Auxiliary assembly for packaging and packer

A technology of auxiliary components and balers, which is applied to the parts of packaging and bundling machinery, paper/cardboard containers, etc., can solve the problems of unstable bundling and large space occupation, and reduce the space occupied by packaging, save space, and reduce bundling. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

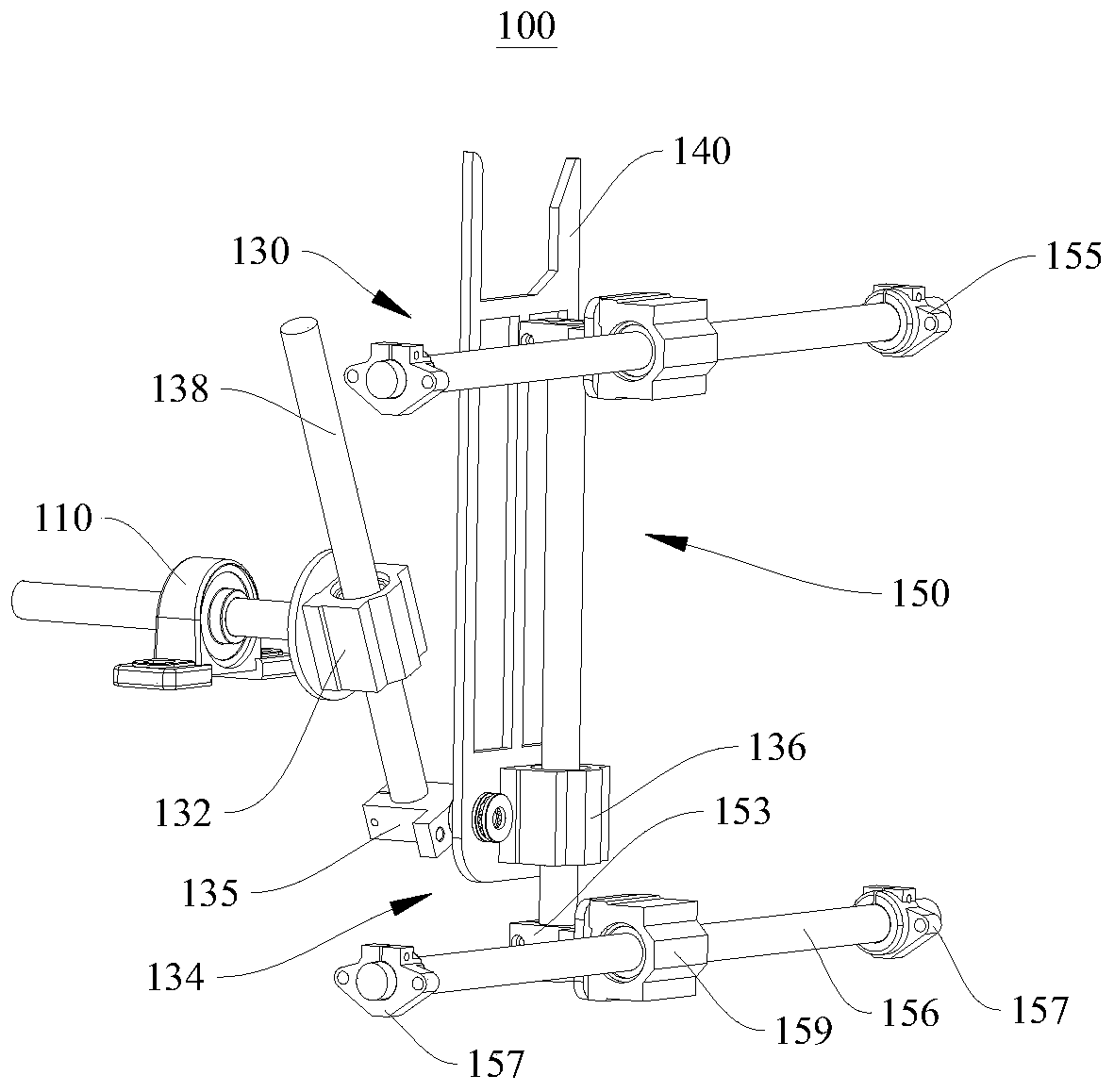

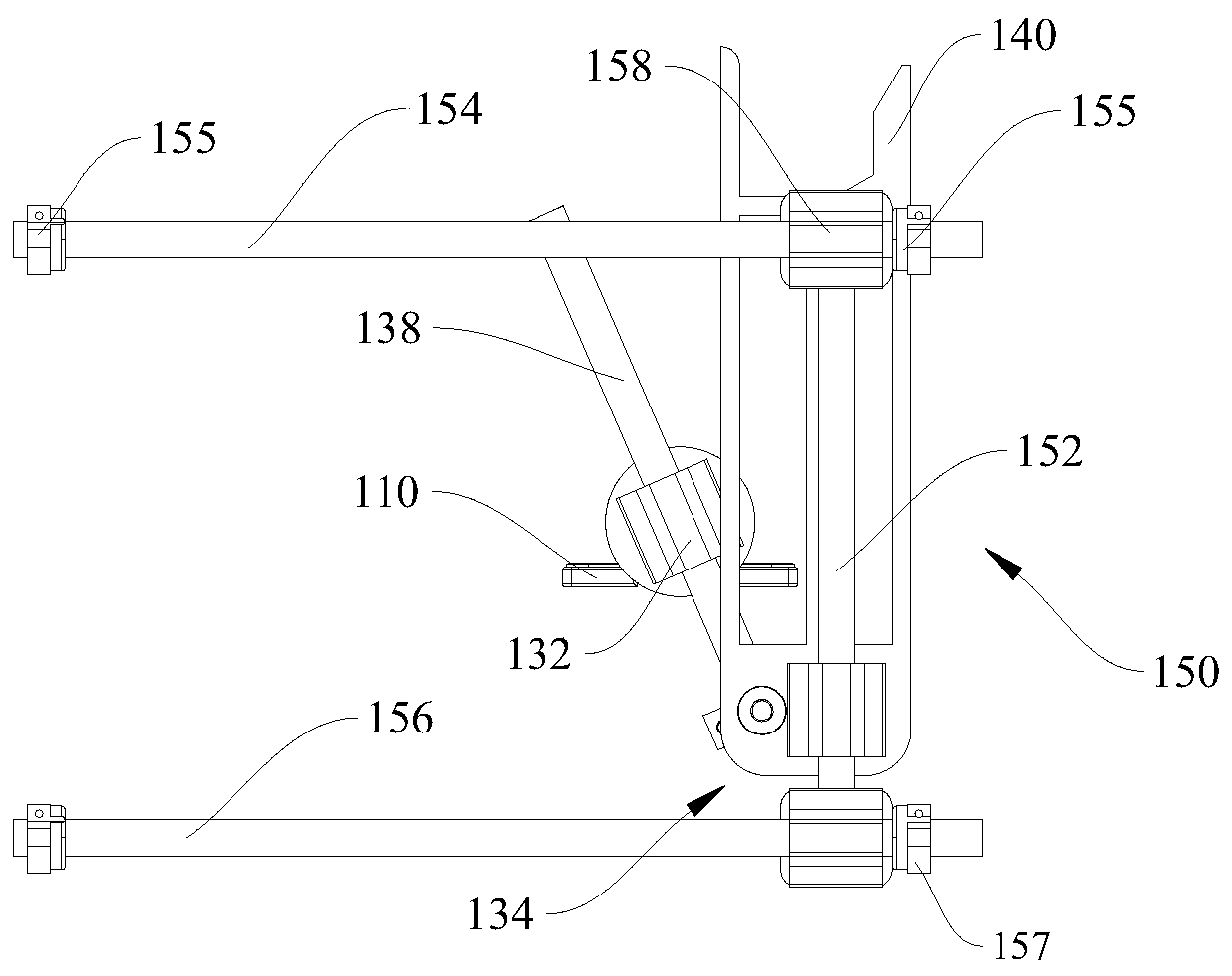

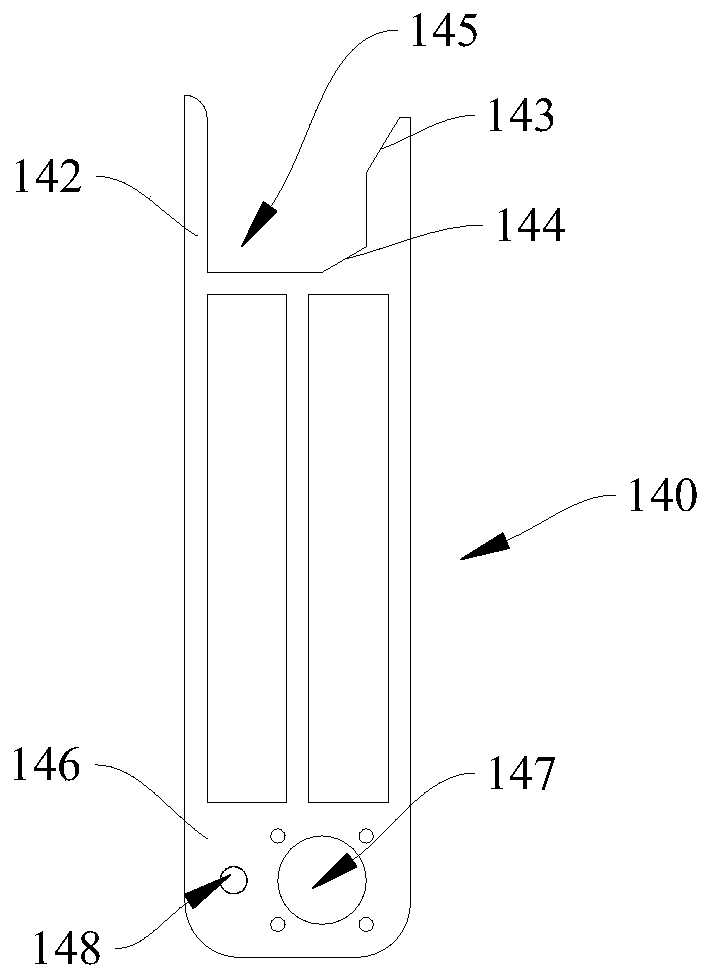

[0039] Please refer to figure 1 , figure 1 Shown is a schematic structural view of the auxiliary assembly 100 for packing. This embodiment provides an auxiliary assembly 100 for packaging, which is used to assist specified components to be stacked. Among them, the specified element can be any item that needs to be stacked, such as U-shaped keel, L-shaped keel, semi-circular profile and other types that can be stacked by using the shape fit between two elements to reduce the occupied space and facilitate packaging. other profiles. In this embodiment, for the sake of uniformity of description, the stacking of U-shaped keels is taken as an example for illustration in the following. The auxiliary assembly 100 for packing has a simple structure and is convenient for packing the U-shaped keel. Compared with the traditional packing method, the packing auxiliary assembly 100 provided by the present invention can reduce the space occupied by the U-shaped keel when packing the U-sha...

Embodiment 2

[0055] Please refer to Figure 4 and Figure 5 , Figure 4 Shown is a structural schematic diagram of the packing machine 200, Figure 5 for Figure 4 B direction view. This embodiment provides a packaging machine 200 for packaging specified components. It has the advantages of convenient use, firm binding and high packing efficiency.

[0056] The packing machine 200 mainly includes the conveying component 210, the packing component 250 and the packing auxiliary component 100 provided in the first embodiment. The conveying component 210 is used for transporting the designated components stacked by the packaging auxiliary component 100 to the packaging component 250 for packaging. The baler 200 is equipped with a master controller, which is used to control the automatic operation of the whole baler 200 .

[0057] The conveying assembly 210 mainly includes a first conveying belt 212 , a second conveying belt 214 , a first propelling part 216 and an installation platform 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com