Cone-beam CT beam hardening calibration method based on registration model emulation

A beam hardening correction and registration model technology, which is applied in the fields of material analysis, image data processing, and instruments using radiation, can solve the problems of inflexible application and ineffective application of cone beam CT, etc., and achieve beam hardening artifacts Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

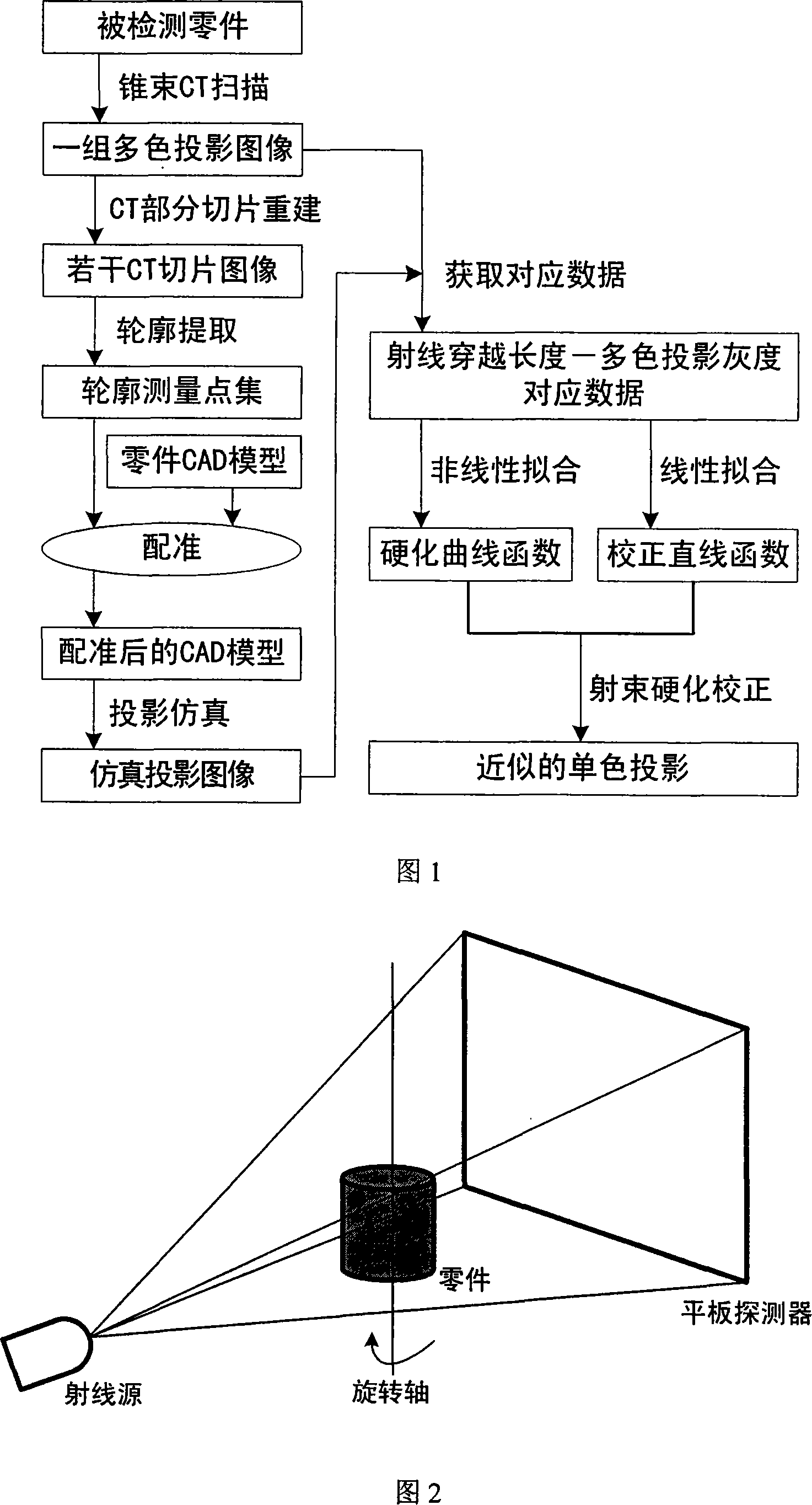

Method used

Image

Examples

Embodiment Construction

[0025] For a detected cylindrical part made of iron, apply the method of the present invention to correct its cone-beam CT beam hardening artifact, and perform the following steps:

[0026] (1) Carry out a circular trajectory cone beam CT scan on the detected part, and the part is continuously rotated 360 degrees, and a set of continuous 360 pieces of multi-color projection image data are obtained from the PaxScan2520 flat panel detector of Varian Company. These images have been used in the acquisition process The flat panel detector manufacturer's supporting program performs necessary dark field correction, bad pixel correction and gain correction;

[0027] (2) Using the FDK algorithm to reconstruct partial slices of cone-beam CT on polychromatic projection, reconstruct 10 CT slice images at different positions along the axis of the cylindrical part;

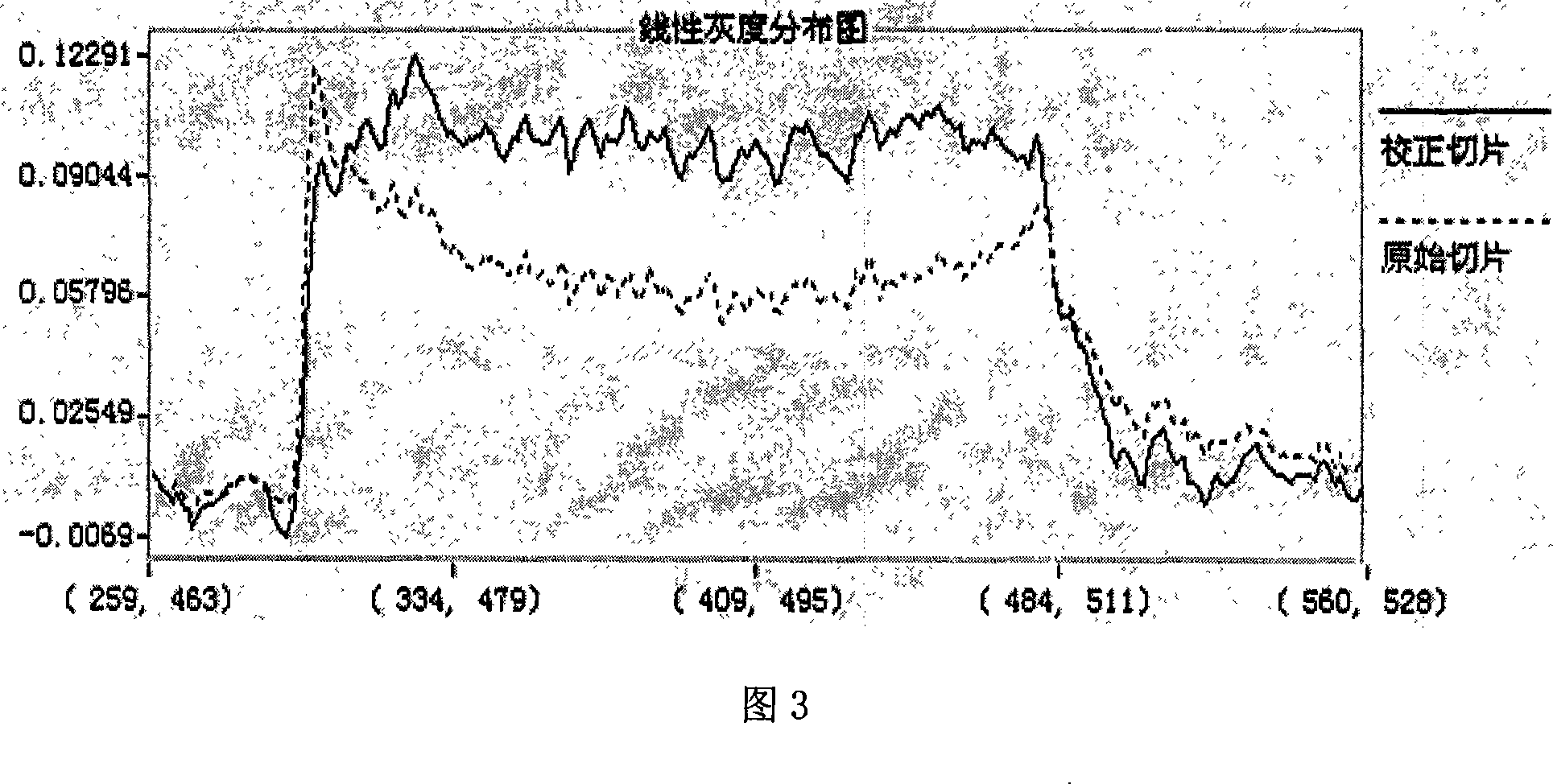

[0028] (3) Using the OTSU algorithm in digital image processing to extract the contours of the reconstructed 10 CT slice imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com