Full-automatic rectification system for cloth plaiting and laying

A fully automatic cloth-spreading technology, which is applied in the field of rectifying system for cloth yarding and spreading, can solve the problems of unpressed cloth, cloth folded and fixed-length deviation, etc., and achieve the effect of stable work, compact structure and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

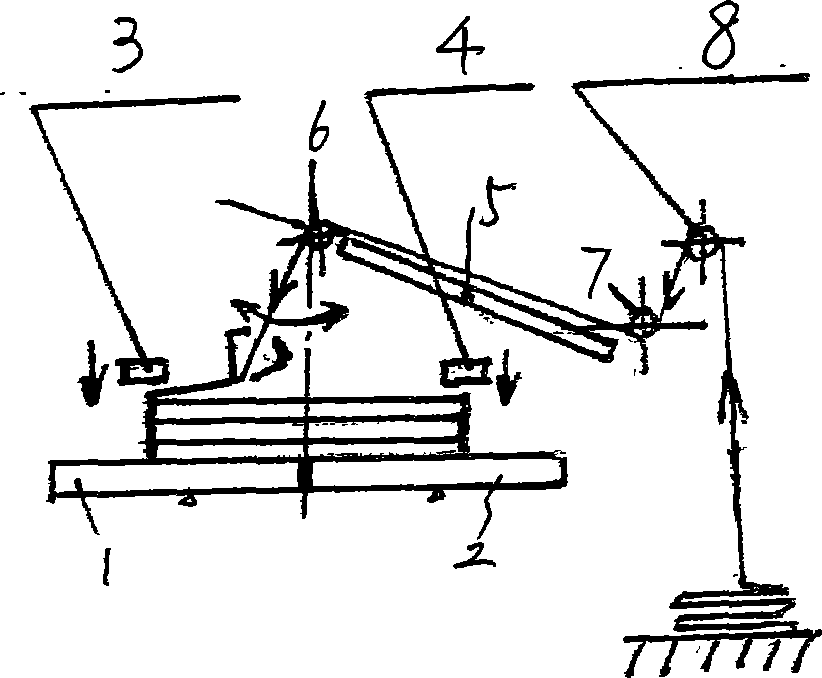

[0012] A fully automatic deviation-correcting system for cloth coding and spreading, comprising a cloth coder support table, front and rear cloth press plates 3, 4, cloth guide plate 5, front and rear cloth guide rollers 6, 7, the support table has two left and right Blocks 1 and 2, and the left and right pallets 1 and 2 are respectively provided with fulcrums that make the pallets in the form of slight movements. In the feeding direction of the cloth feeding side of the rear cloth guide roller, a supporting roller 8 is set to correct the deviation. The eccentricity of the central axis is realized.

Embodiment 2

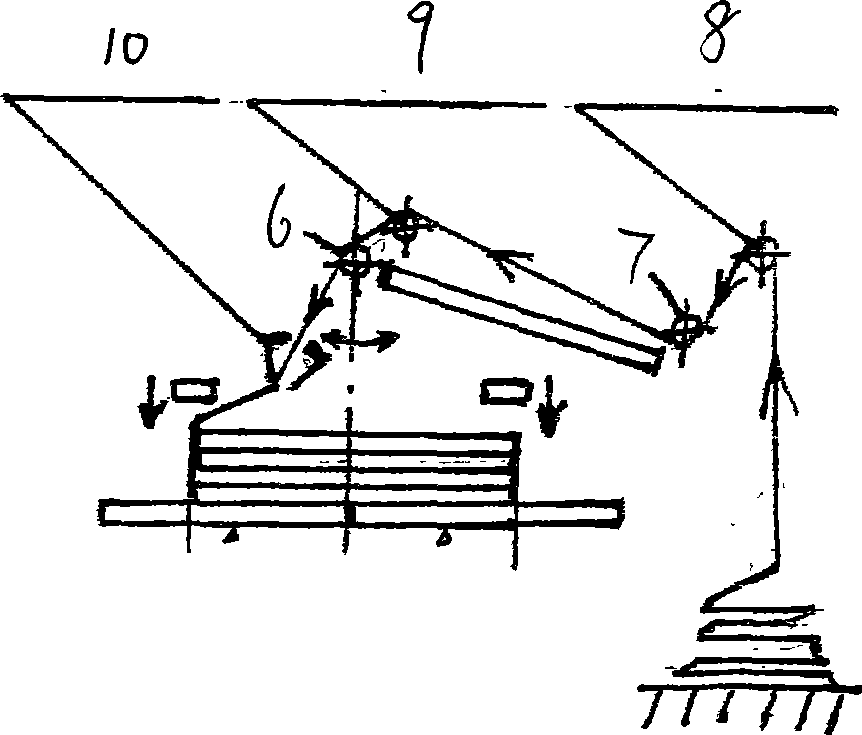

[0014] The supporting cloth roller of the present invention can be arranged side by side with a plurality of, reach coarse, fine centering deviation correcting function, for example between front and rear cloth guide roller, also be provided with the supporting cloth roller 9 that plays the deviation correcting effect. All the other are with embodiment 1. Also have code cloth knife 10 among the figure.

[0015] The invention can use PLC computer technology to collect various photoelectric signals in real time, and control code cloth (spreading) and deviation correction nodes through power transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com