Method and device for measuring X-ray thickness

An X-ray and thickness measurement technology, applied in the field of X-ray thickness measurement methods and devices, can solve the problems of beam hardening, inconvenience, and difficulty in thickness measurement, and achieve high accuracy, strong reliability, simple method and device Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

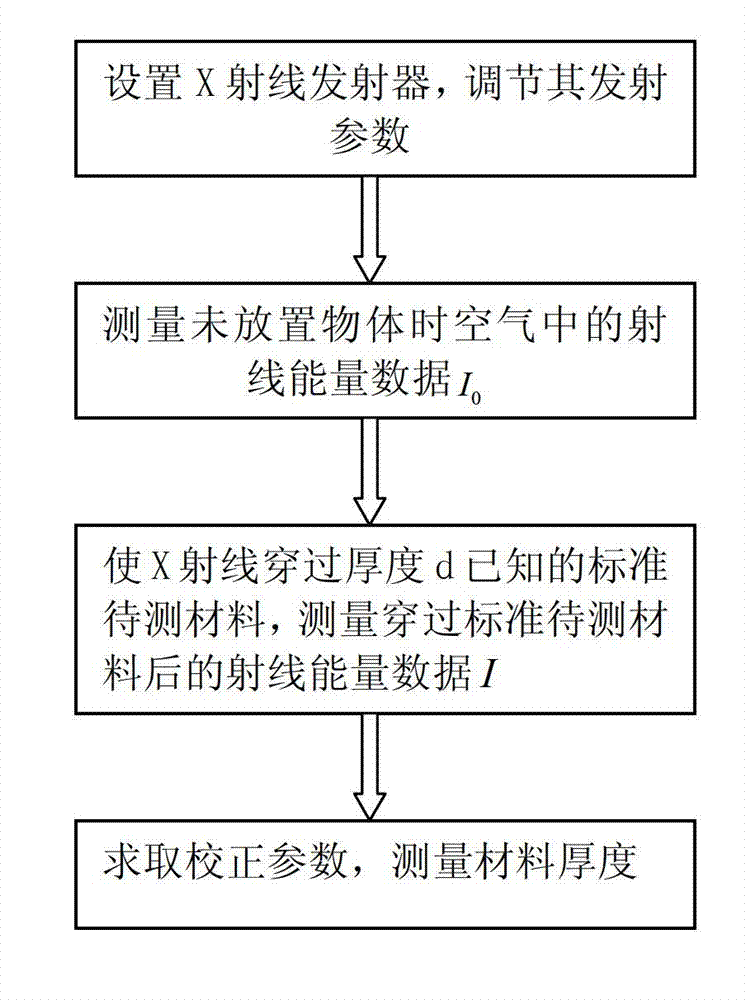

Method used

Image

Examples

Embodiment Construction

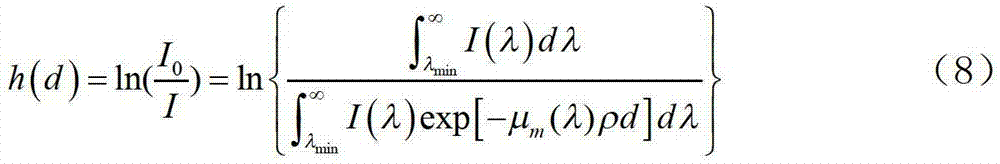

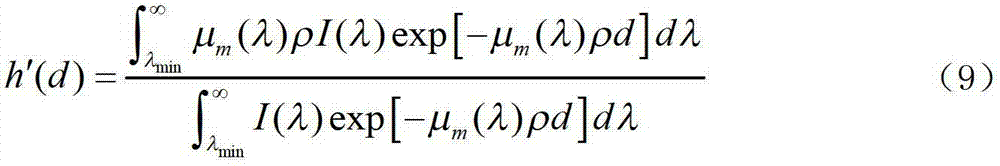

[0018] First, the theoretical basis of the X-ray thickness measuring method in the present invention is as follows: Measuring the thickness of an object by using X-rays is based on the principle that the X-ray intensity is weakened when passing through the measured object. At a specific energy and wavelength, the radiation intensity I of X-rays passing through a material with a thickness d is given by the following formula (Beer's theorem): I=I 0 e -μd (1), where I 0 is the incident X-ray intensity, I is the ray intensity after passing through the measured object, d is the thickness of the measured object, and μ is the linear attenuation coefficient of the material, which is determined by the chemical composition of the material and the wavelength of the X-ray. Transform (1) to get:

[0019] Ideally, the linear attenuation coefficient μ of the measured substance can be expressed as: μ=kρz 3 lambda 3 (3), where k is the coefficient, ρ is the density of the substance, z is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com