Three-dimensional precision measurement and calibration method for industrial CT (computed tomography)

A precision measurement and calibration method technology, which is applied in the direction of material analysis using radiation, can solve problems such as unstable errors, doping, and increased calibration coefficient errors, so as to reduce X-ray refraction, enhance signal-to-noise ratio, and avoid movement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

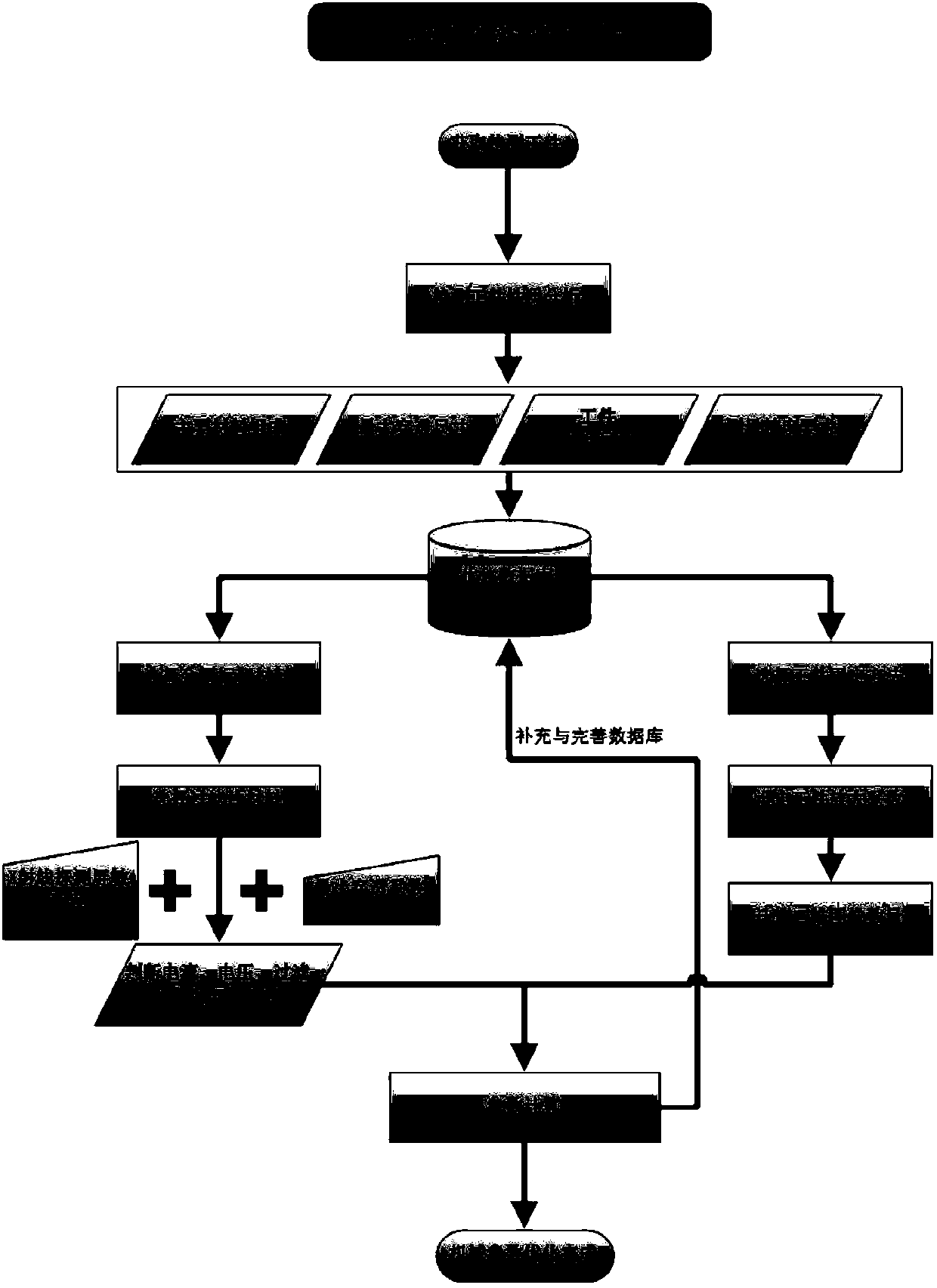

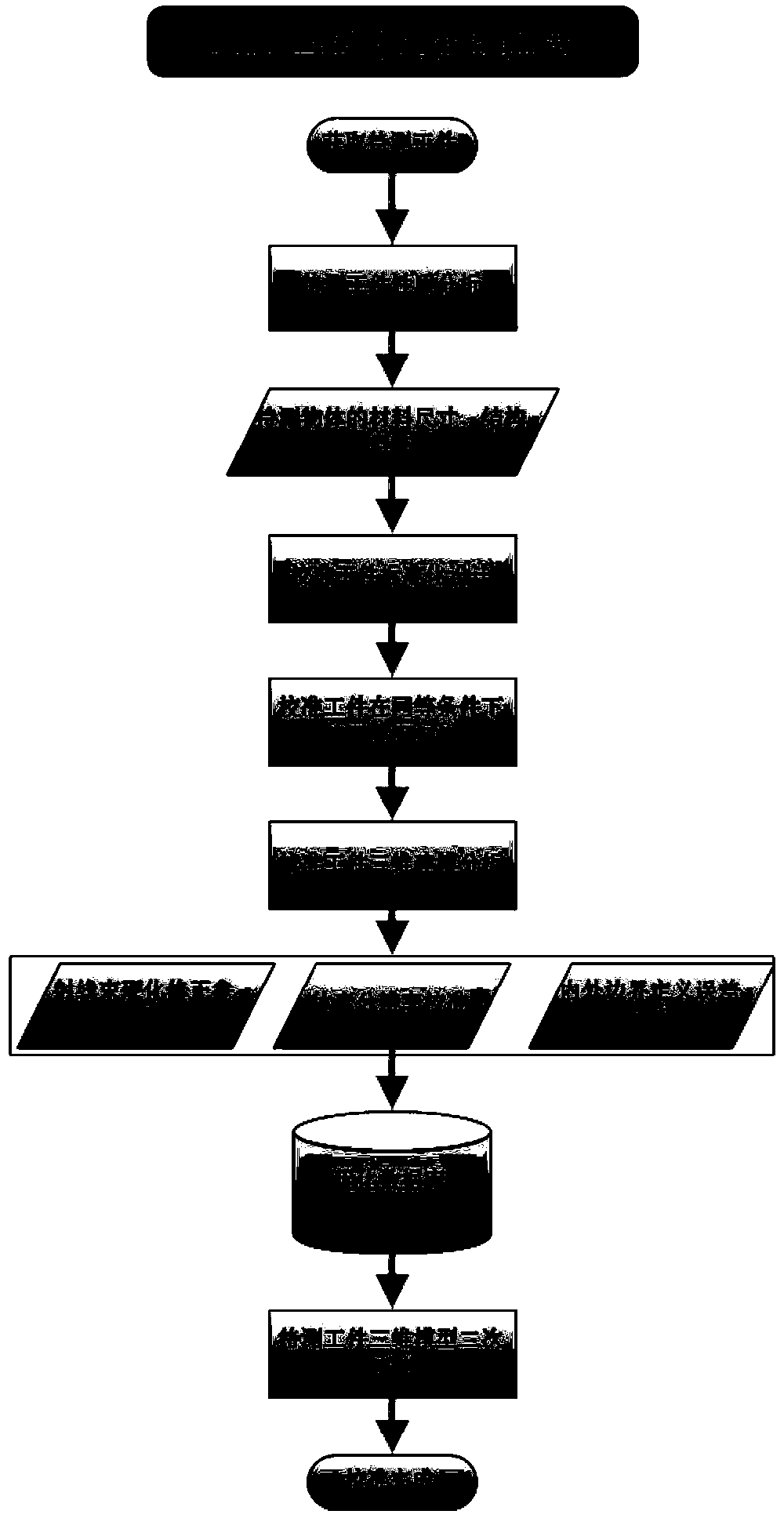

[0103] Embodiment 1: The industrial CT three-dimensional precision measurement and calibration method described in the present invention includes two parts: industrial CT scanning parameter optimization and industrial CT three-dimensional measurement precision calibration.

[0104] Industrial CT scanning parameter optimization methods, such as figure 1 As shown, taking the detection of plastic parts as an example:

[0105] 1. Obtain the workpiece to be tested, and analyze the properties of the workpiece to be tested, analyze its material composition, maximum penetration size, comprehensive size and accuracy requirements;

[0106] 2. Input the property information of the workpiece to be tested into the optimization database, and then optimize the parameters in two systems:

[0107] System one:

[0108] (1) Select the fixing method of the workpiece to be tested:

[0109] a. Select the fixing material of the workpiece to be tested: choose a material whose absorption capacity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com