Patents

Literature

75results about How to "Tied up firmly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

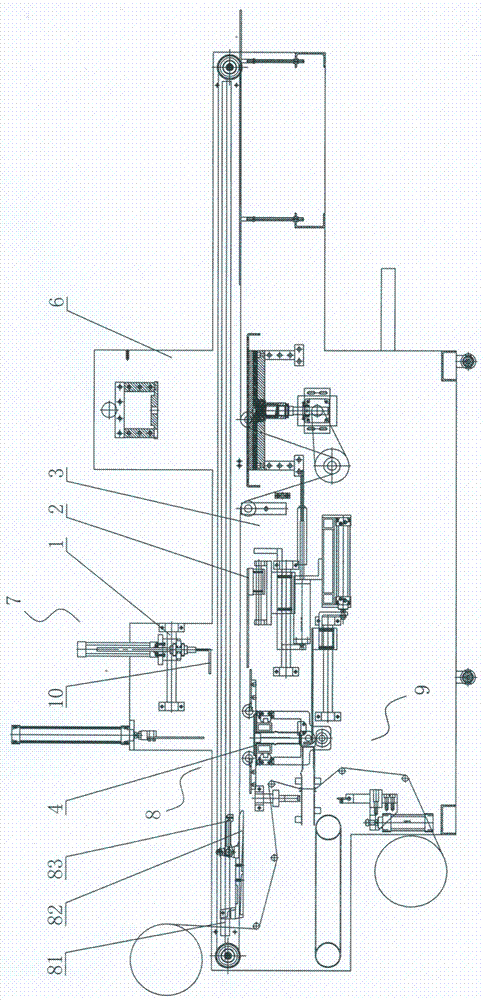

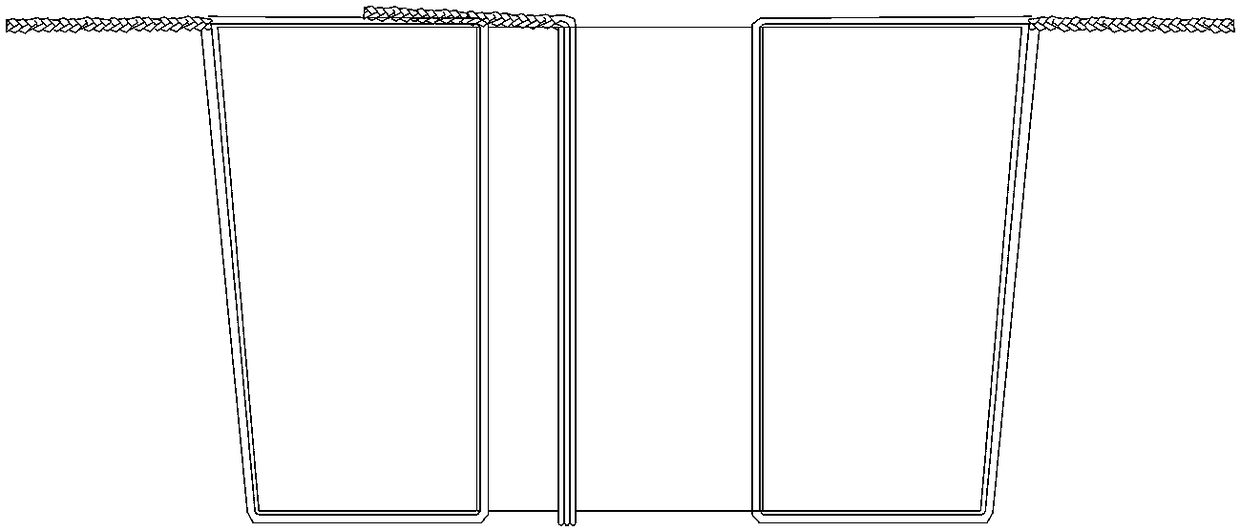

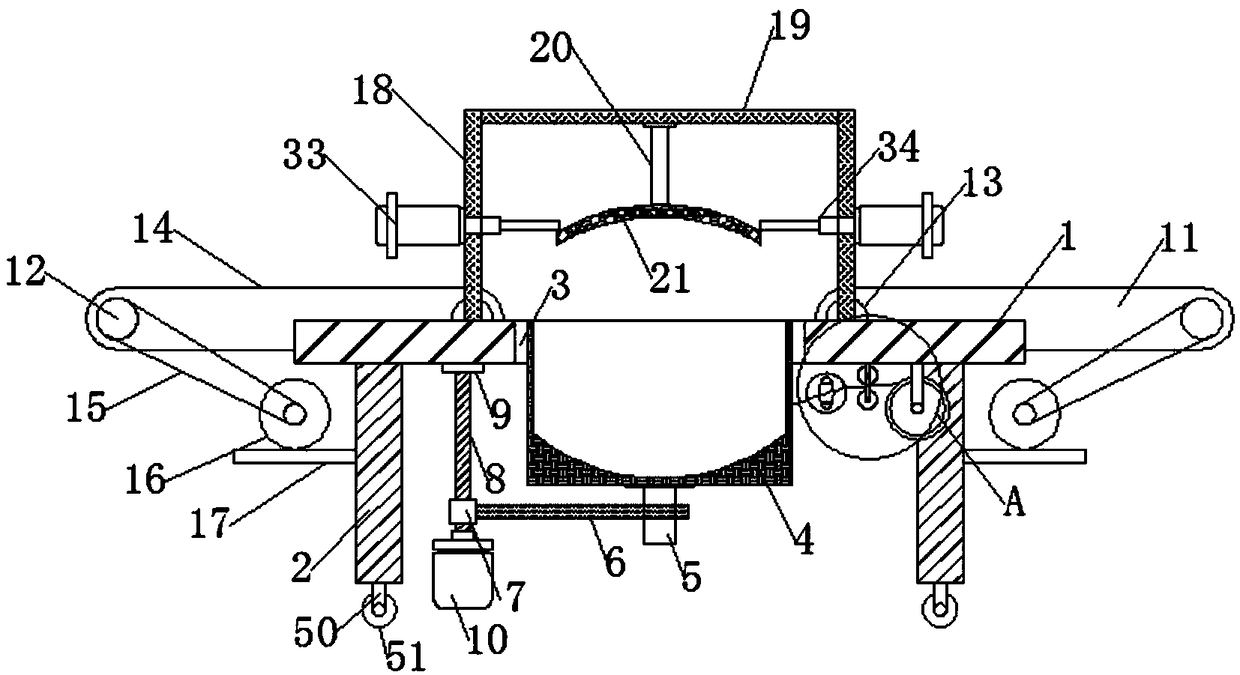

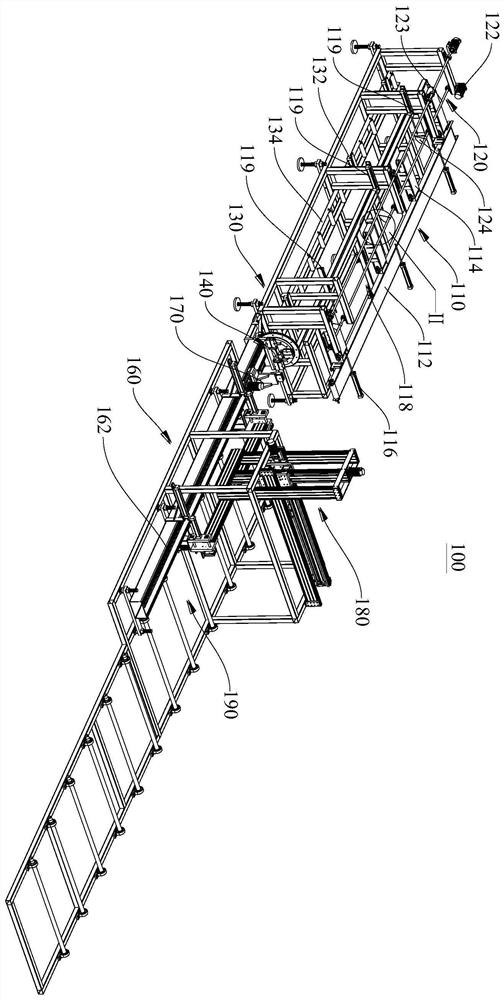

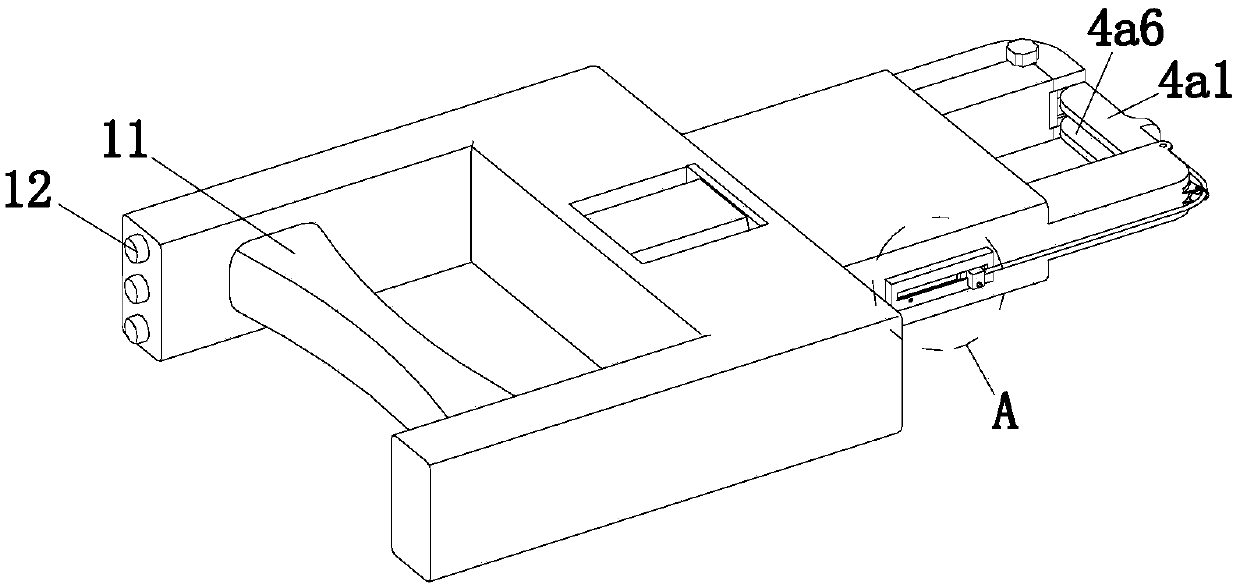

Folding and bundling integrated machine for packaging bag

ActiveCN106864886AImprove folding efficiencyTied up firmlyPaper article packagingBinding material applicationEngineeringMachining

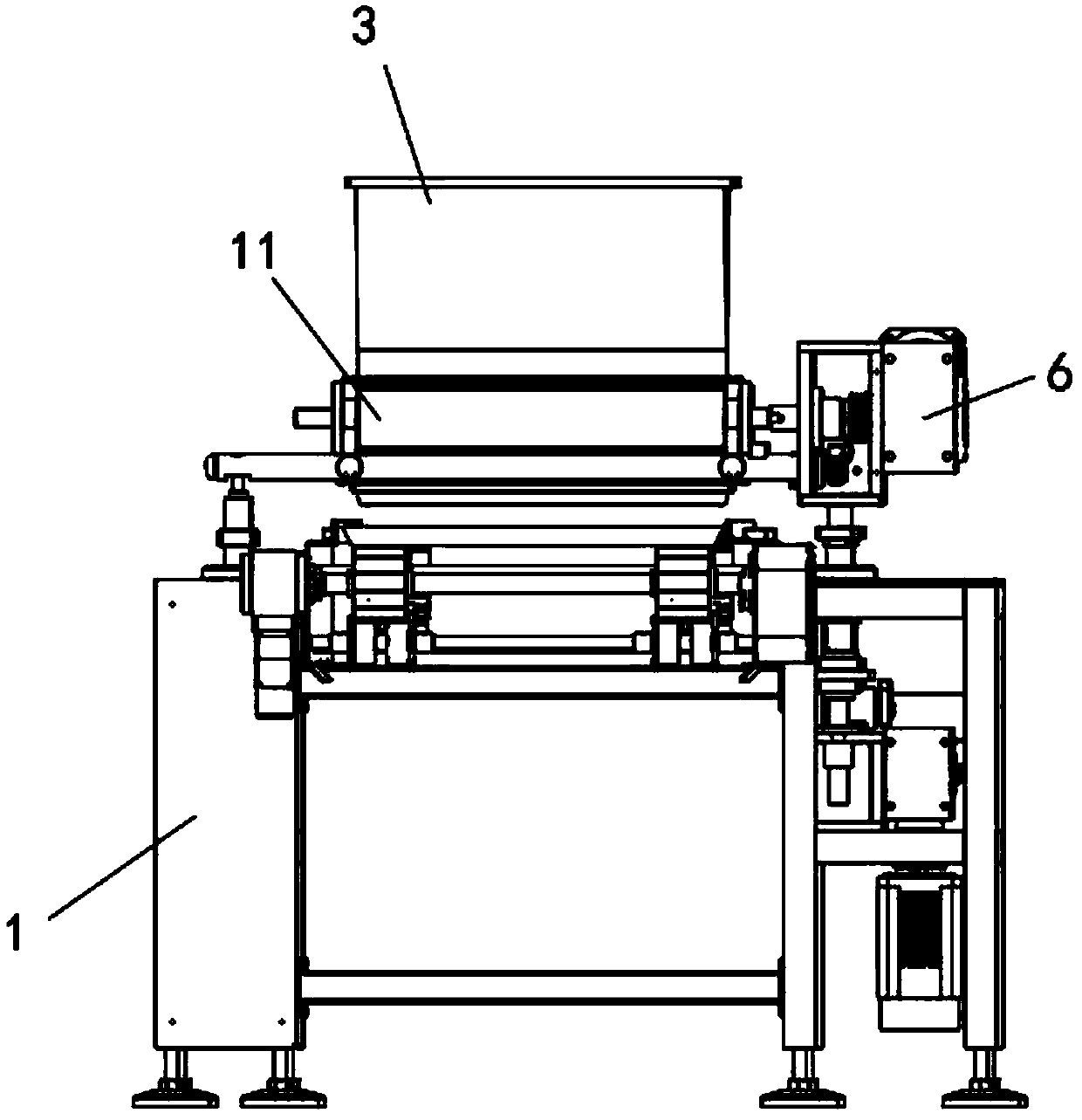

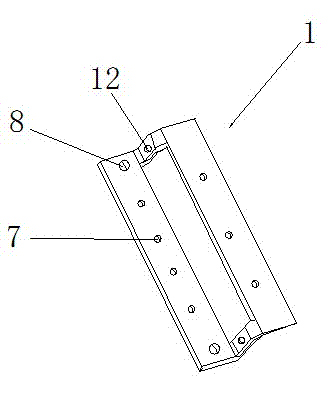

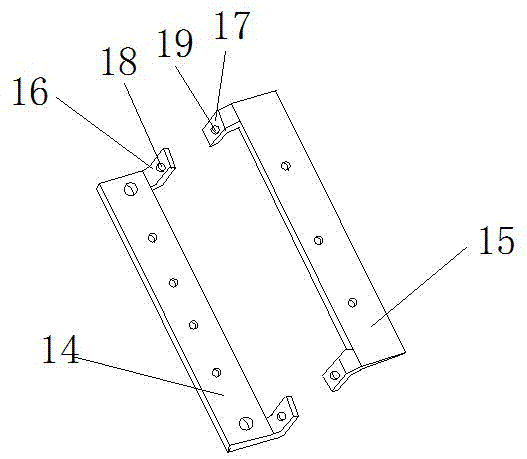

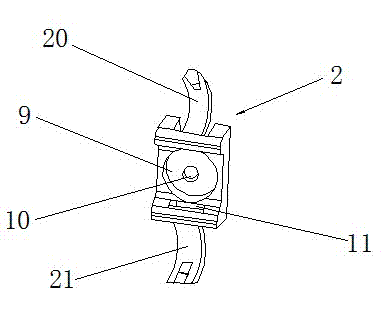

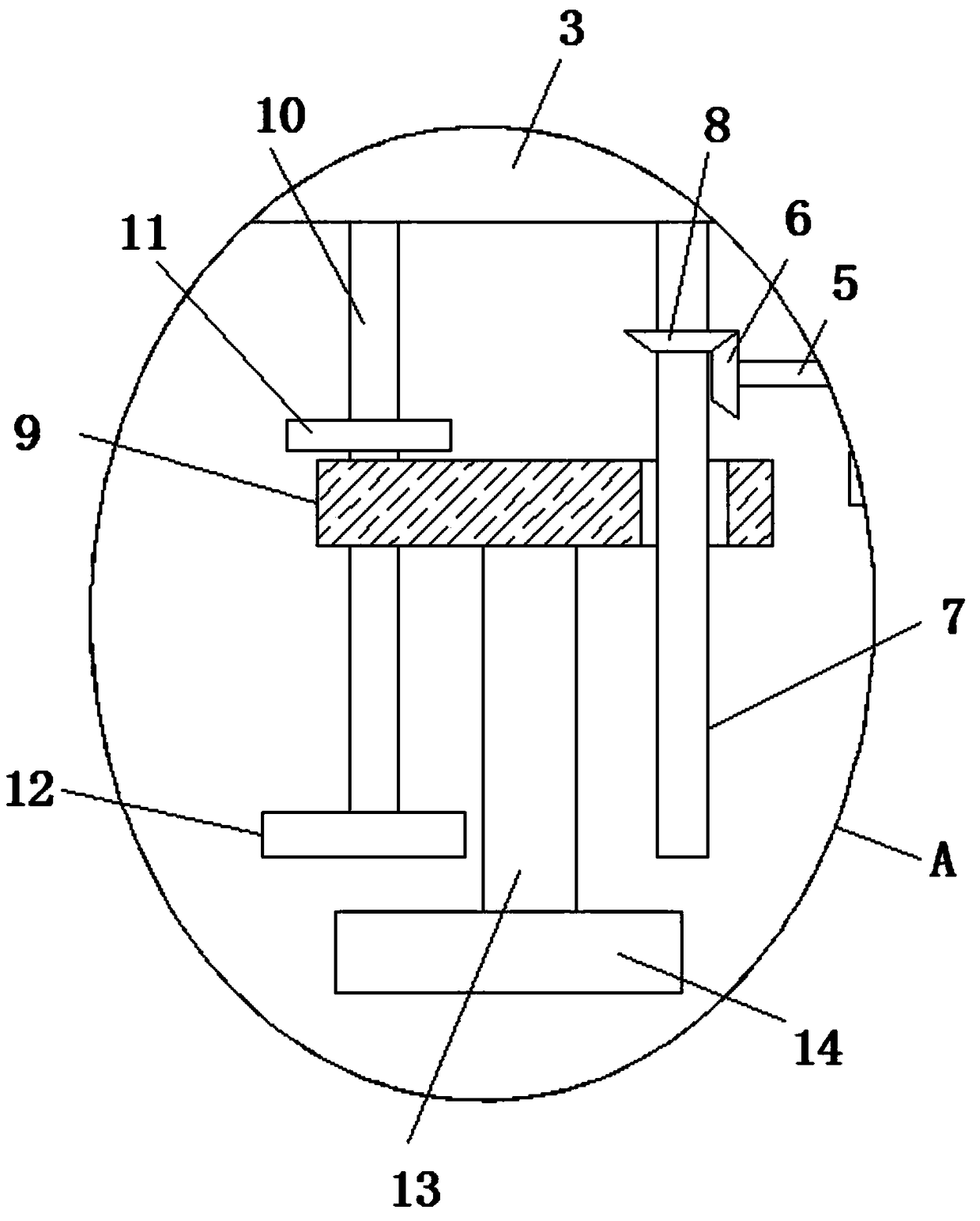

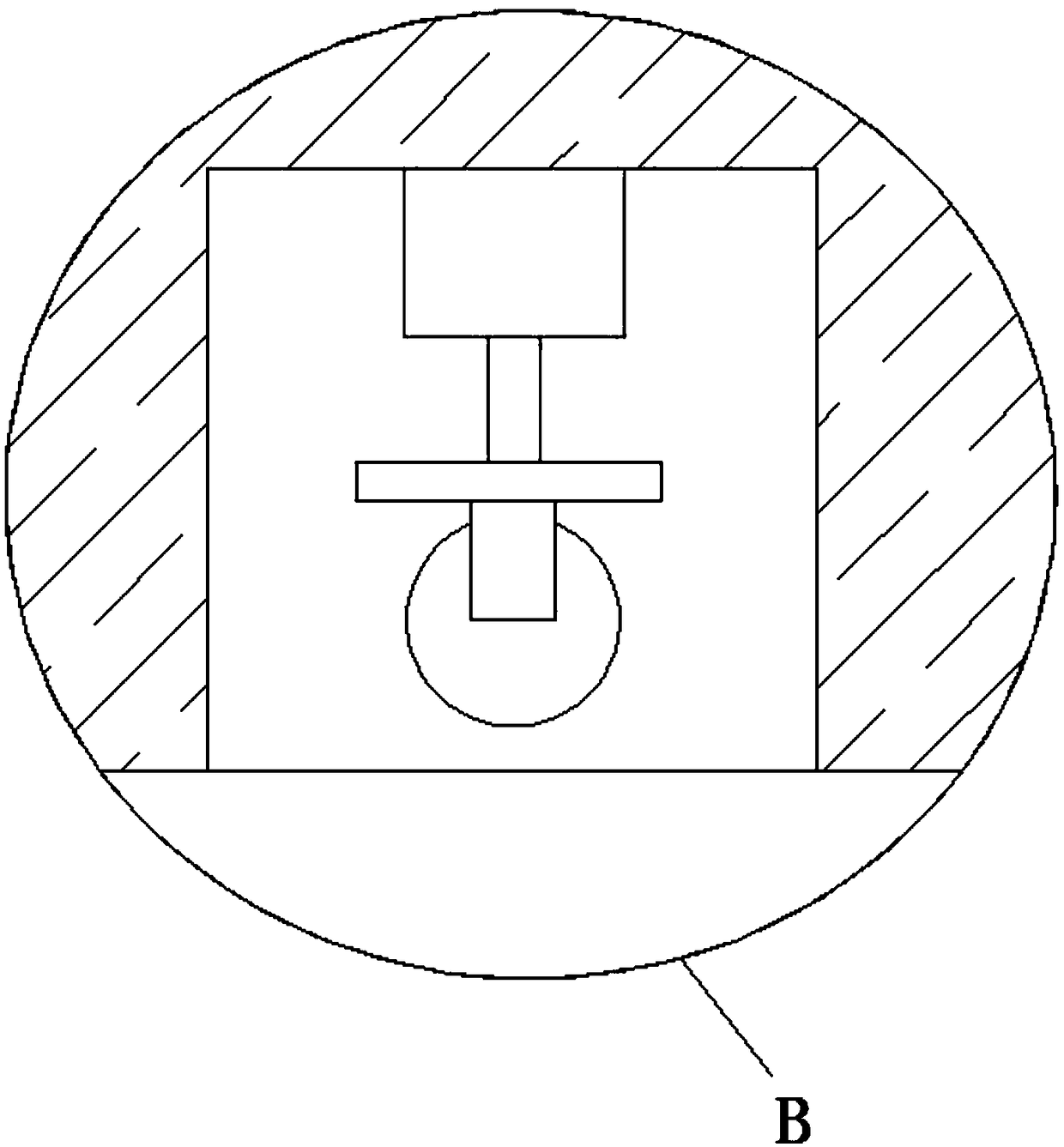

The invention discloses a folding and bundling integrated machine for a packaging bag. The folding and bundling integrated machine comprises a machine frame, a bag body folding mechanism and a bundling mechanism, and is characterized in that the bag body folding mechanism comprises a supporting plate, a center positioning device, a front folding device for folding the bottom of a bag body backwards, and a rear folding device for folding a bag opening part of the bag body forwards. The front folding device and the rear folding device are arranged in front of and behind the supporting plate correspondingly. The center positioning device comprises positioning pressing plates, lifting parts driving the positioning pressing plates to rise and fall, and adjustment parts used for adjusting the transverse positions of the positioning pressing plates. The positioning pressing plates include the left pressing plate and the right pressing plate. The left pressing plate and the right pressing plate are arranged over the supporting plate and arranged on the two sides of the supporting plate correspondingly. Under the folding working condition, the bag body is arranged on the supporting plate, a front pressing plate and a rear pressing plate. According to the folding and bundling integrated machine, folding of the bag body is achieved in a center positioning and frontward-backward folding manner, the structure is simple, the machining cost is low, and the bag body folding efficiency is high.

Owner:浙江晨宇科技股份有限公司

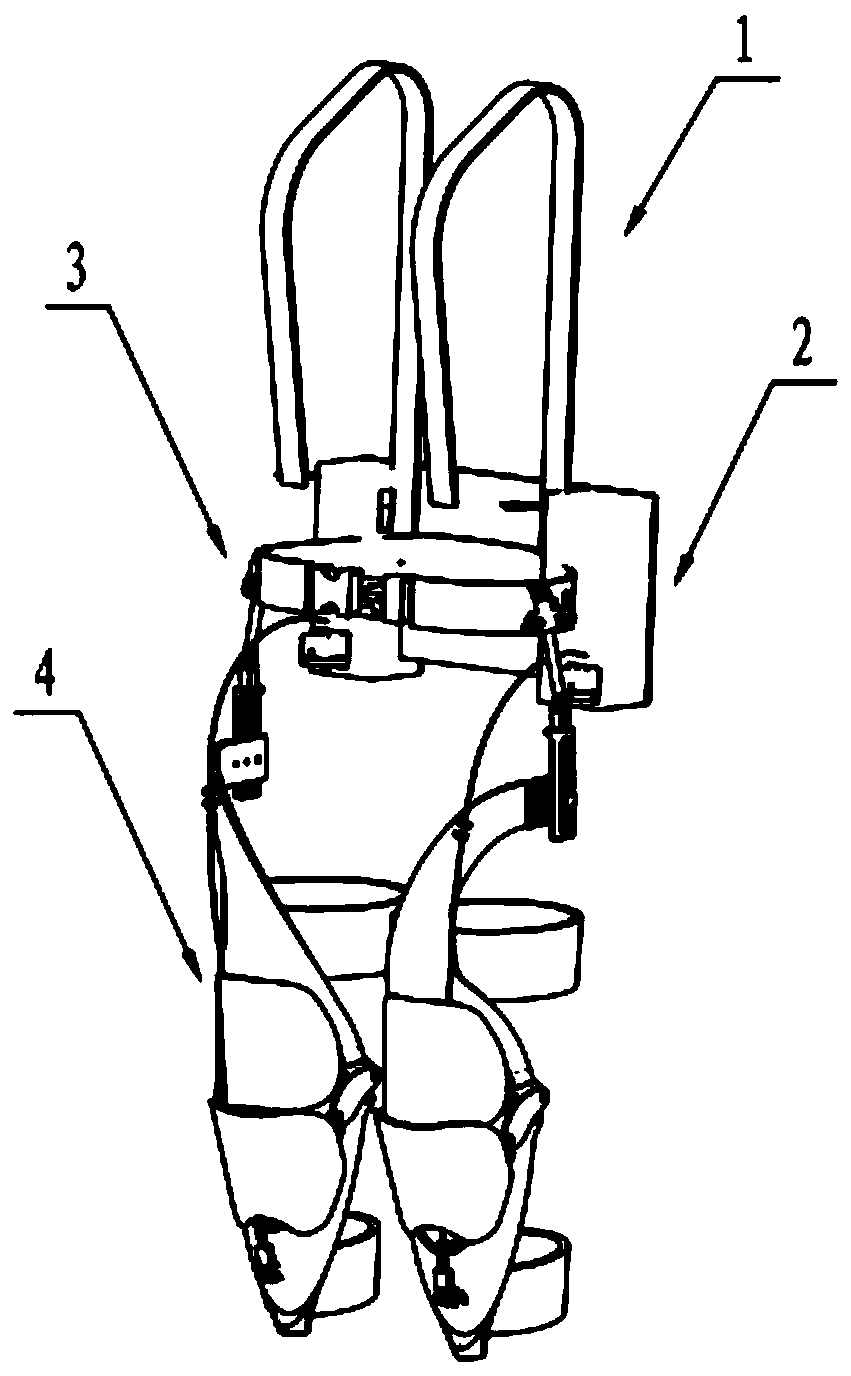

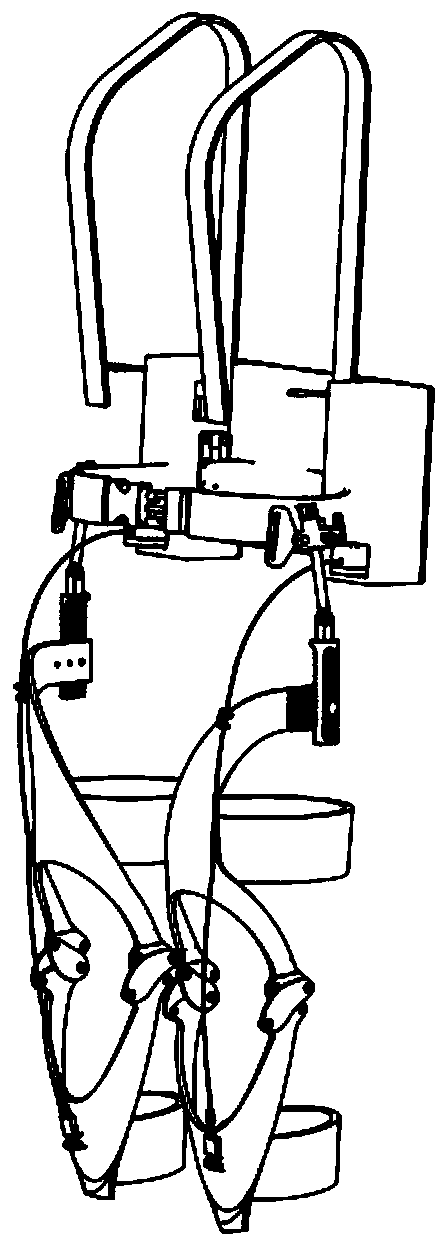

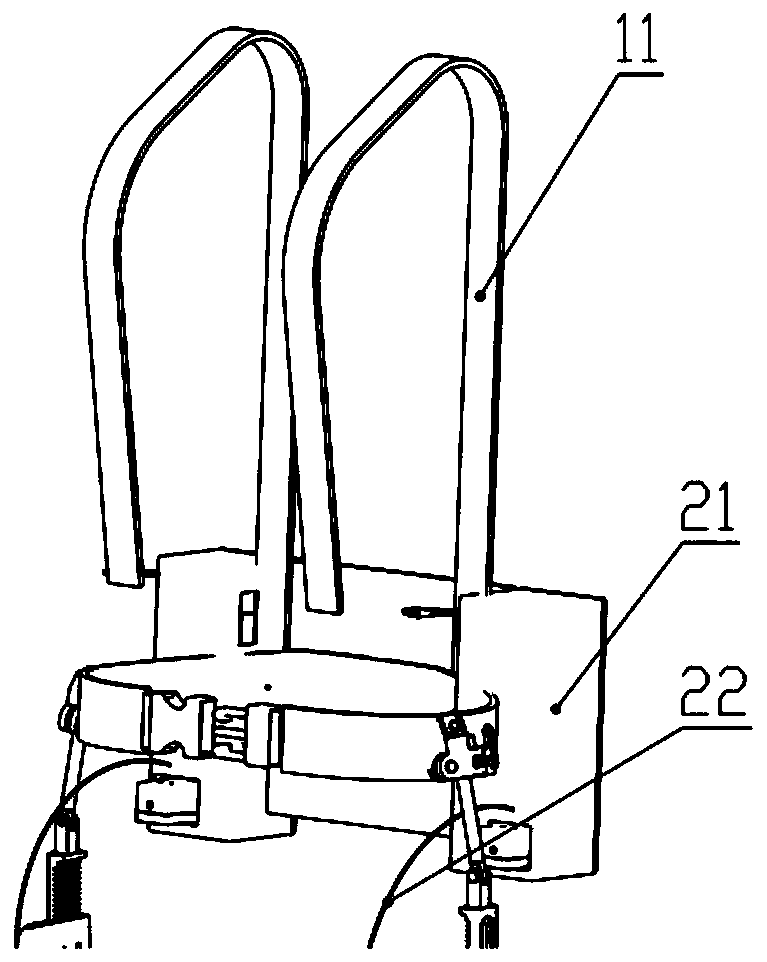

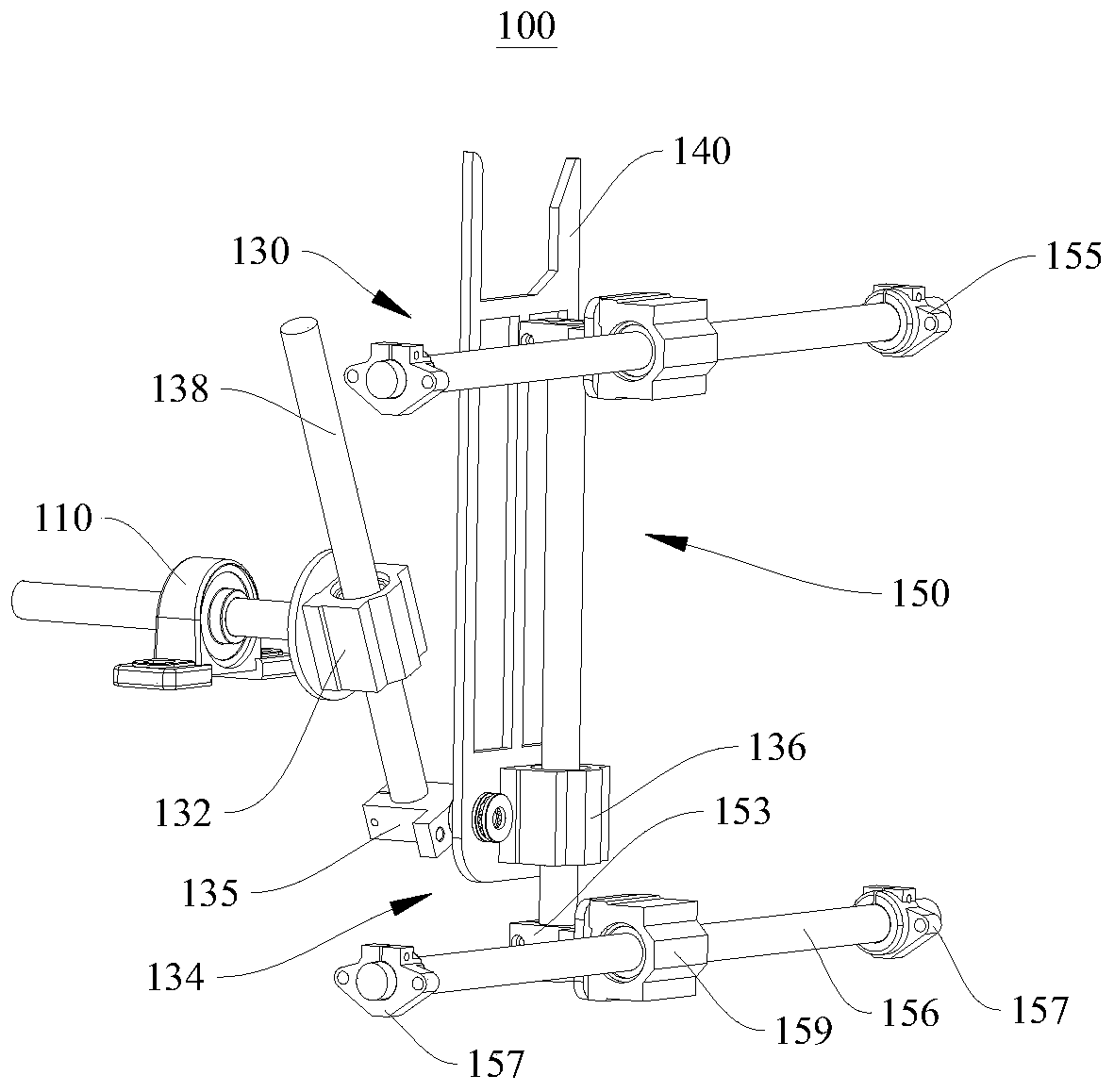

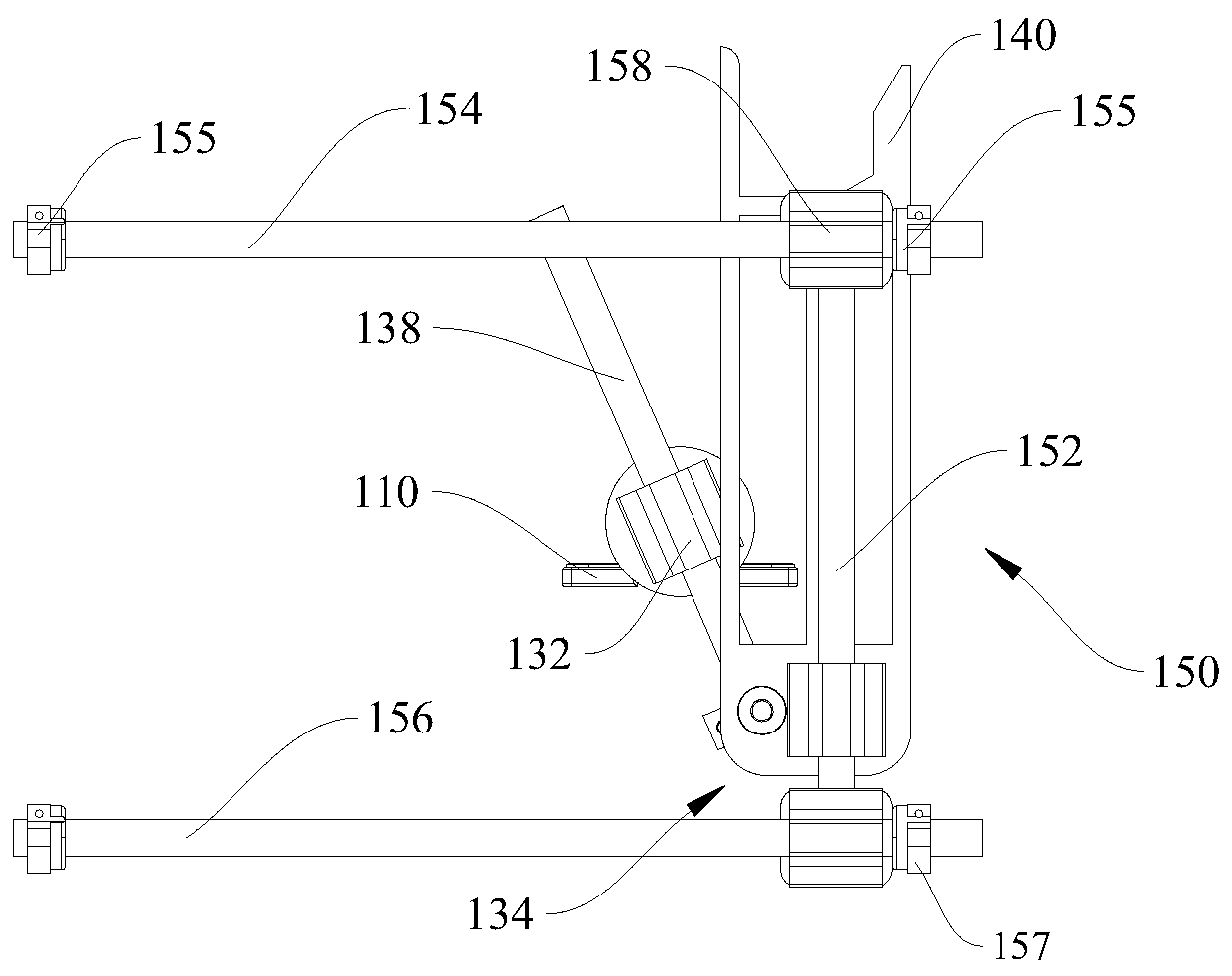

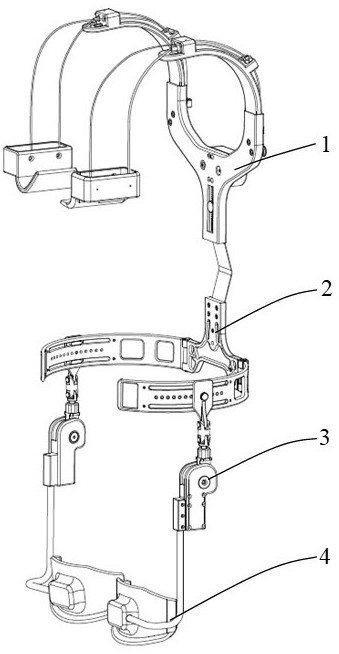

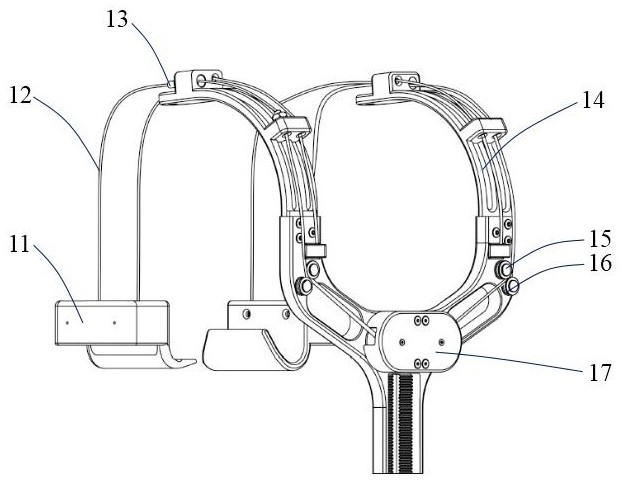

Flexible exoskeleton assisted robot

ActiveCN110653796ADisassembly freeMaintenance freeProgramme-controlled manipulatorDiagnosticsThighPhysical medicine and rehabilitation

The invention provides a flexible exoskeleton assisted robot which is composed of a shoulder strap, a power transmission device, a waist mechanism, a lower limb mechanism and the like from top to bottom in sequence. A binding and fixing system fixes the power transmission device and can be adjusted quickly according to the body shape of a wearer; the power transmission device can realize flexibledriving of knee joints; the waist mechanism fixes a driving unit through a waist belt, and are connected with the lower limb mechanism through a quick disassembly and assembly mechanism; the lower limb mechanism adopts a wrapped-around design, the knee joints adopt a quadrilateral hinge structure design, mechanical legs can be better fit with legs of the wearer to increase the comfort of the wearer, protective boards are arranged designed at the knee joints, on the one hand, the keen joints can be protected, and on the other hand, guiding can be provided for wire transmission; and tool-free rapid height adjustment structures are designed on upper legs.

Owner:西北机电工程研究所

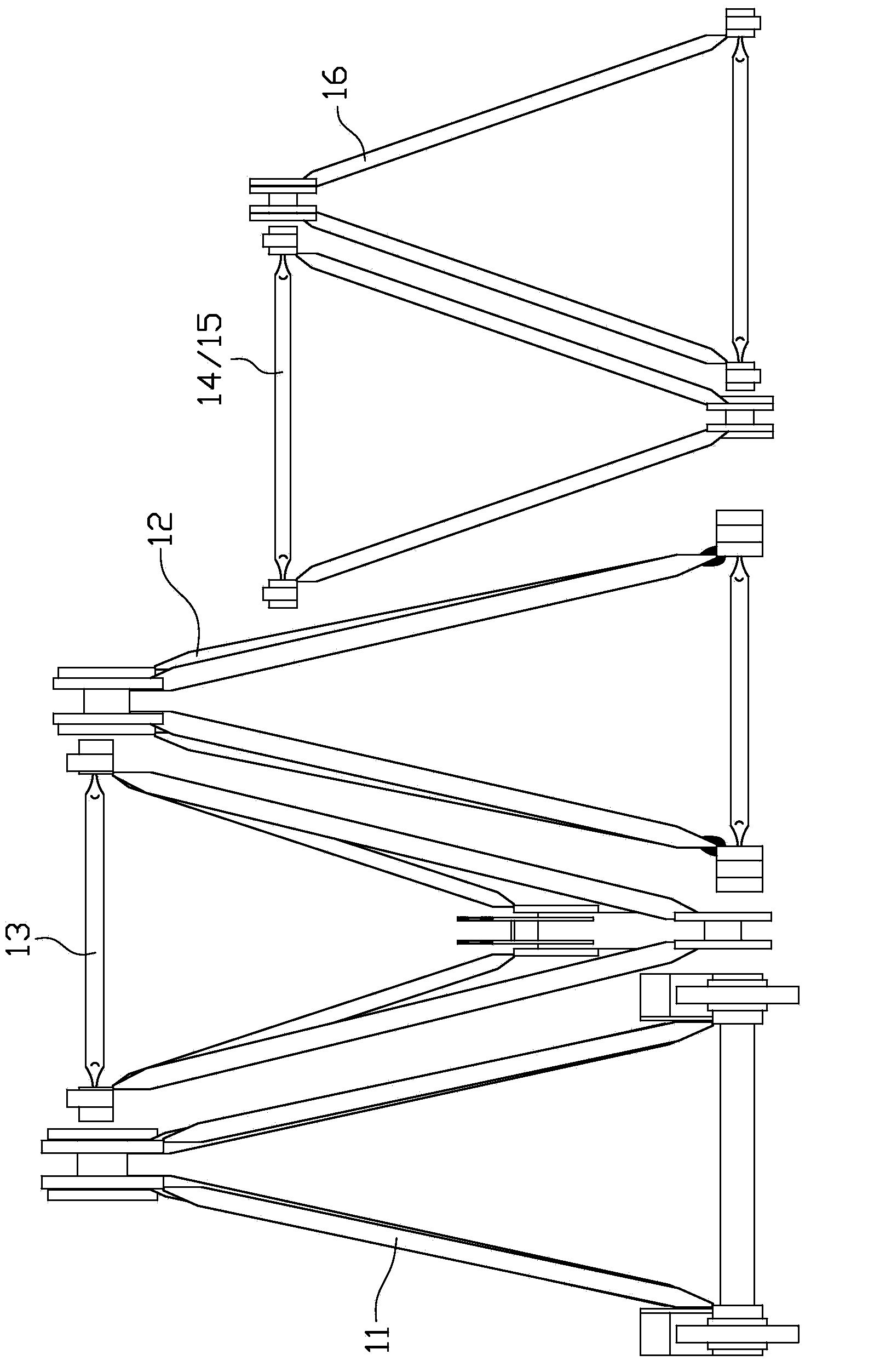

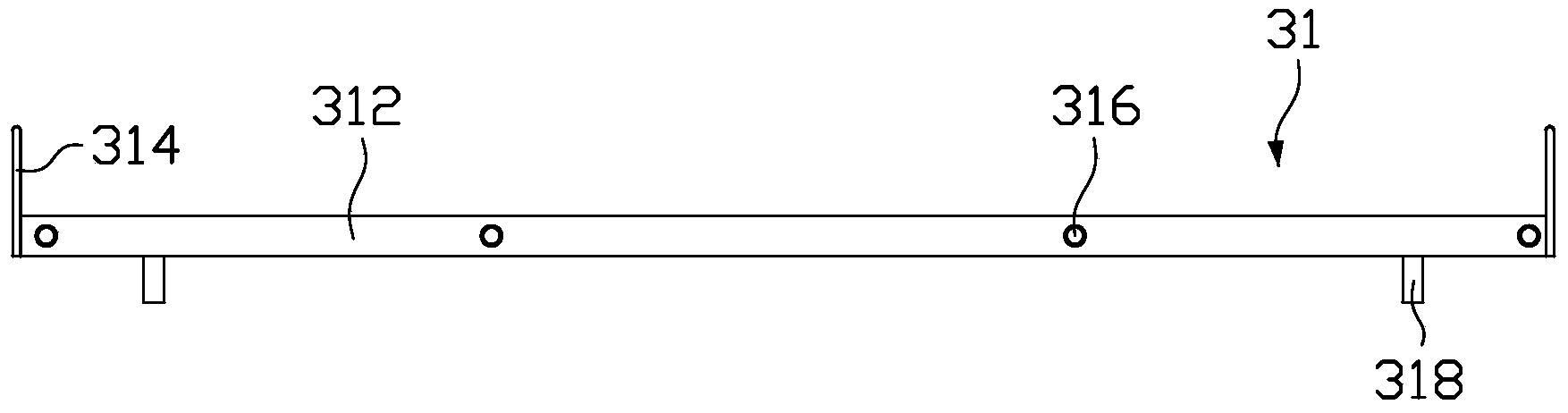

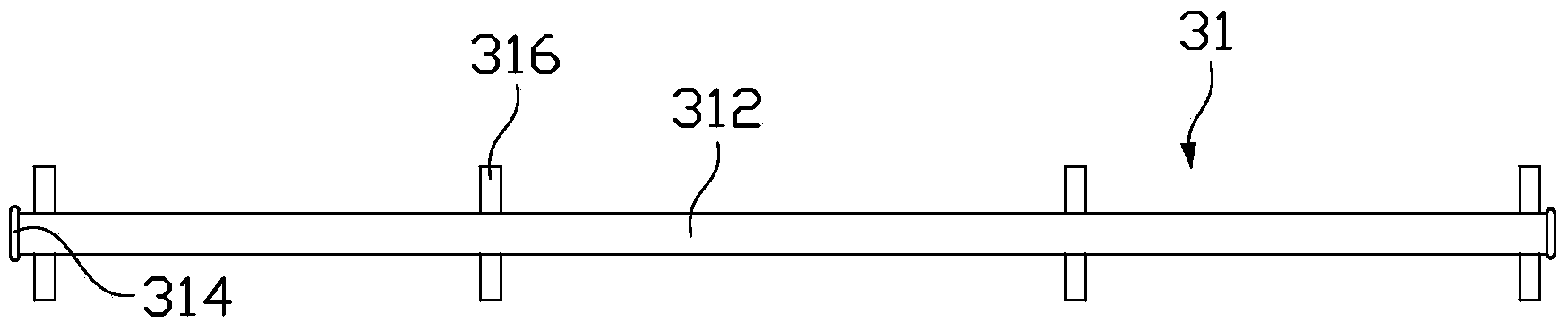

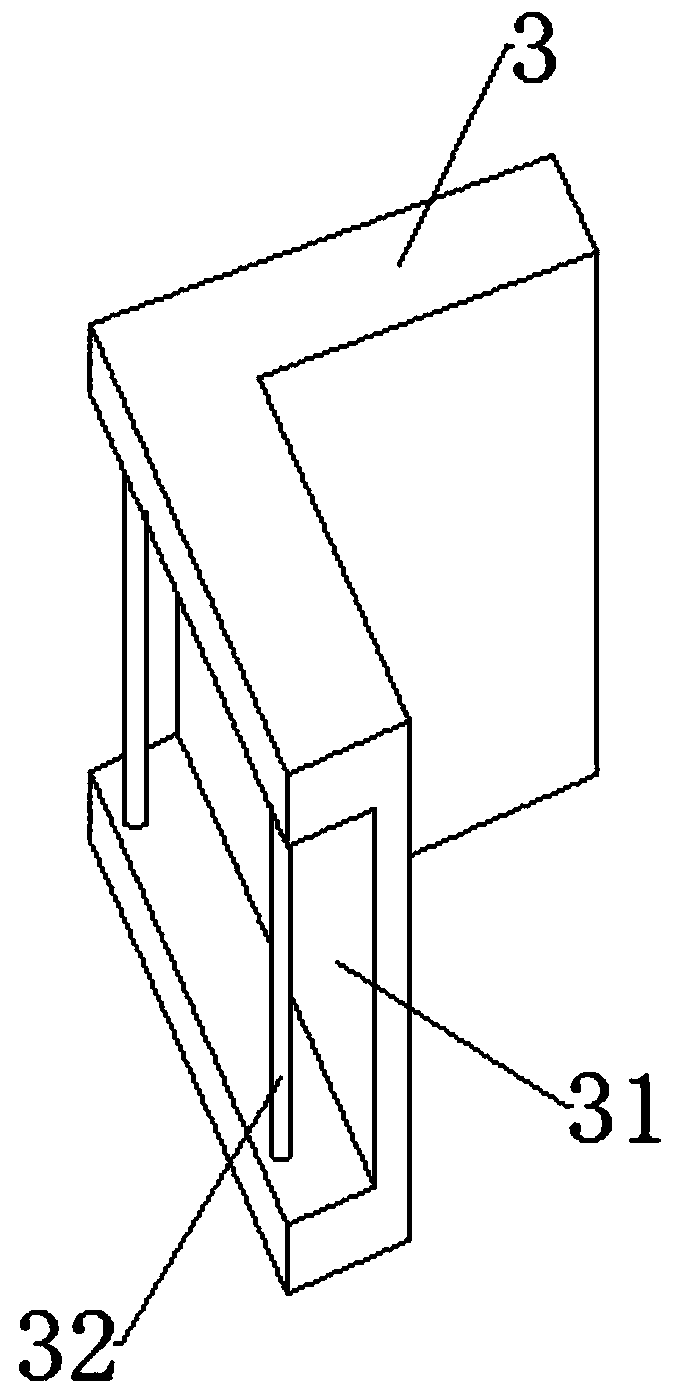

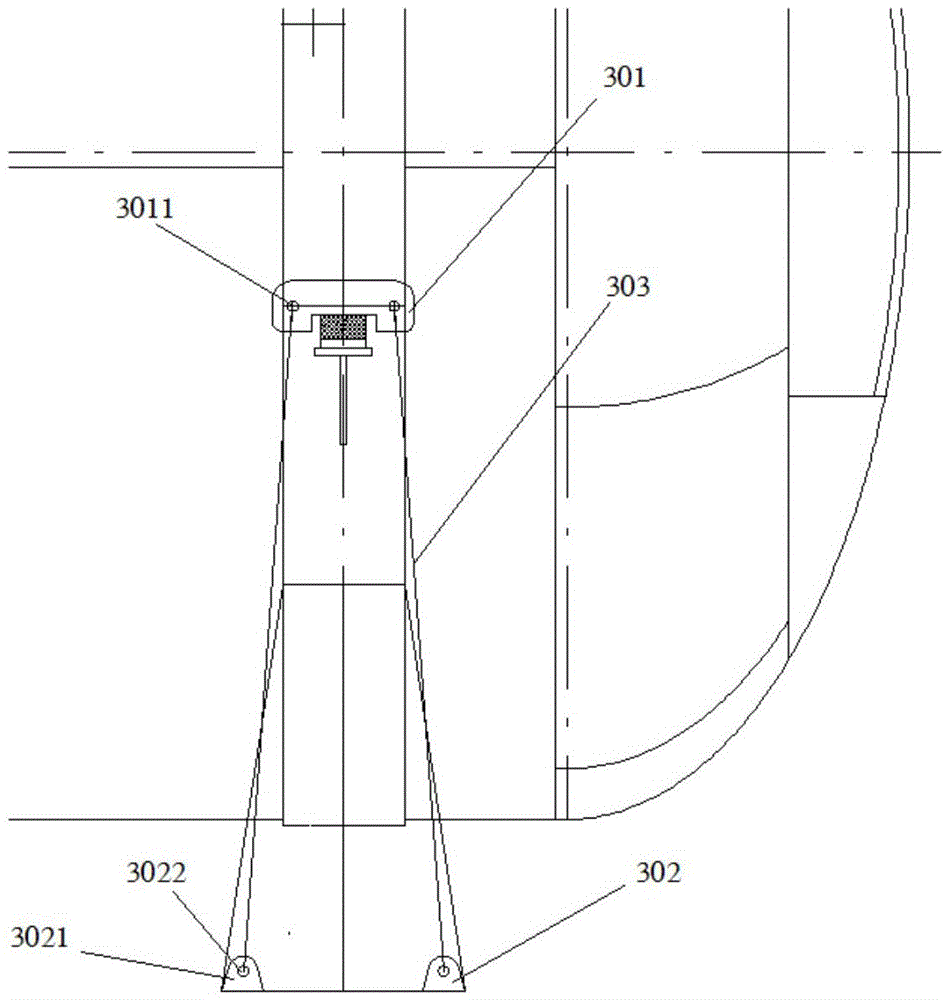

Tower crane boom packing device, system and method

ActiveCN103754504ASimple structureEasy to manufacturePackaging vehiclesContainers for machinesTower craneChassis

A tower crane boom packing device comprises two underframes and two upper-frames. Each underframe comprises an elongated bearing beam, two lugs, and a plurality of fastening parts; the lugs are disposed at two ends of the bearing beam respectively; the fastening parts are distributed on two sides of the bearing beam at intervals in the length direction of the bearing beam. Each upper-frame which is L shaped comprises a support rod and a stop rod which is arranged vertically downwards from one end of the support rod. The invention further provides a tower crane boom packing system and method using the tower crane boom packing device. When the tower crane boom packing device is used in loading, a whole boom can be loaded just by a single hoisting; transferring and delivering are more efficient; the segments of the boom packed are all firmly tied; especially, the different segments at different heights are isolated by the underframes and the upper-frames, so that mutual friction is avoided and wear is avoided.

Owner:ZOOMLION HEAVY IND CO LTD

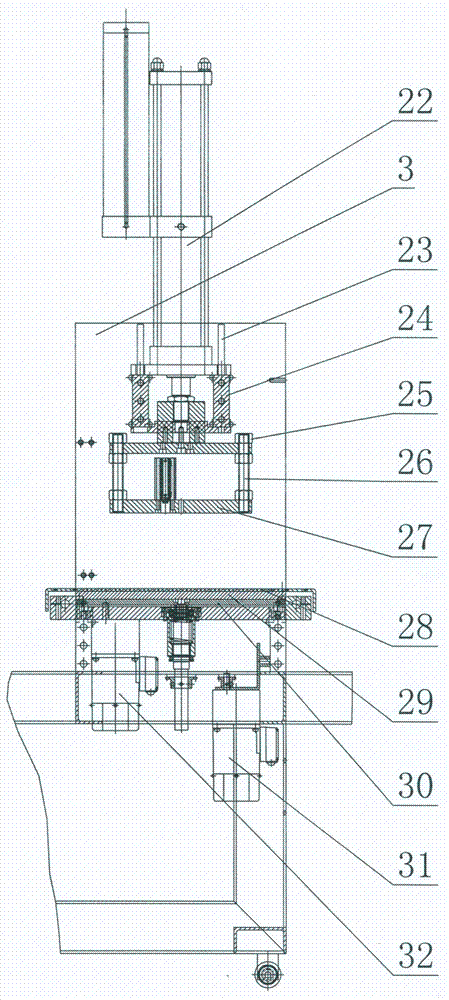

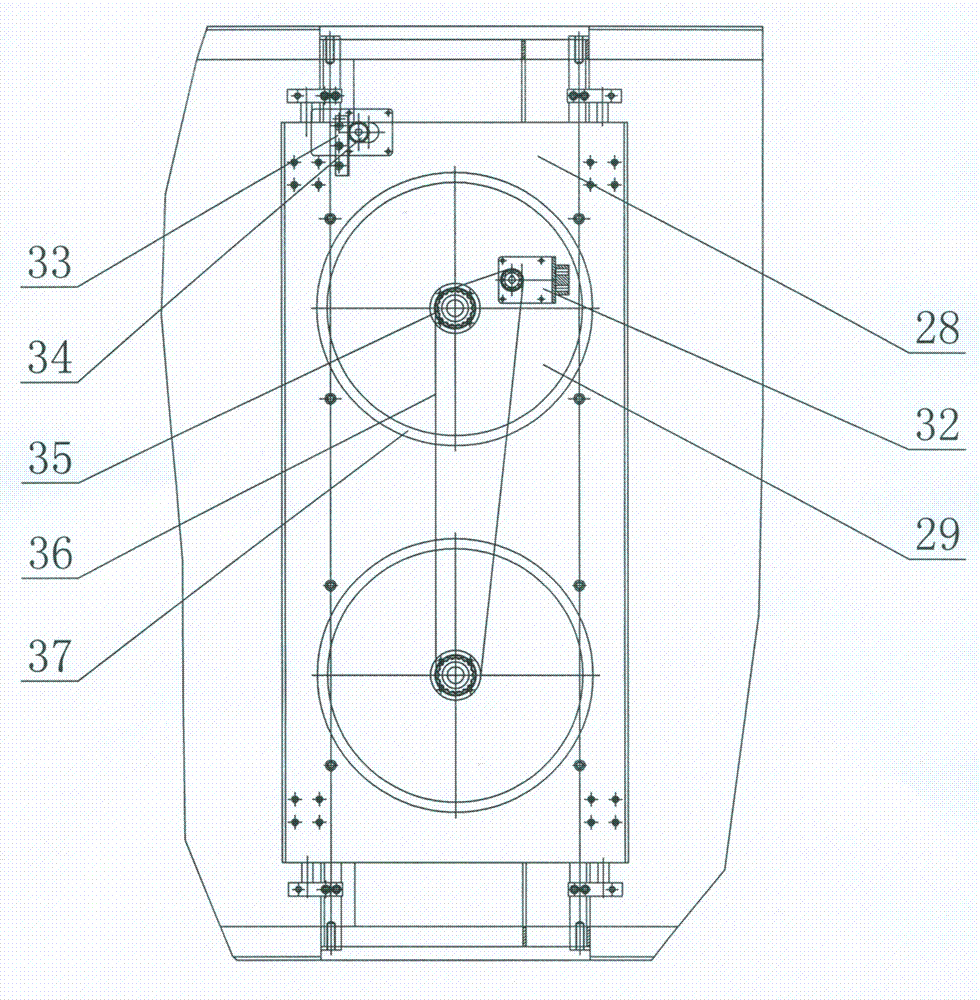

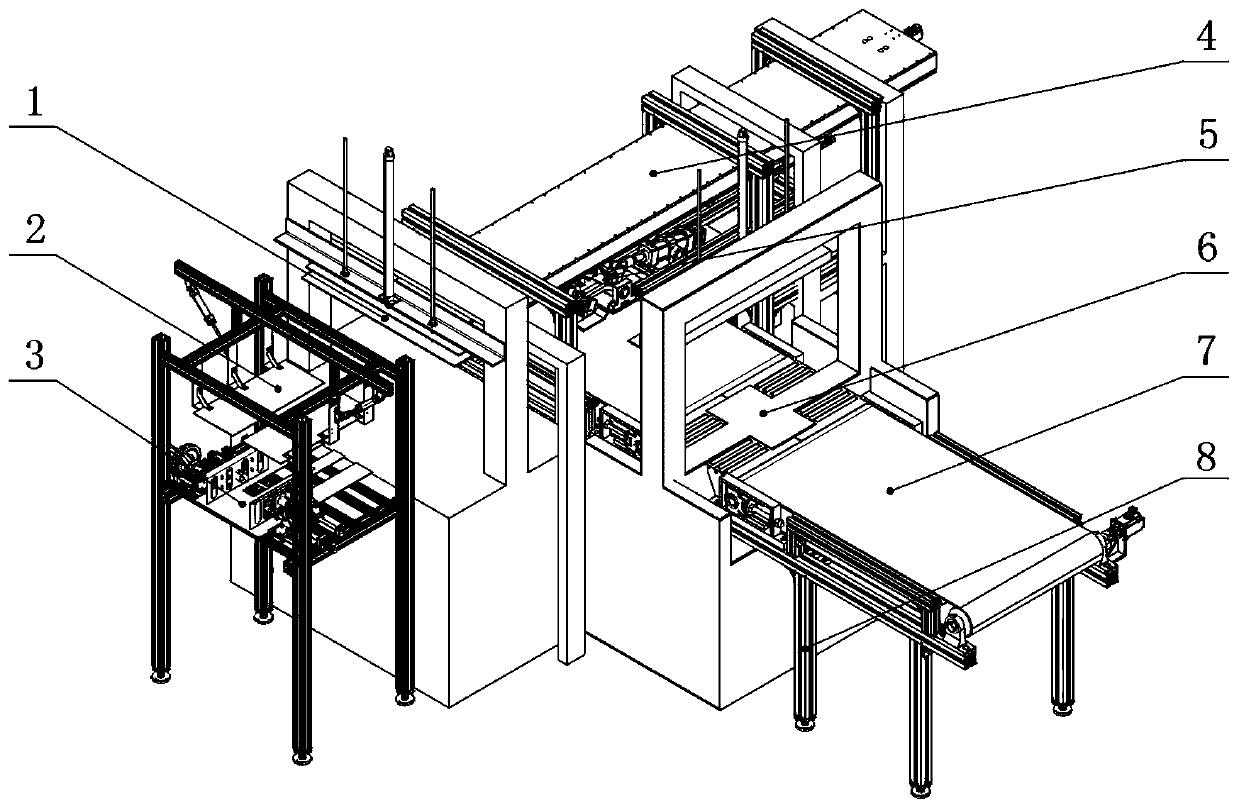

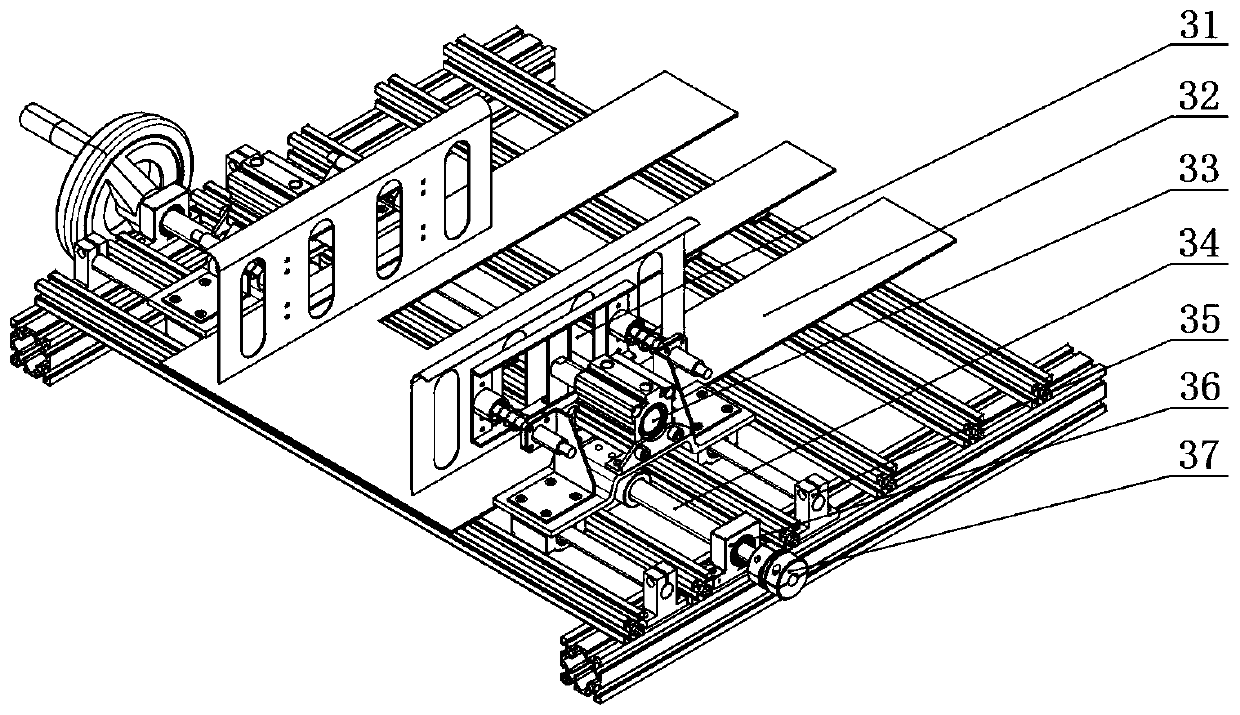

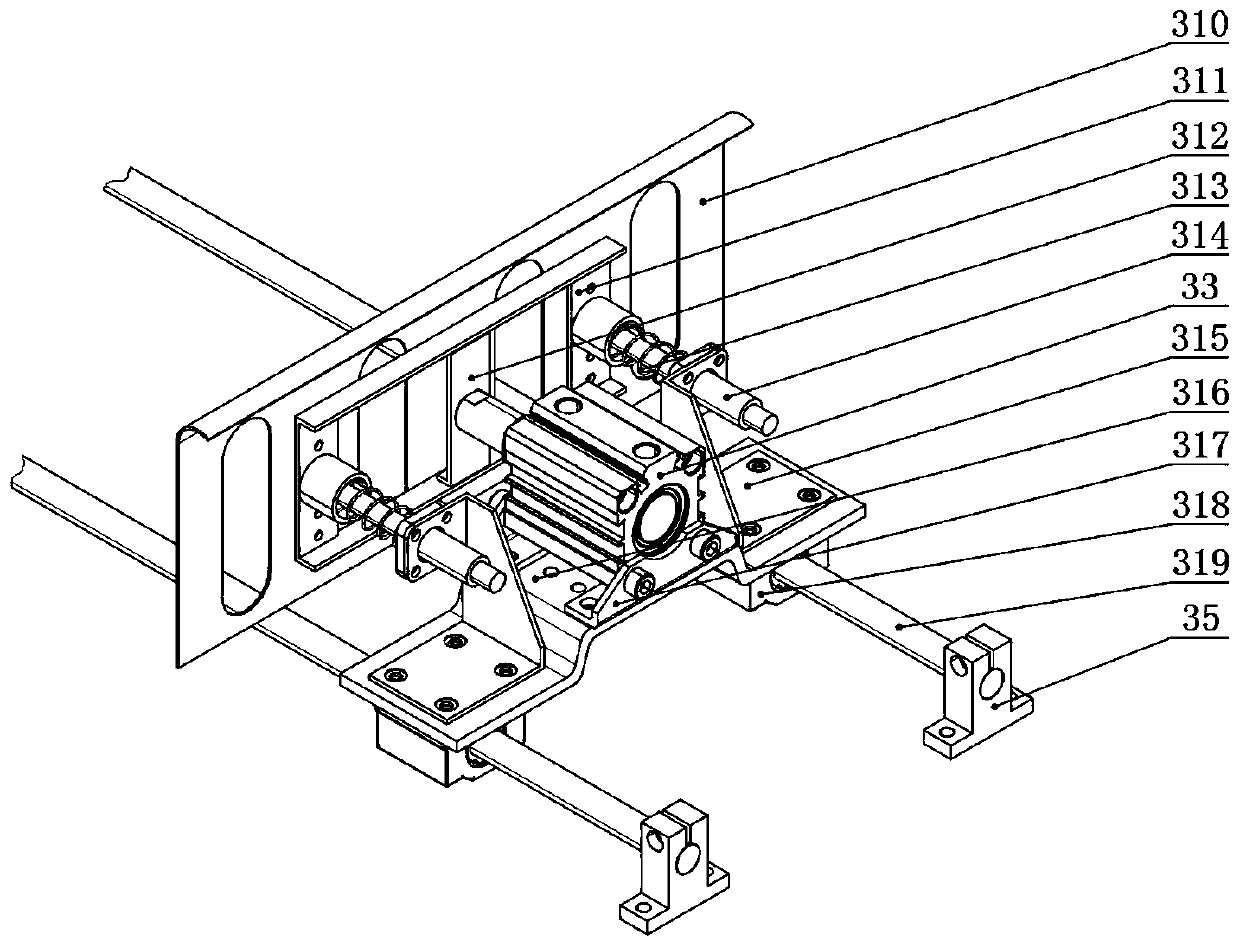

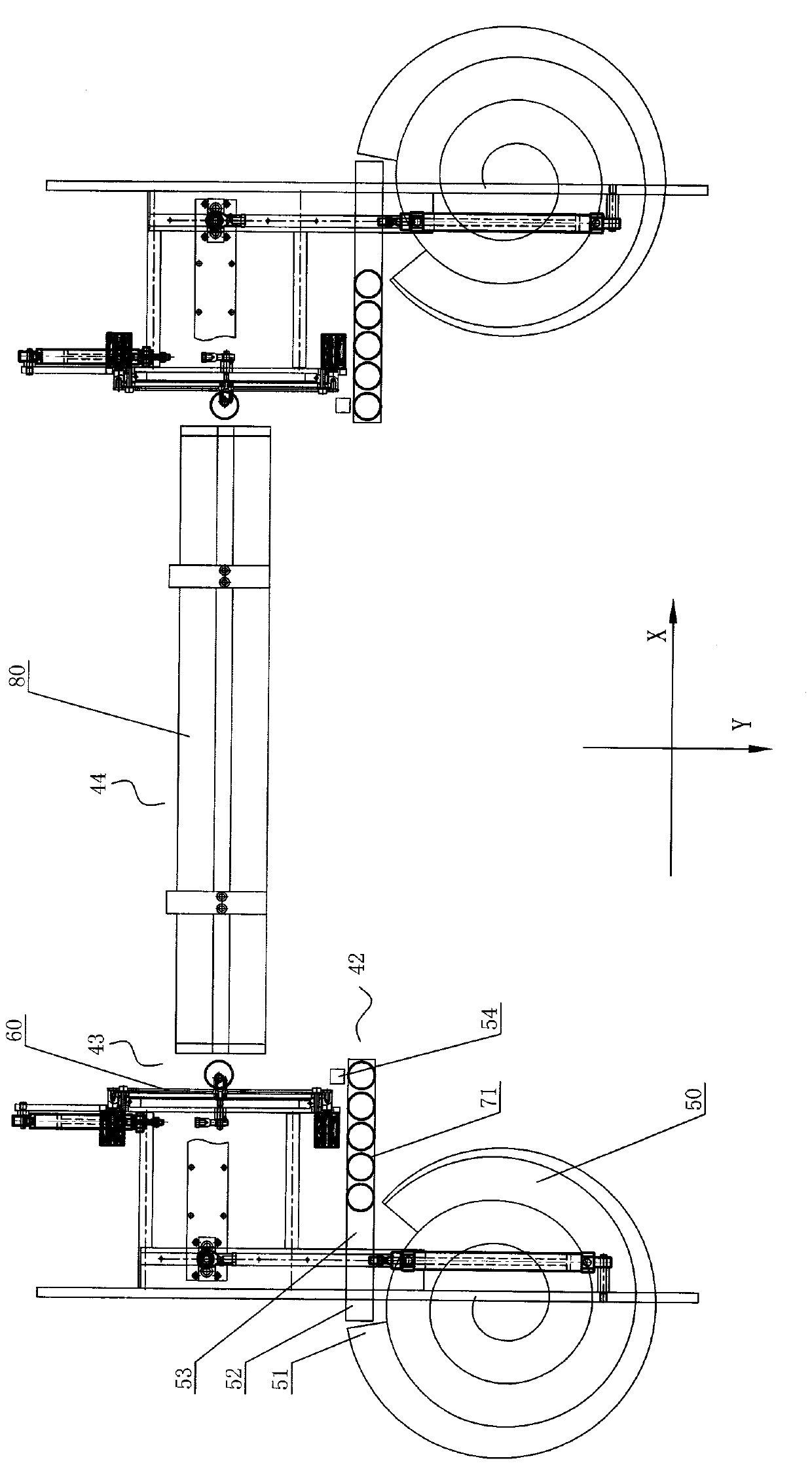

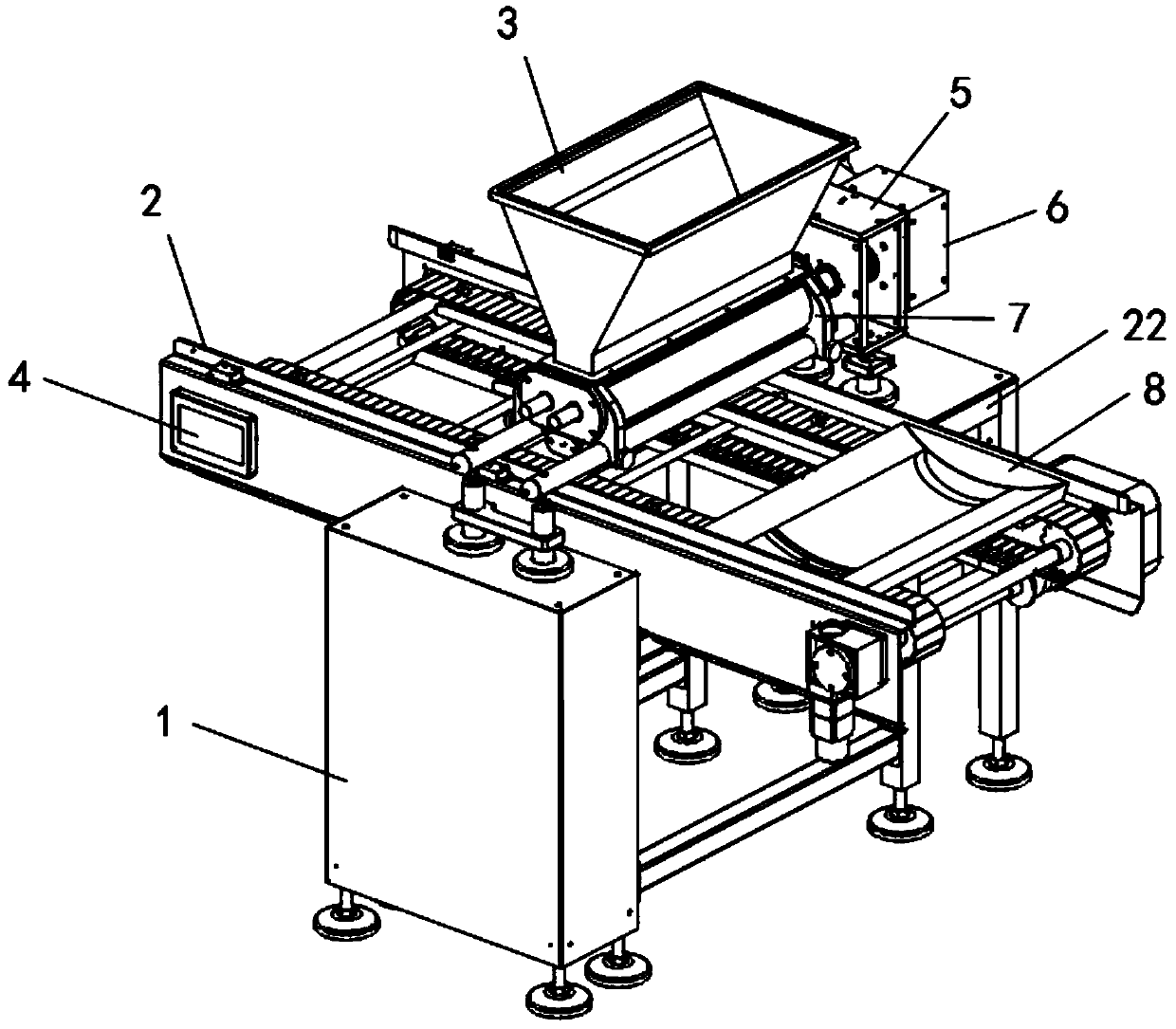

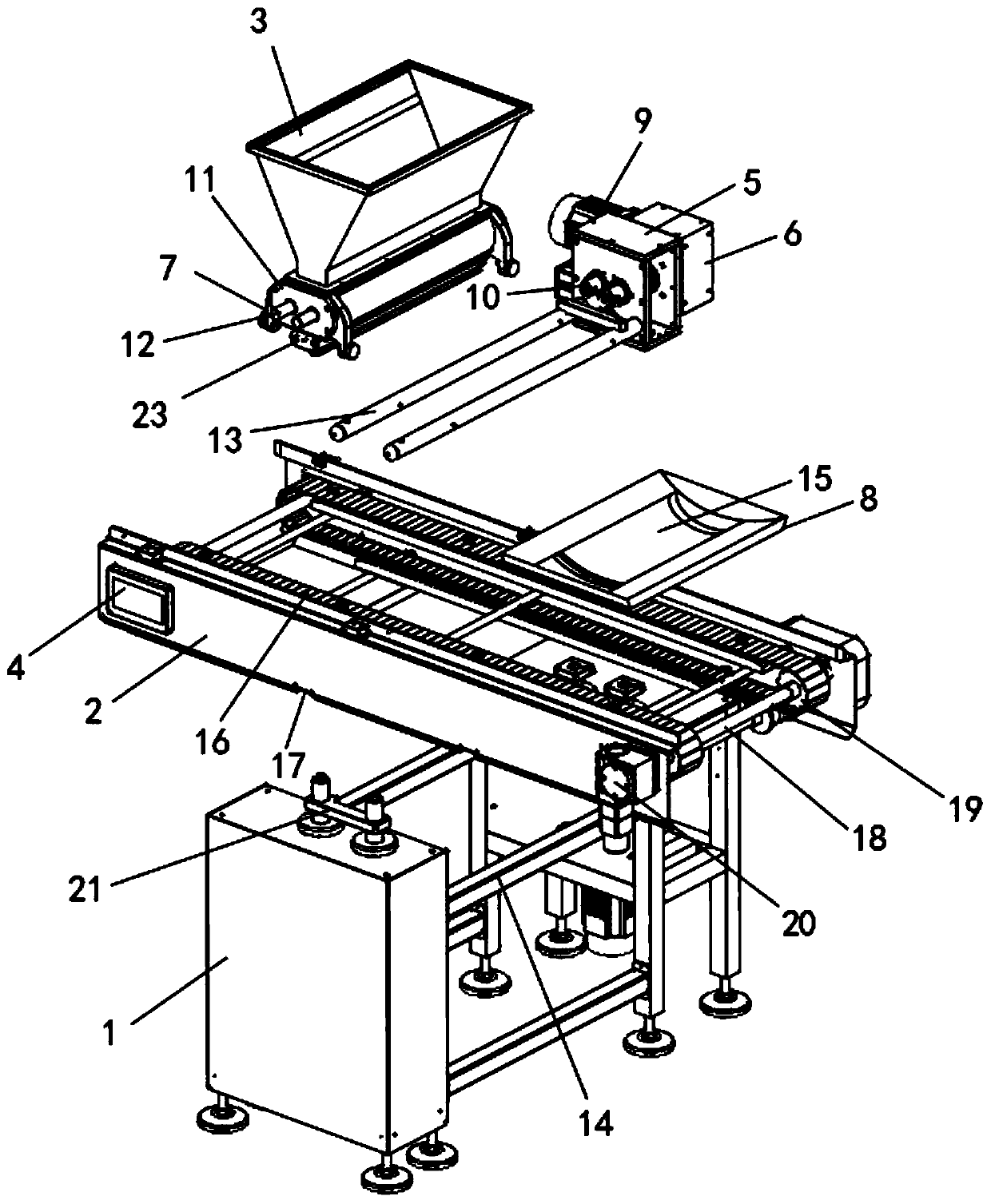

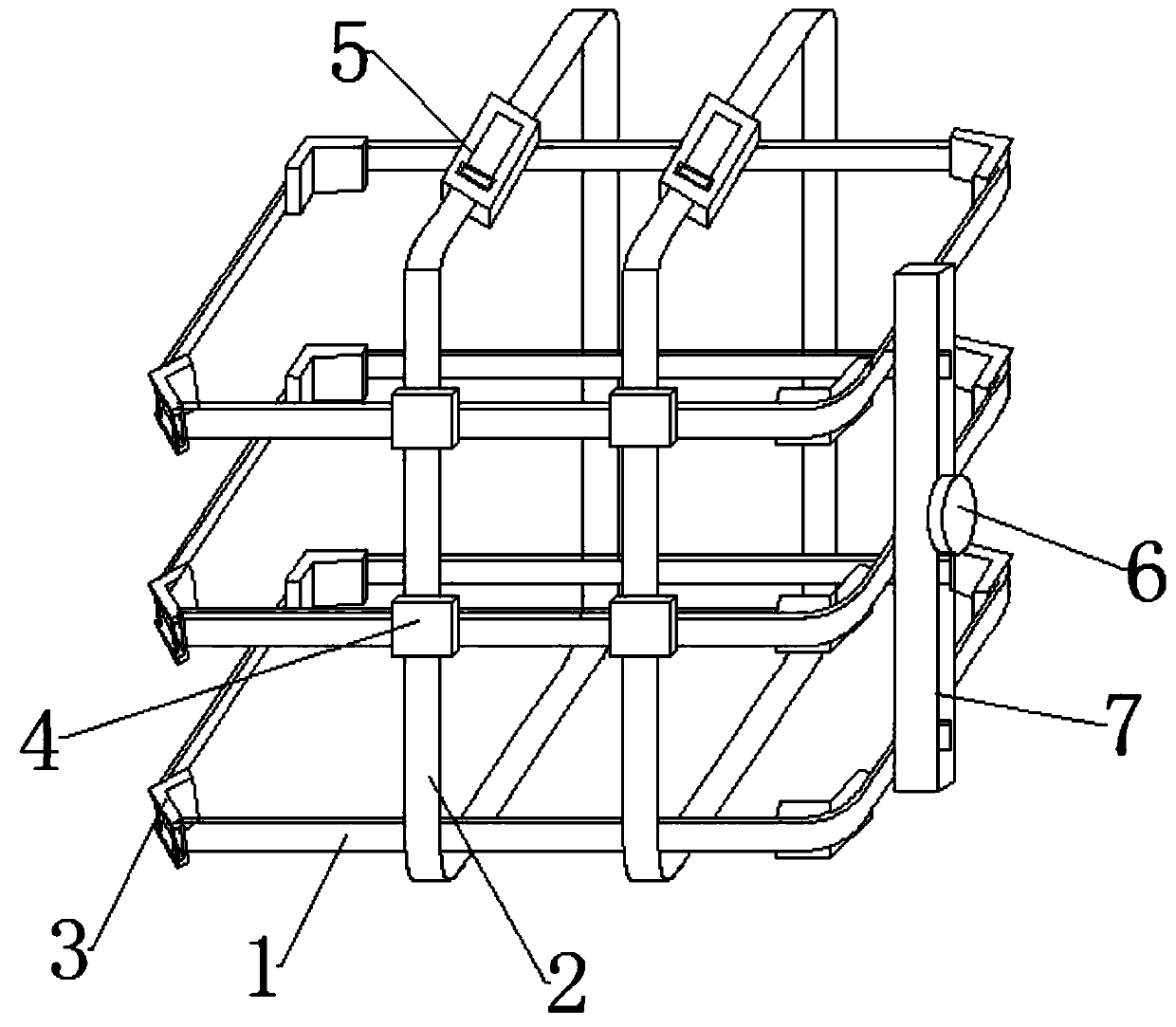

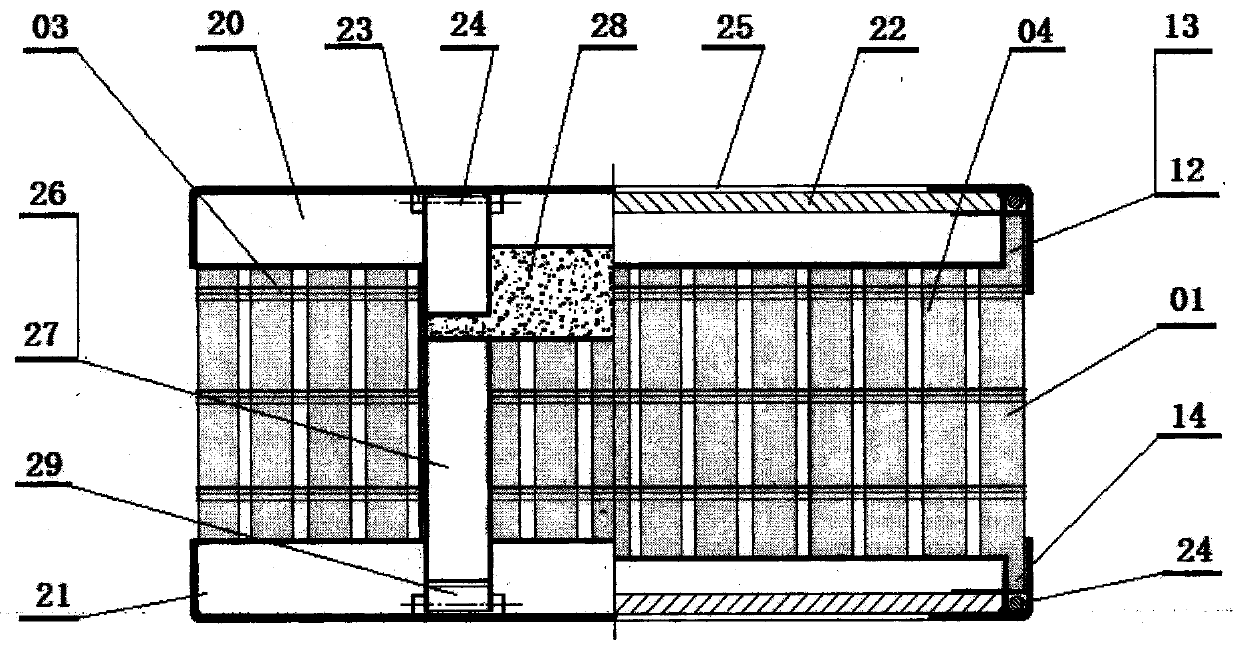

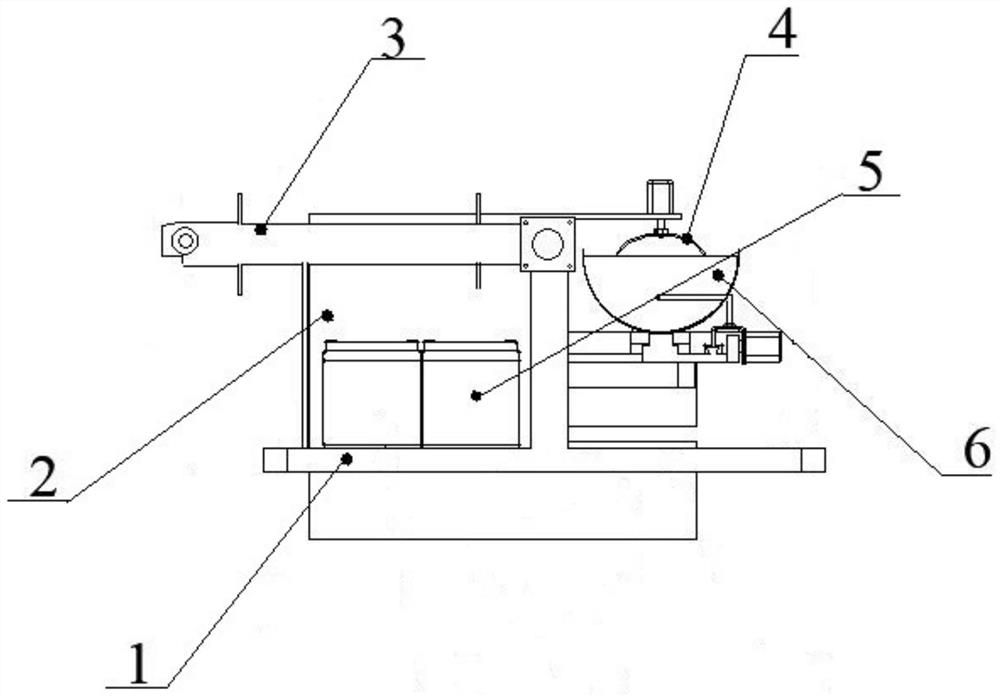

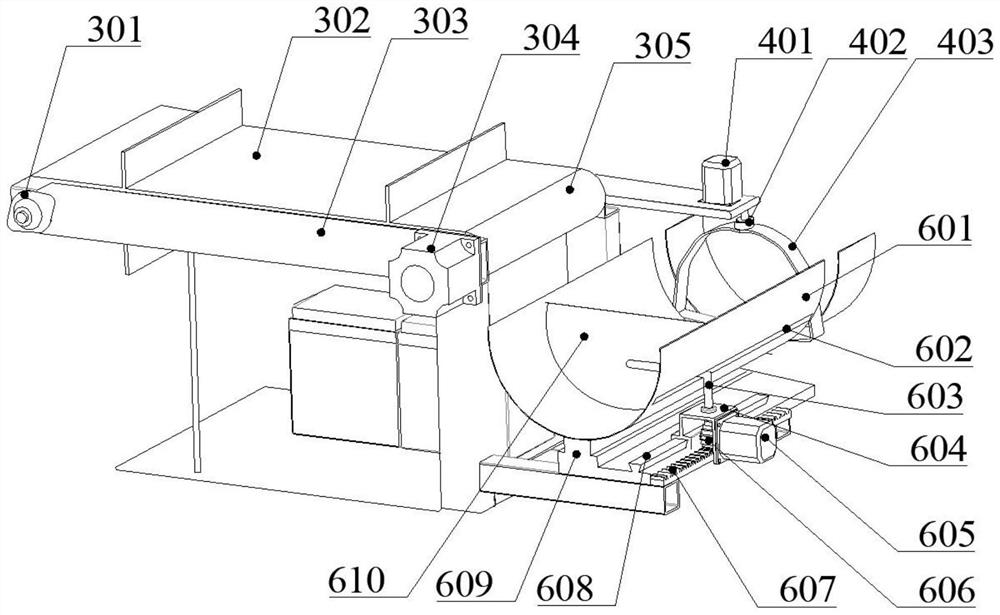

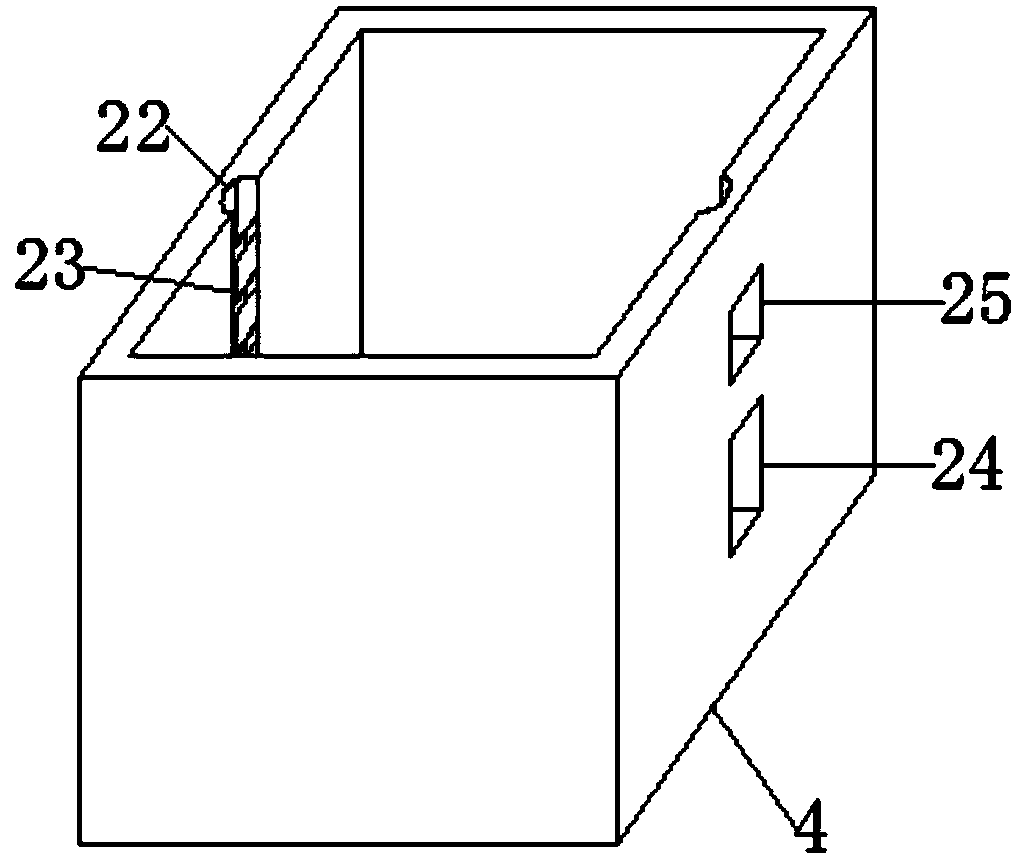

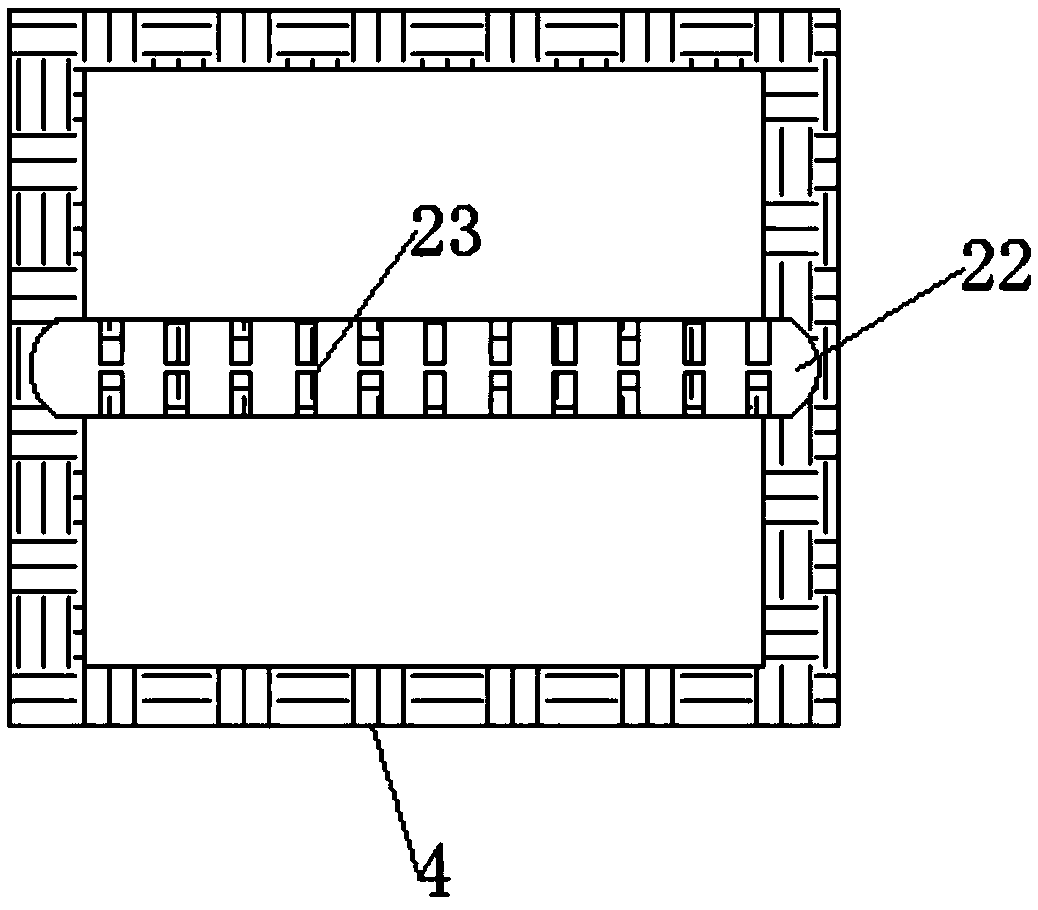

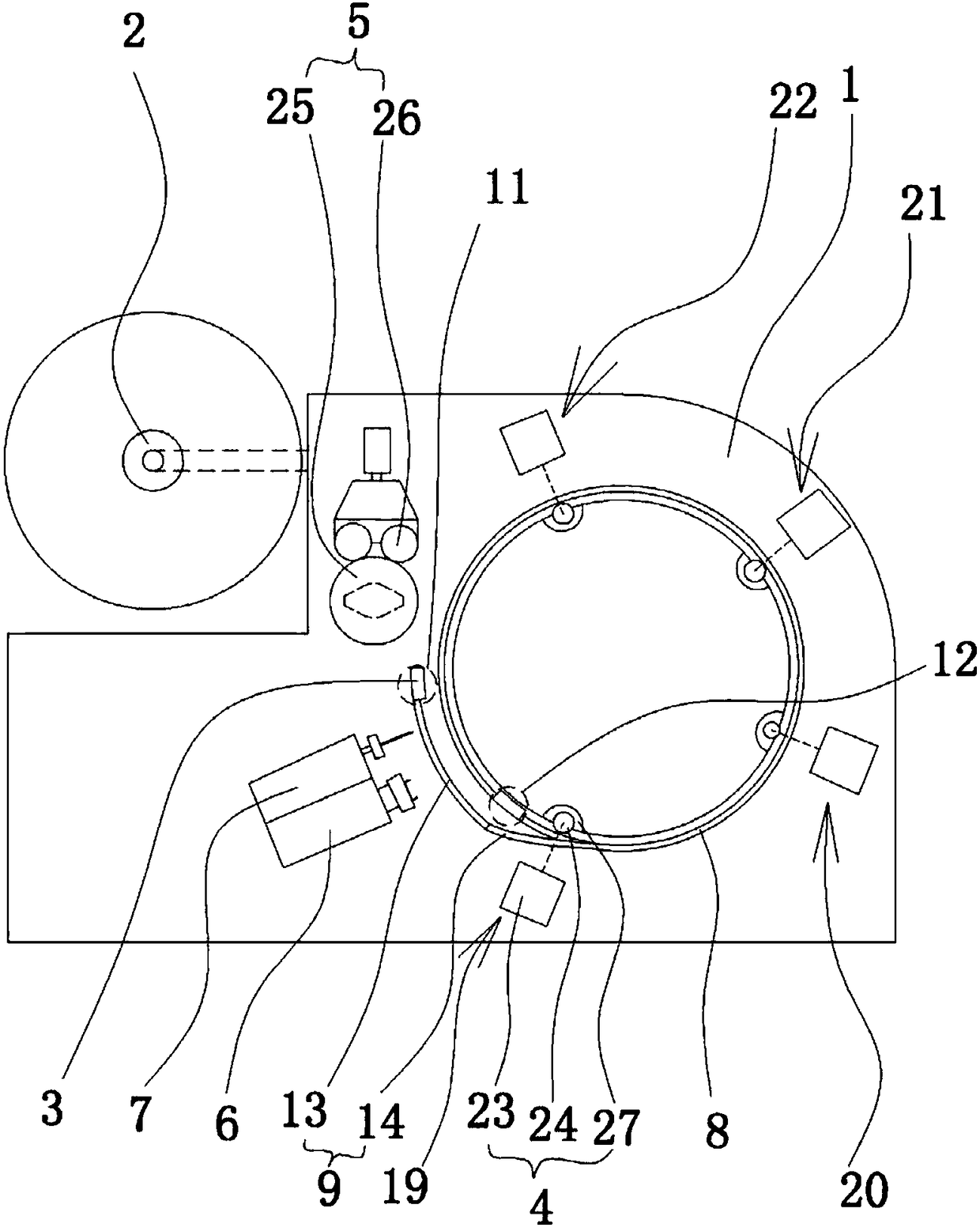

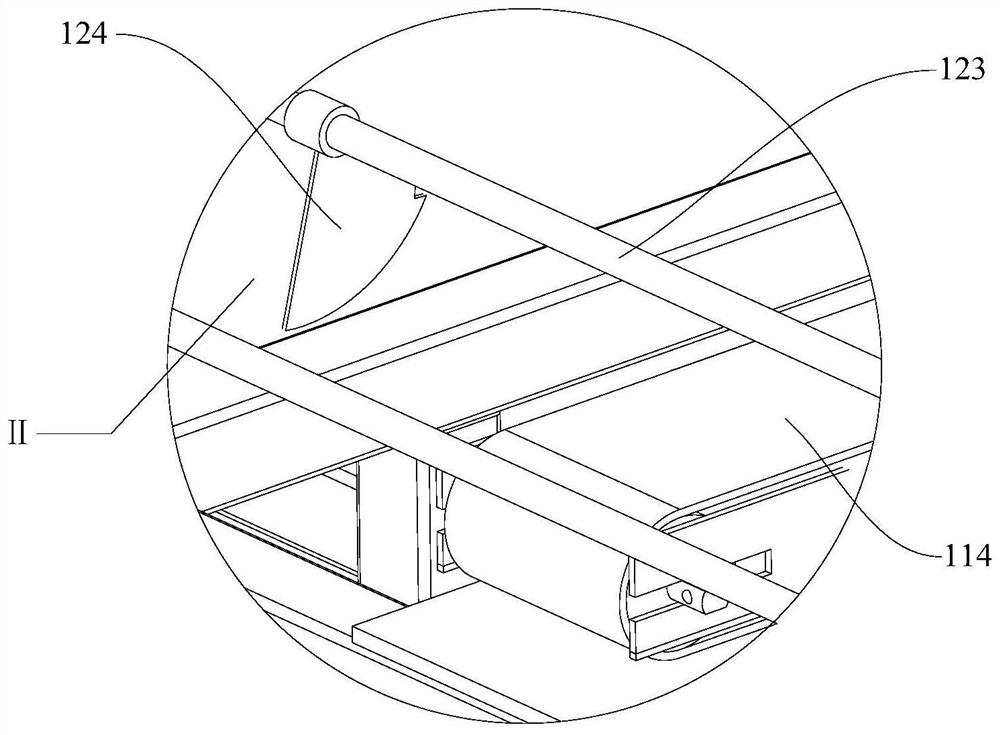

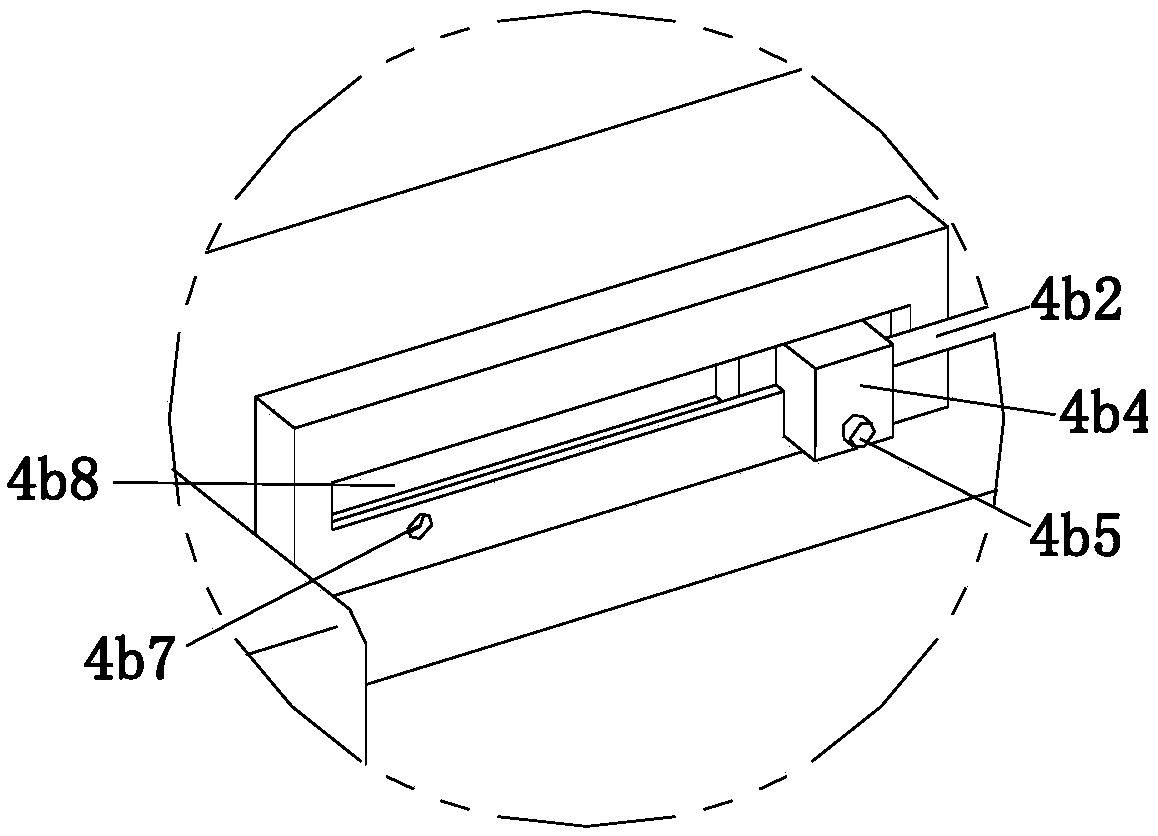

Automatic collecting and bundling device for packaging bags

ActiveCN110182403ARealize the collectionAchieve finishingPaper article packagingBag making operationsEnvironmental resistanceElectric machinery

The invention provides an automatic collecting and bundling device for packaging bags. The device comprises a pressing device, a bag stopping baffle device, a collecting and arranging device, a conveying positioning device, a clamping device, an automatic bundling device, a conveyor and a rack. The bag stopping baffle device comprises a third air cylinder, an L-shaped swing arm, a baffle, a hingeand a connecting support plate. The collecting and arranging device comprises an arranging mechanism, a large flat plate and a bag beating plate positioning device, and the large flat plate is fixed on the rack. The conveying positioning device comprises a linear sliding table mechanism, a lead screw nut, a lead screw and a motor. The clamping device comprises a mechanical claw device, a second air cylinder, a first connecting rod and a pressure head device. The mechanical claw device drives the first connecting rod to move through the second air cylinder. By means of the automatic collectingand bundling device, full automation of the collection, arrangement, bundling and transfer processes of the plastic bags is realized, a motor is adopted for driving, work is stable, cleanliness and environmental protection are achieved, the structure is safe and reliable, the labor cost is reduced, and the production efficiency is improved.

Owner:ZHEJIANG UNIV OF TECH +1

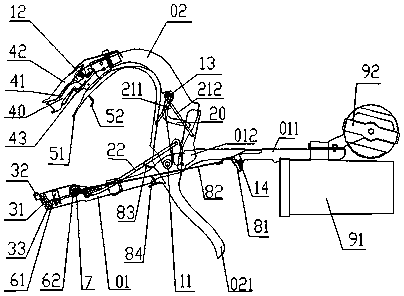

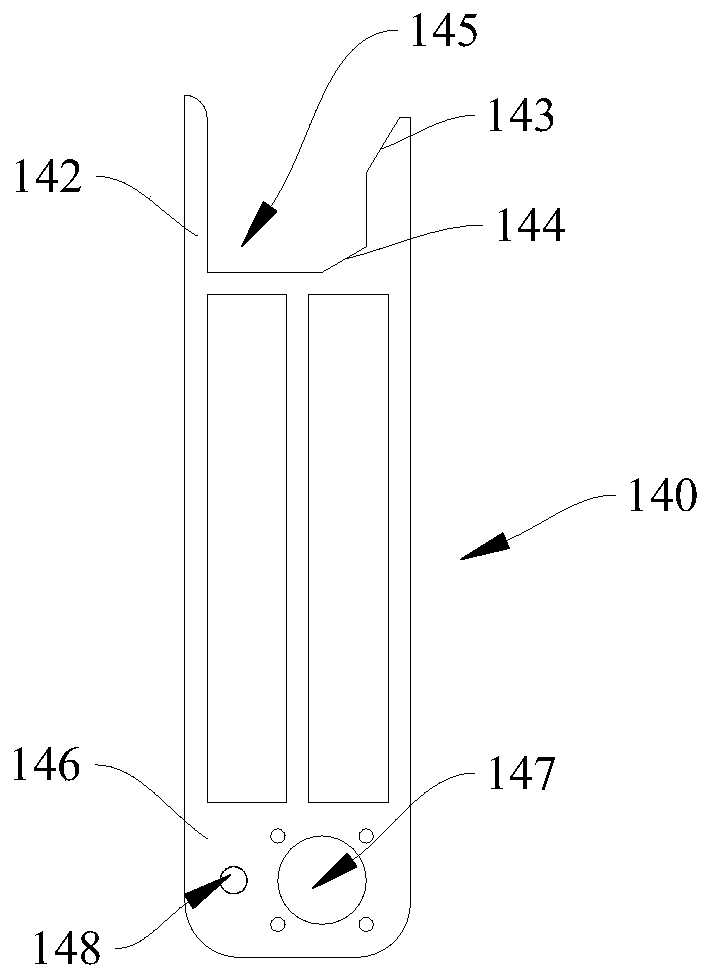

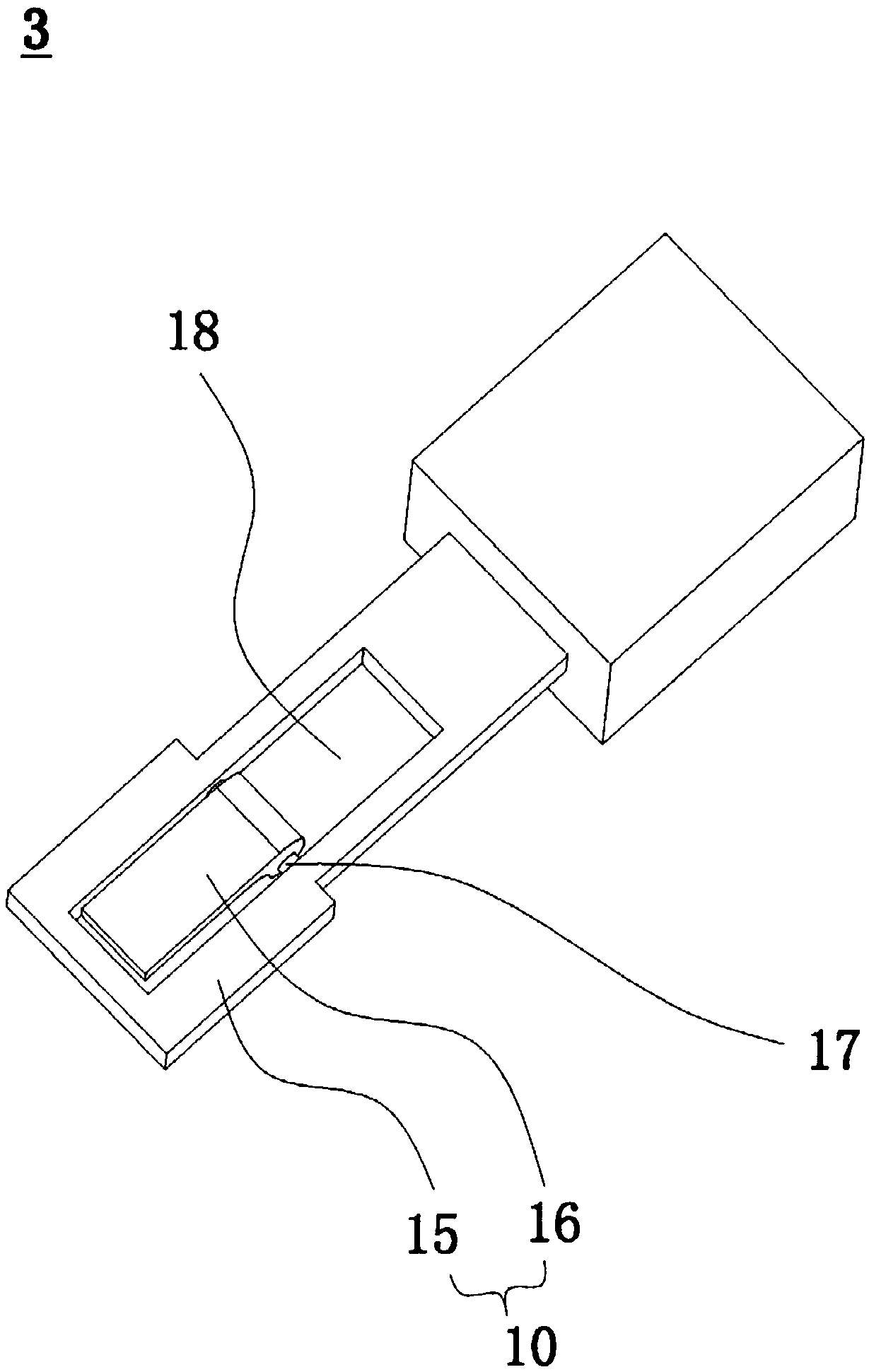

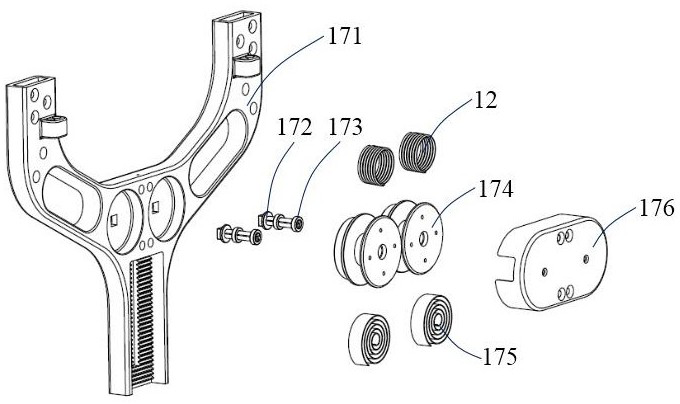

Strapping machine for packaging bags

PendingCN109703805AExquisite structure designTied up firmlyBinding material applicationBundling machine detailsEngineeringMechanical engineering

The invention discloses a strapping machine for packaging bags. The strapping machine comprises a rack and is characterized in that a rubber band conveying mechanism, a rubber band opening mechanism and a packaging bag feeding mechanism are arranged on the rack; the rubber band opening mechanism and the rubber band conveying mechanism are arranged on one side of the packaging bag feeding mechanism; the rubber band conveying mechanism comprises a rubber band feeding piece; and the packaging bag feeding mechanism comprises a bag body feeding piece for sending bag bodies into opened rubber bands.By the aid of the strapping machine, automatic strapping of the packaging bags is realized, and the strapping machine is ingenious in structural design, stable and firm in strapping, small in equipment size and relatively low in processing cost.

Owner:浙江晨宇科技股份有限公司

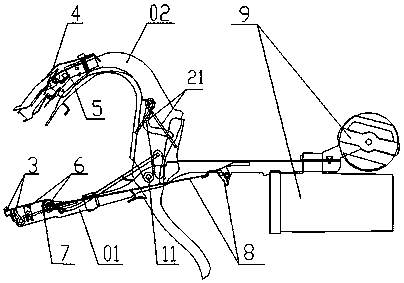

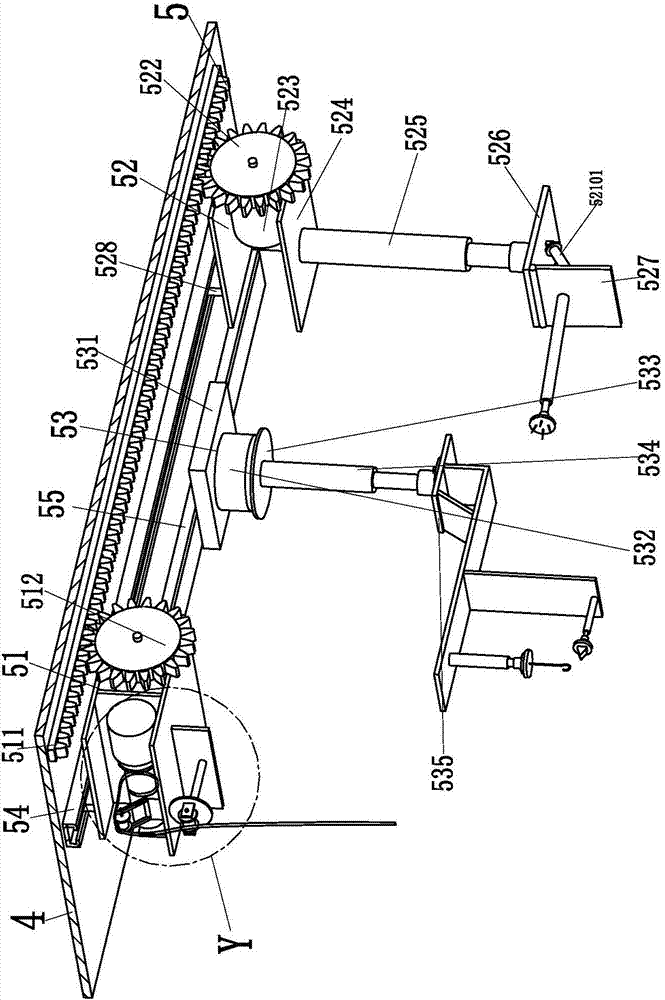

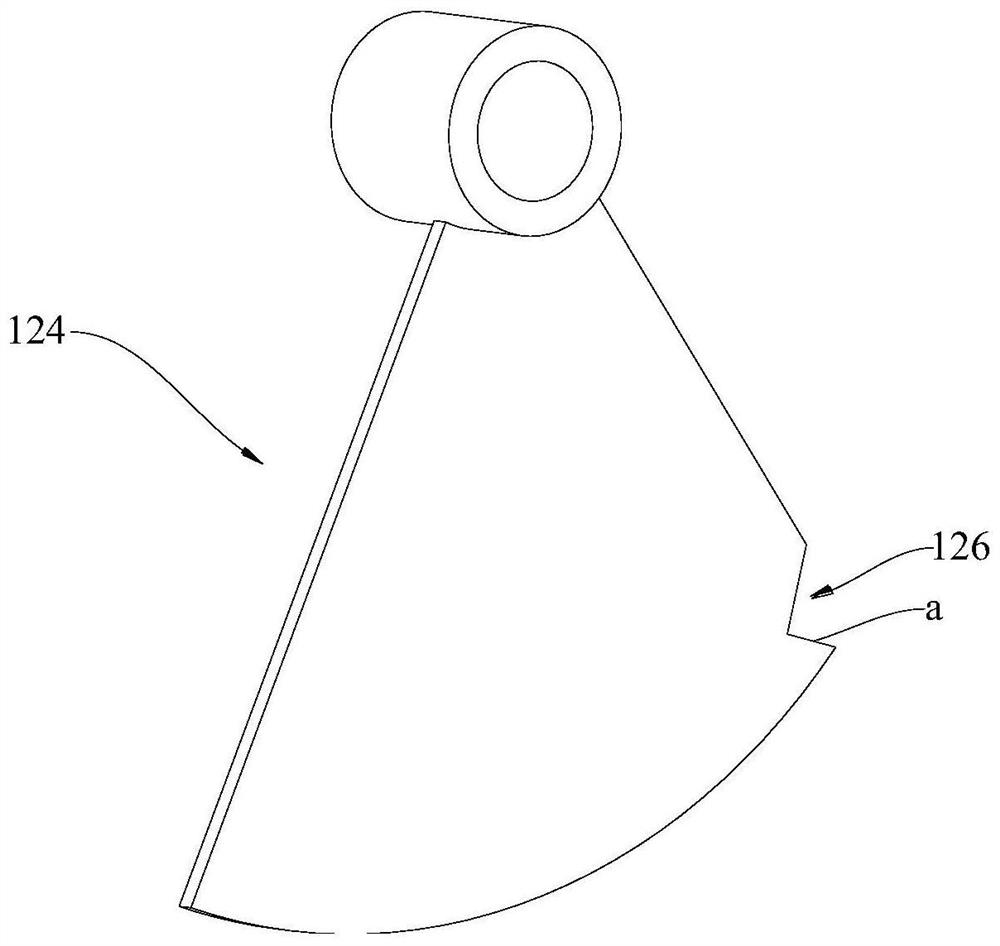

Strapping machine and using method thereof

PendingCN111409890ATied up firmlyReliable strappingCultivating equipmentsBundling machine detailsStrappingAgricultural engineering

The invention discloses a strapping machine and a strapping method thereof, and particularly relates to a strapping machine for strapping strip-shaped objects together or strapping the strip-shaped objects into small bundles. The strapping machine comprises a base frame, a main arm, a rope releasing part, a rope holding part, a rope binding part, a supporting part, a hooping part and a conveying part, a strapping rope is wound on a strapped object, and meanwhile, a hooping material is used for hooping the combination part of the strapping rope wound on the strapped object to form a closed ropeloop so as to realize strapping of the strapped object. Traditional manual bundling is replaced, the bundling process of strip-shaped objects in daily production and life is semi-automatic, and onlyabout one second is needed for completing bundling; bundling is standard, the standardization degree is high, rapidness, attractiveness, safety and practicability are achieved, the production cost iseffectively reduced, and the device is particularly suitable for agricultural production and used for fixing branches and tendrils of crop plants such as tomatoes, cucumbers and grapes; and in addition, the strapping machine can be applied to strapping and binding requirements required in various links of production, transportation, storage, sales and the like of strip-shaped vegetables and otherfoods and strip-shaped non-foods.

Owner:深圳市农科创网络有限公司

Automatic steel pipe bundling device for building construction

ActiveCN109649727AAvoid knotsEasy to usePackaging automatic controlBundling machine detailsArchitectural engineeringBuilding construction

The invention discloses an automatic steel pipe bundling device for building construction. The problems that when a traditional automatic steel pipe bundling device for building construction is used,commonly a steel wire or a rope is adopted for performing bundling, when the steel wire or the rope is applied into the automatic device to perform automatic bundling, operation is extremely inconvenient, the steel wire and the rope are very likely to be knotted during bundling, meanwhile, after bundling is completed, manual tightening of the steel wire and the rope is also needed, a remaining portion is cut off, and when the device is used for bundling one batch of steel pipes, due to the fact that the plurality of steel pipes are arranged in different lengths, consequently bundling is not firm are solved. A bottom frame and a support installed on the bottom frame are included; a feeding hopper is installed above the support; the bottom frame is provided with a plurality of cross rods; two brackets are fixed to the top of the bottom frame; a PLC is installed on the side wall of the support; a caterpillar band is installed in the support; and the two ends of the caterpillar band are each provided with a rotating shaft.

Owner:创际建工集团有限公司

End fixing method for motor stator winding

InactiveCN101359857AImprove operational safetyImprove reliabilityWindingsManufacturing dynamo-electric machinesFiberFree cooling

Disclosed is a fixation method for a motor stator winding overhang, which affixes a reel of double sided tape to an external circumference of the motor winding overhang; a reel of fiber felt is affixed to the double sided tape; a non-woven fiber tape is wound round the fiber felt; a TCP tape is wound round the non-woven fiber tape; the TCP tape is heated and naturally cooled, then naturally shrinks and fixes the fiber felt and the non-woven fiber tape wrapped in the TCP tape on the motor winding overhang to realize motor stator winding overhang fixing. The method adopts the simple technical proposal, has the fixed bundling of the motor stator winding overhang and good structure stability, can effectively improve the safety of motor operation, be applied to industrial production, and act as the fixation method for a small diameter motor stator winding overhang.

Owner:MIN OF RAILWAY TRANSPORT BUREAU +1

Clamp support with tying bands

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

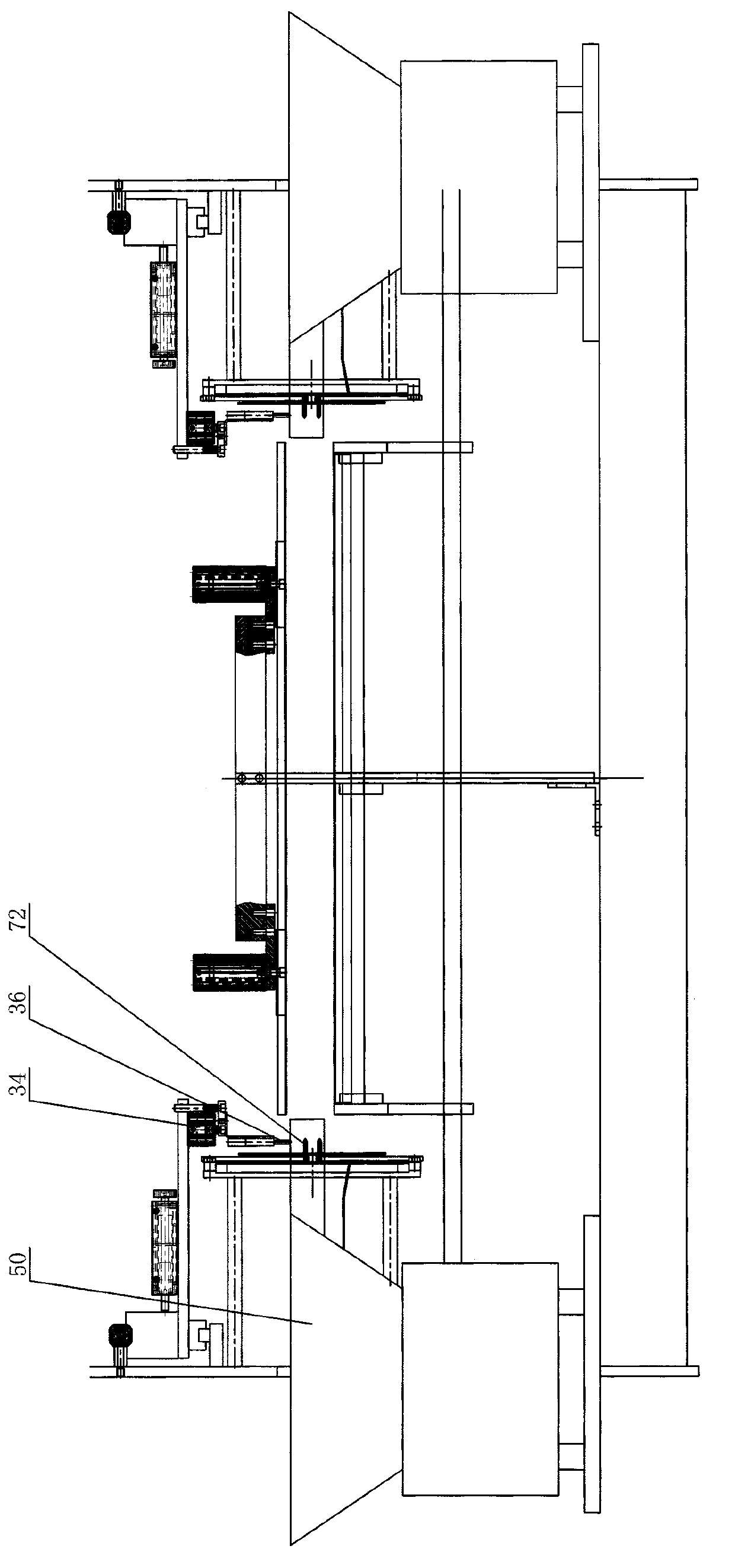

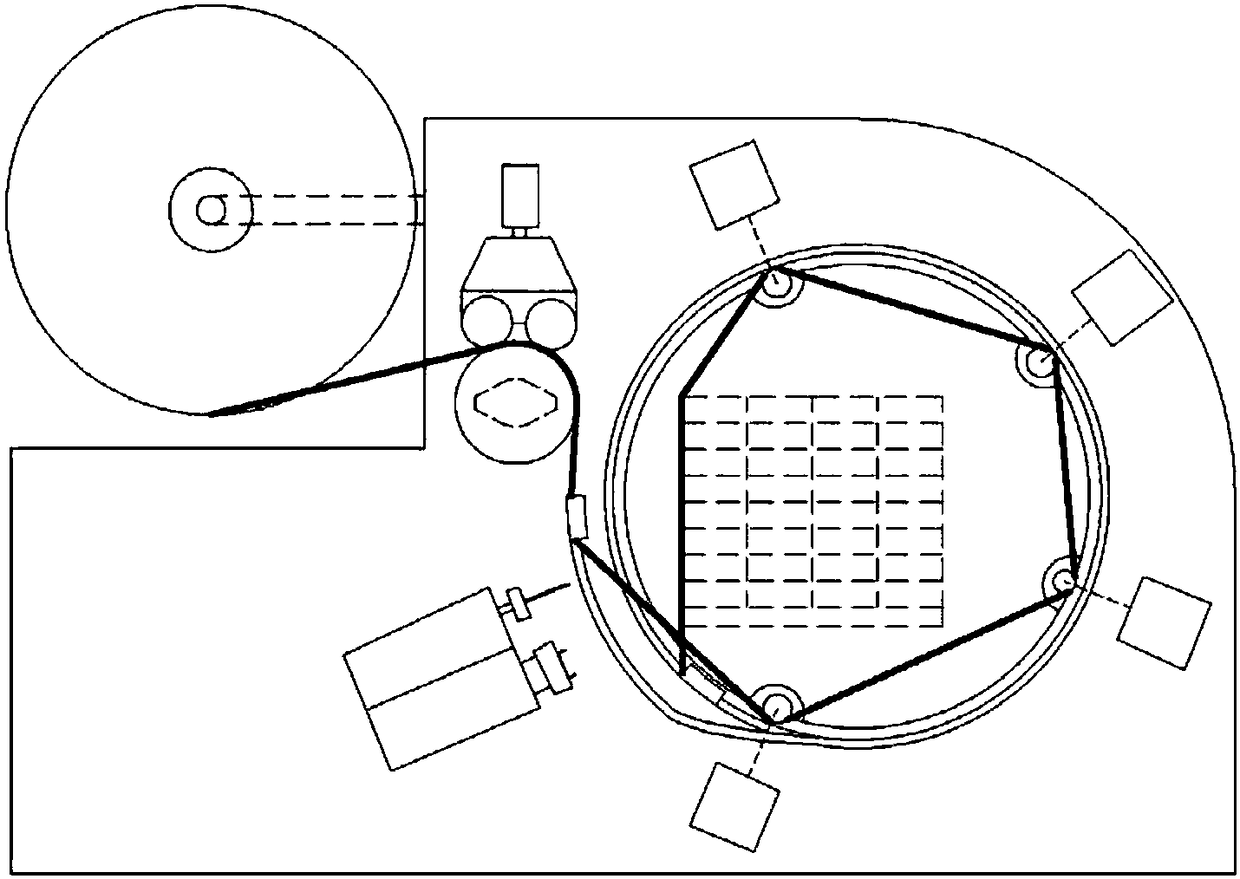

Metal plate coil bundling device and bundling method

ActiveCN108860735AImplementation in placeAchieve openBinding material applicationBundling machine detailsWire rodEngineering

The invention discloses a metal plate coil bundling device. The metal plate coil bundling device comprises a bundling trolley (1), a threading channel, a wire rod cutting mechanism (2) arranged on thebundling trolley (1), a drawing mechanism (3), a horizontal hydraulic sliding table (4), an inclined hydraulic sliding table (5), a vertical moving mechanism and a horizontal moving mechanism. The invention further discloses a bundling method. The beneficial effect is that the metal plate coil bundling device is compact in structure, high in automation degree, and firm in bundling, and capable ofreducing labor intensity of a worker, and improving bundling efficiency.

Owner:成都金中机械设备制造有限公司

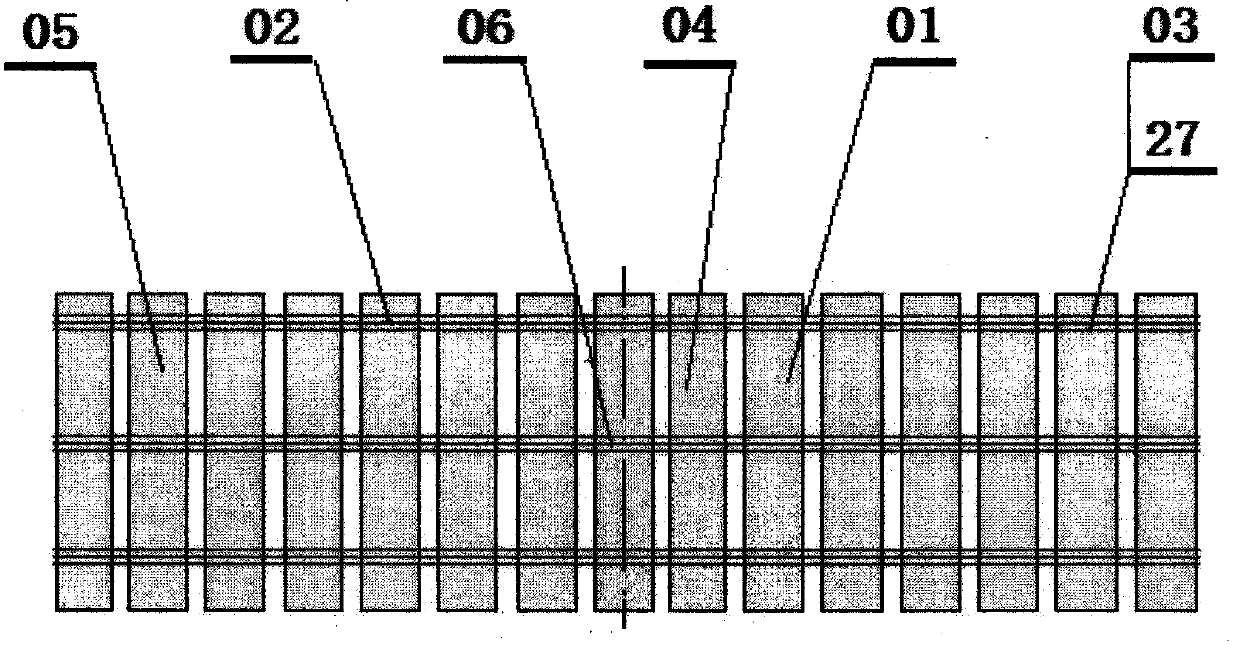

Novel leaf clamping strapping tape

The invention discloses a novel leaf clamping strapping tape in the technical field of leaf clamping production. The leaf clamping strapping tape comprises transverse strapping tapes and longitudinalstrapping tapes, wherein the transverse strapping tapes and the longitudinal strapping tapes are connected through cross sliding blocks; protective blocks sleeve the corners of the transverse strapping tapes; the transverse strapping tapes and the longitudinal strapping tapes fix stacked clamping sheets; the protective blocks cover the corners of the stacked clamping sheets; a connection part of each longitudinal strapping tape is fixedly adjusted through a tensioner; and a fixed adjusting mechanism is installed at the connection part of each transverse strapping tape. With the novel leaf clamping strapping tape, the stacked clamping sheets are conveniently fastened transversely and longitudinally and are stably bundled, so that the clamping sheets are prevented from scattering in the transportation process; the protective blocks are used for fixing the strapped corners, so that the corners where the clamping sheets are placed are prevented from being damaged due to stress; and the cross sliding blocks are used for assembling the transverse strapping tapes and the longitudinal strapping tapes, the transverse strapping tapes can be clamped in the fixed adjusting mechanism, and the transverse strapping tapes can be fast fastened.

Owner:安徽文博纸品印刷有限公司

Auxiliary assembly for packaging and packer

ActiveCN110203453AFirm packagingAchieve stackingBinding material applicationBundling machine detailsKeelEngineering

The invention provides an auxiliary assembly for packaging and a packer, and relates to the technical field of packaging equipment. The auxiliary assembly for packaging is used for assisting specifiedelements to be stacked. The auxiliary assembly mainly comprises a first driving part and a control part, wherein the control part is provided with a shifting fork with preset shapes; the preset shapes are matched with shapes of the specified elements; and the first driving part is used for driving the control part to drive the shifting fork to move along a preset path, so that the specified elements are stacked up according to a preset way. According to the auxiliary assembly, the specified elements can be stacked up by utilizing the shifting fork with the preset shapes, the bundling is morestable while packing space of U-shaped keels is saved. The packer is used for packaging the specified elements and mainly comprises a conveying assembly, a packaging assembly and the auxiliary assembly for packaging, wherein the conveying assembly is used for conveying the specified elements after being stacked by the auxiliary assembly for packaging to the packaging assembly for packaging. The packer has the advantages such as being convenient to use, firm in bundling and high in packaging efficiency.

Owner:河北廊安自动化设备科技有限公司

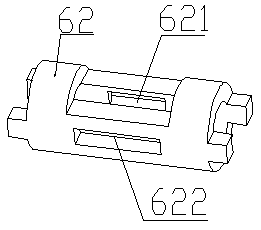

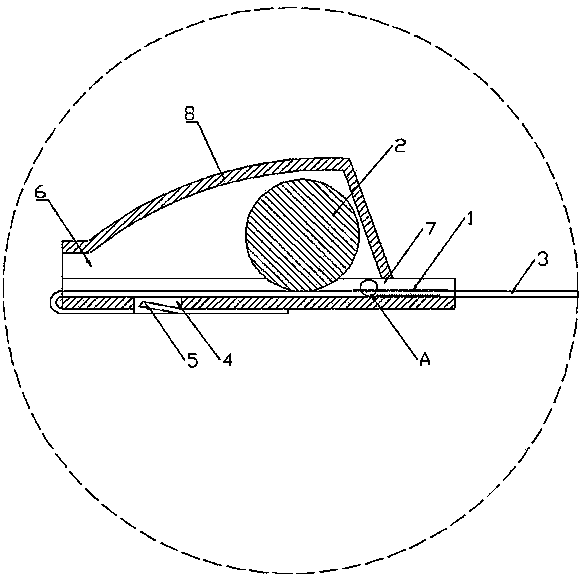

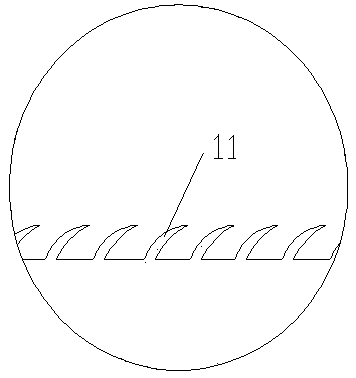

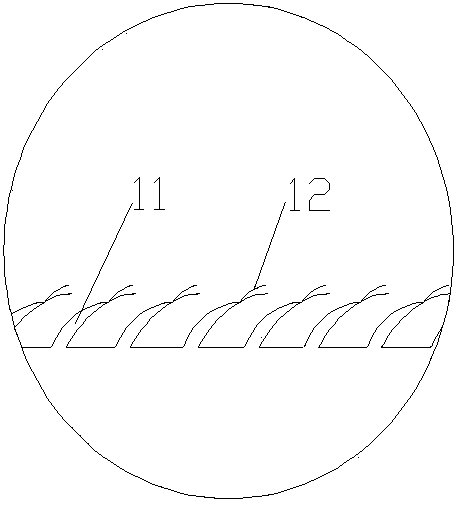

Stainless steel cable tie

InactiveCN103671373AIncrease frictionIncrease frictional resistancePipe supportsElectrical apparatusMetallurgySteel ball

A stainless steel cable tie comprises a locking-buckling mechanism and a cable tie strip. The two ends of the locking-buckling mechanism are provided with a tie inlet and a tie outlet respectively, the tie inlet and the tie outlet are mutually communicated, a steel ball roller path is formed between the tie inlet and the tie outlet, and a steel ball is arranged in the steel ball roller path; the height of the steel ball roller path is increased in the direction from the tie inlet to the tie outlet and shrinks at the tie outlet; one end of the cable tie strip is fixed to the tie inlet, and the other end of the cable tie strip is a free end extending out of the tie outlet; frictional barbs are arranged on the inner wall, between the tie inlet and the tie outlet, of the locking-buckling mechanism, and frictional barbs are further arranged at the position, between the tie inlet and the tie outlet, of the cable tie strip. The frictional barbs can increase friction and be matched mutually so that frictional resistance can be greater after binding, and binding can be firmer. In this way, the problems that in the prior art, tie bodies make contact with each other through smooth surfaces, the friction between the tie bodies is quite small, and the cable tie will slide in the long-term using process.

Owner:STATE GRID SHANDONG ELECTRIC POWER

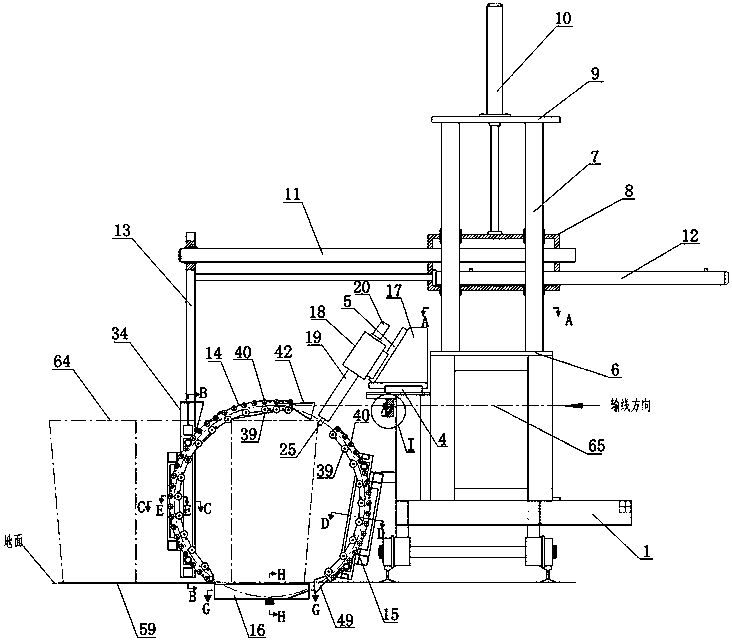

Clamping equipment for assistive bundling of steel bar rings

ActiveCN110775330ATied up firmlyInhibit sheddingBundling machine detailsElectric machineryEngineering

The invention relates to a set of assistive bundling equipment and particularly relates to a set of clamping equipment for assistive bundling of steel bar rings. The clamping equipment for assistive bundling of the steel bar rings is designed to achieve the technical purposes that the steel bar rings do not need to be stabilized in the bundling process, and the steel bar rings can be compacted inthe bundling process. The clamping equipment for assistive bundling of the steel bar rings comprises an installation seat, wheels, a first round plate, a shell, a speed reduction motor, an internal thread casing pipe and the like. The wheels are arranged at the bottom of the installation seat in a rotating mode, the first round plate is arranged at the top of the installation seat, the shell and the speed reduction motor are arranged on the right side of the first round plate, the speed reduction motor is located in the shell, and the internal thread casing pipe is arranged in the middle of the first round plate in a rotating mode. According to the lamping equipment for assistive bundling of the steel bar rings, a clamping component is driven by the speed reduction motor to fix the steel bar rings, and the steel bar rings are more stable when bundled, so that the steel bar rings do not need to be supported manually, and manpower is saved to a certain extent.

Owner:江苏钦宇建设工程有限公司

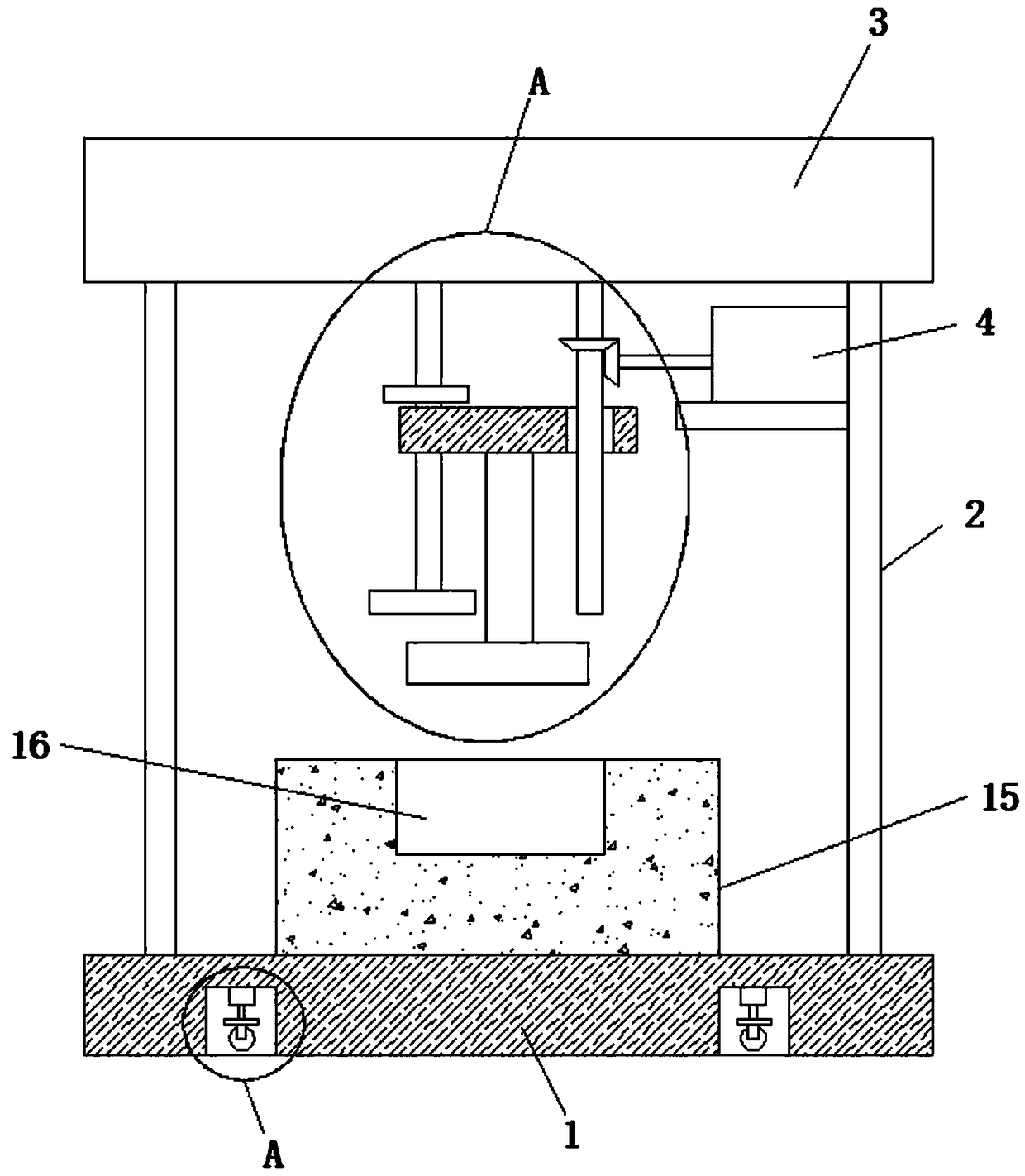

Garment processing and packaging equipment

The invention discloses garment processing and packaging equipment. The garment processing and packaging equipment comprises a base; two supporting columns are fixedly installed on the top side of thebase; one same top plate is fixedly installed at the top ends of the two supporting columns; a motor is fixedly installed on one side of one supporting column; a rotating shaft is fixedly installed on an output shaft of the motor; a first conical gear is fixedly arranged on an output shaft, far away from the motor, of the rotating shaft in a sleeving manner; a lead screw is rotationally installedon the bottom side of the top plate; the lead screw is fixedly sleeved with a second conical gear; the first conical gear is engaged with the second conical gear; a sliding plate is arranged on the lead screw in a threaded sleeving manner; a strut is fixedly installed on the bottom side of the top plate and is sleeved with the sliding plate in a sliding manner; a connecting rod is fixedly installed on the bottom side of the sliding plate; a pressure plate is fixedly installed at the bottom end of the connecting rod; and a placing table is fixedly installed on the top side of the base. Air ina fluffy garment can be discharged, bundling and fastening are facilitated, the garment does not fall easily, and the garment processing and packaging equipment is simple in structure and convenient to operate.

Owner:湖州吴兴华溢服装厂

Special automatic processing equipment for fertilizer preparing process using biomass rice straw

The invention relates to a special automatic processing equipment for the fertilizer production process of biomass rice straw, which includes a bottom plate, two wrapping forming mechanisms, a fixing frame and two winding and shearing mechanisms. The wrapping forming mechanism plays the role of wrapping and forming the rice straw, winding The shearing mechanism plays the role of winding and shearing on the rice straw. Two wrapping forming mechanisms and a fixing frame are installed on the bottom plate. Two winding and shearing mechanisms are installed at the lower end of the fixing frame, and the winding and shearing mechanism is located Right above the forming mechanism, two wrapping forming mechanisms cooperate with two winding and shearing mechanisms to complete the automatic binding process of rice straw. The invention can realize the function of automatic binding of rice straws without manual operation, automatically binds rice straws uniformly and stably, and has the advantages of simple operation, short time consumption, low labor intensity and high work efficiency.

Owner:刘勇

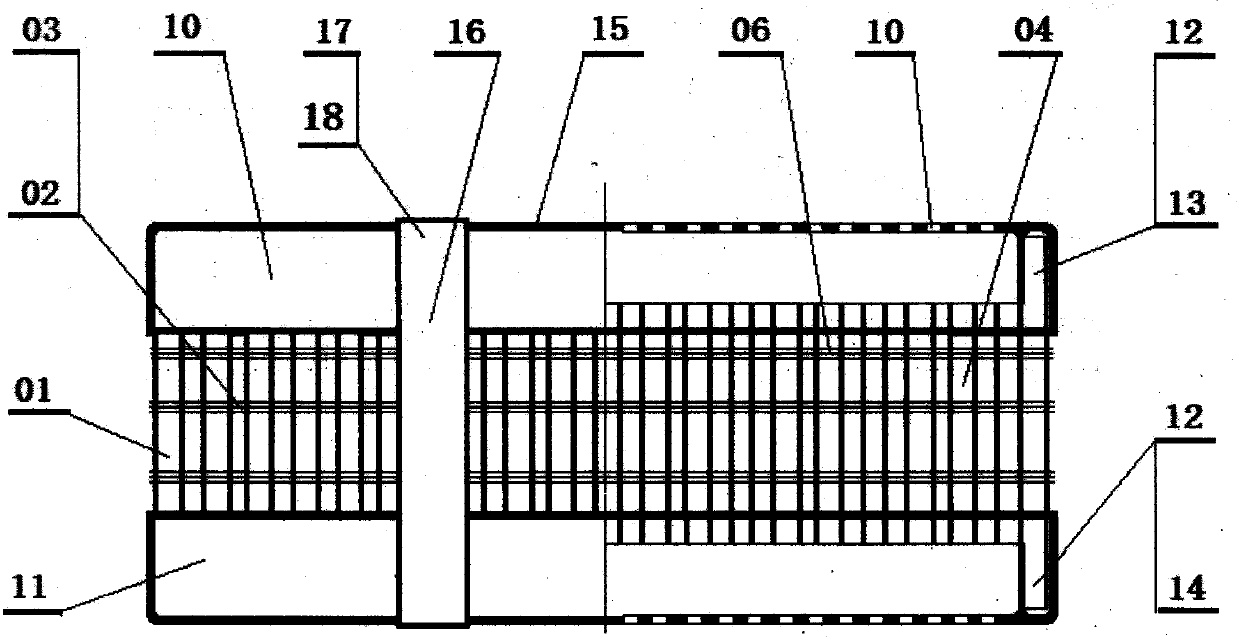

Logistics shared transferring container and manufacturing method thereof

PendingCN109808996AEasy to useEasy to reuseBio-packagingRemovable lids/coversLogistics managementEngineering

A logistics shared transferring container is a three-layer structural container body which is formed by clamping a rectangular side curtain through a top cover and a bottom cover, wherein binding assemblies are arranged at the outer side of the container body; the top cover and the bottom cover are rectangular and are symmetric to each other, and inverted U-shaped notches extend from four sides tothe inner sides of the top cover and the bottom cover, and the notches are correspondingly movably connected to the upper side edge and the lower side edge of the rectangular side curtain; the side curtain is in shape of a rectangular soft curtain, and at least one woven belt is arranged on the curtain body; and the binding assemblies are composed of adhesive sticker tapes or woven belt sewed magic tapes and are symmetrically arranged at the outer side of the container body. The logistics shared transferring container has three improvement sections, namely, 1 a dismounting structure is adopted, so that the container body is conveniently dismounted, recovered and repeatedly used; 2, the side curtain is manufactured through bamboo chips, so that the side curtain is light in weight, high insupporting strength and wide in raw material source; and 3, the woven belts provided with the magic tapes are used as the binding assemblies, so that dismounting and mounting are quick; the binding isfirm; and the operation is convenient.

Owner:姚本海

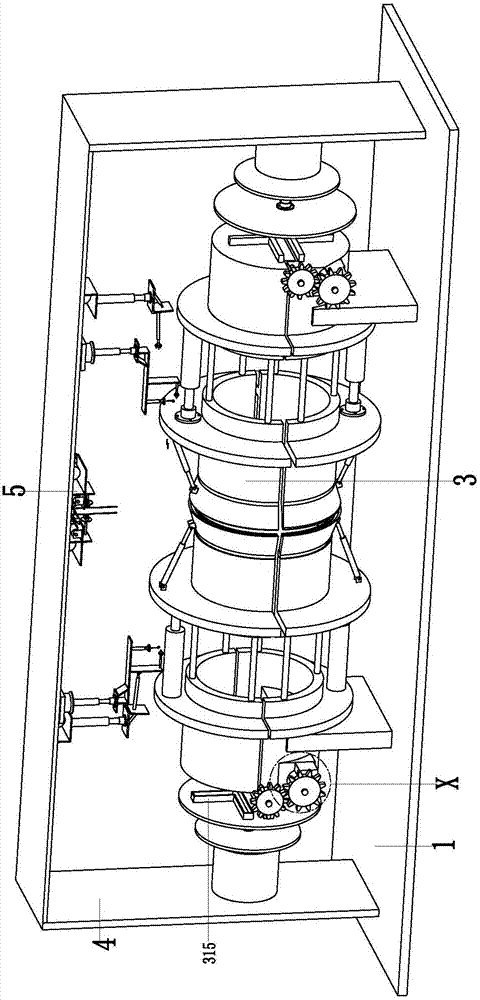

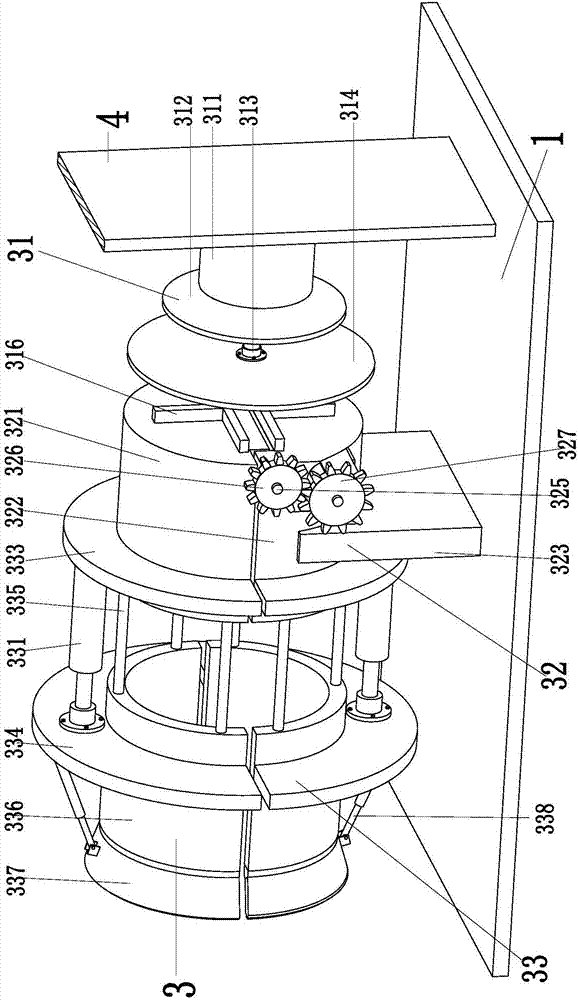

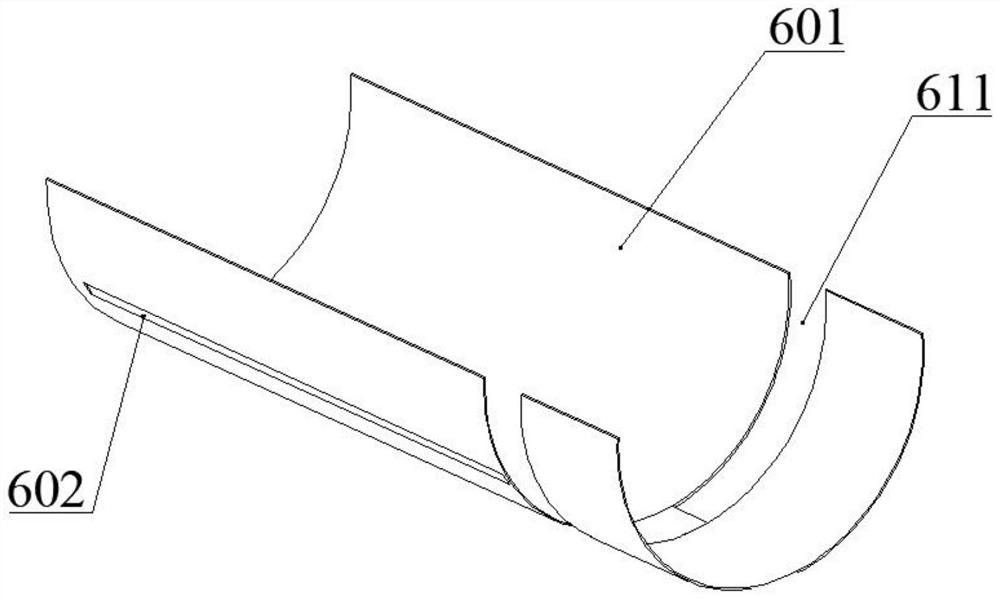

Vegetable automatic clustering and bundling device

ActiveCN111699844BImprove work efficiencyAchieve ordered bundlingHarvestersAgricultural engineeringStructural engineering

The invention relates to agricultural machinery, in particular to an automatic clustering and bundling device for vegetables. It includes a frame, a bundling mechanism and a clustering mechanism. The frame includes a frame I and a side frame. The side frame is located on one side of the frame I. The side frame is fixedly connected to the frame I. In Ⅰ, the bundling mechanism is set on the side frame, and the bundling mechanism is located above the bundling mechanism; the bundling mechanism includes a semicircular buncher, a buncher base, a bunching push plate and a bunching push plate moving part, and the semicircle buncher is equipped with There is a semi-cylindrical cavity, the cluster base is fixedly connected with the bottom of the semicircle cluster, the cluster push plate is set in the semicircle cluster, the cluster push plate is connected with the moving part of the cluster push plate, and the semicircle cluster is arranged along its axial direction. There is an axial slit, and a circumferential slit is provided along the circumference of the semicircular cluster just below the tying mechanism. It realizes automatic clustering and bundling of vegetables, high working efficiency, orderly bundling of vegetables, firm bundling, and good bundling and bundling effects.

Owner:QINGDAO AGRI UNIV

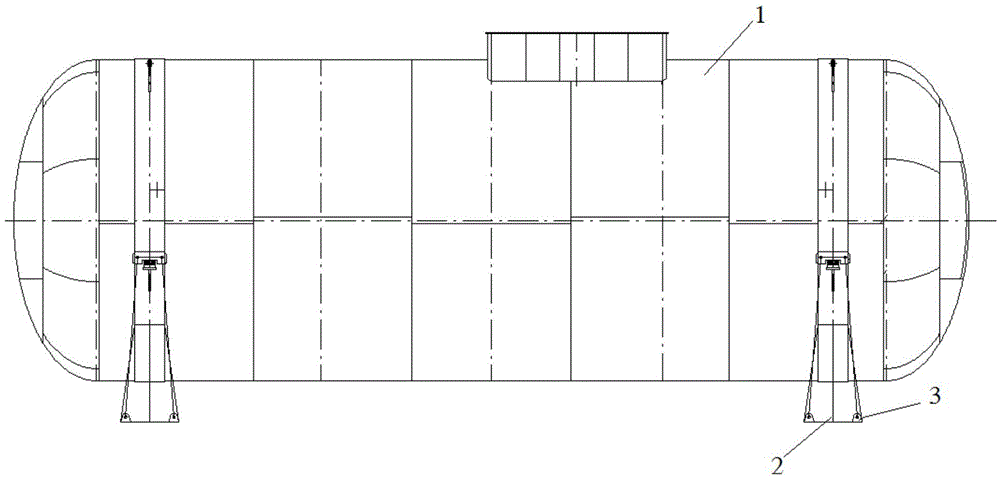

Storage tank lifting lug device and storage tank lifting system

InactiveCN105584745AEasy to installLow costLarge containersLoad-engaging elementsArchitectural engineeringStorage tank

The invention discloses a storage tank lifting lug device. The storage tank lifting lug device comprises a first lifting lug fixed to the outer side of a tank body and a second lifting lug fixed to a bracket, wherein a steel wire rope is connected between the first lifting lug and the second lifting lug. The first lifting lug comprises two first installation holes which are arranged in the horizontal direction. The second lifting lug comprises two supporting lugs arranged in the horizontal direction. Each supporting lug is provided with a second installation hole corresponding to the corresponding first installation hole. The steel wire rope is connected between the corresponding first installation holes and second installation holes. The invention further discloses a storage tank lifting system which comprises the tank body, the bracket and the lifting lug devices, wherein the bracket is supported under the tank body, and the lifting lug devices are symmetrically distributed on the two sides and two ends of the tank body. According to the storage tank lifting lug device and the system, the cost can be effectively controlled, weight is reduced, and construction is facilitated.

Owner:ZHANGJIAGANG FURUI HEAVY EQUIP CO LTD

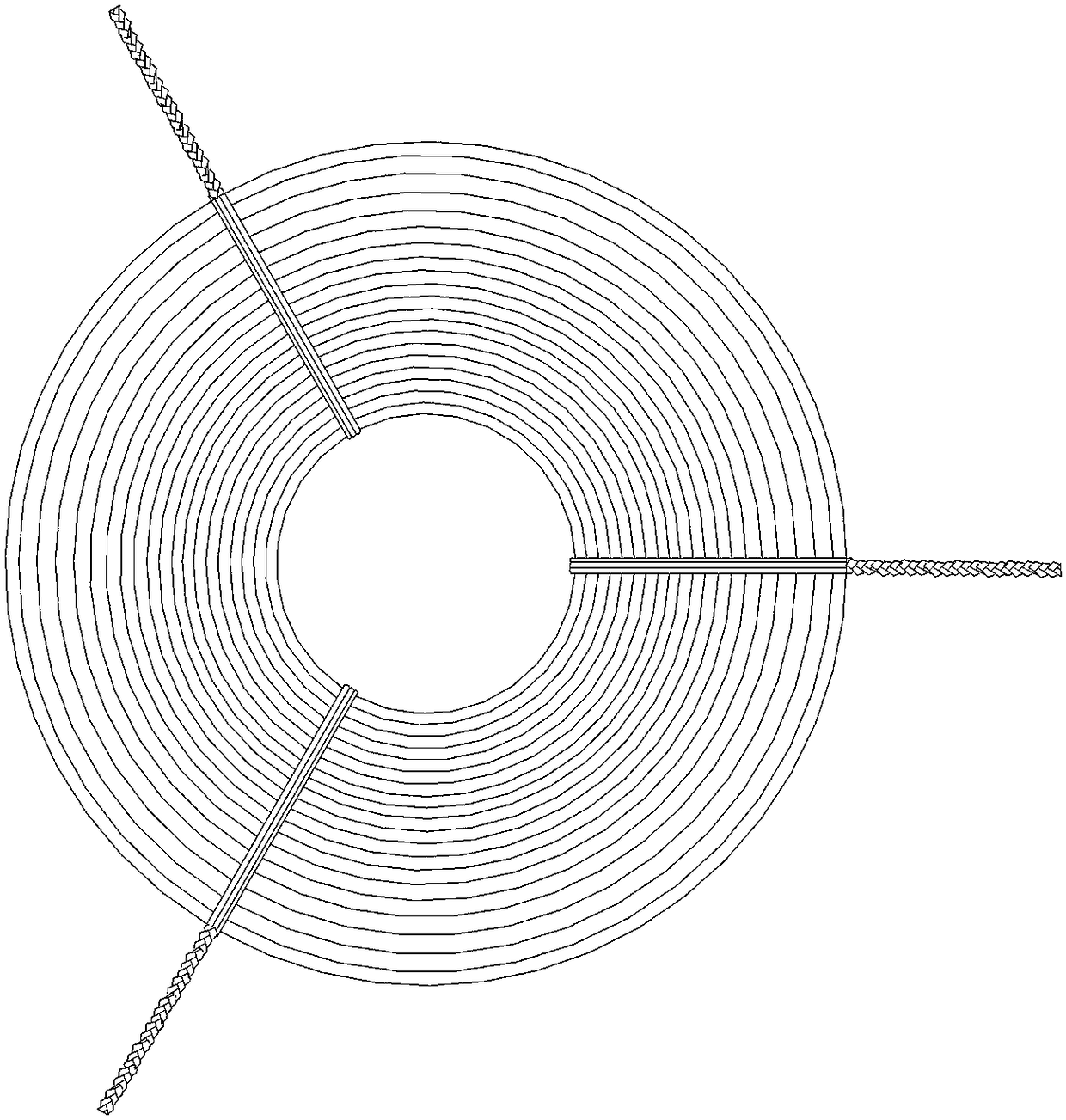

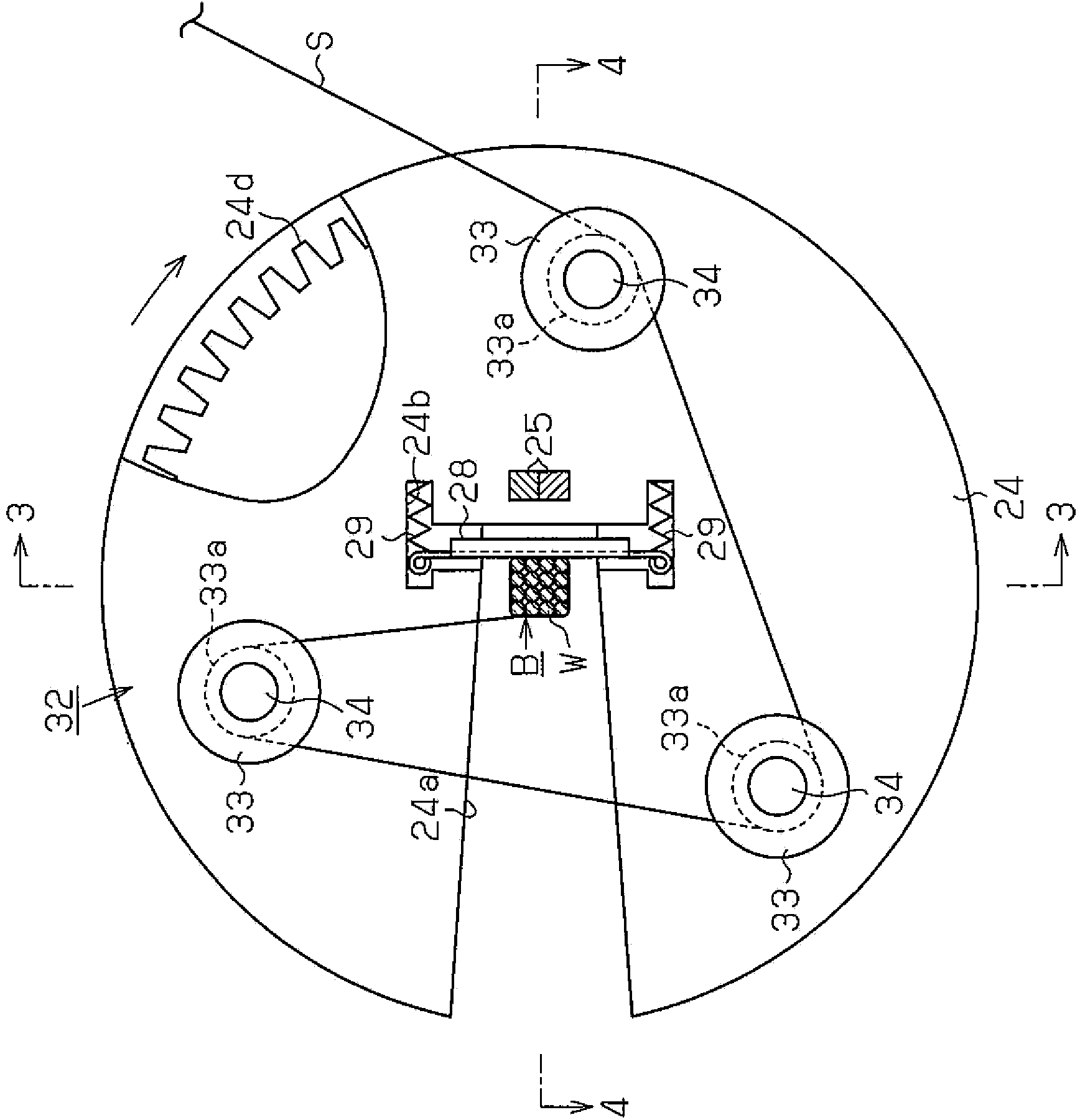

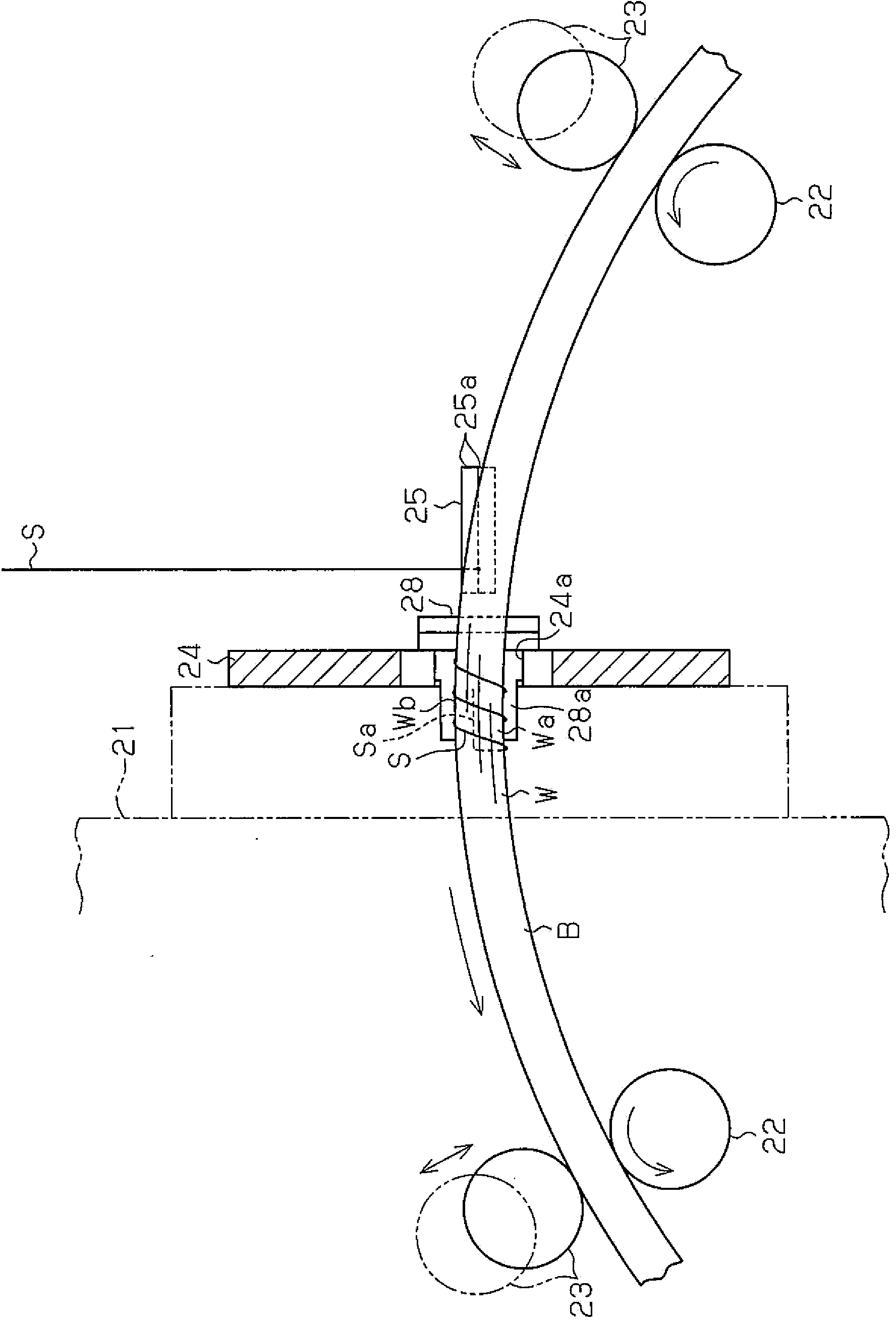

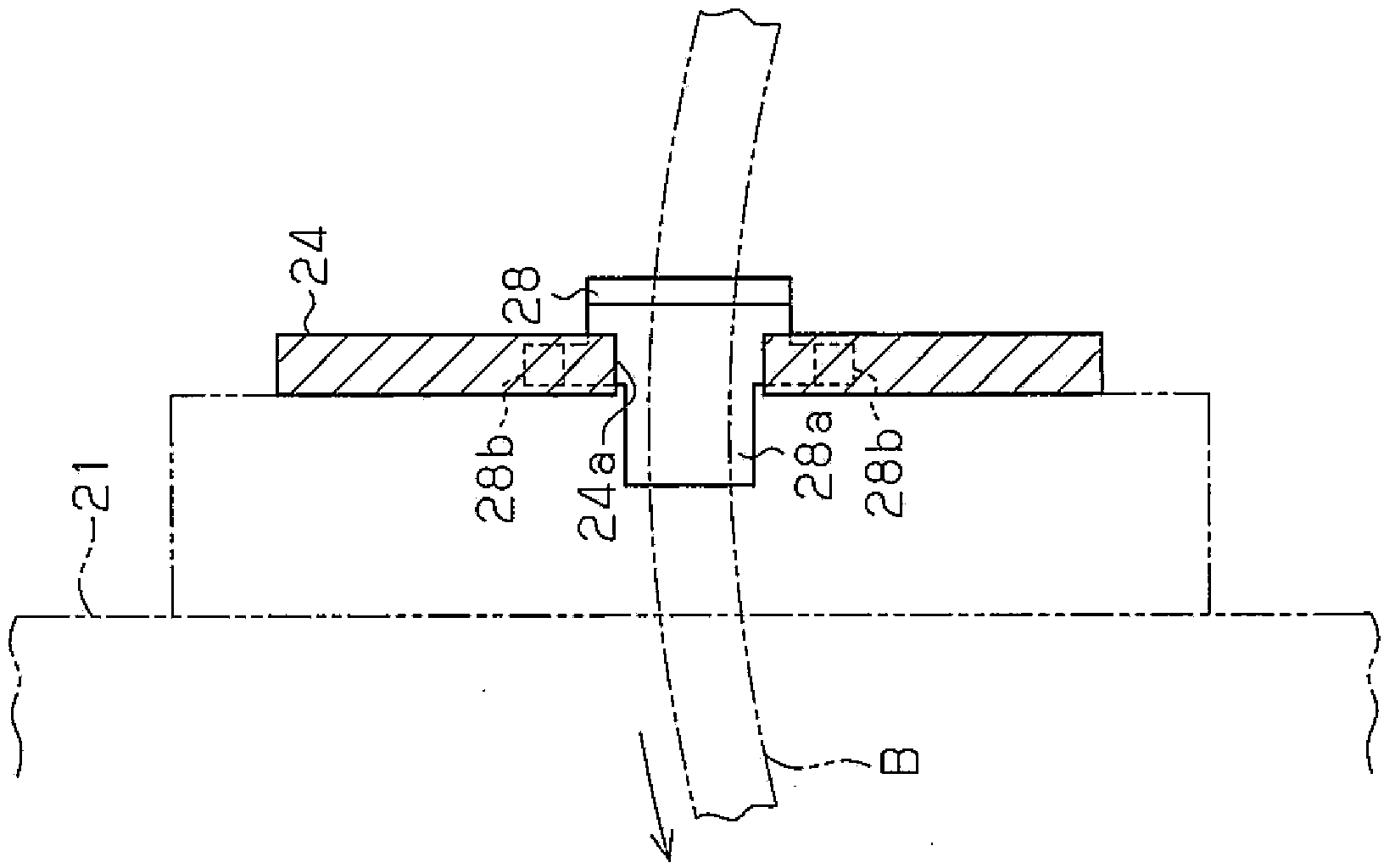

Winding device

A winding device is provided with a rotating body (24) which, while a binding wire (S) is being held, rotates around an internal side and external side of an annular bead ring (B) being fed in the peripheral direction, thereby winding the binding wire (S) around the bead ring (B). A pressing member (28) which elastically presses the binding wire (S) onto the bead ring (B) is provided in the rotating body (24).

Owner:THE YOKOHAMA RUBBER CO LTD

Straw bundling device for agricultural production

ActiveCN109315128AAchieve tighteningAchieving compression and tighteningIndependant bindersDrive wheelAgricultural engineering

The invention discloses a straw bundling device for agricultural production. The straw bundling device comprises a bundling table, four supporting columns are arranged under the bundling table, the middle of the bundling table is provided with a bundling gap, the bundling gap is internally provided with a bundling box, the lower end of the bundling box is provided with a propulsion rod, the propulsion rod is connected with a moving block through a transmission rod, the moving block is arranged on a threaded rod, the threaded rod penetrates through the moving block, the upper end of the threaded rod is connected in a bearing seat on the lower end face of the bundling table, the lower end of the threaded rod is connected to an output end of a stepping motor, the two edges of the bundling boxin the bundling gap are provided with feeding mechanisms respectively, the feeding mechanisms are arranged at the two sides of the bundling table, the feeding mechanisms comprise driving wheels, driven wheels and conveyor belts, the conveyor belts wind around the driving wheels and the driven wheels, rotating shafts of the driving wheels are connected with driving belts, and the other ends of thedriving belts wind around output shafts of rotating motors. The rapid and full-automatic straw bundling device for the agricultural production can achieve efficient bundling of straws.

Owner:王逸帆

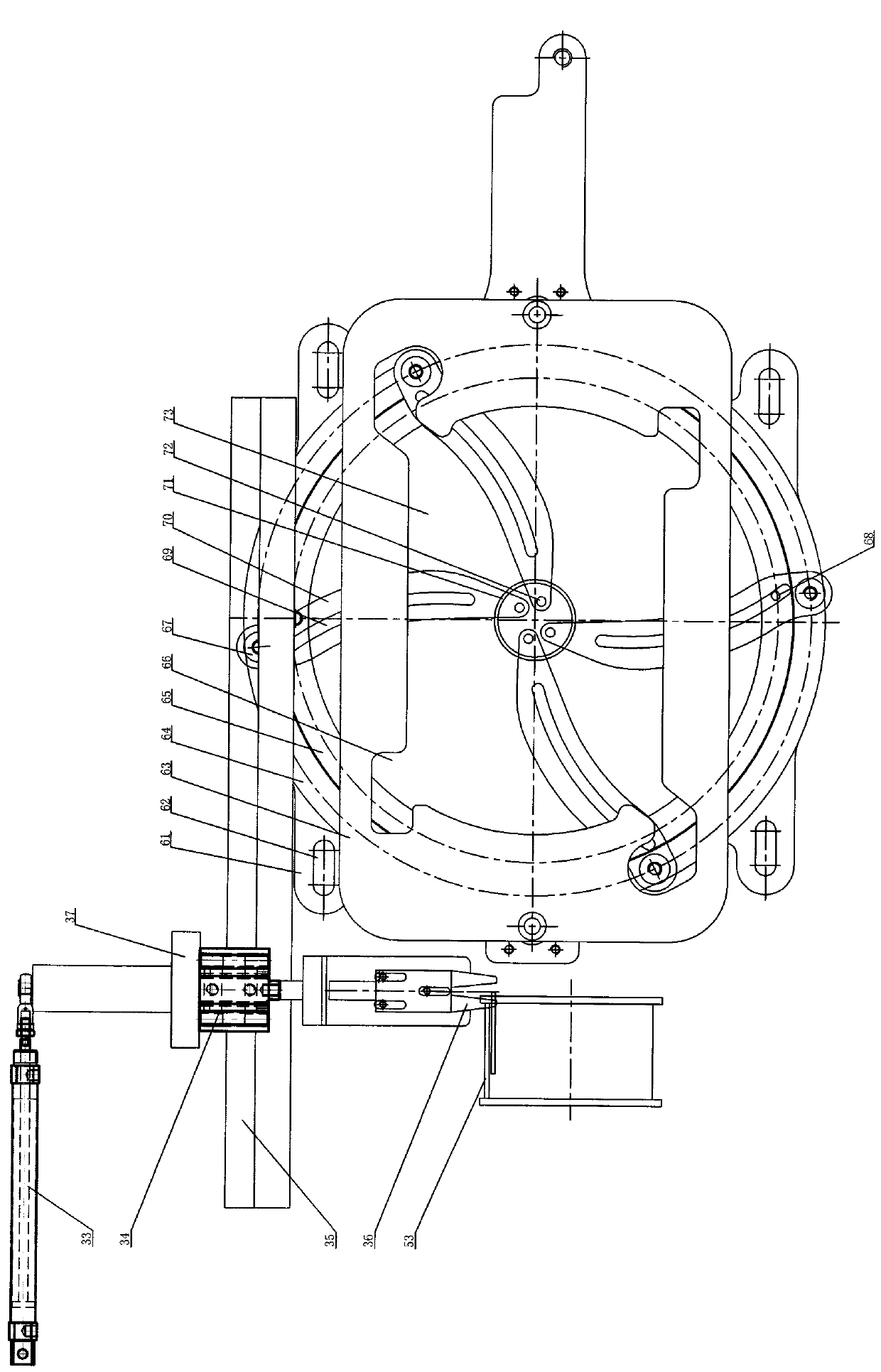

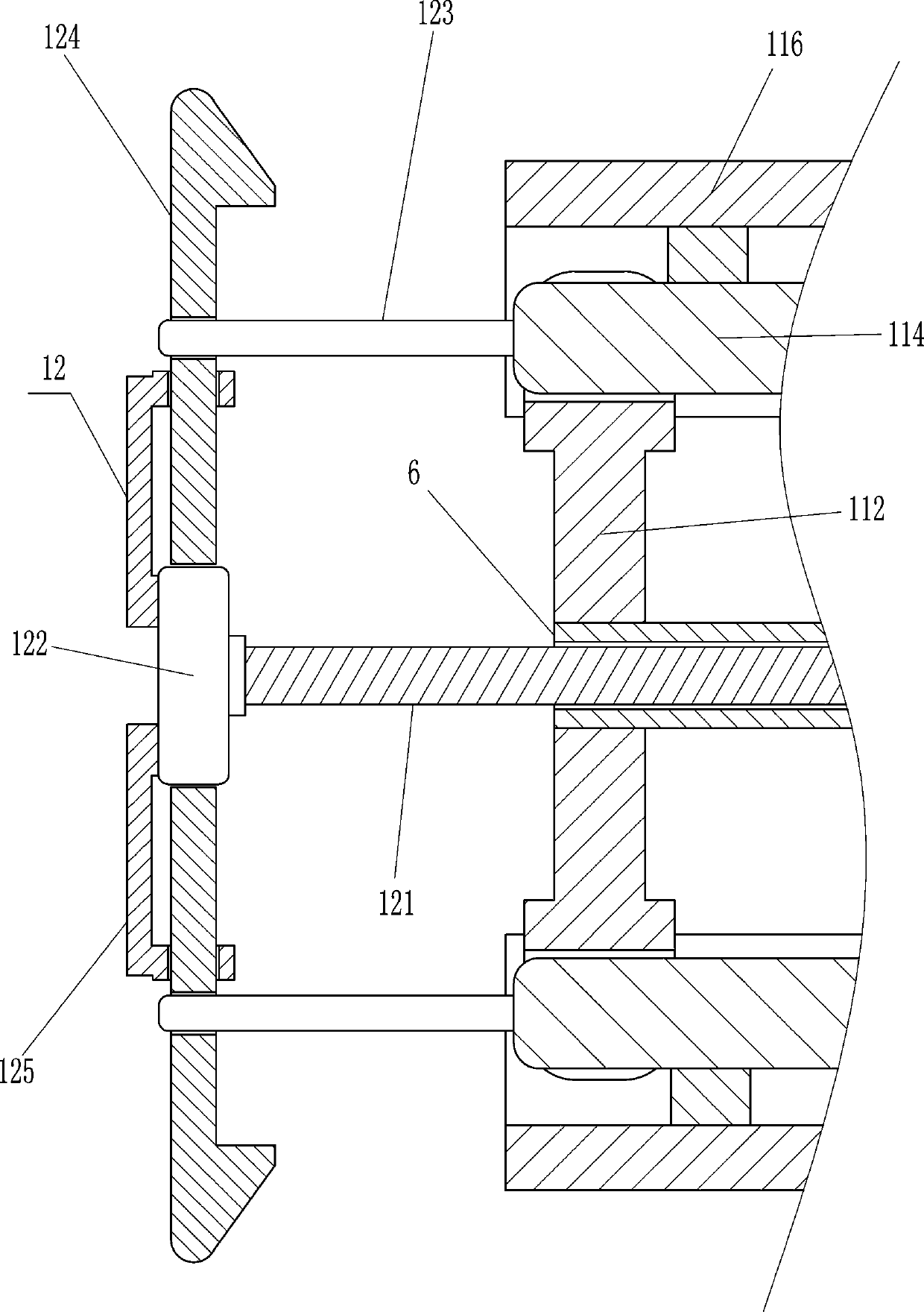

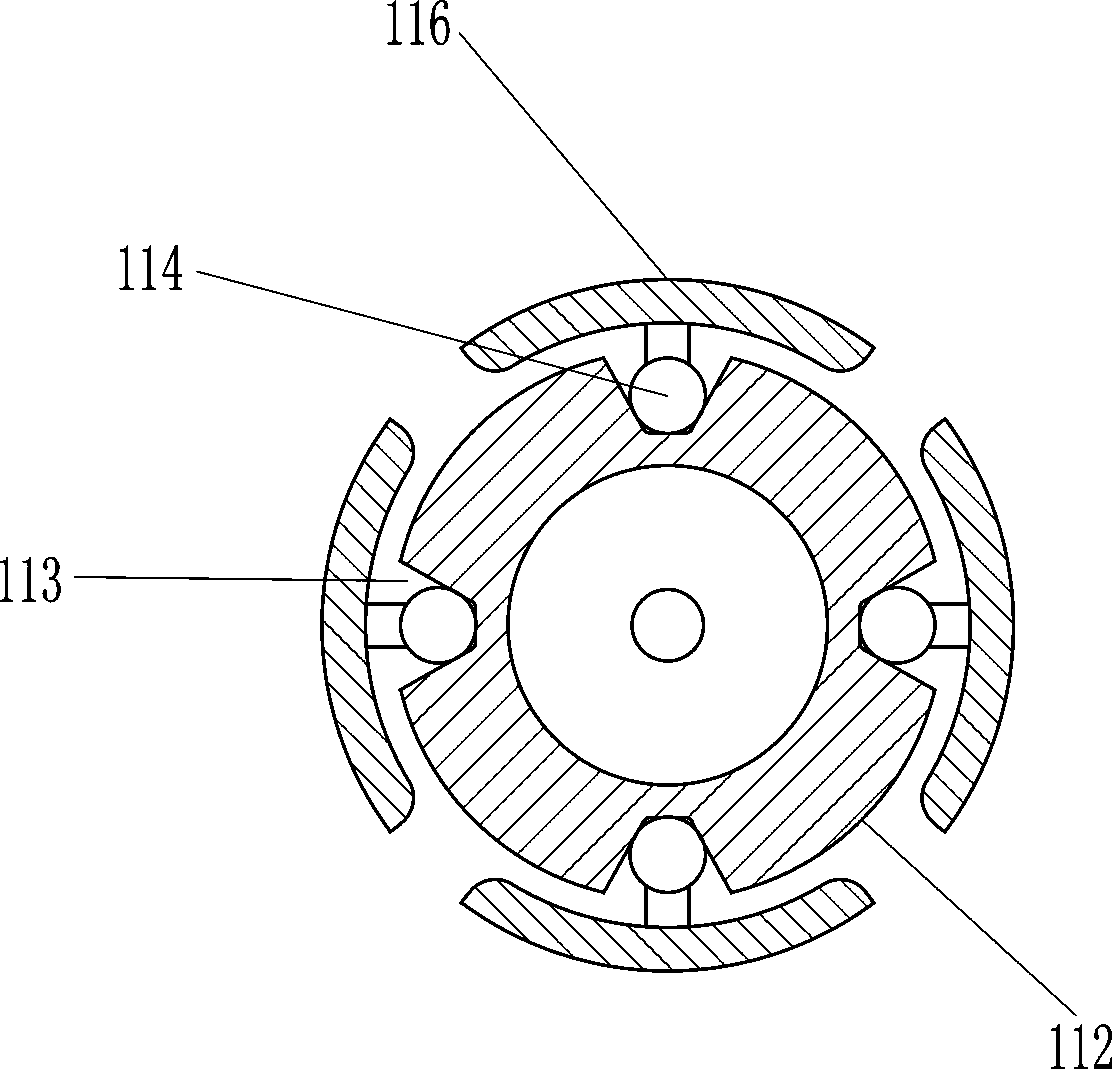

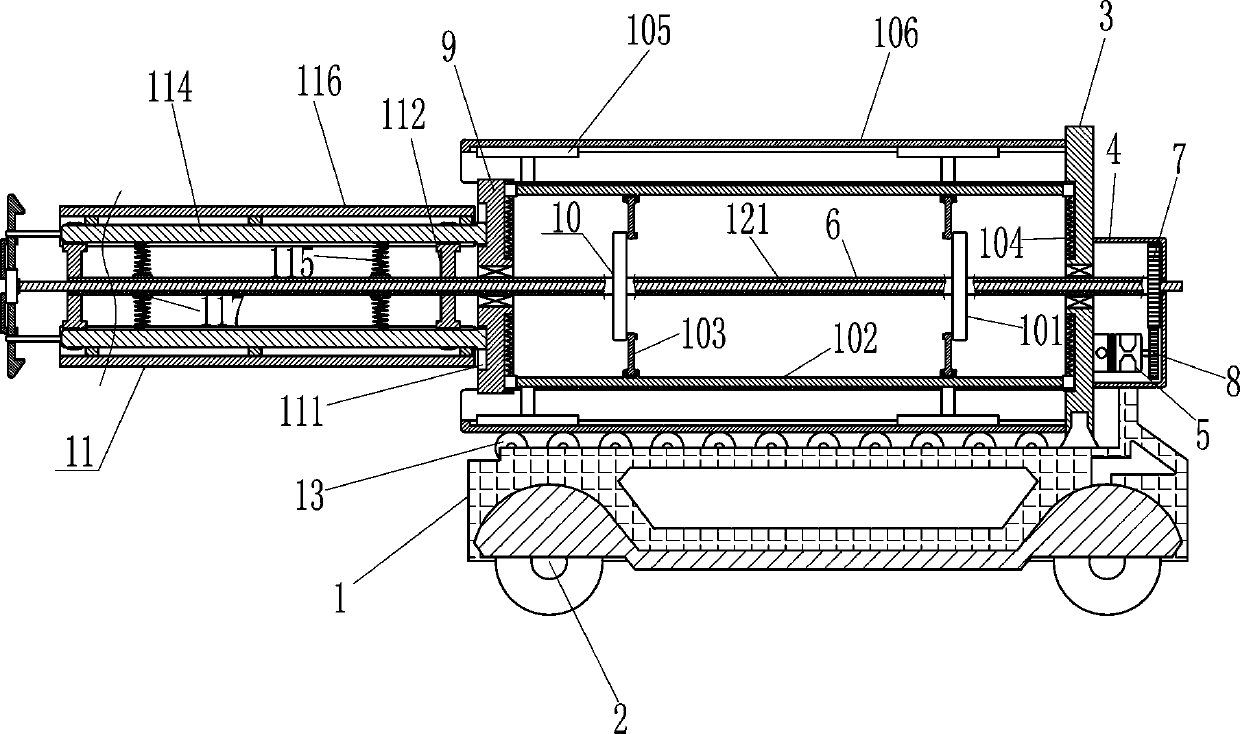

Belt winding device for block packing machine and belt winding method thereof

ActiveCN108438295AEvenly packedTied up firmlyBuilding material packagingBinding material applicationStops deviceEngineering

The invention provides a belt winding device for a block packing machine and a belt winding method thereof, belongs to the technical field of construction material production, and solves such problemsas discontinuous packing of a belt winding device of a traditional block packing machine. The belt winding device comprises a packing device; the packing device comprises a belt loading device, a belt clamping device, a belt stop device, a belt return device, a buckling device and a belt cutting device; a belt winding rail is arranged on the packing device; the belt clamping device can move alongthe belt winding rail; the belt stop device is arranged along the belt winding rail; the belt loading device outputs binding belts; the belt clamping device clamps the binding belts, moves along thebelt winding rail, and hangs the binding belts on the belt stop device; the belt return device reversely transmits the binding belts; the buckling device buckles the binding belts; the belt cutting device cuts off the binding belts; the packing device is provided with a belt clamping rail; the belt clamping rail is connected with the belt winding rail; the belt clamping device comprises two belt clamping heads; and the belt clamping rail is provided with a belt clamping position and an ending position. The belt winding device has the advantages of continuous packing and the like.

Owner:杭州径缘新型墙体材料有限公司

Auxiliary assembly for packaging and packaging machine

InactiveCN111661400ASimple structureEasy to installBundling machine detailsIndustrial engineeringManufacturing engineering

The invention provides an auxiliary assembly for packaging, and a packaging machine, and relates to the technical field of packaging equipment. The auxiliary assembly for packaging is used for assisting designated elements in stacking and mainly comprises a first driving part and a buckling part which are in transmission connection, the first driving part is used for driving the buckling part to rotate to enable the designated elements to be stacked according to the preset manner, the auxiliary assembly for packaging carries out packaging, the space occupied by packaging can be reduced, packaging of t he designated elements can be firmer, and not prone to loosening, the auxiliary assembly for packaging comprises has the advantages of being simple in structure, convenient to mount, small inoccupied space and the like, the packaging machine is used for packaging the designated elements and is convenient to operate and high in automation degree, the packaging machine mainly comprises a conveying assembly, a packaging assembly and the auxiliary assembly for packaging, and the conveying assembly is used for conveying the designated elements stacked through the auxiliary assembly for packaging to the packaging assembly to be packaged.

Owner:河北廊安自动化设备科技有限公司

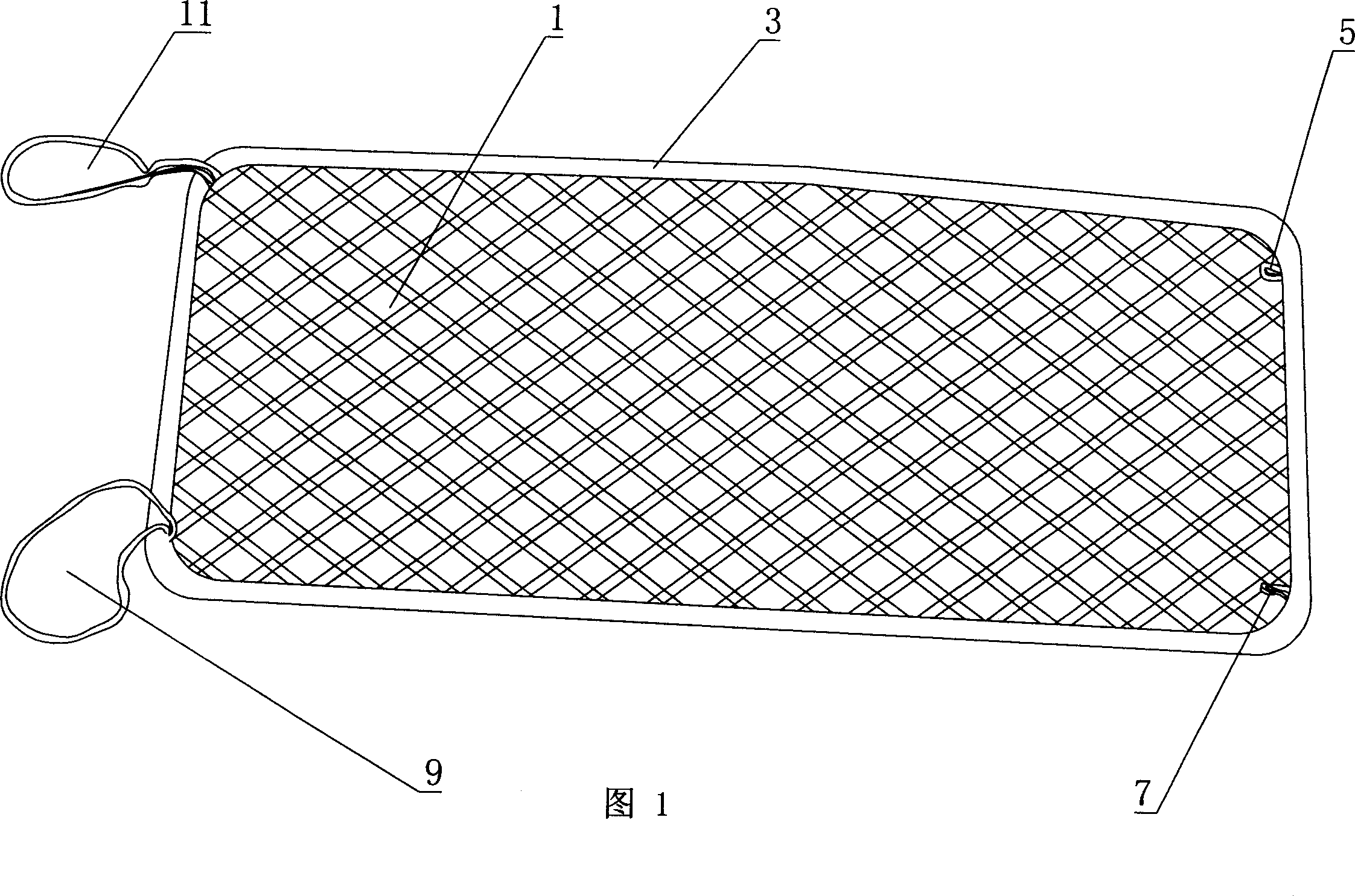

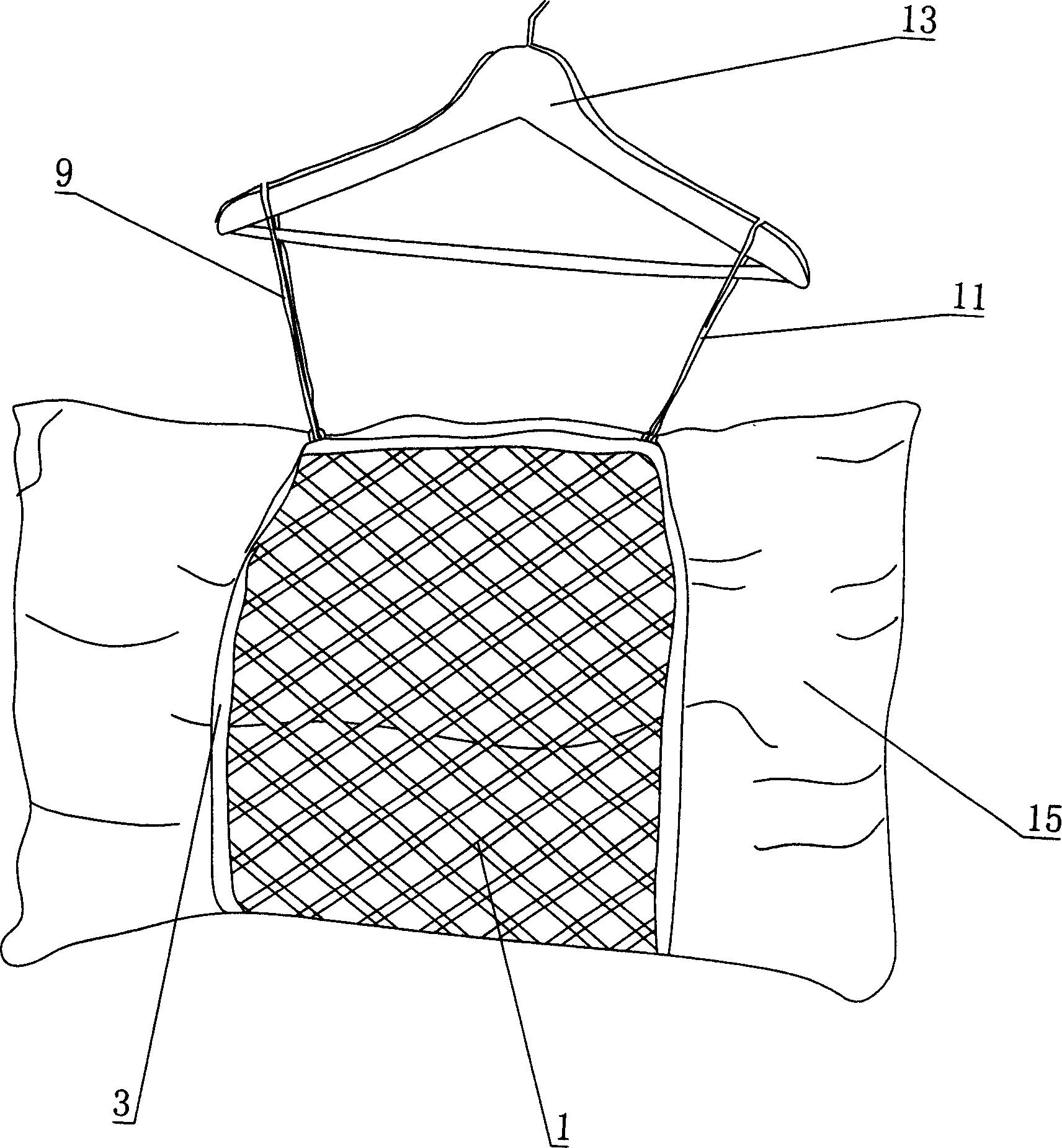

Binding-hanging net for suspensing domestic articles

InactiveCN1743538AShape is not damagedLittle elastic effectOther drying apparatusTextiles and paperPunchingEngineering

This invention relates to a suspended hanging net for drying household subjects in the sun including a rectangu lar net cloth sewed with strips surrounding it, two ears in a certain distance hang on one short edge by sewing, fixedly connecting with rivets, integrated connection or punching two holes keeping in a certain distance are connected on the other short edge by sewing, fixing with rivets, integrated connection or punching.

Owner:王萱

Hand-held automatic steel wire strapping equipment

ActiveCN109098451ARealize automatic deliveryReduce the amount of operationBuilding material handlingAssistive device/technologyStrapping

The invention discloses hand-held automatic steel wire strapping equipment, and belongs to the technical field of building construction auxiliary equipment. The hand-held automatic steel wire strapping equipment comprises a first mounting block, a second mounting block, a wire discharging mechanism, a limiting mechanism and a cutting mechanism, wherein the second mounting block is positioned at the front end of the first mounting block and is connected with the first mounting block in a rotary manner; a first connecting column and a second connecting column are arranged at the front end of thesecond mounting block; the wire outlet mechanism and the limiting mechanism are fixedly connected with the first connecting column and the second connecting column respectively; the limiting mechanism comprises a limiting component and a linkage component; the linkage component is mounted on the side of the second mounting block and is connected with the limiting component; the cutting mechanismcomprises a driving component and a cutting component; the driving component is connected with the cutting component; and the wire discharging mechanism comprises a feeding component and a wire discharging component. According to the invention, the working procedures of wire discharging, strapping and cutting can be automatically completed without manual auxiliary operation, so that the strappingefficiency of steel bars is higher, the structure is simple, and the cost and maintenance difficulty can be reduced.

Owner:广西盛隆钢铁材料研究院有限公司

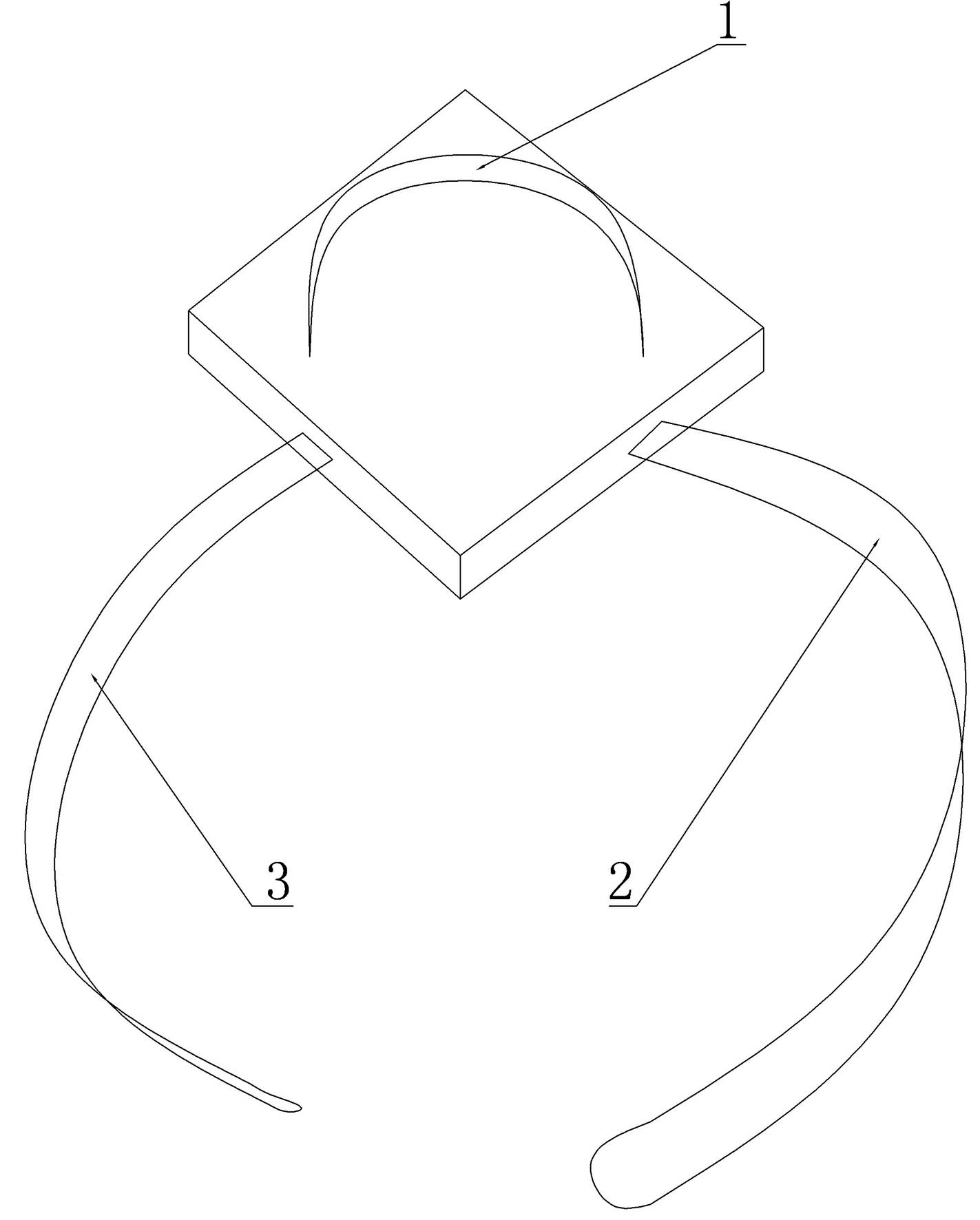

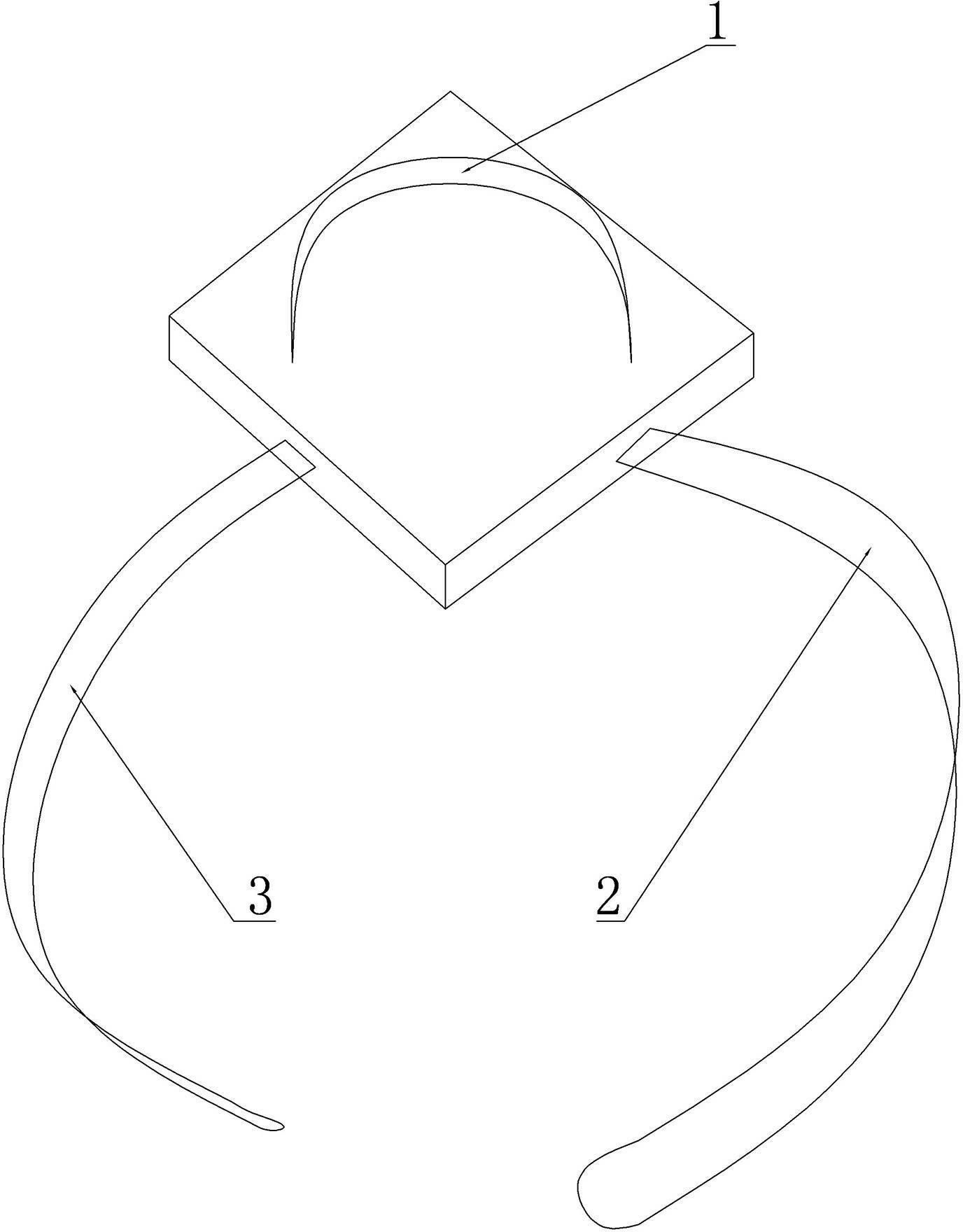

Exoskeleton power-assisted robot for material carrying

ActiveCN113370191ARelieve sorenessIncrease flexibilityProgramme-controlled manipulatorEngineeringLeg mechanism

The invention provides an exoskeleton power-assisted robot for material carrying. The exoskeleton power-assisted robot comprises a back frame mechanism, a first energy storage mechanism, a waist mechanism, a second energy storage mechanism and a leg mechanism from top to bottom; the front end of the back frame mechanism is connected with a hand mechanism, the rear end is connected with the first energy storage mechanism, and the lower end of the first energy storage mechanism is connected with the waist mechanism; the waist mechanism is connected with the leg mechanism through the second energy storage mechanism; when a wearer bends down to carry materials, the first energy storage mechanism is deformed and stores energy along with bending down, meanwhile, the hand mechanism pulls the back frame mechanism, the back frame mechanism pulls the waist mechanism, and then the waist mechanism transmits the pulling force to the second energy storage mechanism; when the wearer gets up, the first energy storage mechanism and the second energy storage mechanism release elastic potential energy, and assistance is provided for the waist and the arms of the wearer; in the material transferring process of the wearer, the weight is transmitted to all parts of the body of the wearer through the hand mechanism, and the burden of the arms is relieved.

Owner:西北机电工程研究所

Hand lifted belt

The invention belongs to a hand lifted tool and discloses a hand lifted belt, which comprises a transverse belt, a longitudinal belt and a handle, wherein the transverse belt and the longitudinal belt extend out from the handle; a transverse through hole and a longitudinal through hole are formed on the upper edge of the hand lifted belt at positions along the transverse belt and the longitudinal belt respectively; and clamping buttons are arranged in the through holes.

Owner:童思华

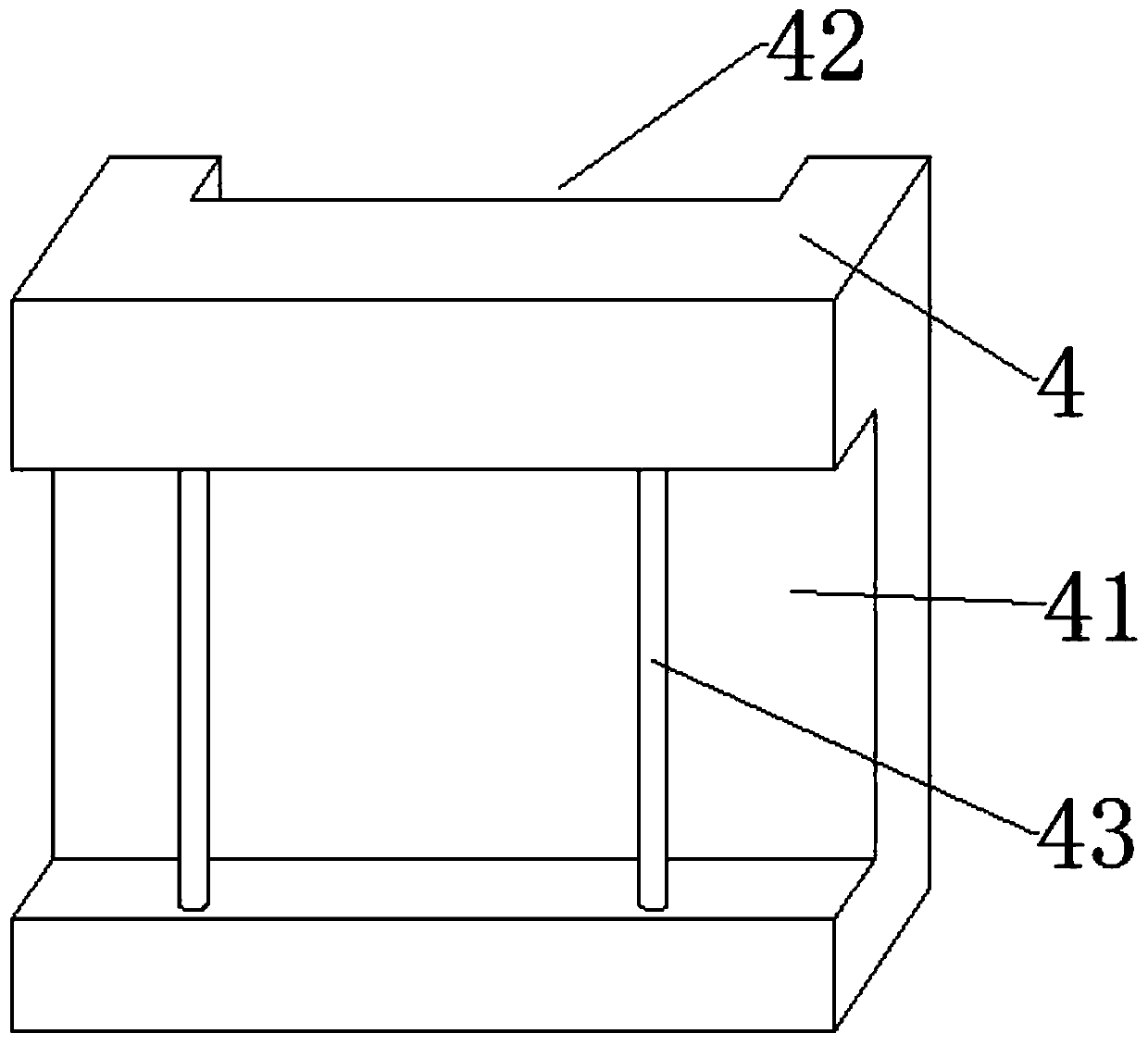

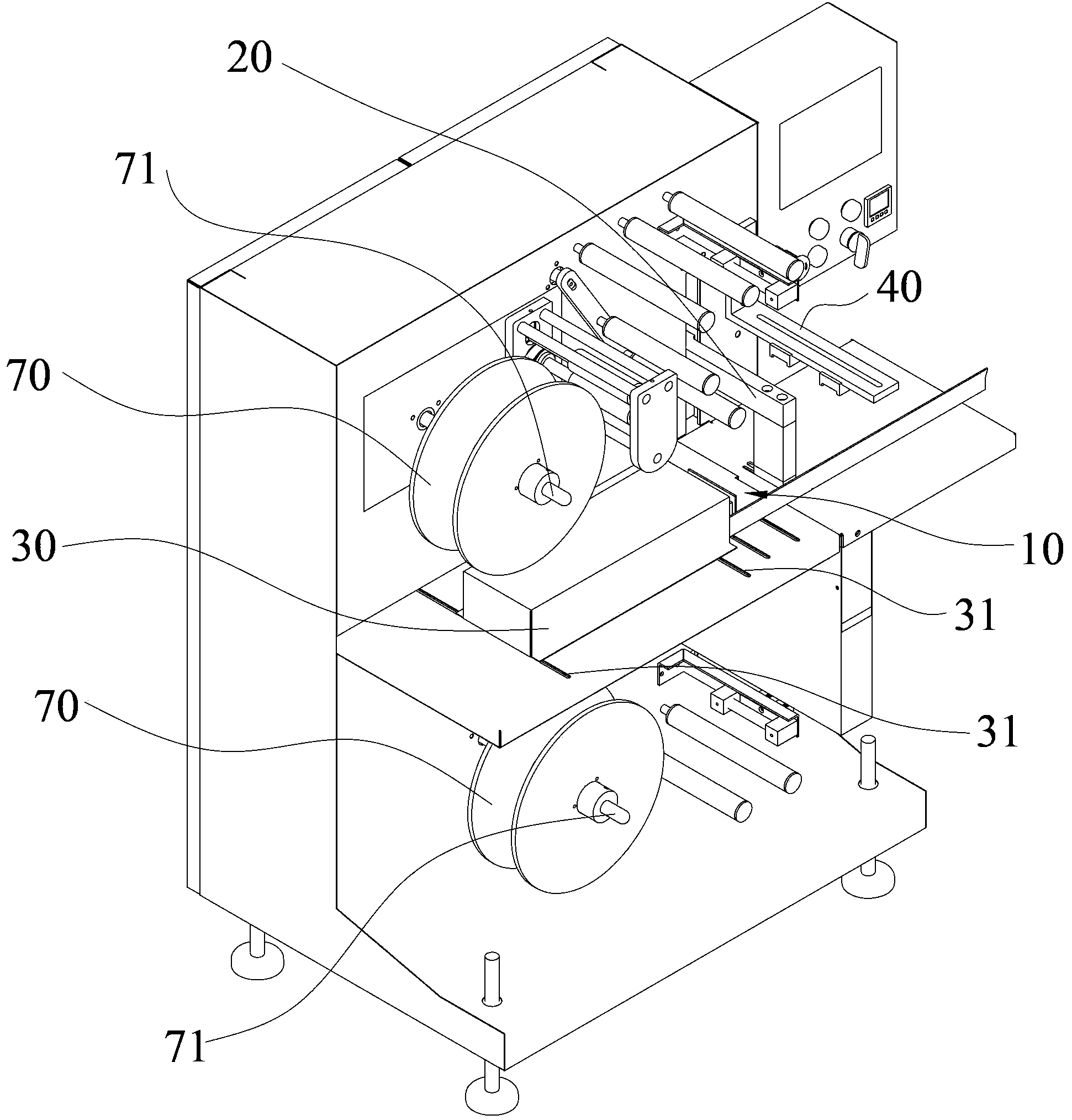

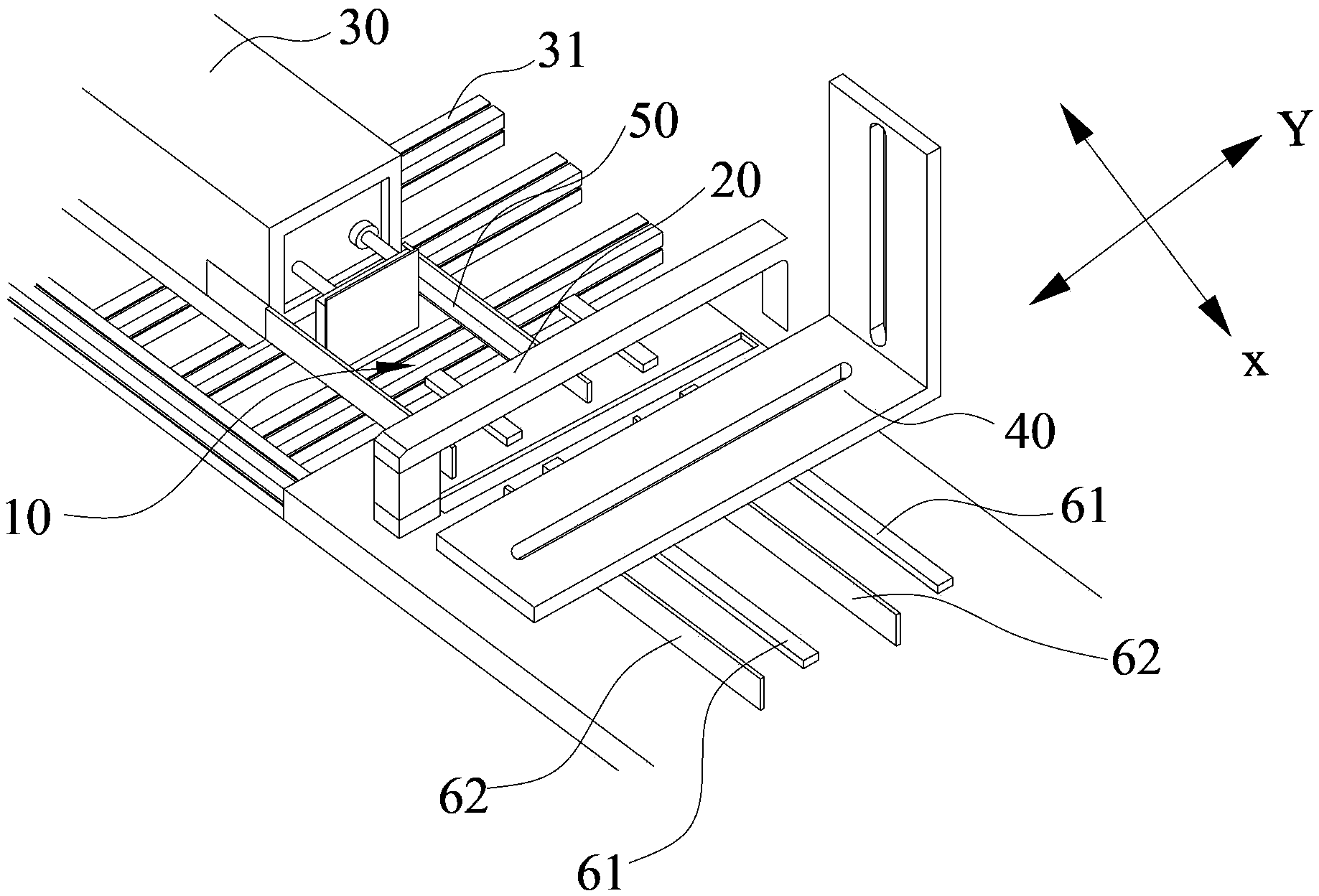

Automatic banding machine and material banding method thereof

InactiveCN103350777AHigh degree of automationHigh tie efficiencyBinding material applicationBundling machine detailsMachiningAutomation

The invention relates to the technical field of packaging box machining and provides an automatic banding machine and a material banding method thereof. The automatic banding machine comprises a feeding opening (10) and a banding device (20), the feeding opening (10) is used for placing banding materials, the banding device (20) is used for completing material banding, and the automatic banding machine further comprises a material driving device (30) and a material pressing device (40). The material driving device (30) and the material pressing device (40) are relatively arranged on the first side and the second side of the feeding opening (10), when the material driving device (30) and the material pressing device (40) conduct interaction to compress the banding materials, the banding device (20) completes material banding, the material pressing device (40) can move up and down, after the banding device (20) completes the material banding, the material pressing device (40) is elevated, and the material driving device (30) drives the banding materials to shift out of the feeding opening. The automatic banding machine is high in automation degree and high in banding efficiency.

Owner:SHENZHEN NINE STARS PRINTING & PACKAGING GRP

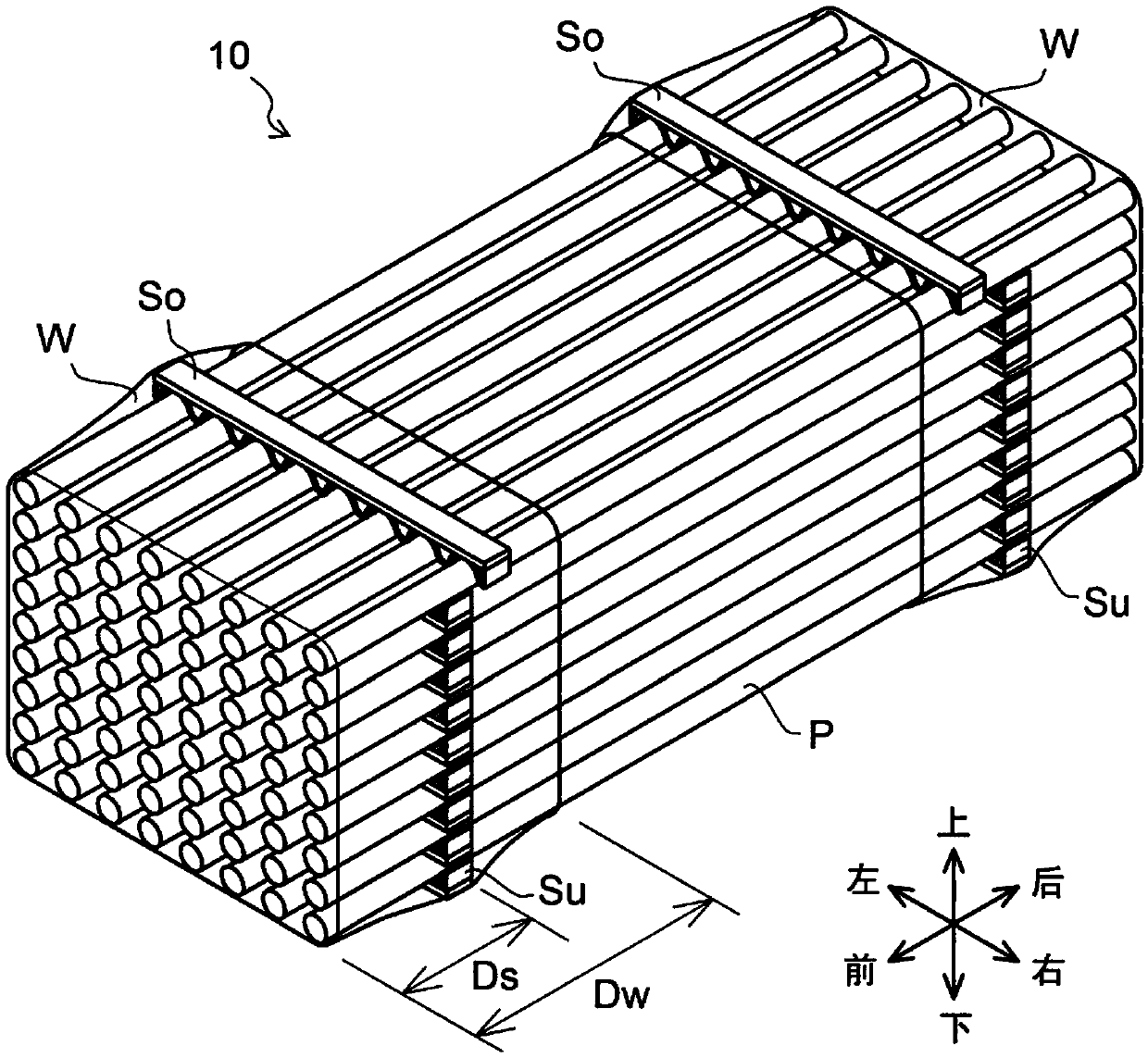

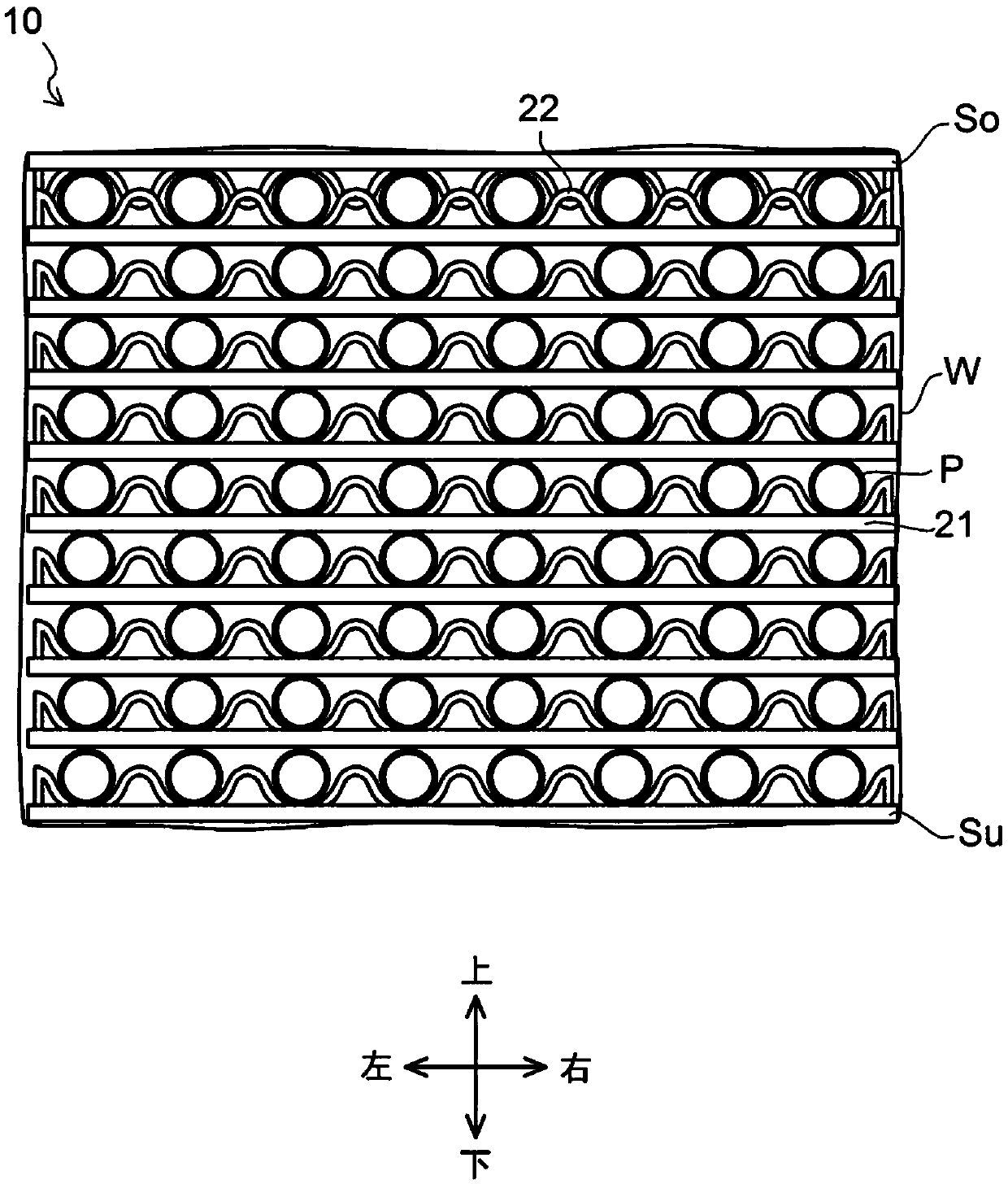

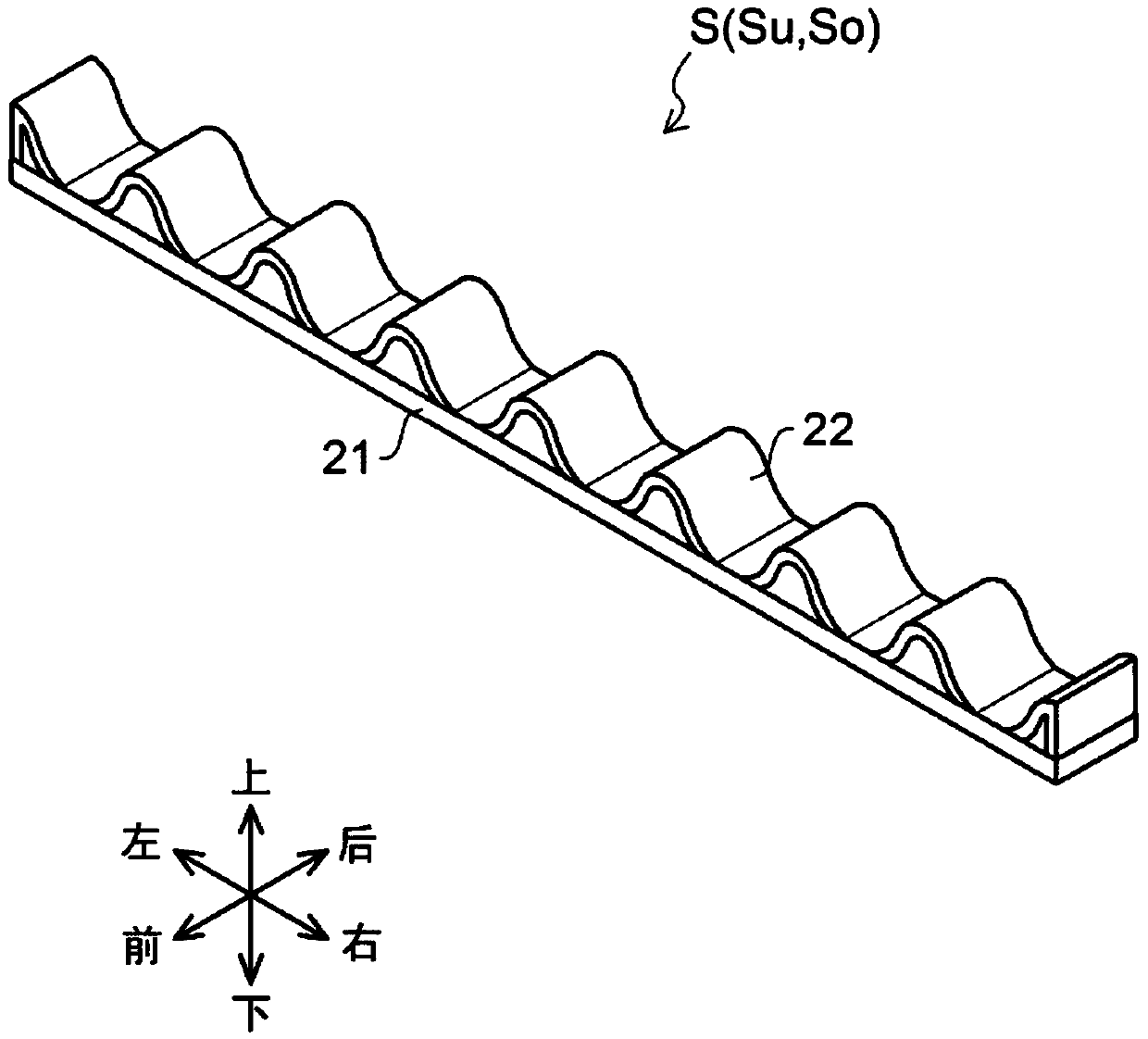

Glass tube package

InactiveCN105531198AInhibition of scratchesLight in massInternal framesDamagable goods packagingEngineeringGlass tube

Provided is a glass tube package that can suppress the occurrence of damage to glass tubes and prevent degradation of the quality of glass tubes. A glass tube package (10) is provided with: a plurality of glass tubes (P) that are arrayed in a plurality of rows and a plurality of columns; a plurality of spacer members (S) (bottom side spacer members (Su) and top side spacer members (So)) that are arranged on the bottom side and / or top side of each column of the plurality of glass tubes (P); and a film wrapping (W) that is obtained by shrinking and that covers at least both ends of the plurality of glass tubes (P).

Owner:NIPPON ELECTRIC GLASS CO LTD

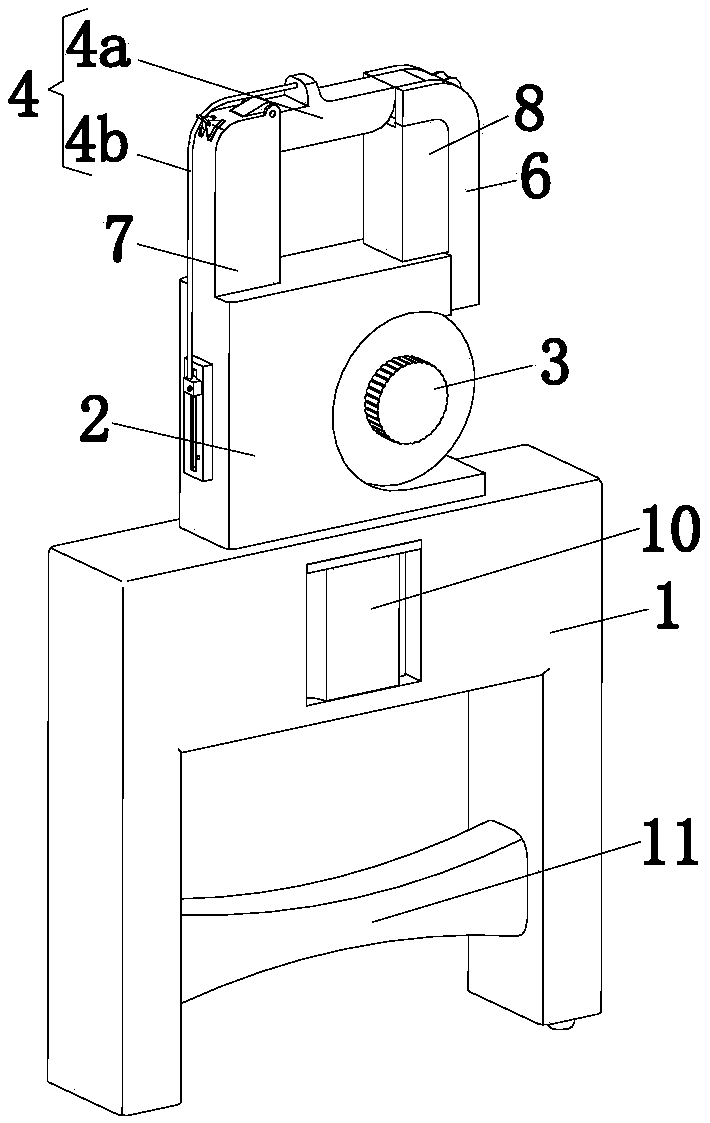

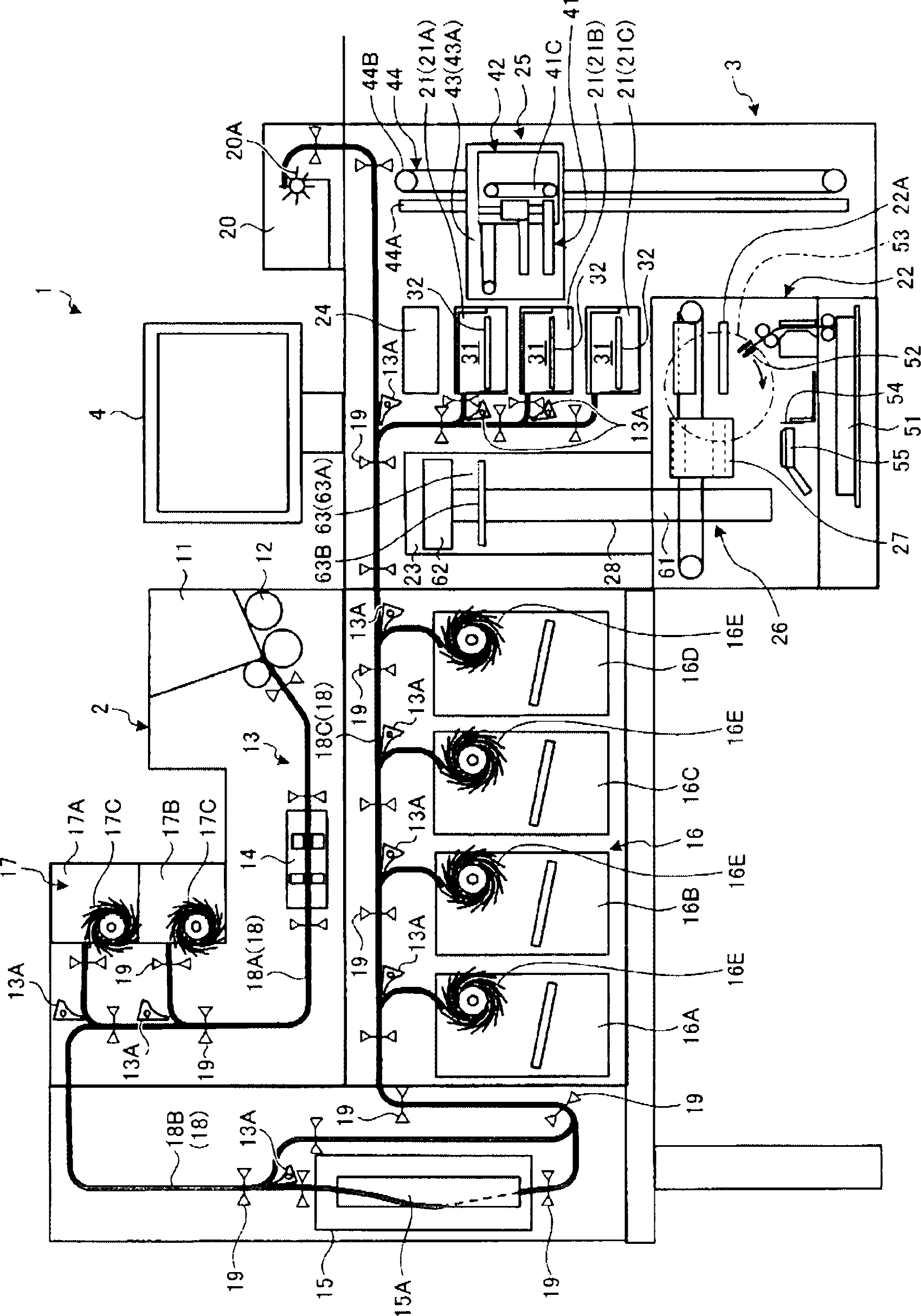

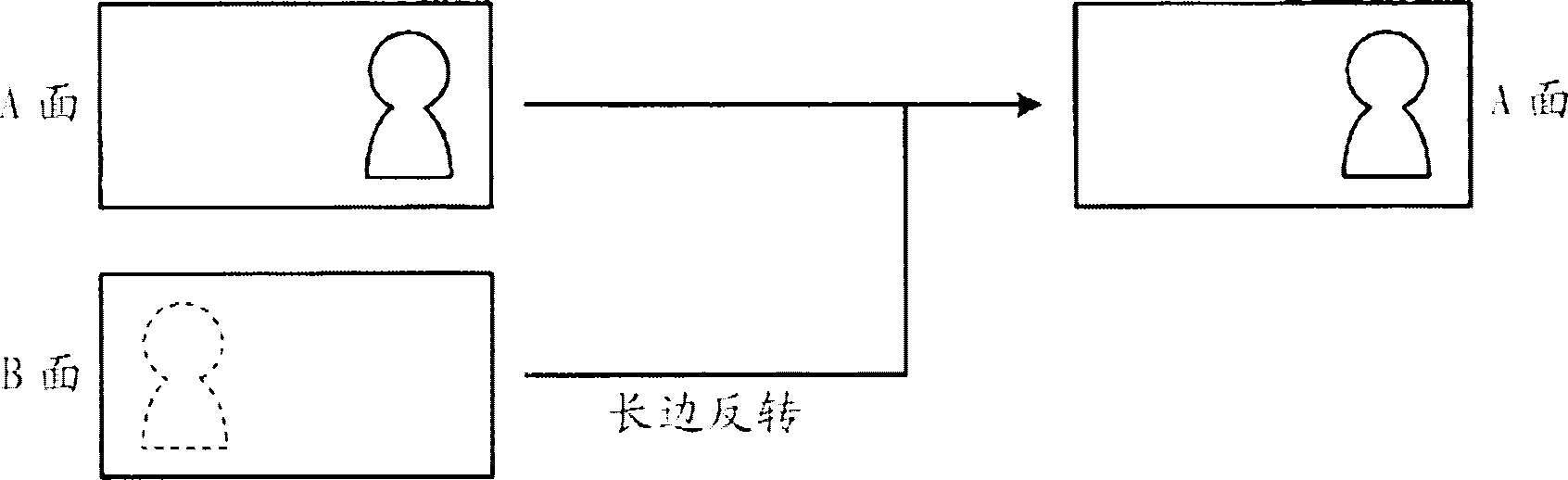

Banknote binding device and banknote binding method

ActiveCN102348606BThe setting is set freelyTied up firmlyPaper article packagingCoin countersEngineering

Owner:GLORY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com