Auxiliary assembly for packaging and packaging machine

A technology of auxiliary components and balers, which is applied in the direction of packaging and strapping machine parts, etc., can solve the problems of unstable bundling and large space occupation, and achieve the goal of saving the space occupied by packing, not easy to scatter, and reducing the space occupied by packing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

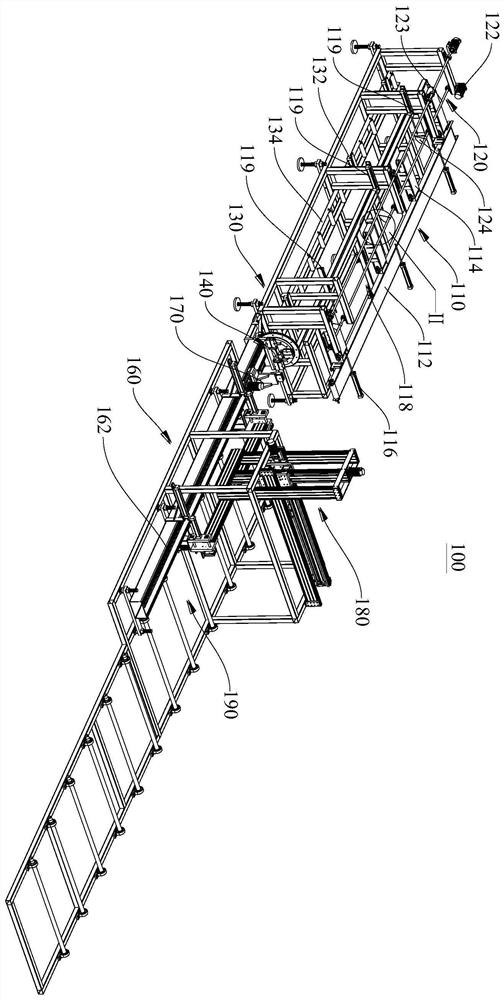

[0038] Please refer to figure 1 , figure 1 Shown is a schematic structural view of the packing machine 100 . This embodiment provides a packing machine 100 for packing specified components, which is easy to operate and has a high degree of automation. Compared with the existing packing machine, the packing machine 100 provided by the present invention has the advantages of convenient use, simple operation, high packing efficiency and firm packing.

[0039] The packing machine 100 mainly includes a conveying unit 110 , a packing auxiliary unit 120 and a packing unit 130 . The conveying component 110 is used for transporting the designated components stacked by the packaging auxiliary component 120 to the packaging component 130 for packaging. The baler 100 is equipped with a master controller, which is used to control the automatic operation of the whole baler 100 .

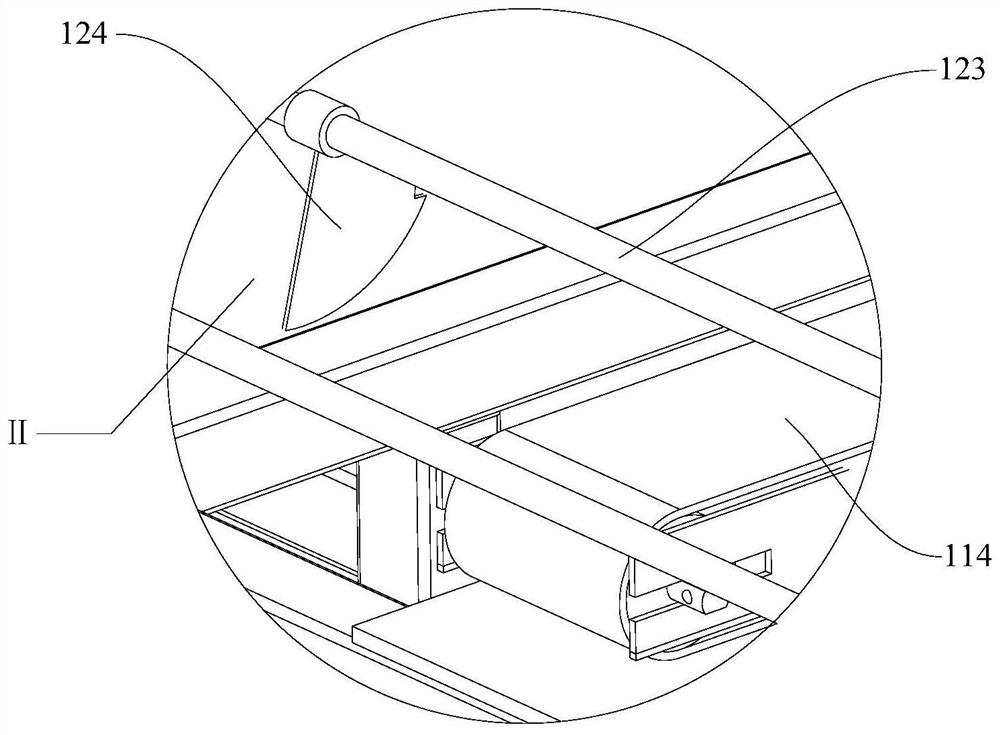

[0040] The conveying assembly 110 mainly includes a first conveying belt 112 , a second conveying belt 114 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com