Clamping equipment for assistive bundling of steel bar rings

A technology for clamping equipment and rebar rings, which is applied to the parts and packaging of bundling machinery, which can solve the problems of easy loosening of rebar rings, labor-intensive, affecting transportation and loading and unloading, etc., so as to reduce friction, avoid falling off, and avoid loosening. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0018] first implementation

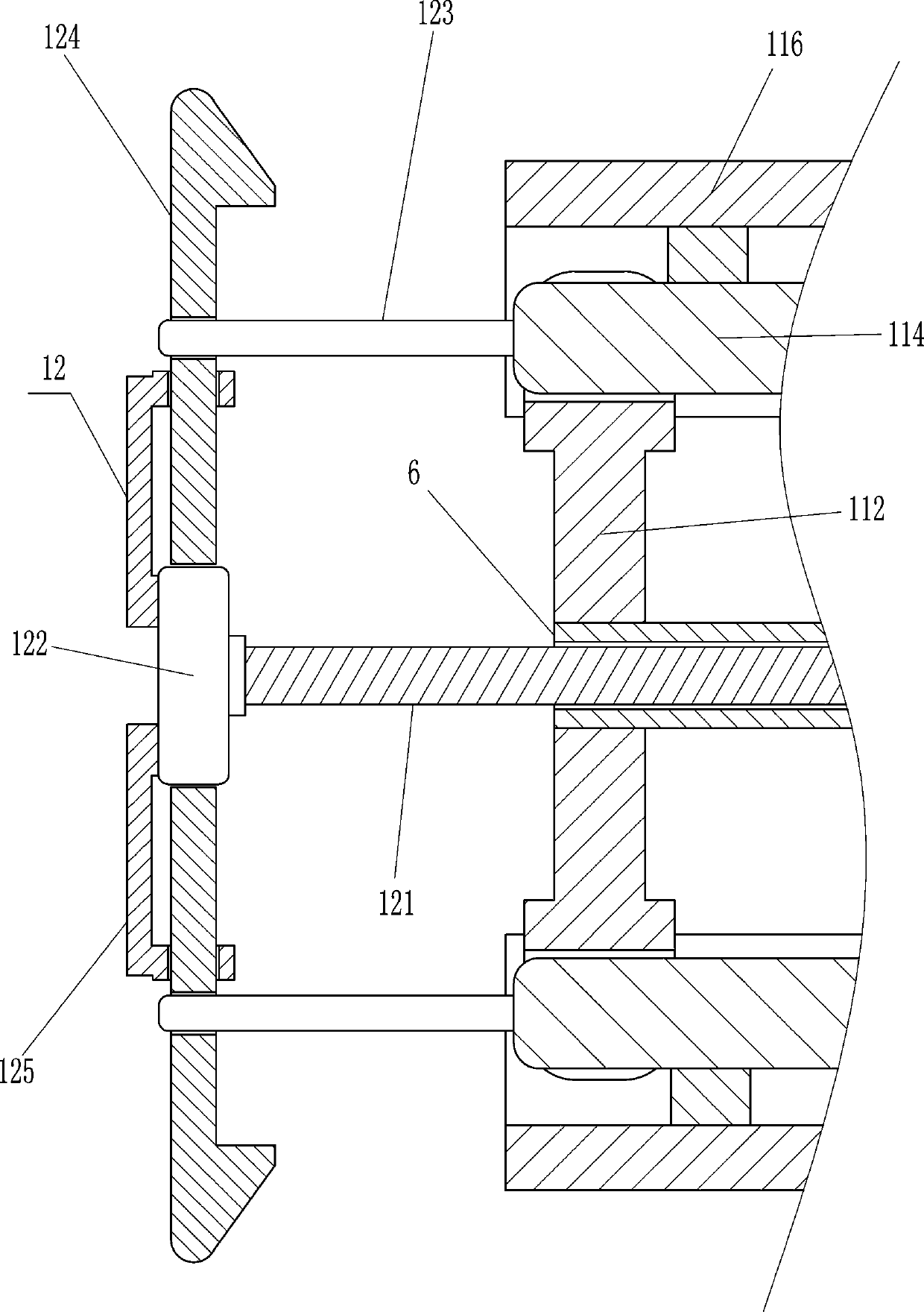

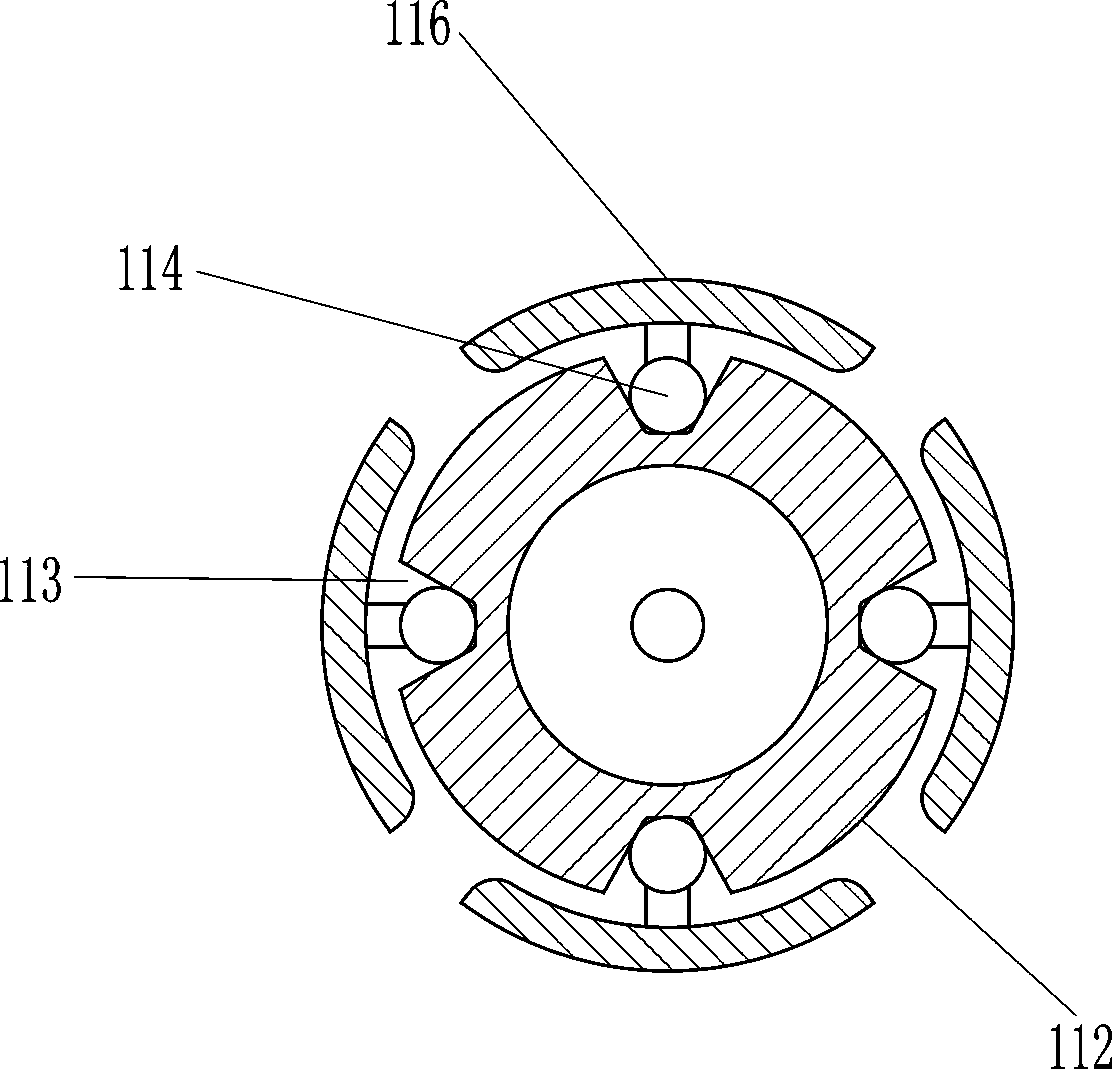

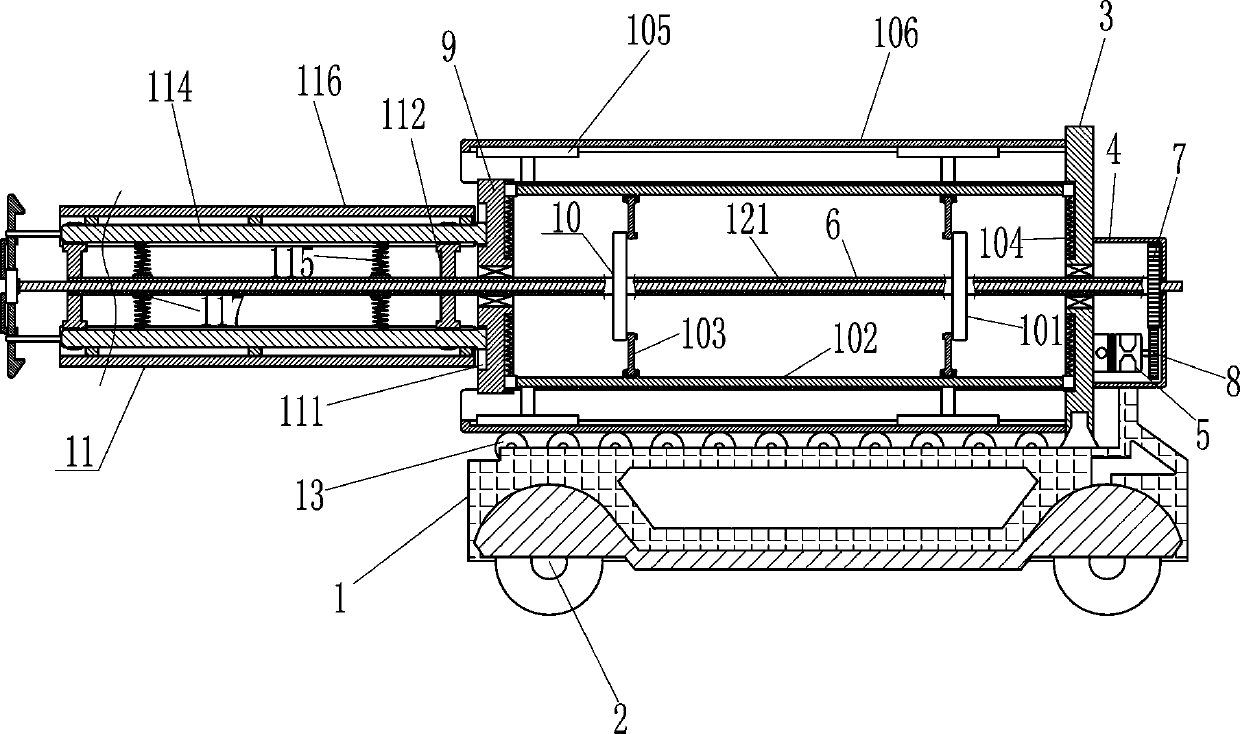

[0019] see figure 1 , a clamping device for auxiliary binding of steel bars, including a mounting seat 1 and a roller 2, the bottom of the mounting seat 1 is rotatably provided with a roller 2, and the roller 2 is used for the movement of the clamping device, and also includes a first circular plate 3 , housing 4, reduction motor 5, internally threaded casing 6, transmission gear 7, drive gear 8, second circular plate 9 and clamping assembly 10, the right side of the top of mounting base 1 is provided with first circular plate 3, the first The right side of the circular plate 3 is provided with a housing 4 and a geared motor 5, the housing 4 is connected with the first circular plate 3 through a bolt connection, the geared motor 5 is located in the housing 4, and the middle part of the first circular plate 3 is ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com