Bagged material loading machine

A loader and material technology, which is applied in the stacking, transportation and packaging, loading/unloading of objects, etc., can solve the problems of low loading efficiency, easy deformation and damage of material bags, and great harm to human body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

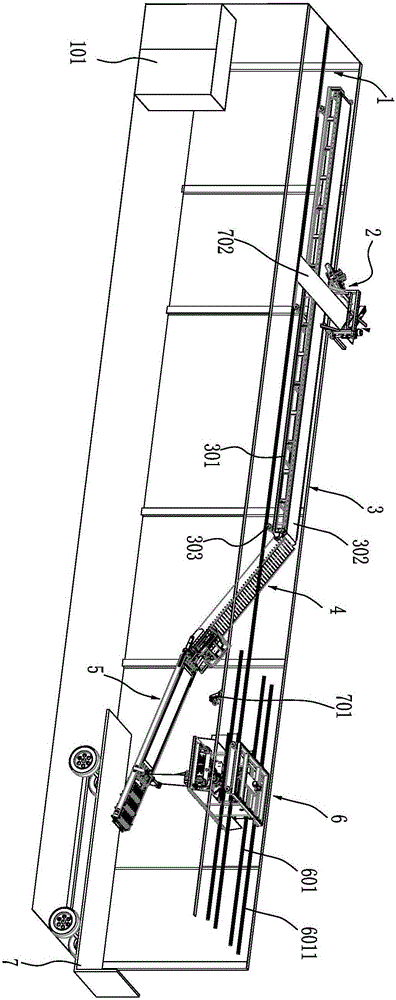

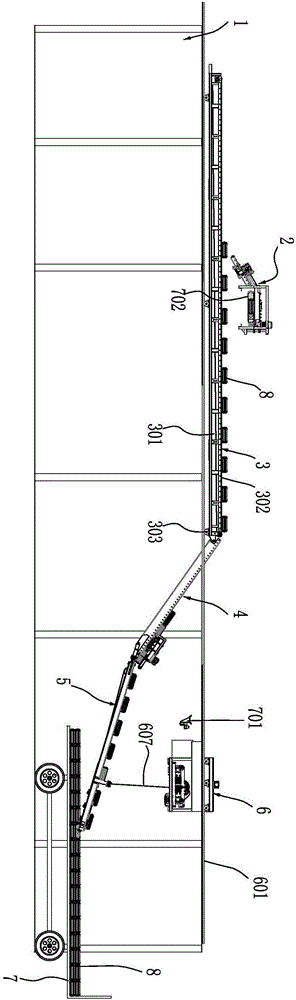

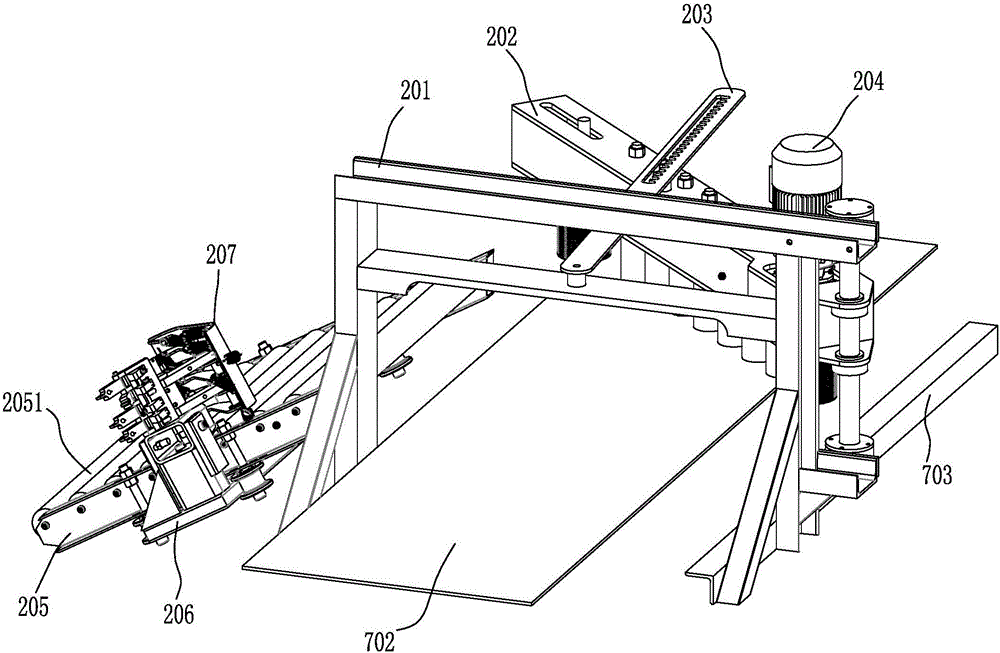

[0054] Such as figure 1 and figure 2 As shown, the bagged material loading machine includes a bracket 1 and a controller 101. The bracket 1 can be made of steel frame or concrete material, and a material bag conveying device 3 is movable on the bracket 1. A mobile drive device is provided between the bracket 1 and the bag conveying device 3; a bag transfer device 2 is provided above the bag conveying device 3, and the output end of the bag conveying device 3 is connected with a bag buffer Device 4, the output end of the material bag buffer device 4 is connected with a material bag delivery palletizing device 5, and the top of the material bag delivery palletizing device 5 is provided with a delivery palletizing adjustment device 6, and the delivery palletizing adjustment device 6 Connect the material bag delivery palletizing device 5 . The controller 101 connects and controls the work of each part of the material bag transfer device 2, the material bag conveying device 3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com