Tower crane boom packing device, system and method

A tower crane and jib technology, applied in the field of tower crane jib packaging devices, can solve the problems of stable placement of post-placed units, affecting product appearance and quality, and wear and tear on the surface of the jib section. Clean, simple structure, avoiding wear and tear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

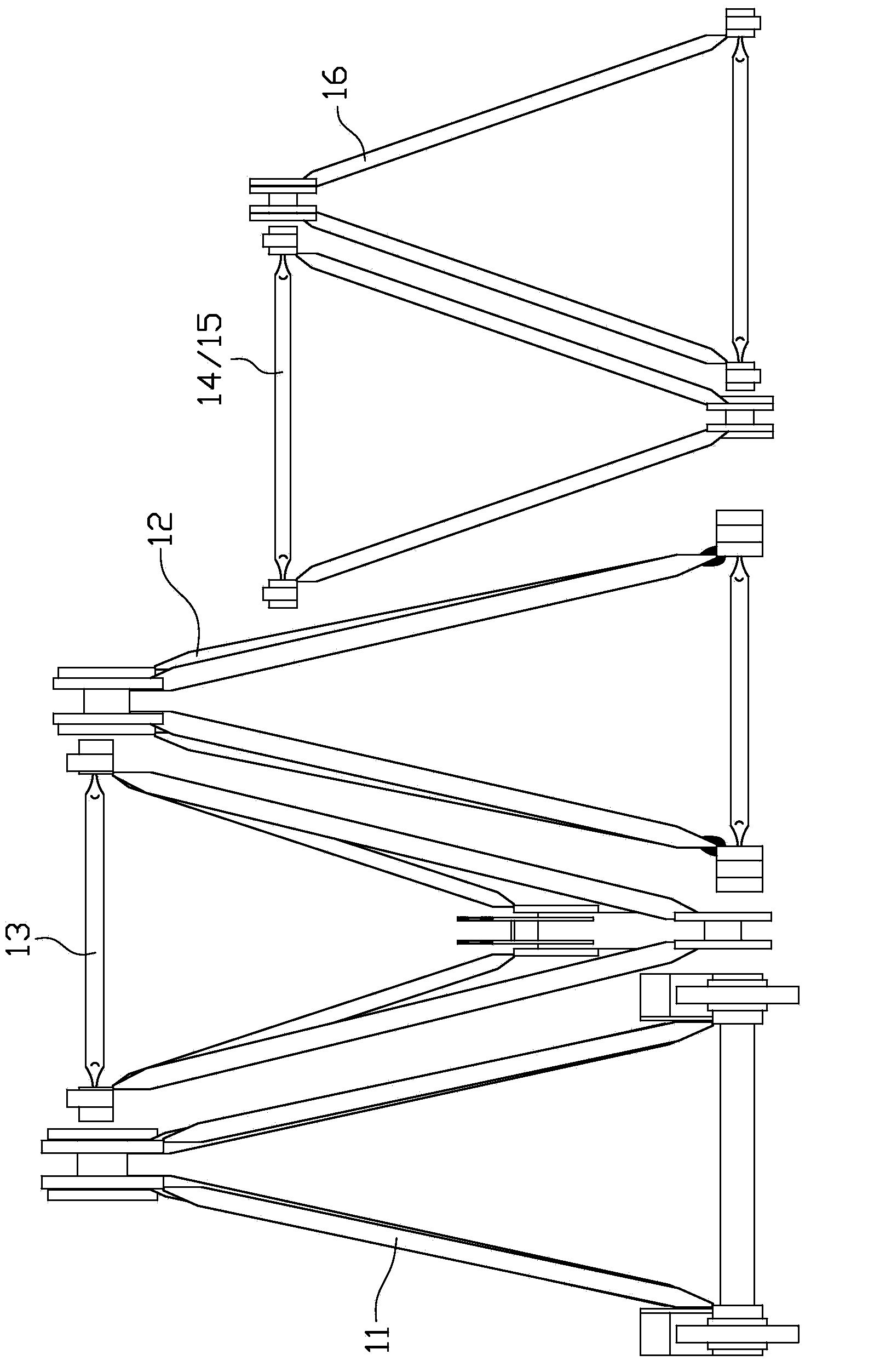

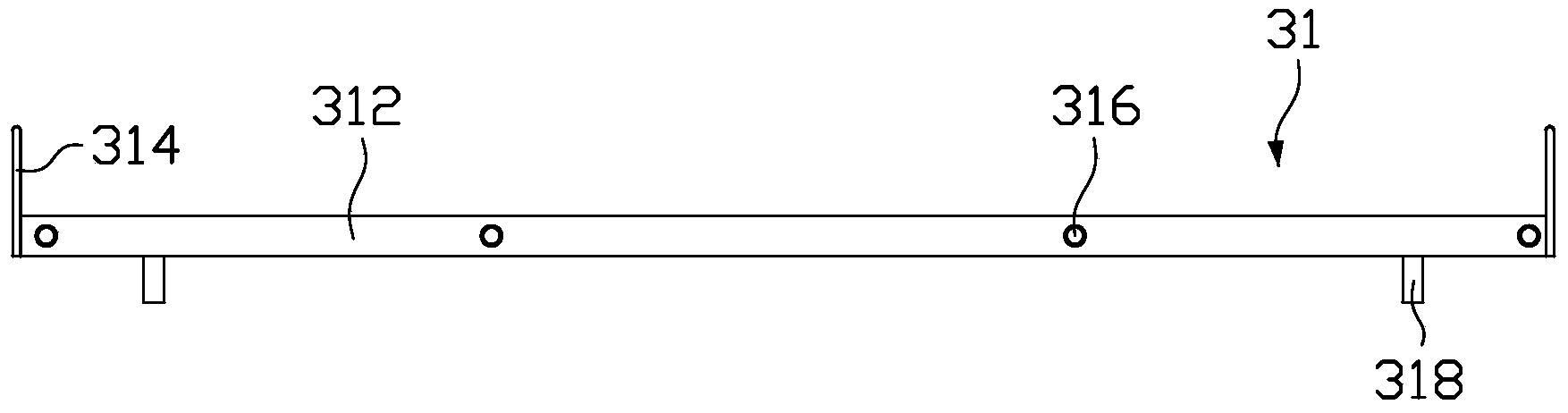

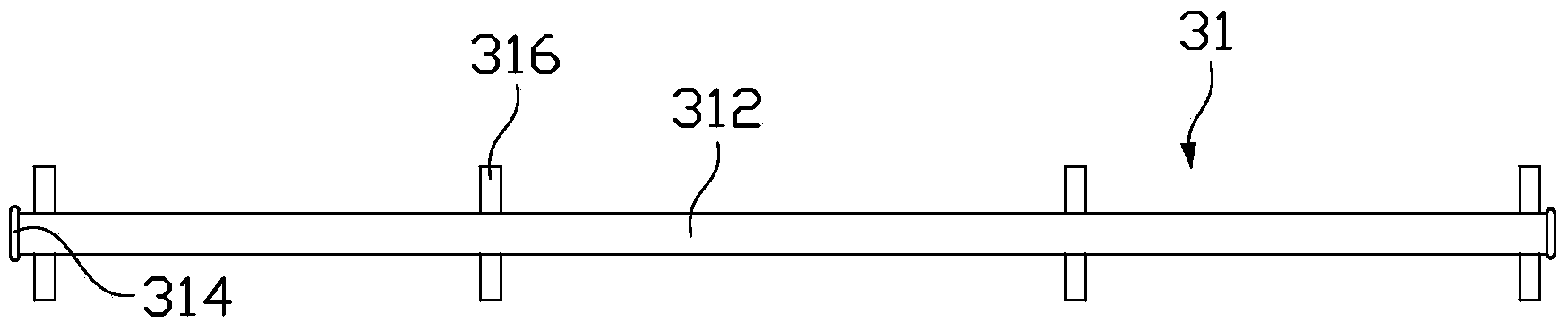

[0036] The invention discloses a tower crane arm frame packing device, which is used for packing the tower crane arm frame (that is, the tower crane boom) firmly, so as to facilitate the storage, transition or delivery and transportation of the tower crane. see Figure 2 to Figure 6 , The tower crane jib packing device of the present invention includes two bottom frames 31 and two top frames 33 . Each chassis 31 includes a strip-shaped load-bearing beam 312 , two lifting lugs 314 respectively arranged at both ends of the load-bearing beam 312 A plurality of fixed parts 316 are distributed. The top frame 33 is L-shaped and includes a support rod 331 and a stop rod 333 perpendicularly disposed downward from one end of the support rod 331 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com