Automatic collecting and bundling device for packaging bags

An automatic collection and bundling device technology, applied in packaging, transportation and packaging, paper product packaging, etc., can solve the problems of unsuitability for mass production, low production efficiency, and high production costs, achieve firm bundling, improve production efficiency, reduce The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] specific implementation

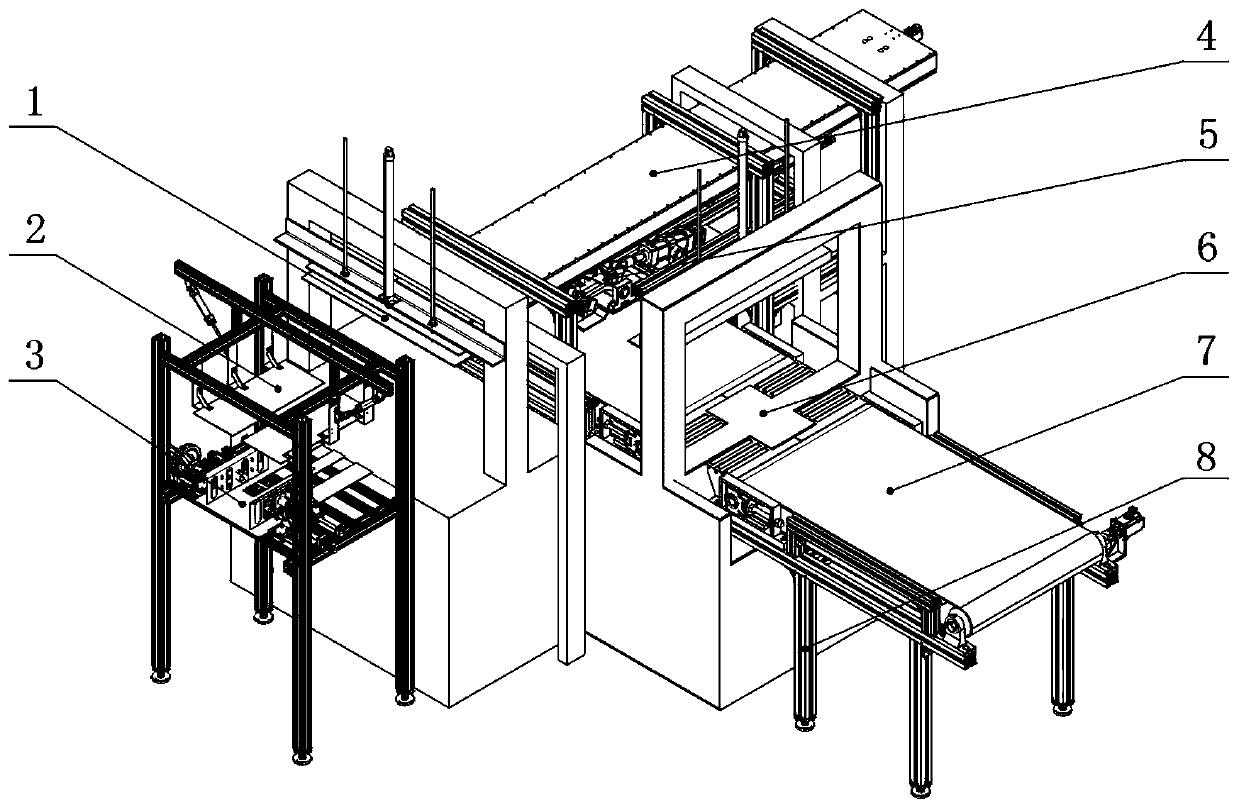

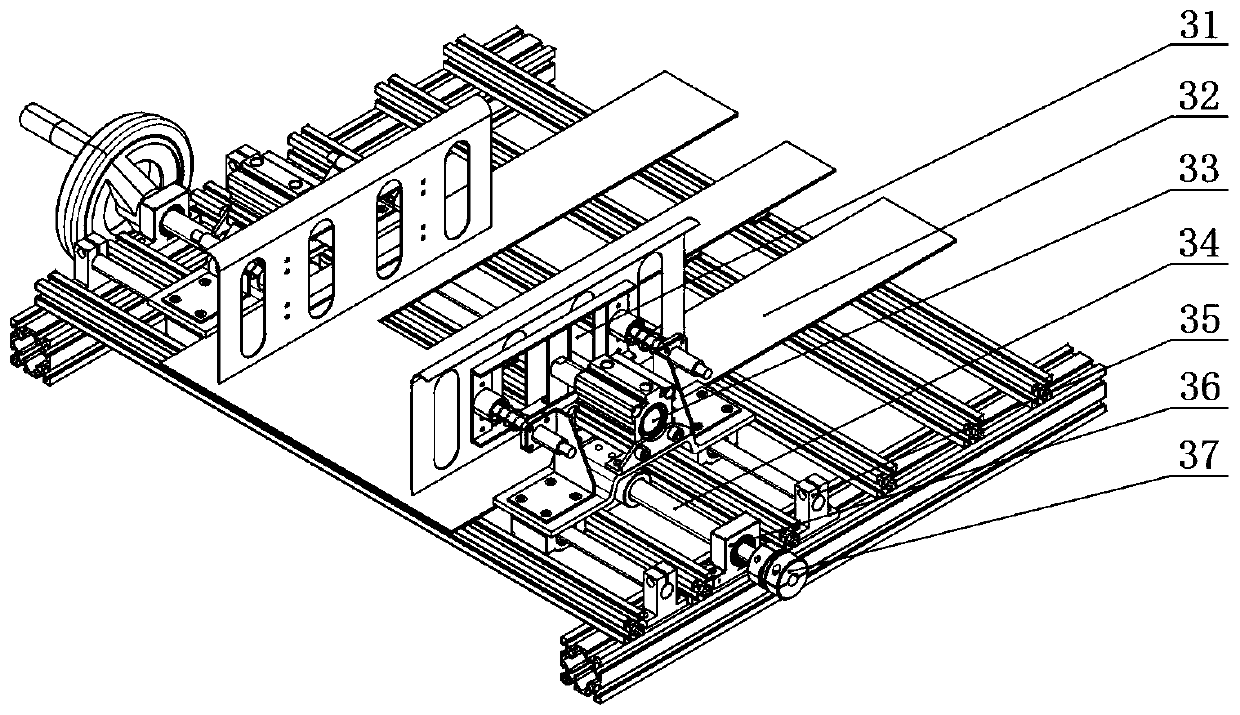

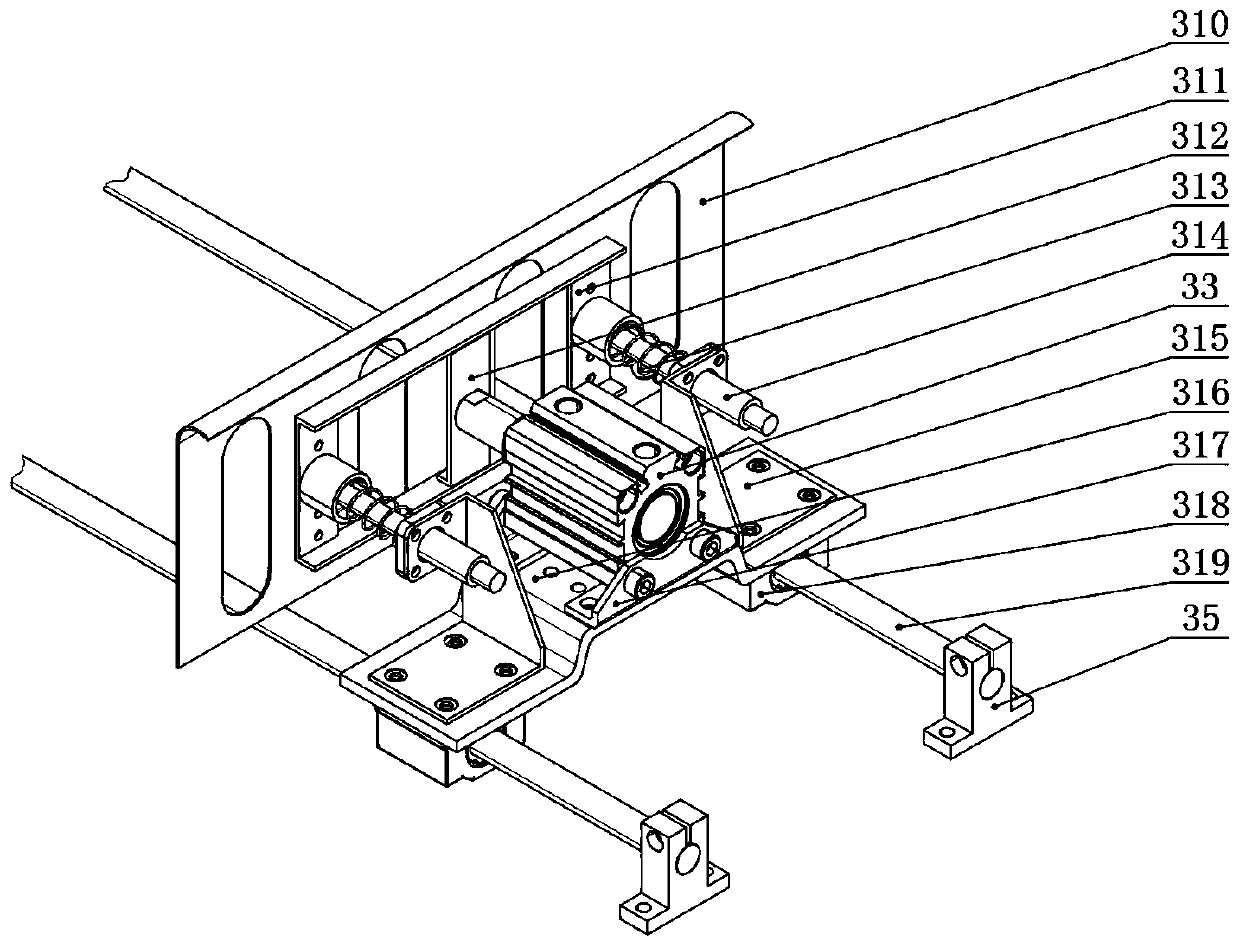

[0037] Such as Figure 1-20 As shown, a packaging bag automatic collection and binding device of the present invention, wherein figure 1 It is a schematic diagram of the overall structure of the automatic collection and binding device for packaging bags. Its structure consists of a pressing device 1, a bag stop baffle device 2, a collecting and finishing device 3, a conveying and positioning device 4, a clamping device 5, an automatic binding device 6, and a conveyor 7 , Frame 8 is made up of, and wherein automatic strapping device 6 is to adopt existing strapping device. The plastic bags coming out from the high-speed bag making machine are collected and arranged in the collecting and finishing device 3 . When the number of bags reaches the set number, the bag stop baffle device 2 starts and works, and its left and right baffles 24 are closed to catch the bags; at the same time, the conveying positioning device 4 moves the clamping device 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com