Metal plate coil bundling device and bundling method

A technology for metal discs and equipment, applied in the directions of bundling materials, parts of bundling machinery, packaging, etc., can solve the problems of increasing labor intensity of workers, low production efficiency, high size, etc., and achieve improved bundling efficiency, compact structure, and automation. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

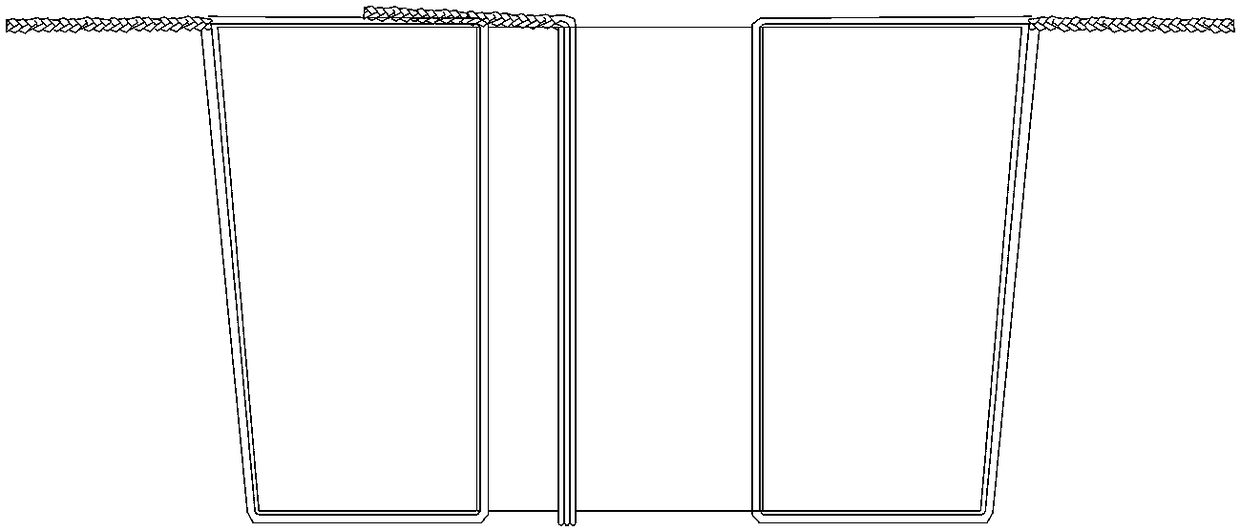

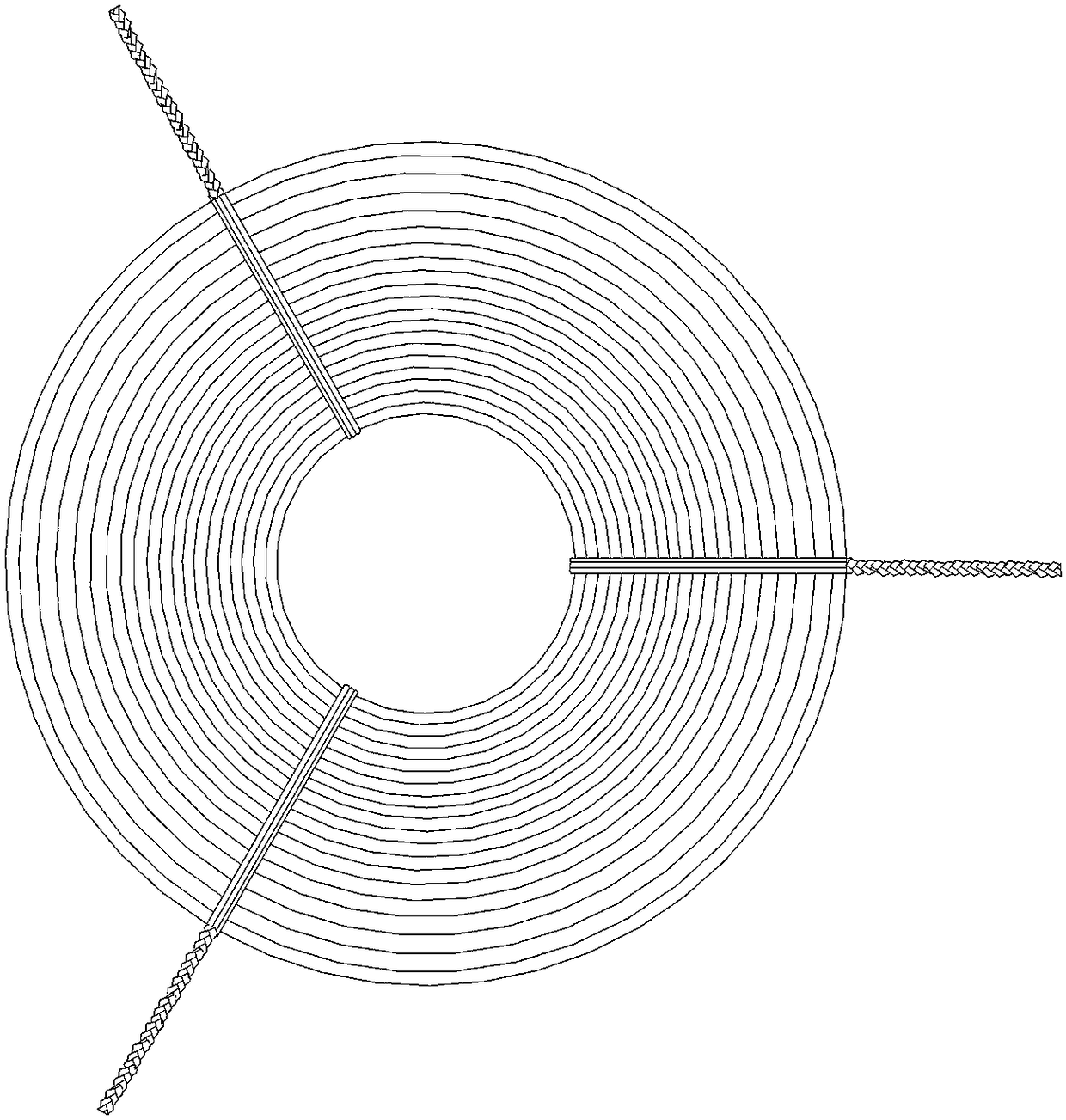

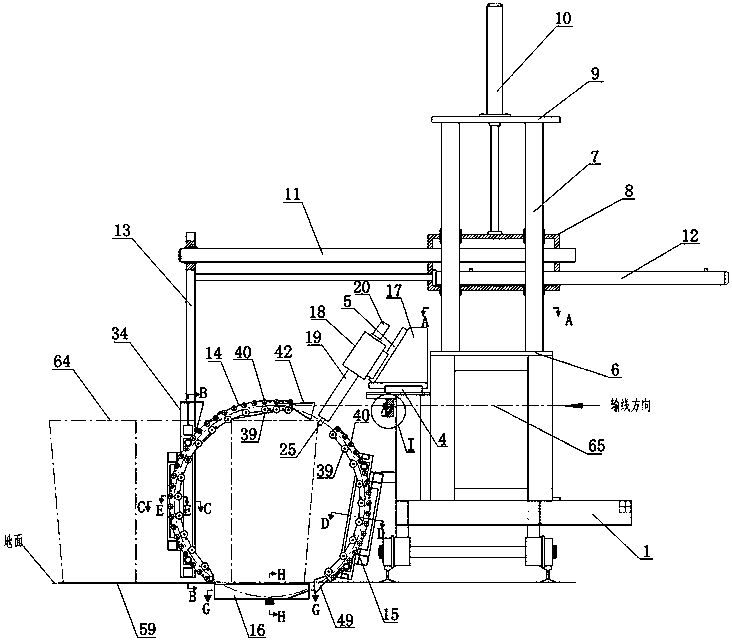

[0048] Embodiment one: if Figure 1~15 As shown, a metal coil binding equipment includes a binding trolley 1, a threading channel, a wire rod cutting mechanism 2 arranged on the binding trolley 1, a traction mechanism 3, a horizontal hydraulic slide 4, an oblique hydraulic slide 5, Vertical movement mechanism and horizontal movement mechanism, the traction mechanism 3 is installed on the traction wheel and the pressing wheel on the front surface of the platform B31, wherein the rotating shaft of the traction wheel is connected with the output shaft of the hydraulic motor, when the aluminum rod is placed on the traction wheel After it is between the pinch wheel and the hydraulic motor, the torque output by the hydraulic motor drives the traction wheel to rotate, thereby transporting the aluminum rod to the left.

[0049] Described vertical motion mechanism comprises the platform A6 that is fixed on the binding trolley 1, the vertical guide rail 7 that is fixed on the platform A...

Embodiment 2

[0070] Embodiment two: if Figure 16 As shown, a metal coil binding equipment, the difference between this embodiment and Embodiment 1 is that it includes a hinge seat 66, a main beam 67, a movable plate 13, a main oil cylinder 69 and an auxiliary oil cylinder 70, and the right end of the main beam 67 The bottom of the bottom is provided with a hinge seat 66, the hinge seat 66 is arranged on the platform A6, the lower surface of the left end of the main beam 67 is provided with an auxiliary oil cylinder 70, the auxiliary oil cylinder 70 is arranged parallel to the main beam 67, and the acting end of the piston rod of the auxiliary oil cylinder 70 A movable plate 13 is arranged on the movable plate 13, and a main channel 14 is arranged on the movable plate 13. The cylinder barrel of the main oil cylinder 69 is hinged on the strapping trolley 1, and the piston rod of the main oil cylinder 69 is hinged on the main beam 67. By controlling the extension of the piston rods of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com