Clamp support with tying bands

A technology of clamps and cable tie holes, which is applied in the direction of manufacturing tools, workpiece clamping devices, etc., and can solve the problems of unreliable fixing of air pipes and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

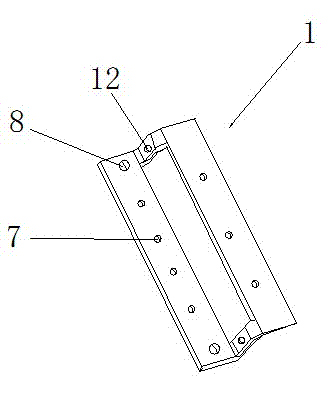

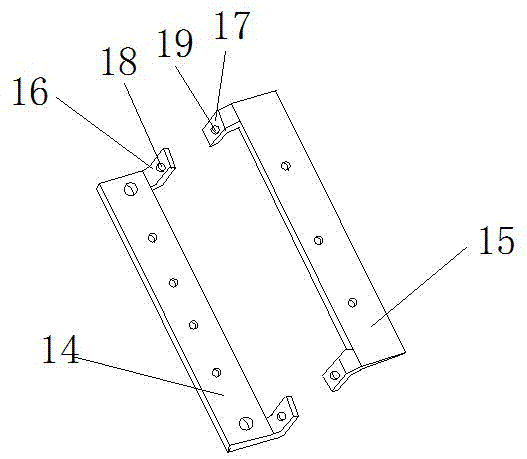

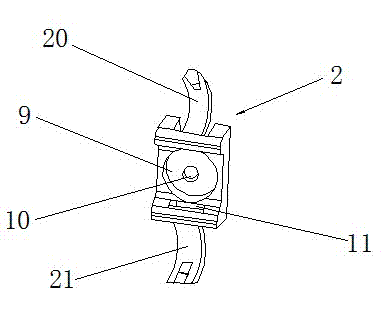

[0018] Such as Figure 1 to Figure 4 As shown, a clamp bracket with a cable tie includes: a bracket 1, a clamp 2 and a cable tie 6, the cable tie 6 is connected to the clamp 2, and the bracket 1 is detachably connected to the clamp 2 , the bracket 1 is provided with a fixing mechanism connected with the platform.

[0019] Such as figure 1 and figure 2 As shown, the bracket 1 includes a first bearing plate 14 and a second bearing plate 15, a first connecting bar 16 and a first connecting hole 18 are arranged on the first bearing plate 14, and a second connecting bar 16 is arranged on the second bearing plate 15. Connecting bar 17 and second connecting hole 19, there are several threaded holes 7 on the first loading plate 14 and the second loading plate 15, and there is also a fixing mechanism connected with the assembly platform on the first loading plate 14 There are two fastening screw holes 8, and the first connecting hole 18 is opposite to the second connecting hole 19 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com