Convolution-based X-ray CT system beam hardening correction method

A beam hardening correction and X-ray technology, applied in the field of industrial CT system applications, can solve problems such as inconsistency of projection values, loss of image information, etc., and achieve high-precision detection and remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

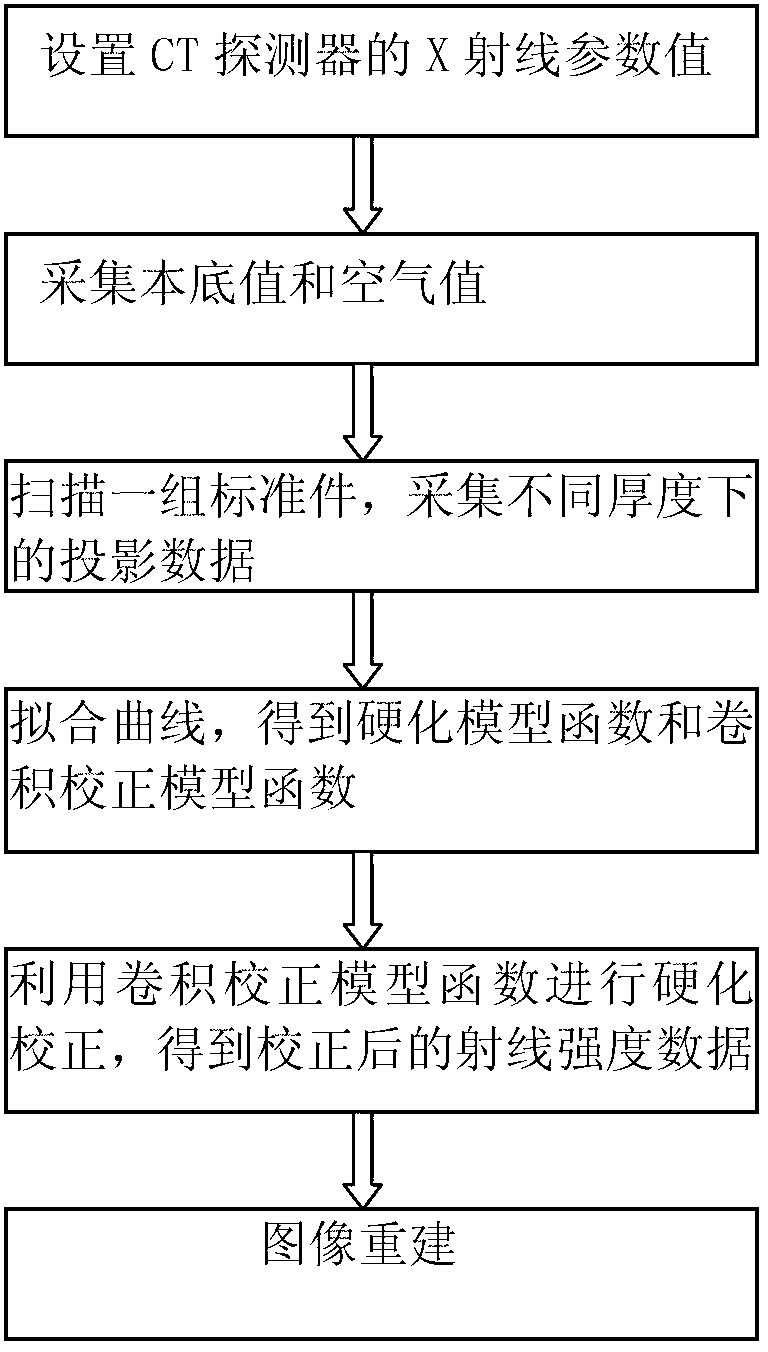

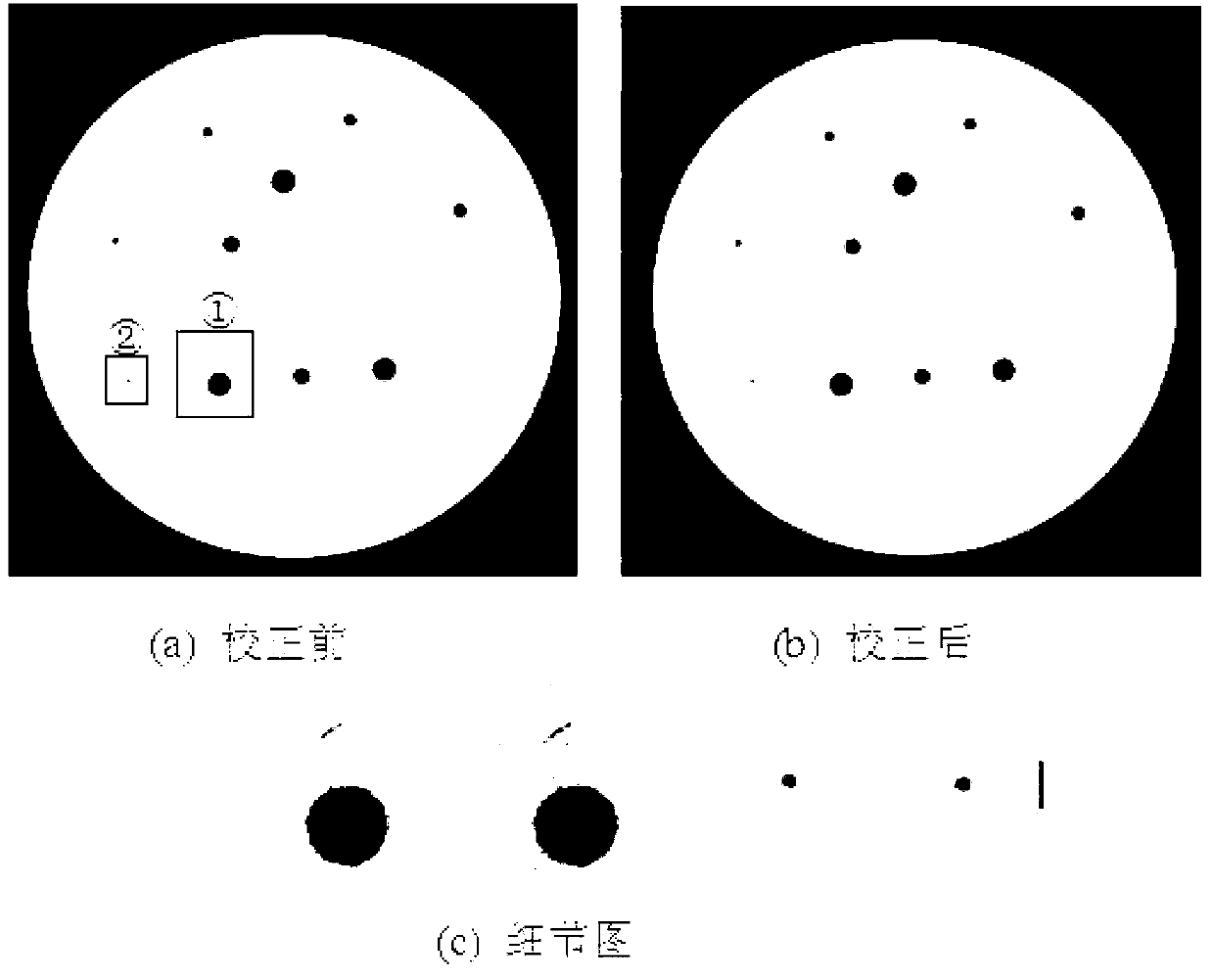

[0041] figure 1 Be beam hardening correction method flow chart of the present invention, this correction method comprises the following steps: Step 1: setting CT system scanning parameter; Step 2: do not open ray source, the background value I of acquisition system bkg ; Step 3: Turn on the ray source, scan the air under the current laboratory, and obtain the current air ray intensity I 0 ; Step 4: Utilize the X-ray CT system to scan a group of standard parts with known thickness, subtract the background value from the obtained sampling data to obtain the actual effective radiation intensity data I; substitute I into the formula p p =ln(I 0 / I), get the polychromatic projection value p under different thicknesses p ;Step 5: take the thickness l as the abscissa, the polychromatic projection value p p As the ordinate, the hardening model ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com