Semi-fixed crushing station and arrangement method

A crushing station, semi-fixed technology, applied in the direction of grain processing, etc., can solve the problems of large impact on the safety of the chamber, difficult inspection and maintenance, etc., to achieve the effect of increasing ventilation, convenient inspection and maintenance, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

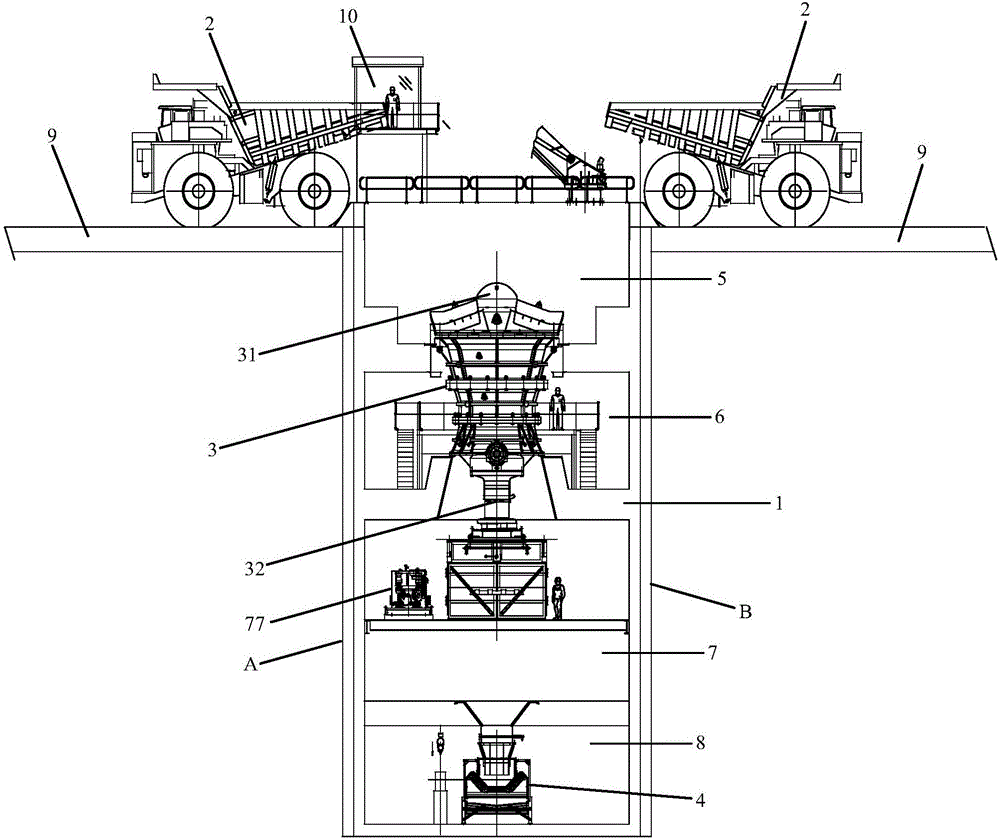

[0033] In order to solve the existing problems in the prior art of crusher equipment overhaul and maintenance, the safety of the chamber is greatly affected by the lithology of the rock, and a large number of supports are required, such as figure 1 As shown, the embodiment of the present invention provides a semi-fixed crushing station, which includes a crushing station foundation 1, a truck 2, a crusher 3 and a discharge belt 4;

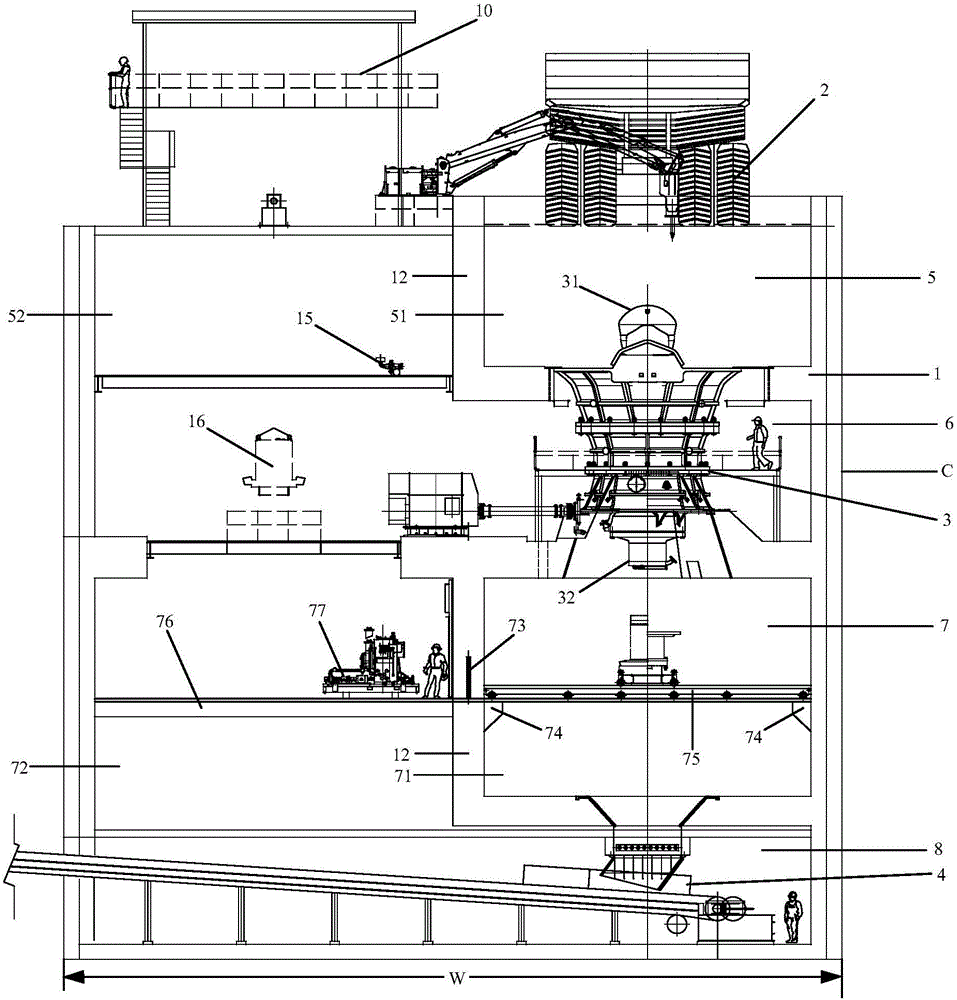

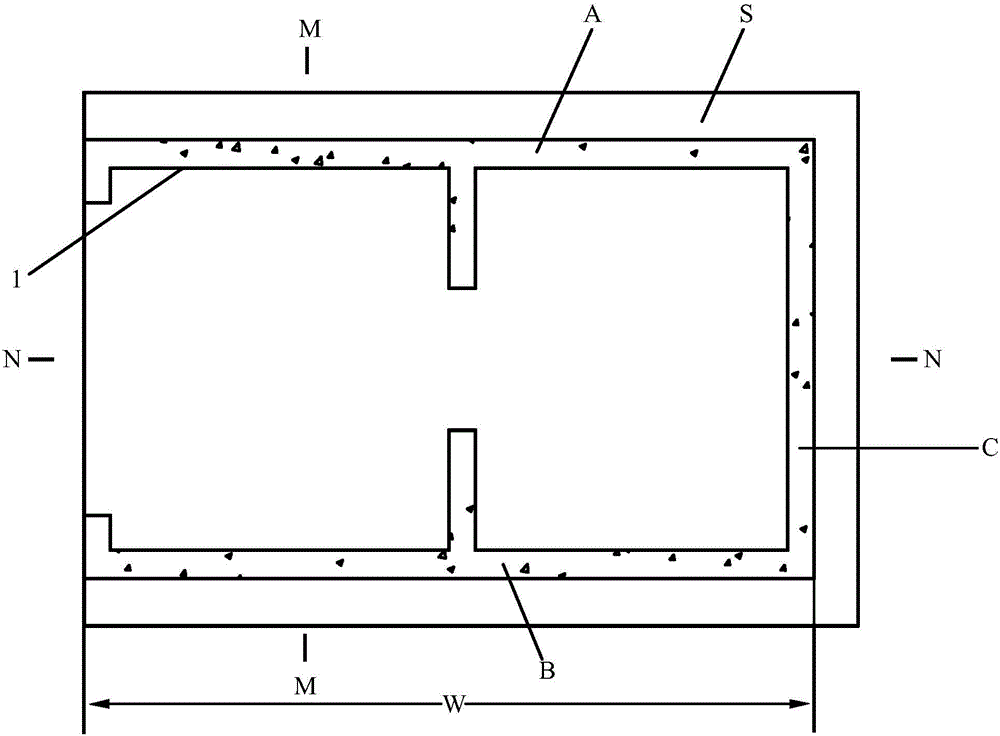

[0034] The foundation 1 of the crushing station includes three sides and the bottom surface, and the three sides and the bottom surface are arranged in the open-air slope, such as figure 1 shown, and see figure 2 and image 3 , in the embodiment of the present invention, the three sides of the crushing station foundation 1, namely side A, side B and side C are arranged in the open-air slope S, and the crushing station foundation 1 is divided into four layers from top to bottom, followed by the upper part The silo 5, the crusher silo 6, the lower ...

Embodiment 2

[0044] An embodiment of the present invention provides a method for arranging the semi-fixed crushing station in Embodiment 1, the method comprising:

[0045] Such as image 3 As shown, slotting is carried out on the open-air slope S, and reinforced concrete is arranged on the three sides and the bottom of the tank to form the foundation 1 of the crushing station. Reinforced concrete beams 11 can be used as the support of the foundation 1 of the crushing station, and reinforced concrete is used as The walls 12 on three sides of the crushing station foundation 1;

[0046] Such as Figure 4 As shown, steel plates or reinforced concrete are arranged in the foundation 1 of the crushing station to divide the foundation 1 of the crushing station into four layers, which are successively used as the upper bin 5, the crusher bin 6, the lower bin 7 and the belt bin 8 from top to bottom. Open a hole 13 on the steel plate or reinforced concrete between every two layers, so that every tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com