Electric power cable shearing device

A technology for a power cable and a cutting device, which is applied in the field of power equipment, can solve the problems of high hardness of the power cable or steel wire, inconvenient construction and operation, inconvenient cutting, etc., and achieves the effects of being convenient to carry, convenient for replacement and maintenance, and convenient for operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

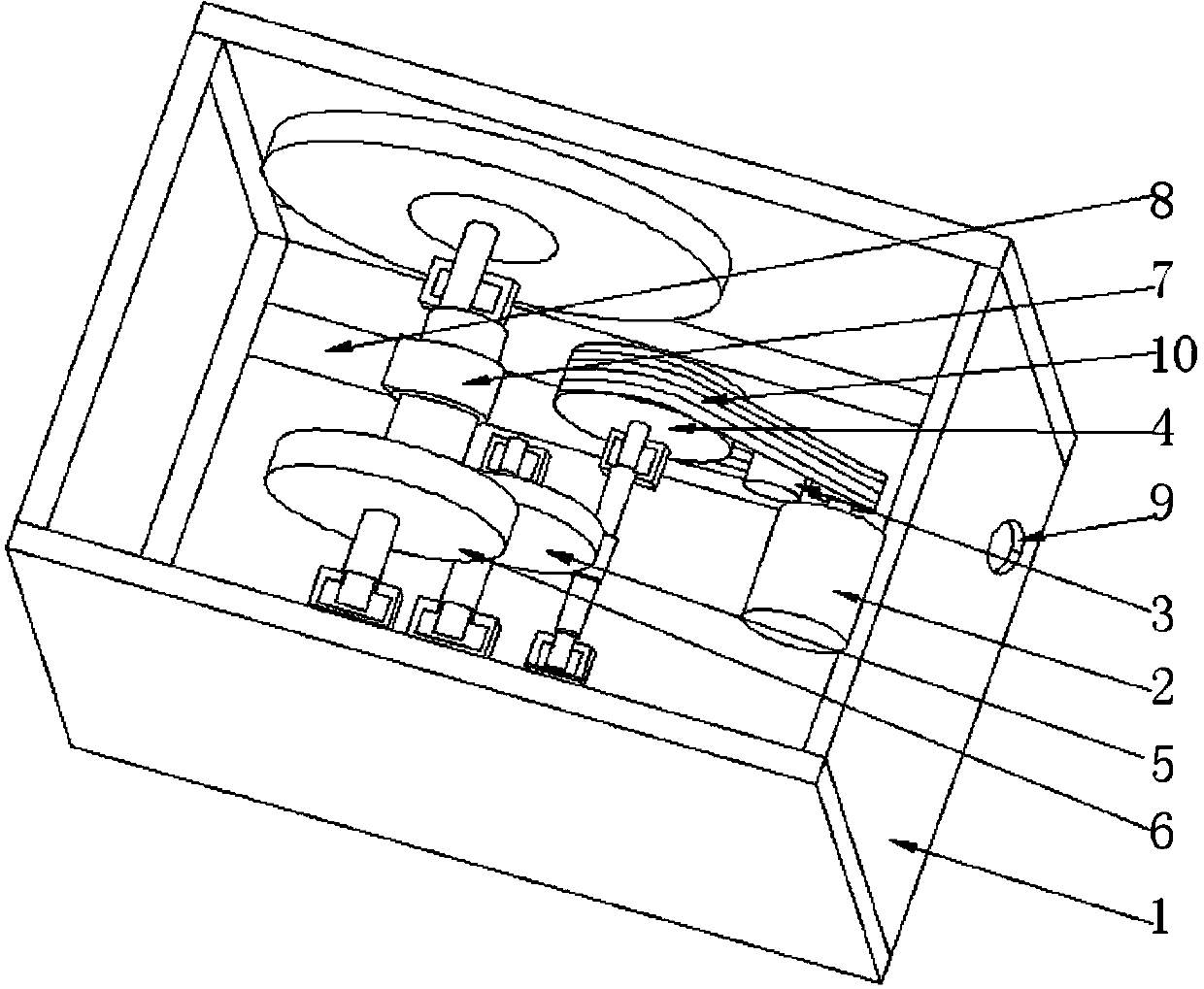

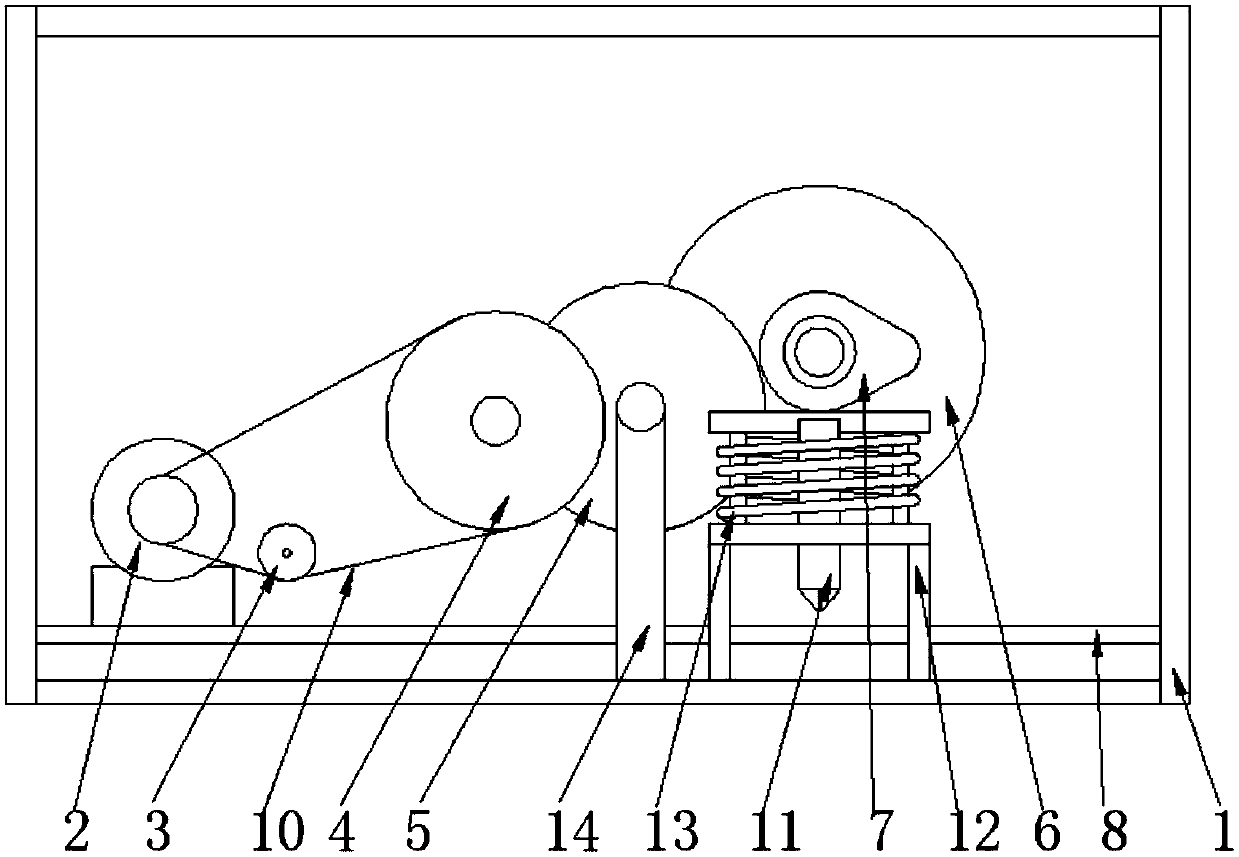

[0024] Such as figure 1 , figure 2 As shown, an electric power cable cutting device is mainly composed of a motor 1, a driven wheel 4, a small flywheel 5, a large flywheel 6, a cam 7, a cutter 11, and a cutter bracket 12. Between the motor 1 and the driven wheel 4 Connected by transmission belt 10, gears are provided on the shaft where the driven wheel 4 is located, and the small flywheel 5 is meshed with the gear on the shaft of the driven wheel 4, and gears are provided on the shaft where the small flywheel 5 is located, so The gear on the big flywheel 6 is meshed with the small flywheel 5 shaft, the cam 7 is located on the shaft where the big flywheel 6 is located, the upper end of the cutter 11 is connected with the upper part of the cutter holder 12, and the cutter holder 12 is located below the cam 7 , the tool holder 12 is provided with a spring 13 . When needed, the staff can place the power cable to be cut under the cutter, start the motor 2, and drive the driven w...

Embodiment 2

[0026] In order to better realize the present invention and facilitate adjustment of the tightness of the belt 10 , this embodiment further includes a tensioning wheel 3 on the basis of the first embodiment, and the tensioning wheel is located inside the belt 10 on the side close to the motor 2 . By setting the tensioning pulley 3, the tension force of the belt can be adjusted, so that the transmission system is stable, safe and reliable. Other parts of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0028] In order to better realize the present invention and facilitate the control of the trajectory of the power cable, this embodiment further includes a chute 8 on the basis of the embodiment 2, and the chute 8 is located below the cutter 11 . By setting the chute 8, the power cable can be placed inside the chute 8 for cutting operation, so as to prevent the power cable from being difficult to organize during the cutting process. Other parts of this embodiment are the same as those of Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com