Roadheader suitable for vertical shaft drilling in presence of pilot shaft

A technology for roadheaders and shafts, which is applied in the field of mining machinery, can solve problems such as failure to meet the functional requirements of shafts, and achieve the effects of saving labor costs, saving costs, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings.

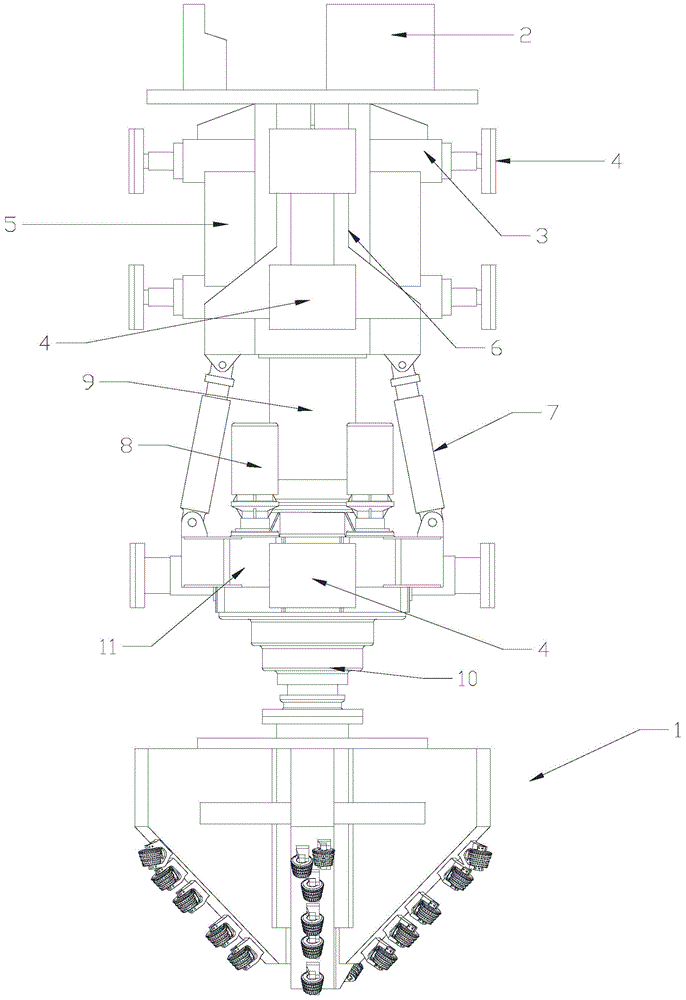

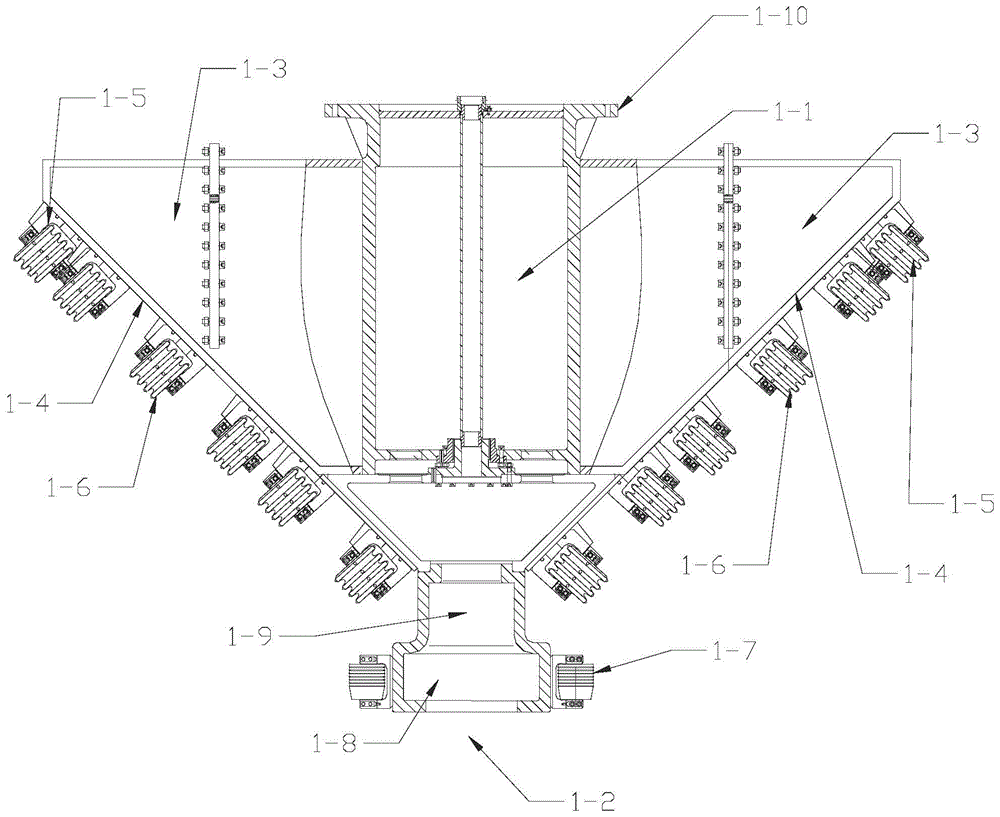

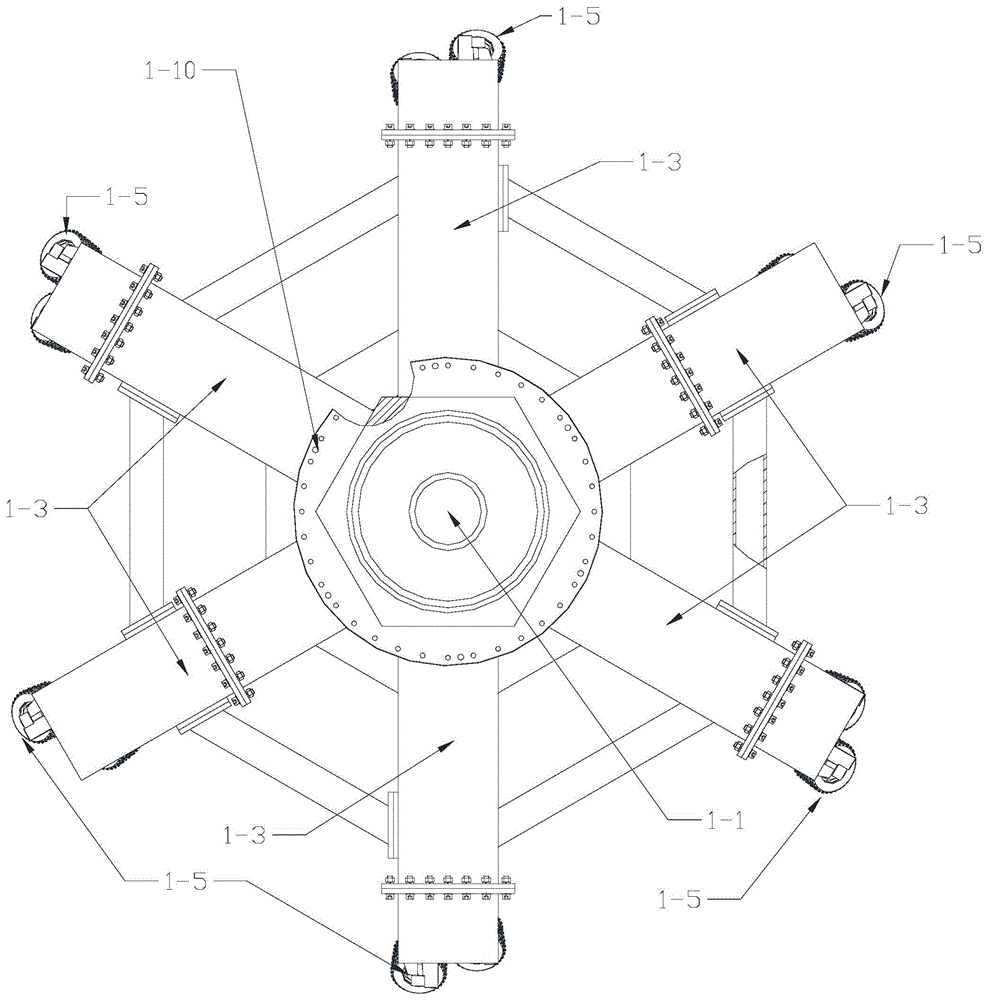

[0032] Such as Figure 1-6As shown, the present invention is suitable for a roadheader for drilling a shaft with a guide shaft, including a main body frame, a rock breaking drill bit 1, a drive system, a support system 6 and a control system 2, and the drive system includes a rotary drive subsystem 10, a propulsion drive subsystem and hydraulic station, the rock-breaking drill bit 1, the rotary drive subsystem 10, the propulsion drive subsystem, the support system 6 and the control system 2 are respectively installed on the main frame, and the The rotary drive subsystem 10 is in transmission connection with the rock-breaking drill bit 1; the rock-breaking drill bit 1 includes a cutter head and a guide device 1-2. Wherein, the rotary drive subsystem 10 includes a drive motor 8 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com