crawler self-moving tail

A self-moving tail and crawler-type technology, which is applied in the direction of slitting machinery, earthwork drilling, etc., can solve the problems of bulky continuous transportation system, poor equipment adjustment convenience, complex operation coordination, etc., and achieve efficient and reliable reloading , Safety monitoring, monitoring and protection devices are perfect, and the operation is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

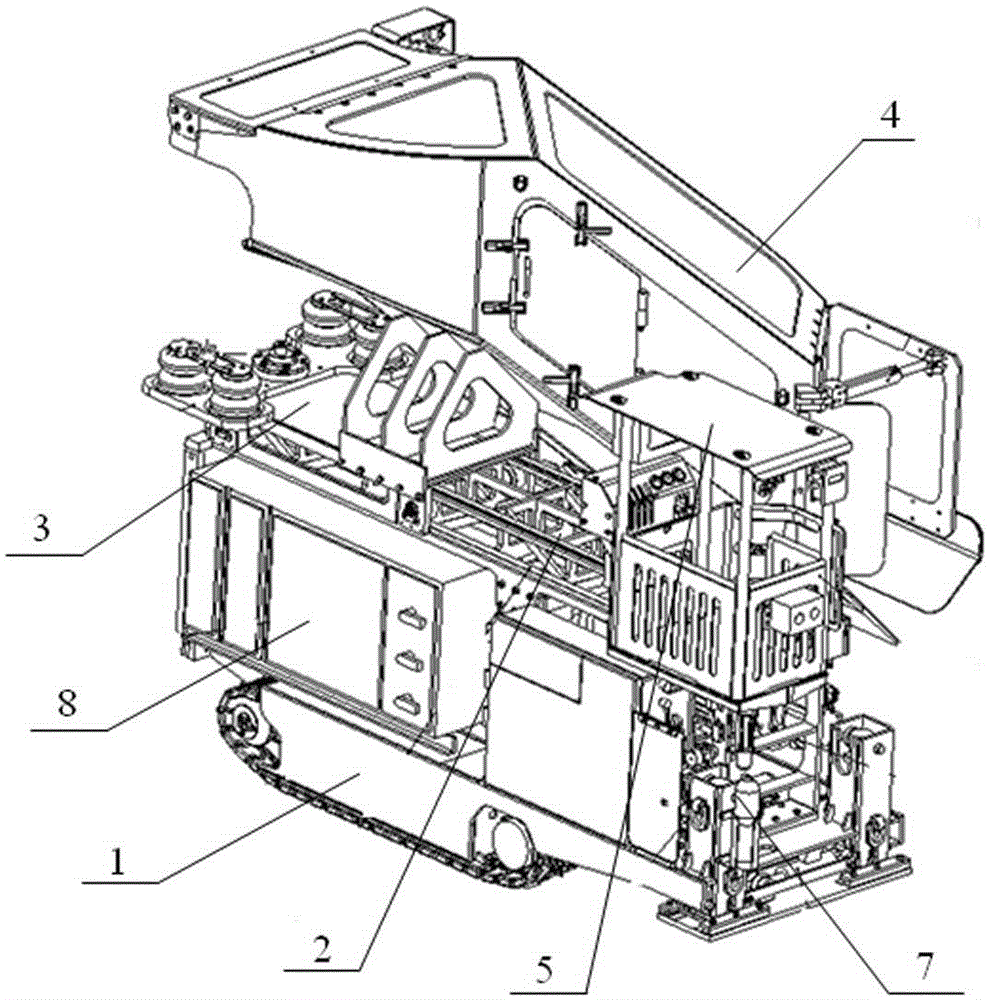

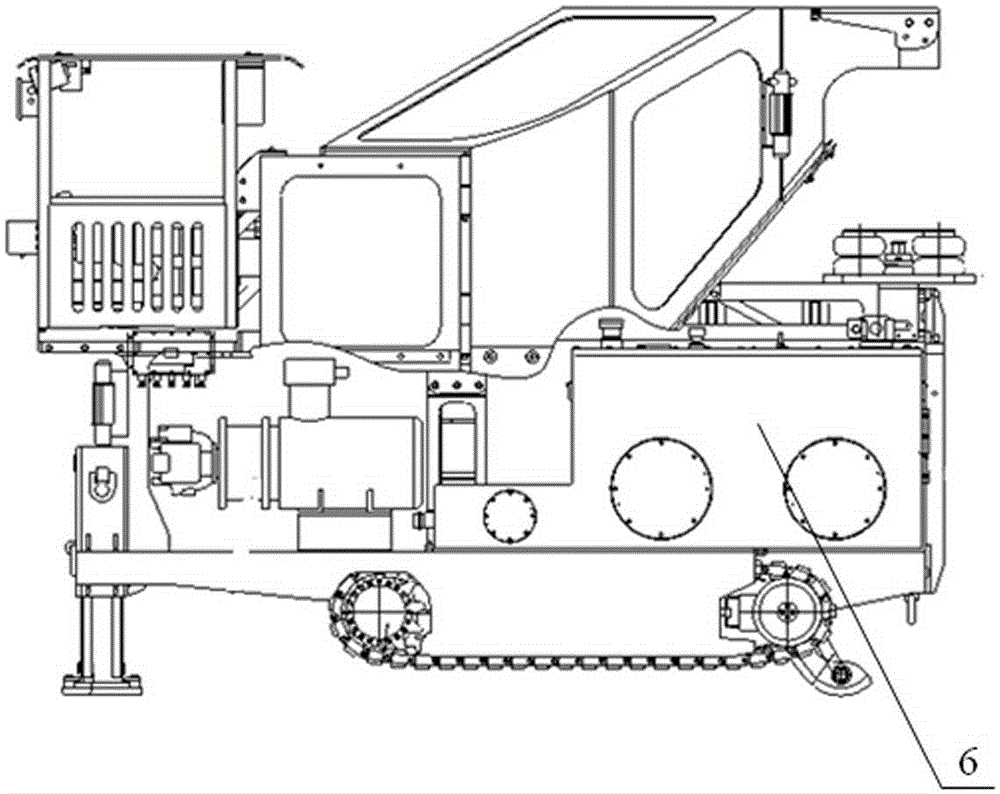

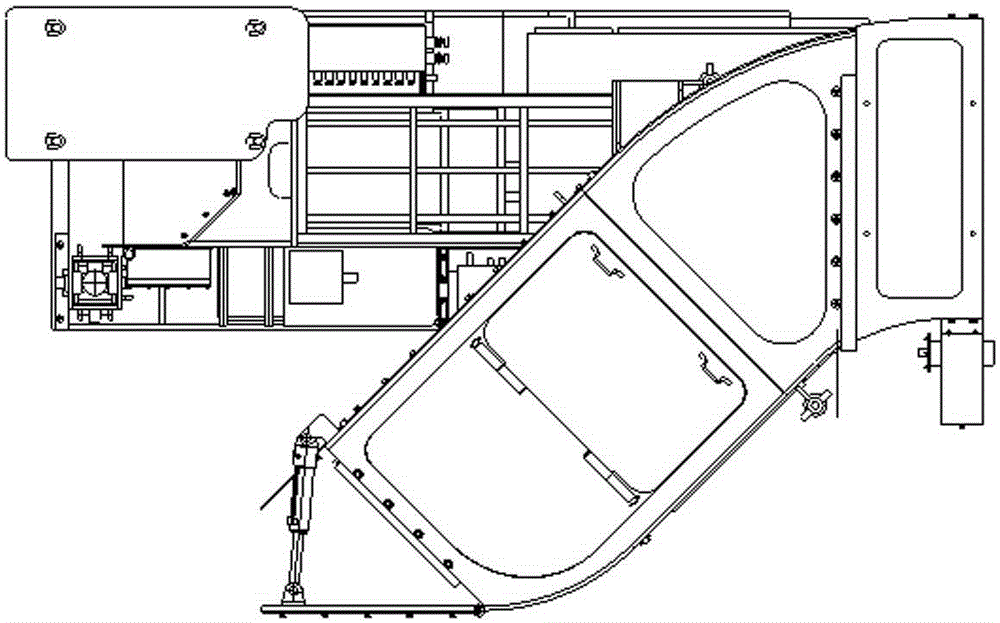

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] The supporting technology and equipment after efficient and rapid excavation consist of crawler walking straddle type bolter, belt loader, crawler self-moving tail, and stepping self-moving tail. The belt loader is driven by the crawler walking straddle type bolter and walks directly following the full-section roadheader. The unloading part of the belt loader overlaps the tail of the crawler self-moving machine, and the tail of the crawler self-moving machine overlaps the stepping self-moving machine. Tail (slotted belt). The crawler-type self-moving tail can realize self-propelled movement, and the walking speed should be synchronized with the belt transfer machine. As an important transportation equipment in the complete set of equipment, the crawler-type self-moving tail needs to have the function of following the main excavation equipment to move. Due to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com