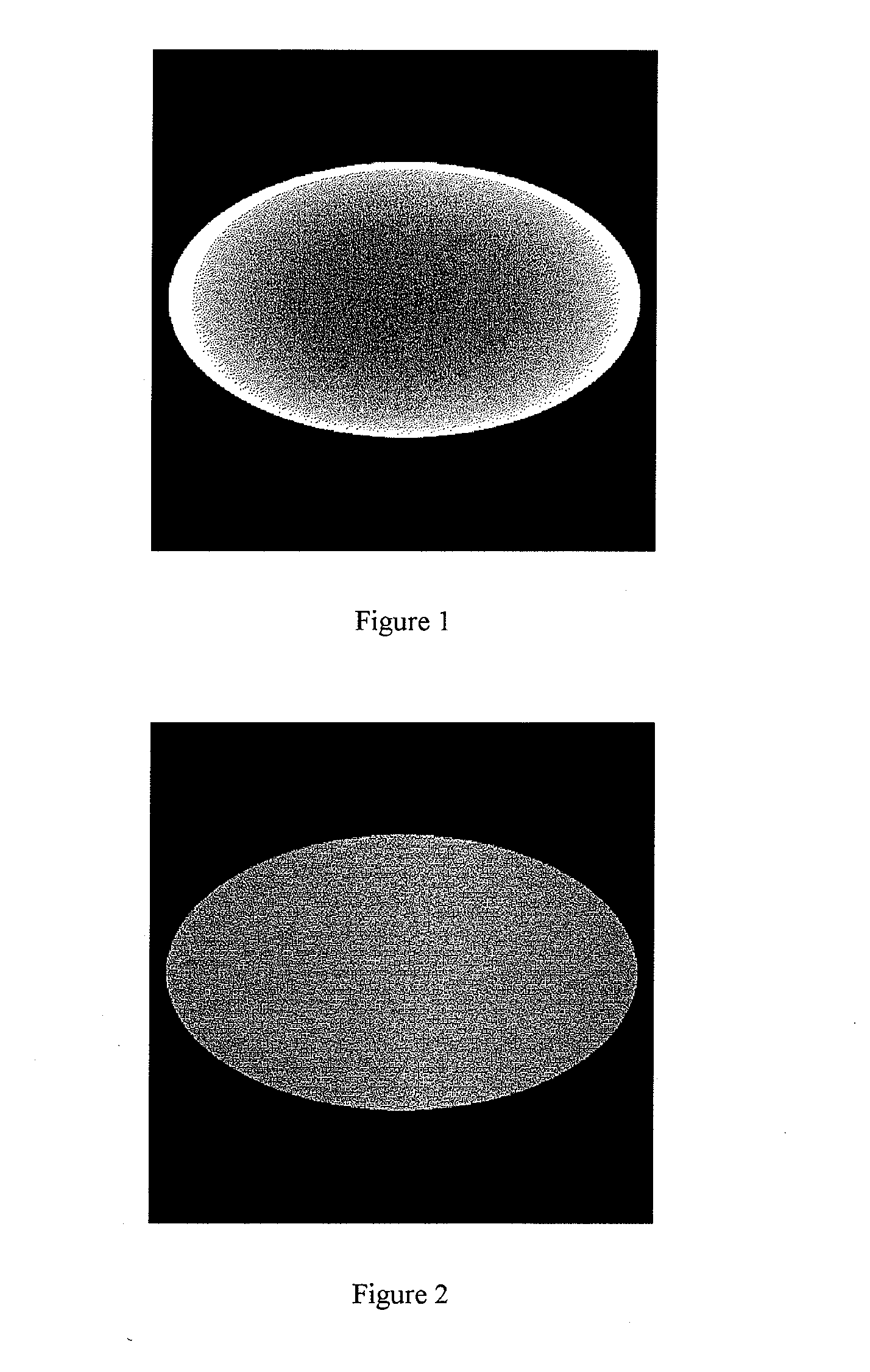

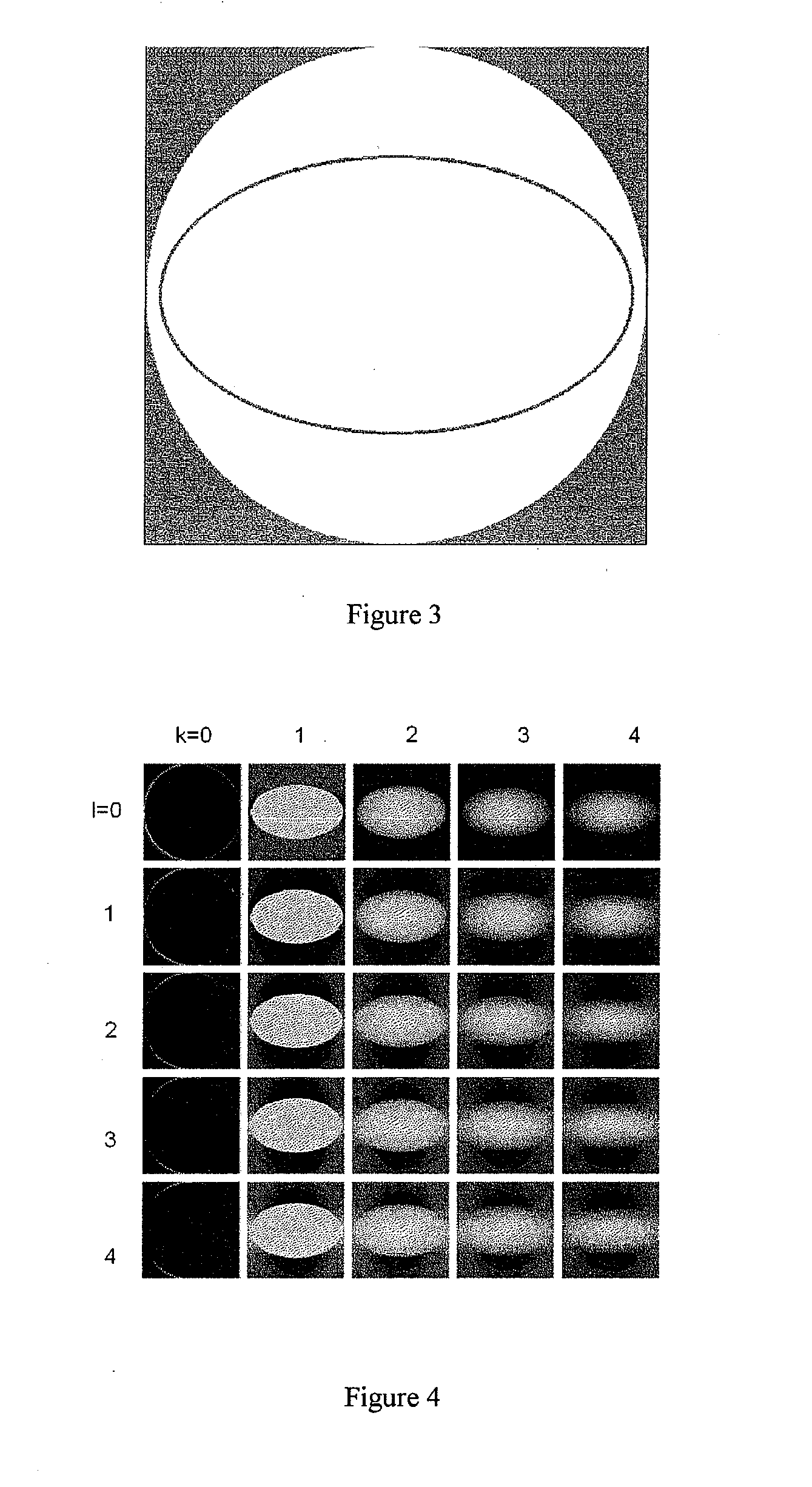

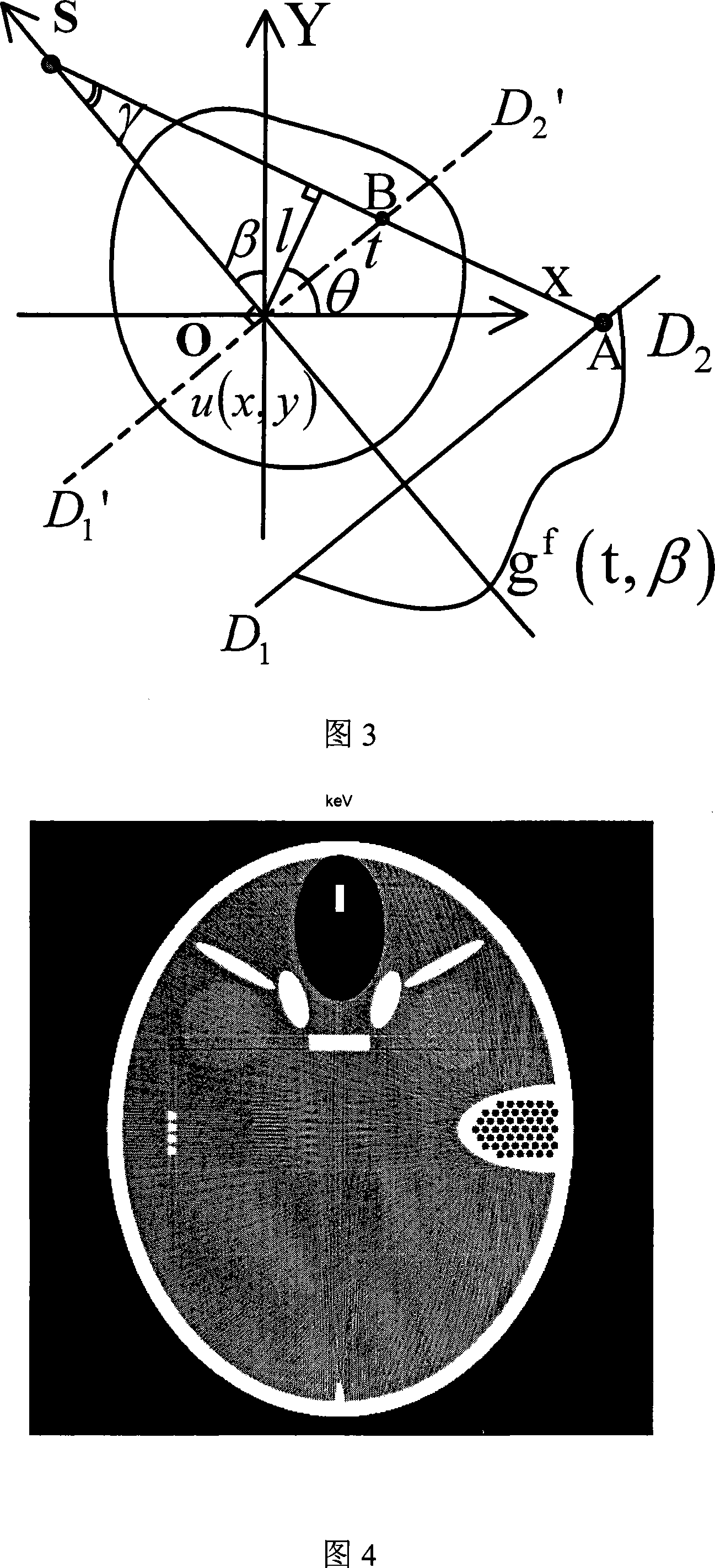

According to the present invention, data of arbitrary penetration thickness can be easily obtained in carrying our a beam hardening calibration. A center tomographic image reconstructed parallel to a center line of a projection data of a water phantom and an X-ray tube is read from an image data server. The read center tomographic image is two-dimensionally modeled on a circle. A radius and a center coordinate of the circle on which the image is two-dimensionally modeled are used to re-arrange the X-ray tube, the sensor, and the modeled circle. Points of intersection A and B of the re-arranged circle and a path along which the X-rays reach the sensor from the X-ray tube are determined to obtain a penetration thickness of the water phantom based on the points of intersection A and B. Accordingly, in order to determine an attenuation property when the X-rays are penetrated through a subject, a larger quantity of data of an output value of a sensor with respect to the penetration thickness is gathered with ease.

Owner:CANON KK

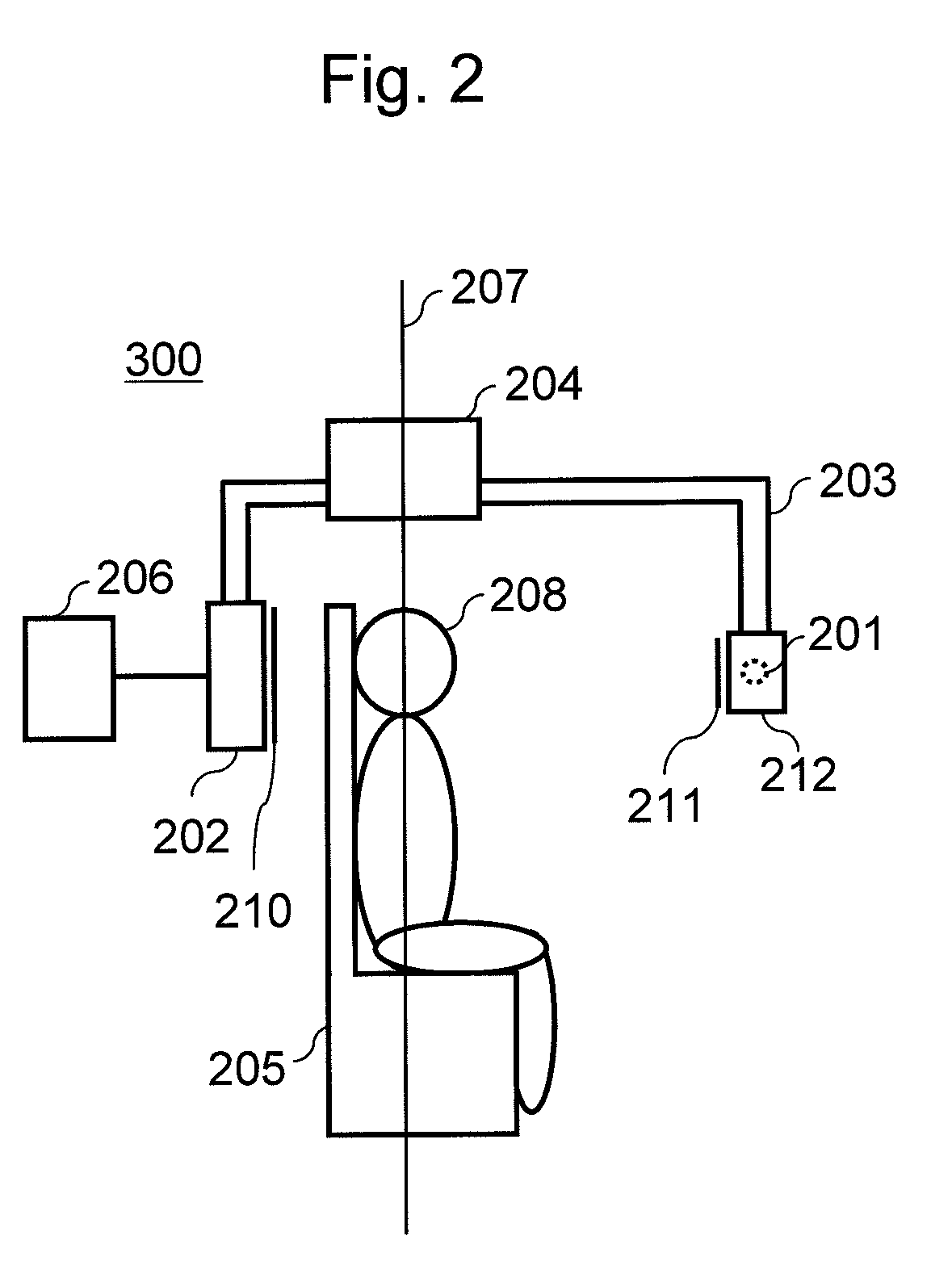

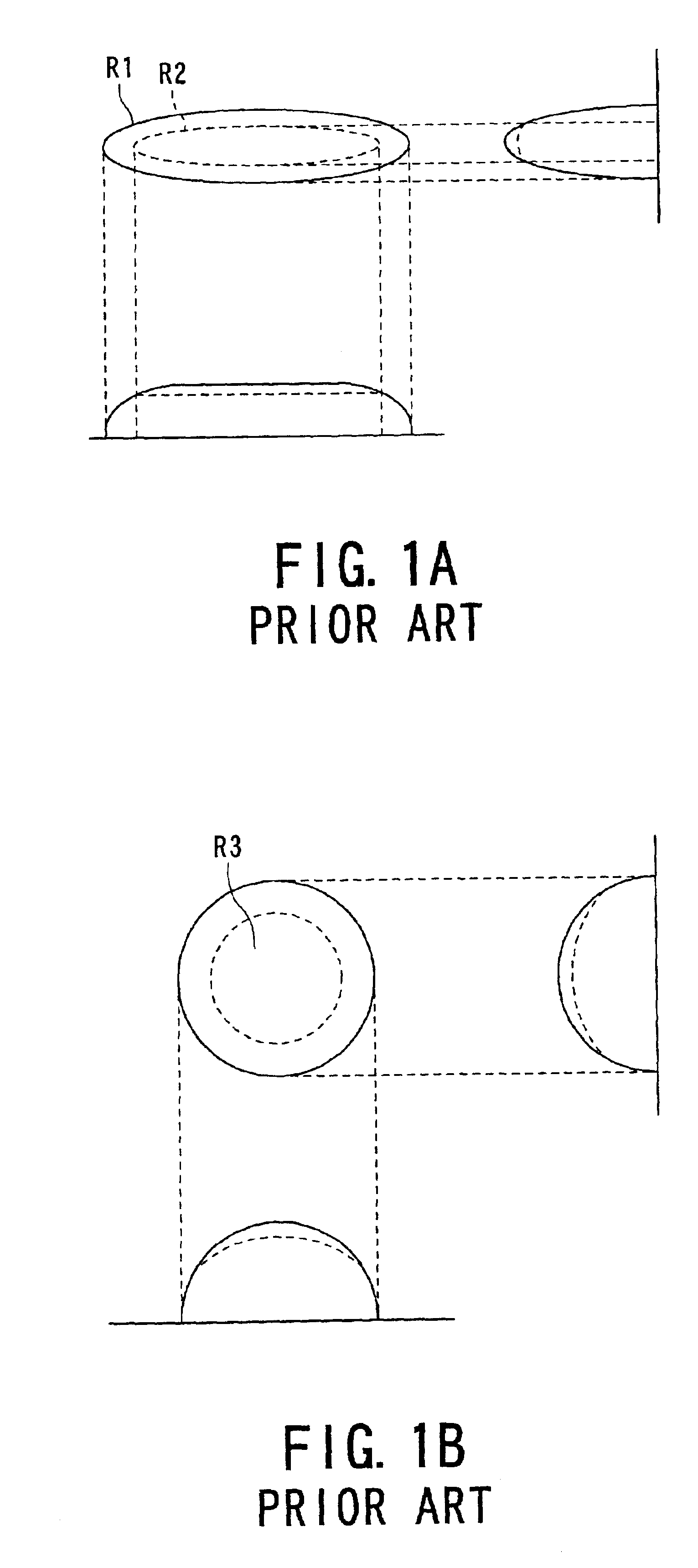

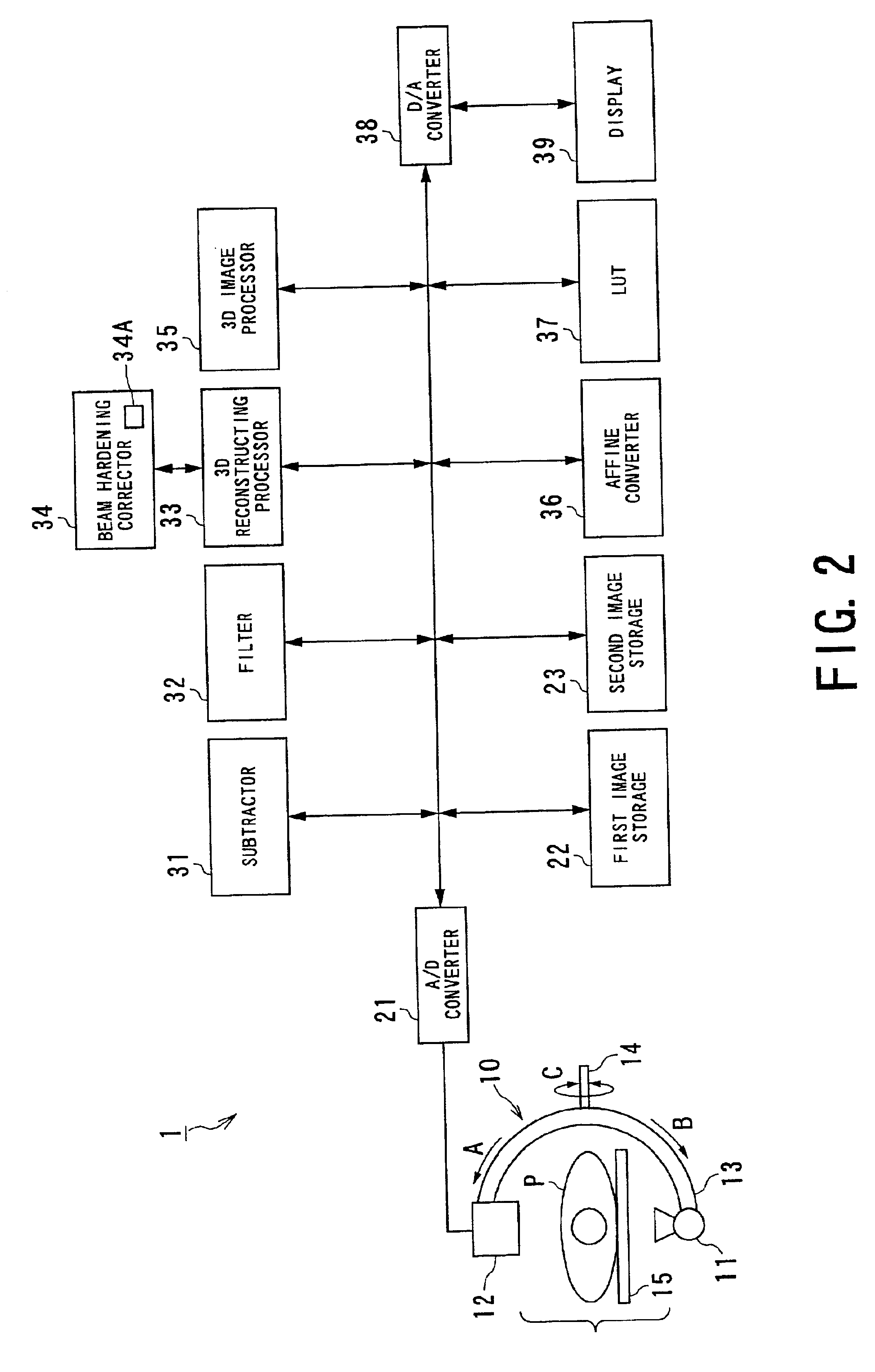

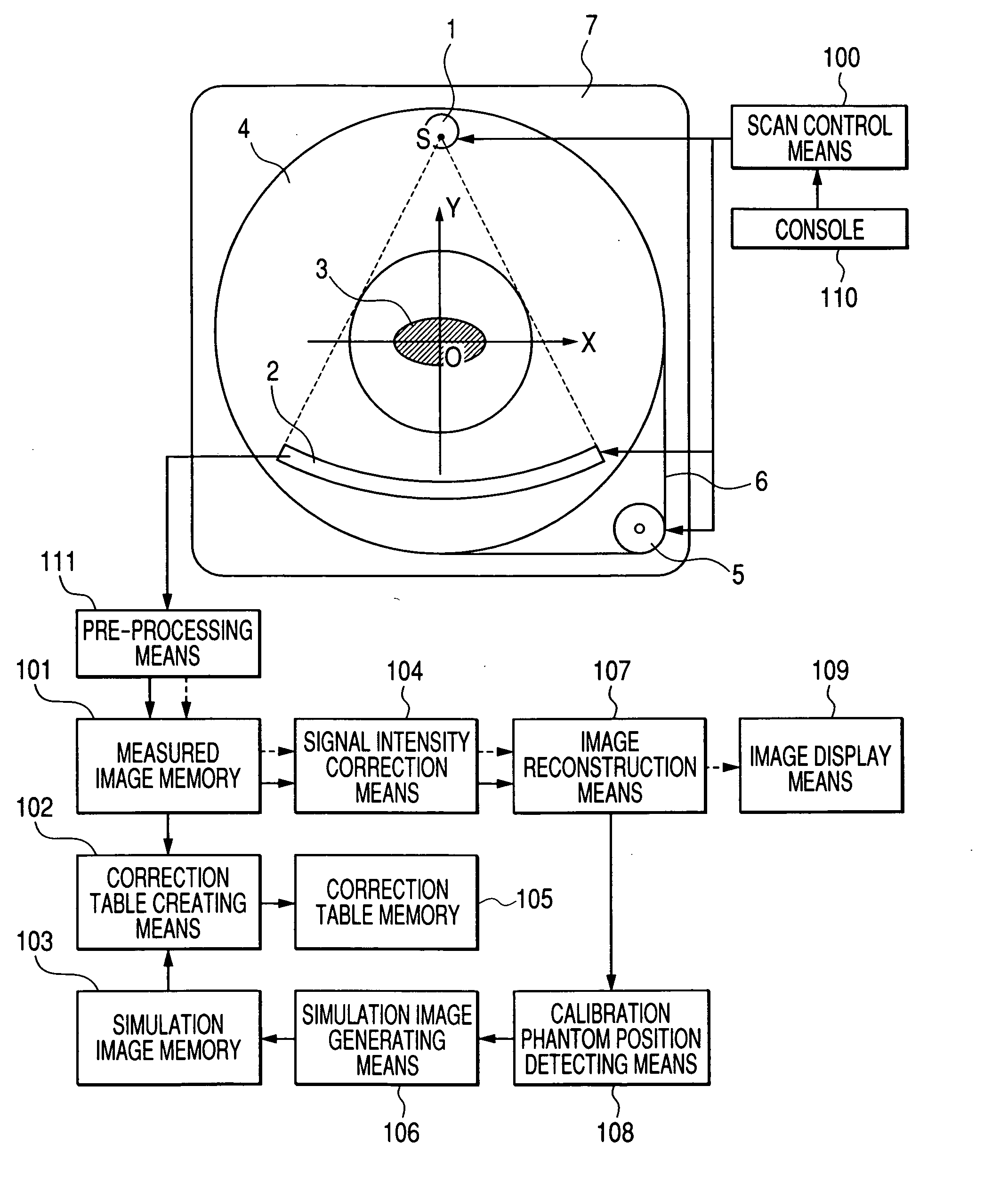

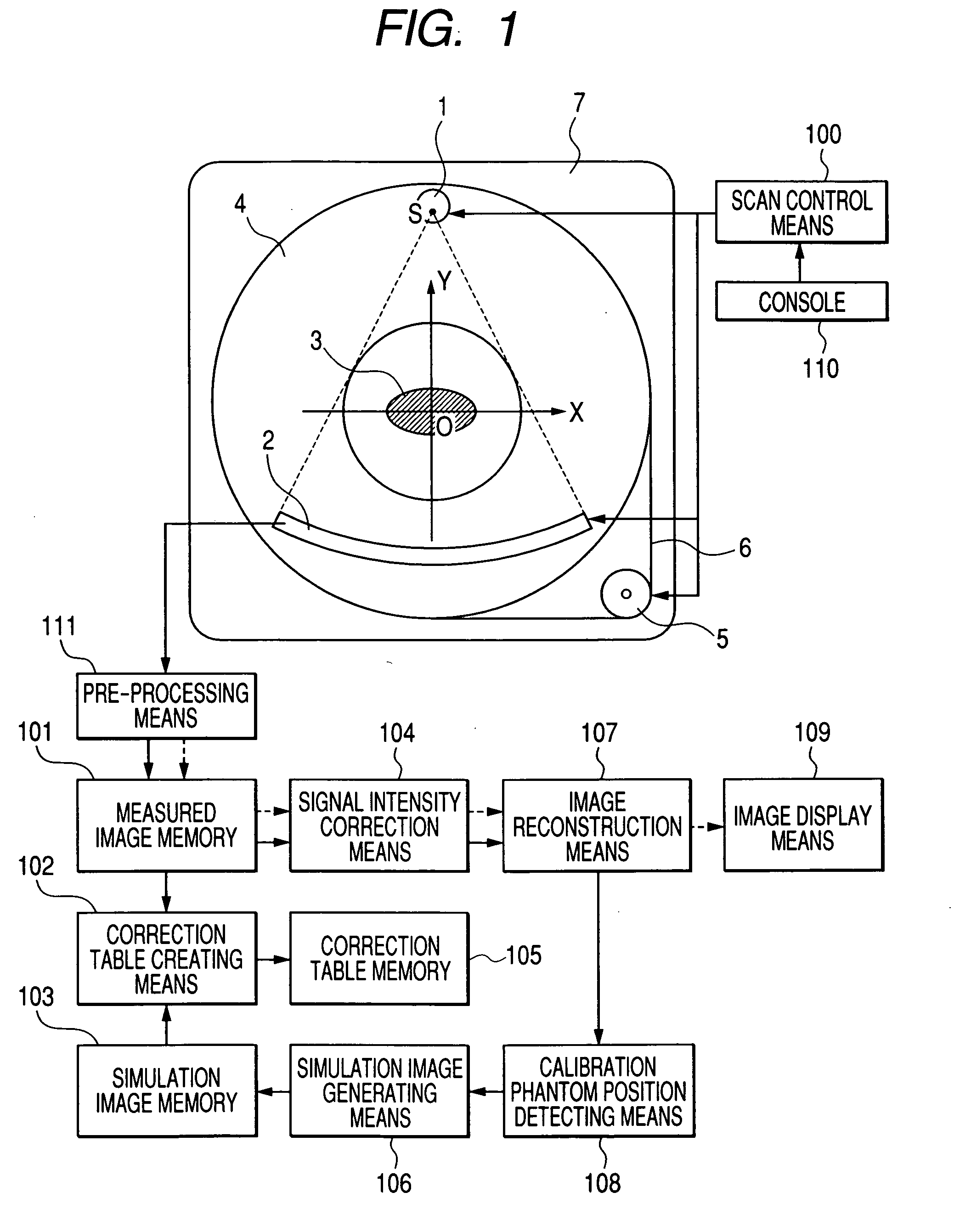

Tomograph

InactiveUS20070116183A1Minimize ring artifactMinimize artifactInstrumentsRadiation diagnosticsLight beamBeam hardening

The present invention provides a technology for reducing artifacts attributable to the non-linearity in the input-output characteristic of a radiation detector and beam hardening of radiation in a tomograph. The tomograph includes a scanning system that includes a generation means which generates radiation to be irradiated to a subject and a detection means which is opposed to the generation means in order to detect the radiation transmitted by the subject, and a rotation means that rotates the scanning system about the subject, and reconstructs a tomographic image of the subject using a plurality of transmitted images produced by projecting the radiation from a plurality of rotational angular positions while rotating the scanning system about the subject. The tomograph further includes: a first storage means in which measured images that are three or more transmitted images produced by rotating the scanning system about a plurality of phantoms including at least one phantom whose section perpendicular to an axis of rotation of the scanning system has different dimensions in two directions orthogonal to the axis of rotation are stored; a production means that produces calculated images as the transmitted images through calculation; a second storage means in which the produced calculated images are stored; and a correction means that corrects the intensities represented by the transmitted images of the subject according to the measured images and calculated images.

Owner:HITACHI MEDICAL CORP

Method and system for CT reconstruction with pre-correction

A method for reconstructing image data from measured sinogram data acquired from a CT system is provided. The CT system is configured for industrial imaging. The method includes pre-processing the measured sinogram data. The pre-processing includes performing a beam hardening correction on the measured sinogram data and performing a detector point spread function (PSF) correction and a detector lag correction on the measured sinogram data. The pre-processed sinogram data is reconstructed to generate the image data.

Owner:GENERAL ELECTRIC CO

Scatter and beam hardening correctoin in computed tomography applications

InactiveUS20050185753A1Reconstruction from projectionRadiation/particle handlingSpectral response3d image

A method of correcting scatter includes obtaining a voxellized representation of a 3D image of an object from a plurality of projection data. A single scatter profile for the object is calculated using the voxellized representation of the 3D image of the object. A total scatter profile for the object is determined using the single scatter profile and an adjustment factor and the projection data is corrected using the total scatter profile to obtain a scatter corrected projection data. A beam hardening correction method includes simulating a number of attenuation data for an x-ray spectrum, at least one object material, and a detector spectral response. A function is fitted to the attenuation data to obtain an attenuation curve. A number of projection data for an object are corrected using the attenuation curve to obtain a number of beam hardening corrected projection data. A corrected image of the object is reconstructed from the beam hardening corrected image data.

Owner:GENERAL ELECTRIC CO

Method for correcting projection pencil sclerosis based on CT data consistency

InactiveCN101226642AImprove the correction effect2D-image generationComputerised tomographsHigh densityX-ray

The invention discloses a beam hardening correction method of CT projection data based on data dependency. The method is based on physics imaging model of medical X-ray, constructs a minimization solution problem between CT projection data, combines the minimization problem and obtains solution of intermediate parameter. For realizing more precise correction result, the method estimates reducing proportion of substance with high density in projection data according to primary correction construction result and CT reprojection. The invention is adaptable for realizing beam hardening correction function of various X-ray CT devices. Compared with the existing method only with water modeling correction, the method of the invention respectively considers differences of beam hardening effect of tissues with different density. Compared with the existing method of bone correction, the method of the invention can automatically adapted to different imaging subjects more flexibly and has better correction precision.

Owner:XI AN JIAOTONG UNIV

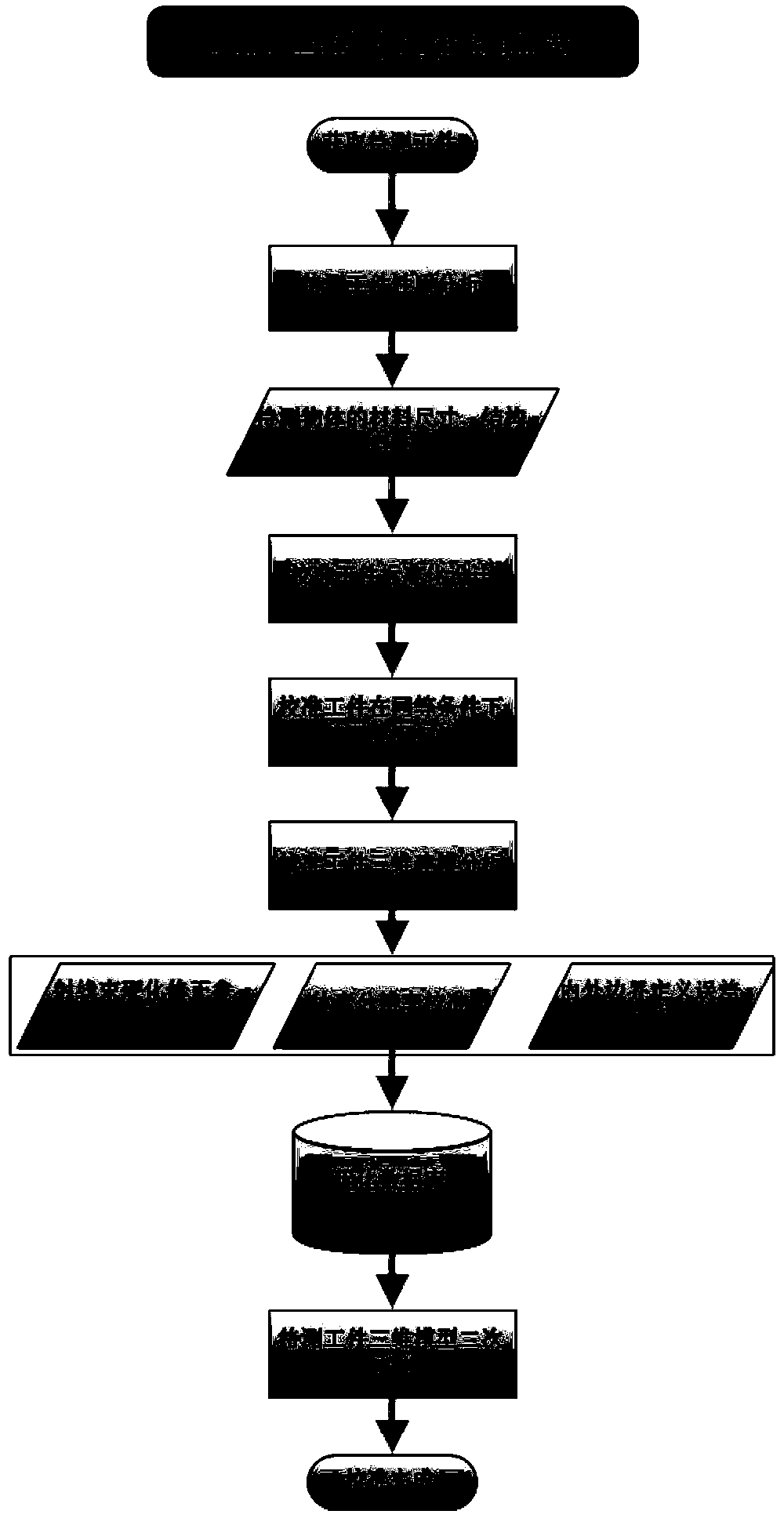

Three-dimensional precision measurement and calibration method for industrial CT (computed tomography)

InactiveCN103558237AEasy to fixReduce refractionMaterial analysis by transmitting radiationVoxelDimensional modeling

The invention discloses a three-dimensional precision measurement and calibration method for industrial CT (computed tomography). The three-dimensional precision measurement and calibration method comprises two parts, namely industrial CT scanning parameter optimization and three-dimensional precision industrial CT measurement and calibration. According to the method, the conventional technology is innovatively optimized on the basis of a large quantity of laboratory researches and industrial applications aiming at three important processes, including setting of main scanning parameters, correction of a ray beam hardening phenomenon in a three-dimensional reconstruction process and voxel dimension and boundary definition calibration in a three-dimensional modeling and precision measurement process, which affect the three-dimensional industrial CT measurement quality. According to the method, the precision and the stability of the three-dimensional industrial CT measurement can be greatly improved, so that the applications of the three-dimensional industrial CT measurement in the fields of precision measurement and control, three-dimensional modeling, quantitative and qualitative analysis of internal and external structures of complicated machinery, reverse engineering and the like can be greatly expanded.

Owner:谭晔

Method and apparatus for correcting for beam hardening in CT images

InactiveUS7391844B2Material analysis using wave/particle radiationRadiation/particle handlingBeam hardeningCt imaging

A method for determining a correction for beam hardening in CT images includes obtaining air scans at a plurality of kVp's, determining detection efficiencies for detector elements of the CT imaging apparatus, and estimating projection values through a combination of at least two different materials of different thicknesses. The method further includes determining a transfer function that translates the estimated projection values into ideal projection values for at least two of the different materials and storing the transfer function as the beam hardening correction for images of the CT imaging apparatus.

Owner:GENERAL ELECTRIC CO

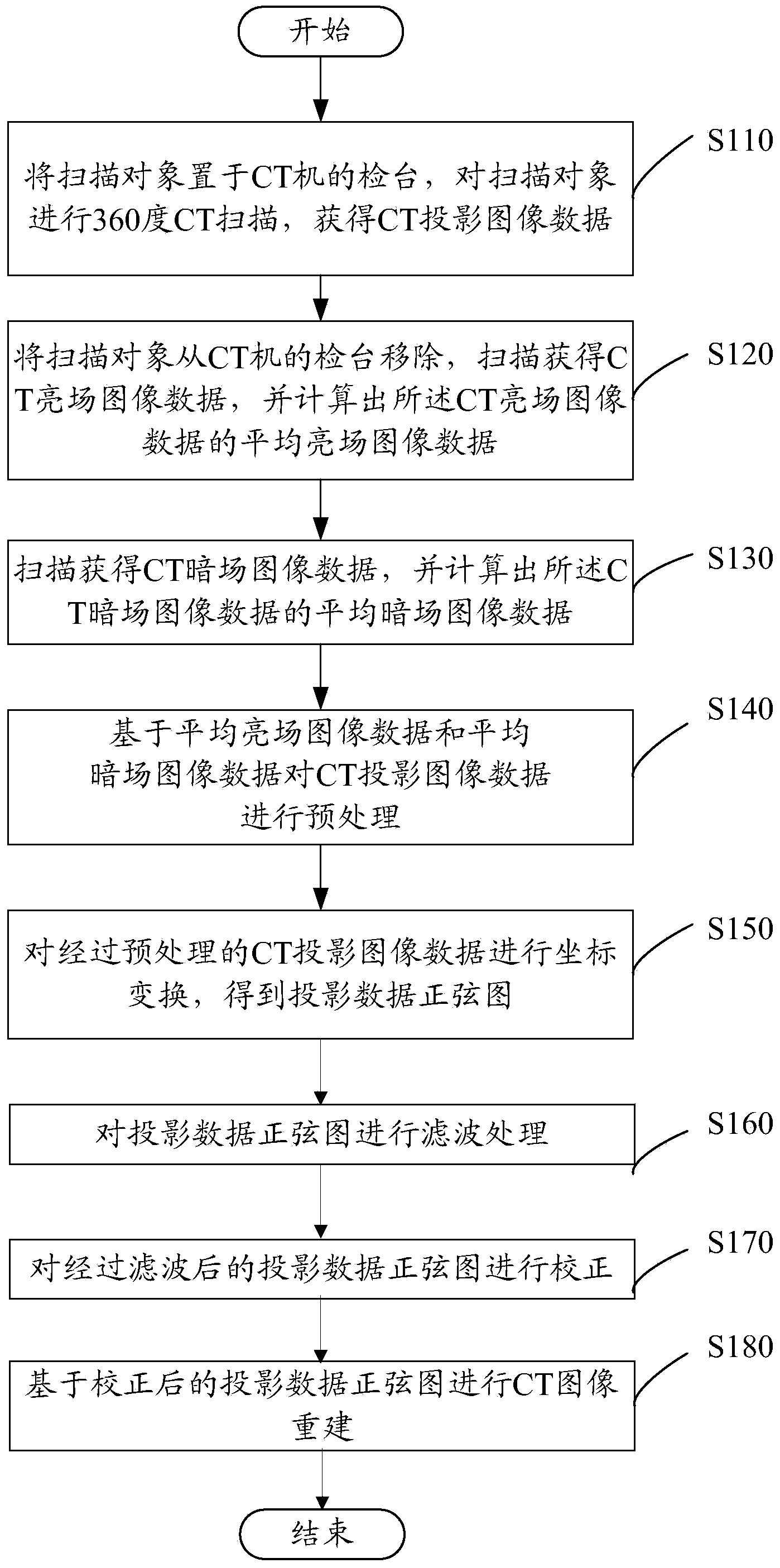

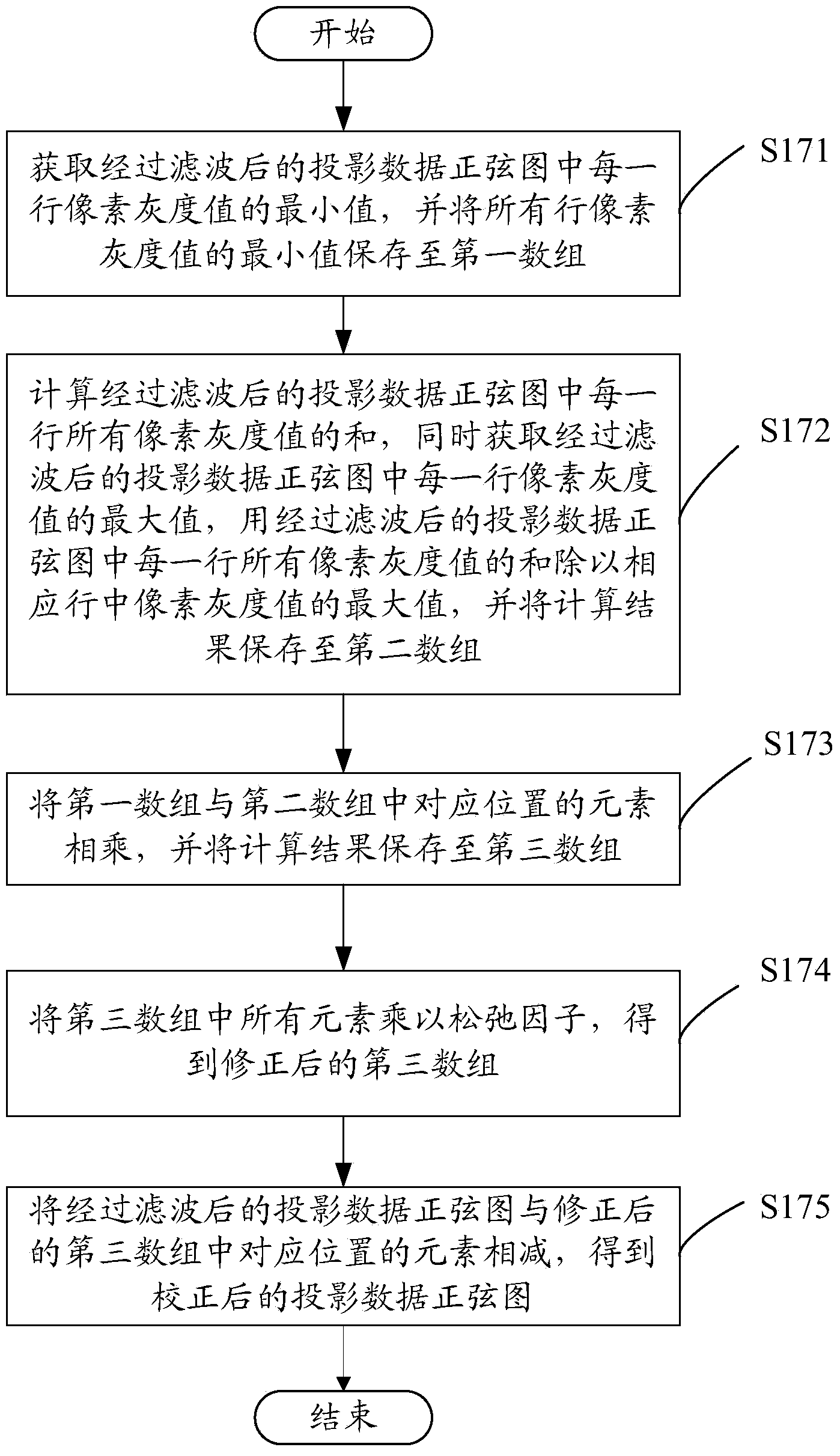

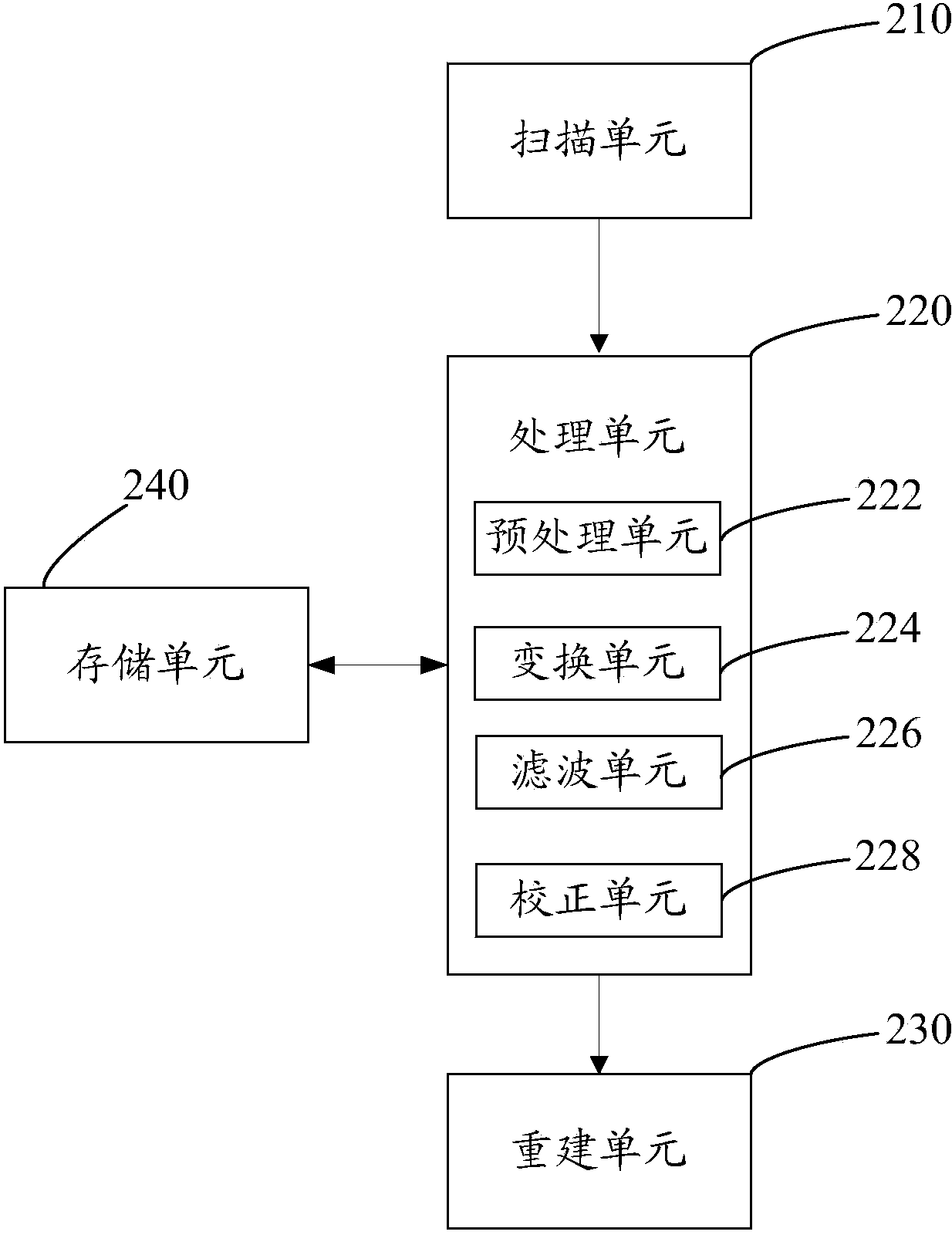

CT system beam hardening elimination method and CT system beam hardening elimination system based on sonogram

ActiveCN103445803ABeam Hardening EliminationHigh degree of fitImage enhancement2D-image generationProjection imageGoodness of fit

The invention relates to a CT system beam hardening elimination method based on a sonogram. The method comprises the following steps of obtaining CT projection image data; removing a scan object from a check platform of a CT machine for scanning to obtain CT bright field image data and calculating average bright field image data of the CT bright field image data; scanning to obtain CT dark field image data and calculating average dark field image data of the CT dark field image data; performing preprocessing and coordination transformation on the CT projection image data to obtain a projection data sonogram and performing filtering processing and correction on the sonogram; rebuilding a CT image based on the corrected projection data sonogram. According to the CT system beam hardening elimination method and a CT system beam hardening elimination system based on the sonogram, a series of processing is performed on the CT projection image data before rebuilding the CT image, so that the goodness of fit between the CT projection image data and the actual image data is improved, therefore the beam hardening can be precisely eliminated.

Owner:SHENZHEN INST OF ADVANCED TECH

Computerized roentgenographing apparatus

In an X-ray computed tomography apparatus with retrospective beam hardening correction, an overall image of a body slice under examination is determined from overall attenuation values that are obtained from the body slice. At least one partial image that shows essentially only one body substance, such as bone substance, is extracted from this overall image. Attenuation partial values are employed for determining a correction value. The attenuation values are determined for each overall attenuation value from the at least one partial image by re-projection. A correction value is derived from the beam hardening error that is determined for a material combination of two different reference materials.

Owner:SIEMENS AG

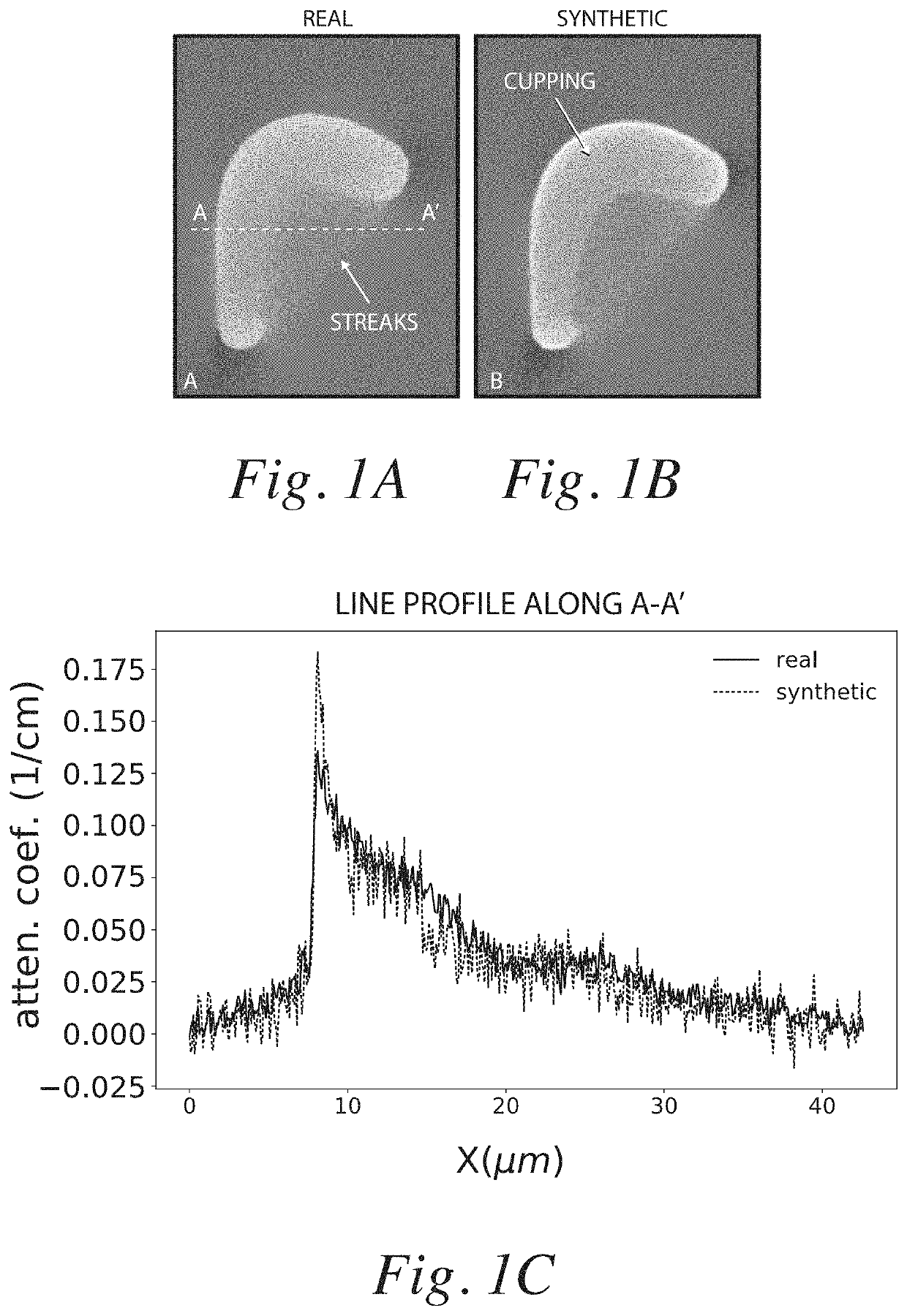

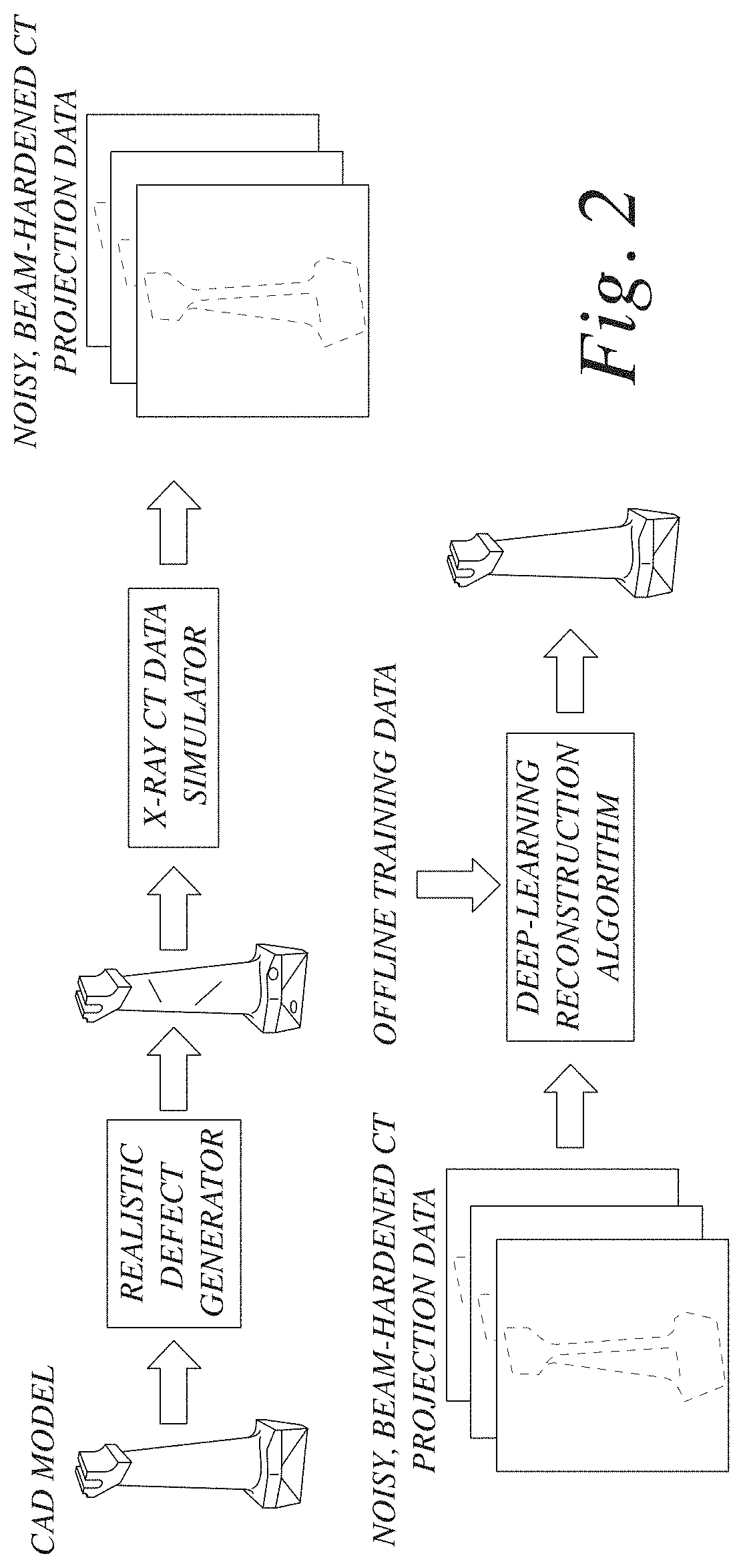

System and method for artifact reduction of computed tomography reconstruction leveraging artificial intelligence and a priori known model for the object of interest

PendingUS20220035961A1Reduce artifactsComplicated processingGeometric CADImage enhancementPattern recognitionAlgorithm

Nondestructive evaluation (NDE) of objects can elucidate impacts of various process parameters and qualification of the object. Computed tomography (CT) enables rapid NDE and characterization of objects. However, CT presents challenges because of artifacts produced by standard reconstruction algorithms. Beam-hardening artifacts especially complicate and adversely impact the process of detecting defects. By leveraging computer-aided design (CAD) models, CT simulations, and a deep-neutral network high-quality CT reconstructions that are affected by noise and beam-hardening can be simulated and used to improve reconstructions. The systems and methods of the present disclosure can significantly improve the reconstruction quality, thereby enabling better detection of defects compared with the state of the art.

Owner:UT BATTELLE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com