Stone conveying mechanism in tunnel drilling and blasting engineering

A drilling and blasting and engineering technology, applied to conveyors, underground transportation, mechanical conveyors, etc., can solve problems such as difficulty in ventilation and smoke exhaust, time-consuming and labor-intensive outward transportation, and affecting the speed of stone loading and transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

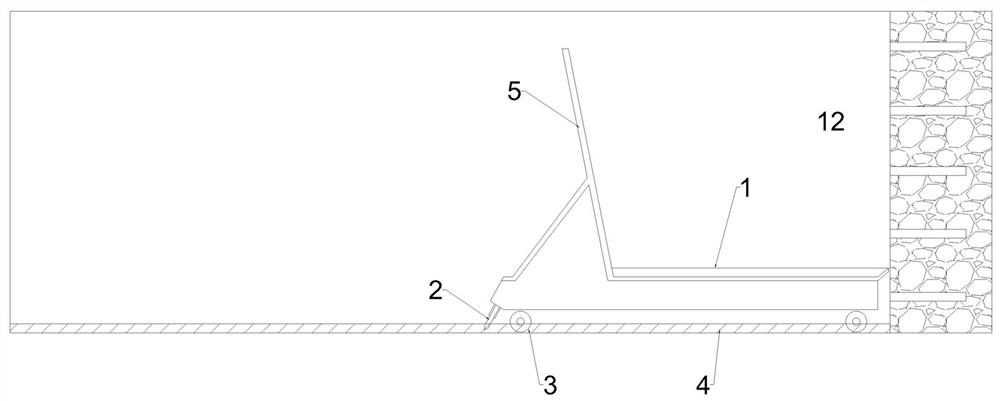

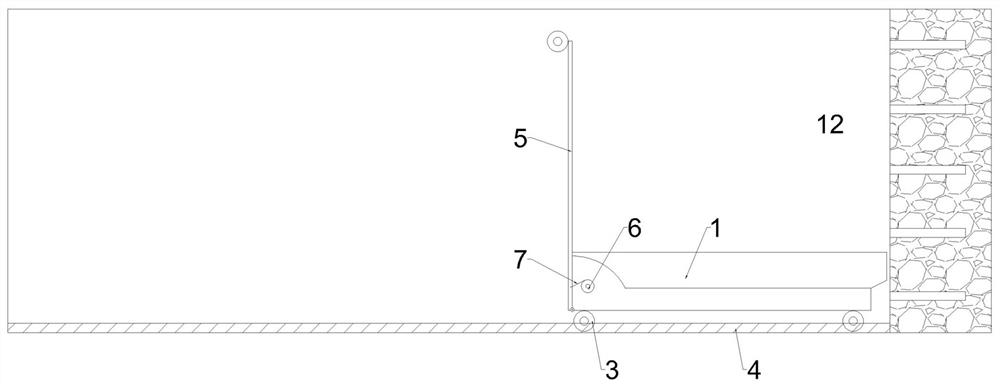

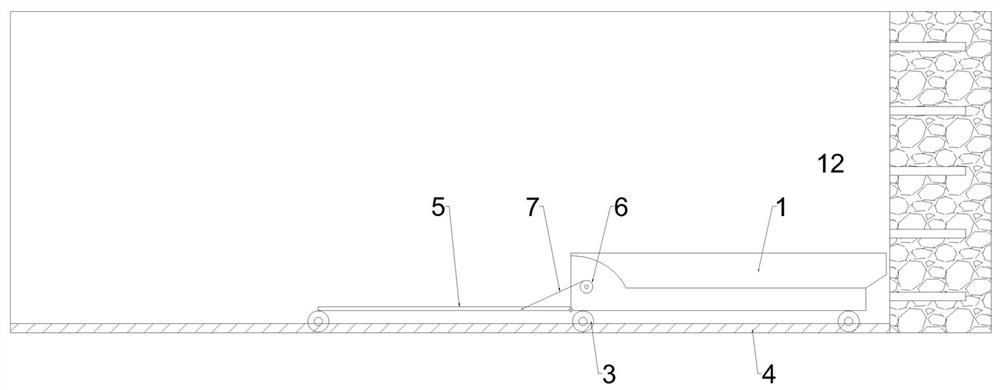

[0018] refer to figure 1 As shown, a stone transportation mechanism in a tunnel drilling and blasting project provided by Embodiment 1 of the present invention includes a transport vehicle, and the transport vehicle is arranged on a track 4. The transport vehicle includes a bucket 1 and wheels 3. Behind the bucket 1 The end is provided with a telescopic oblique support rod 2, and the oblique support rod 2 is equipped with a spiral telescopic drive mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com