Strapping machine for packaging bags

A packaging bag and strapping machine technology, which is applied to the parts of strapping machinery, strapping materials, transportation and packaging, etc., can solve the problems of high equipment cost, poor strapping effect, easy to fall off rubber bands, etc., and achieve small equipment size and low processing cost. The effect of low and exquisite structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

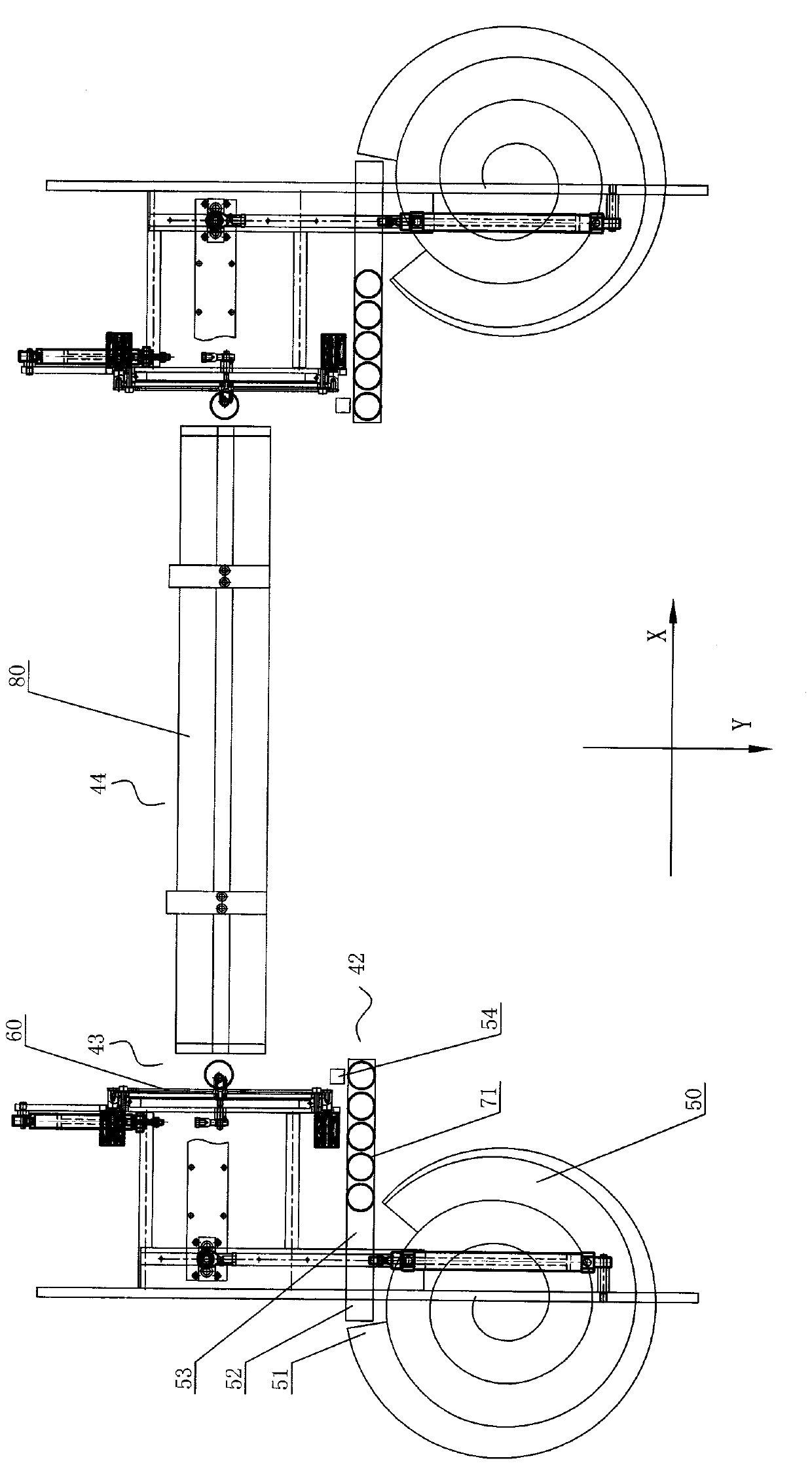

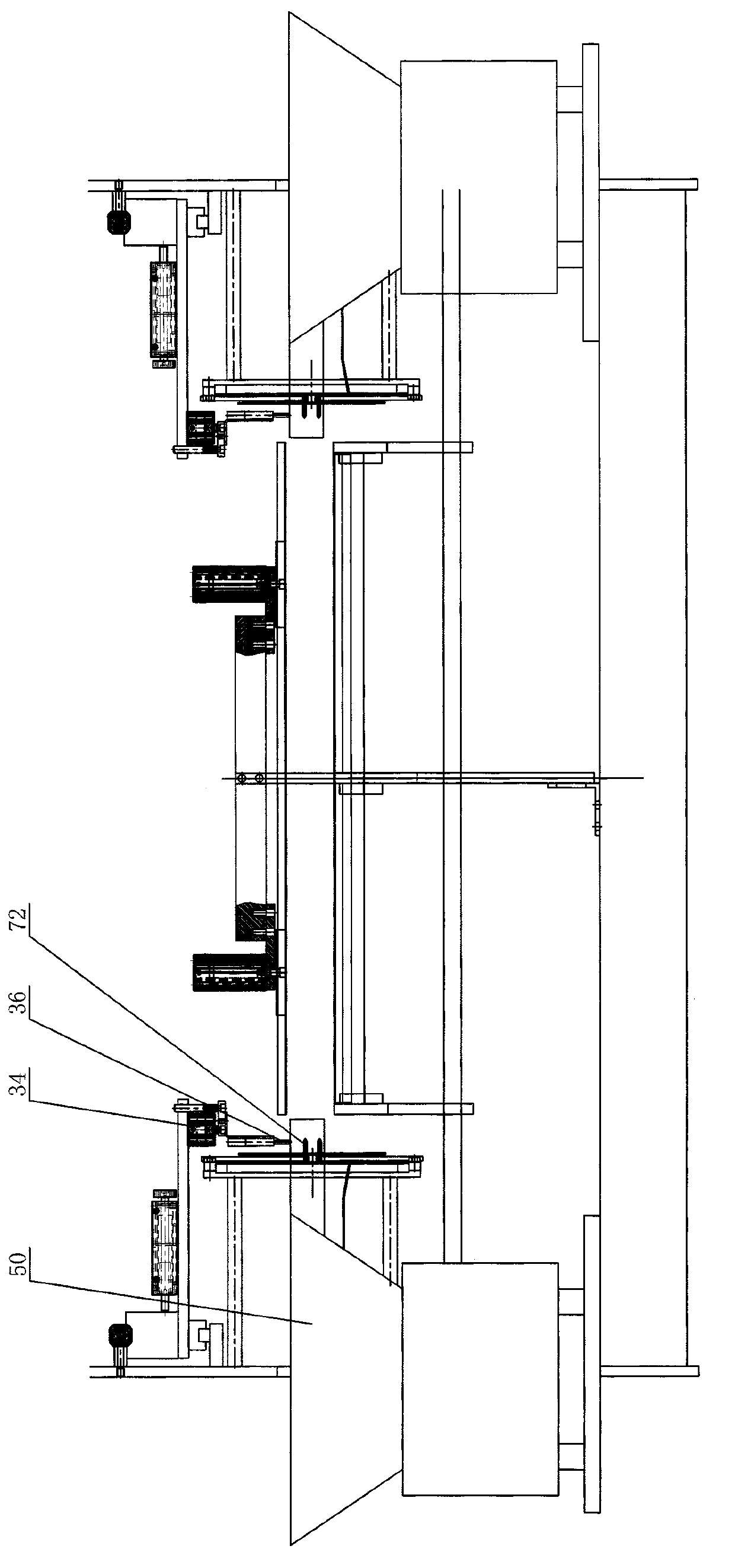

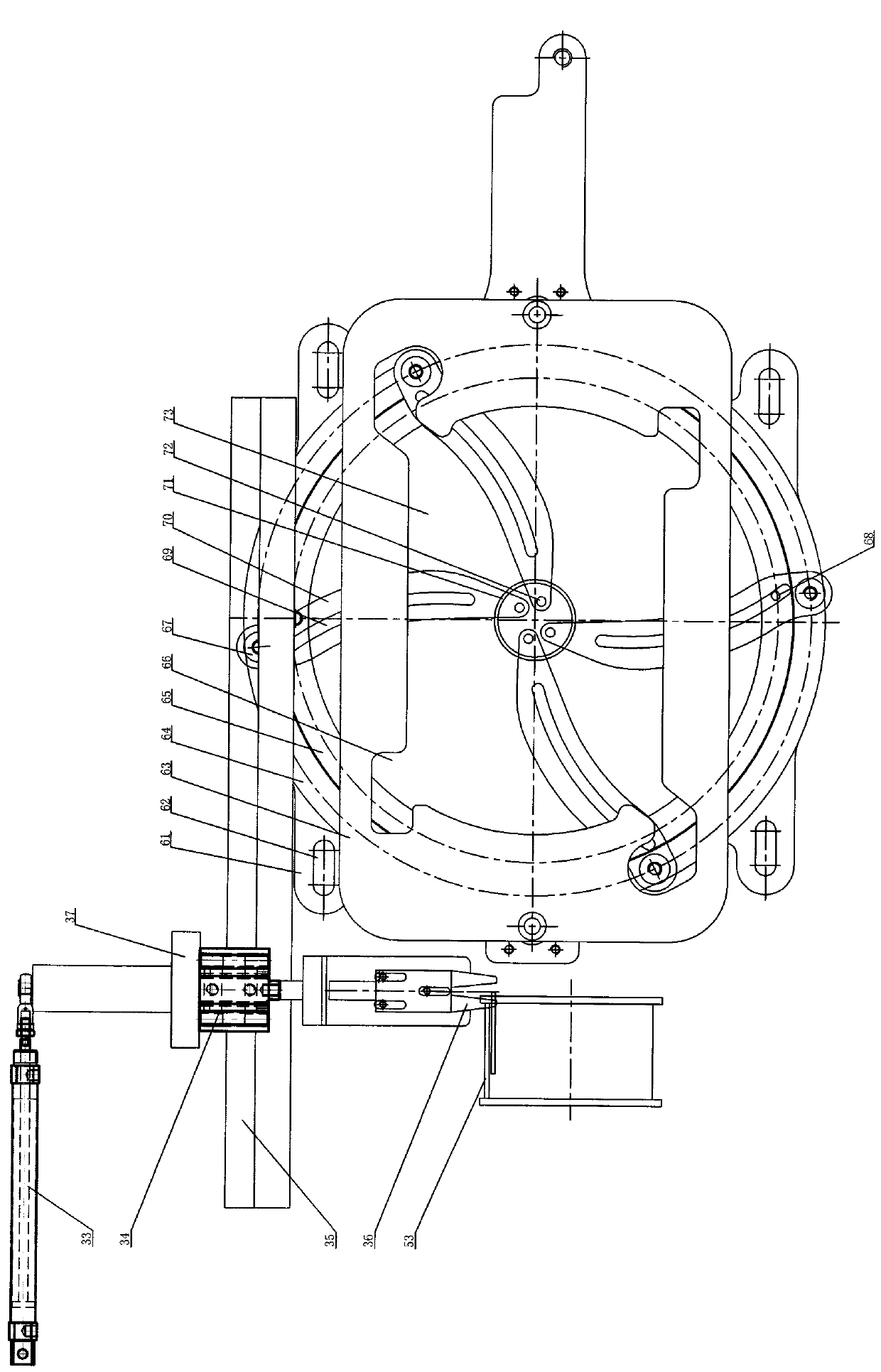

[0023] The following describes the relevant details and working principles of the embodiments and embodiments of the present invention in conjunction with the accompanying drawings. This kind of packaging bag strapping machine includes a frame. The frame is provided with a rubber band feeding station 42, an expansion station 43, and a packaging bag feeding station 44, and the rubber band feeding station, the expansion station and the packaging The bag feeding station is correspondingly provided with a rubber band conveying mechanism, a rubber band spreading mechanism 60 and a packaging bag feeding mechanism 80, see attached figure 1 , The X-axis direction of the present invention is the horizontal direction, also the left-right direction, the Y-axis direction is the longitudinal direction, also the front-rear direction, the arrow direction is the front, the rubber band spreading mechanism 60 and the rubber band conveying mechanism are both set in the packaging bag feeding mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com