Metal powder preparation method and device based on DC (Direct Current) resistance heating non-contact smelting

A metal powder, non-contact technology, applied in the field of gas atomization, can solve the problems of unable to stably control the flow rate of molten metal, and cannot meet the needs of industrial production, so as to facilitate real-time measurement and monitoring, reduce heating burden, and improve feeding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for preparing metal powder based on direct resistance heating non-contact smelting, comprising the following steps:

[0053] Step 1: Make one end of the metal rod pass through the electrified graphite area at a constant speed.

[0054] Step 2: the metal rod is heated and melted in the electrified graphite region.

[0055] Step 3: The molten metal continuously forms metal droplets under the action of gravity.

[0056] Step 4: The metal liquid droplets continuously drop into the gas atomization area.

[0057] Step 5: The high-pressure and high-speed inert gas breaks up the metal droplets in the gas atomization area.

[0058] Step 6: The metal droplets are broken up by the impact and then cooled to form metal powder.

[0059] All the above steps are usually carried out under vacuum conditions, because usually metals can chemically react with certain components in the air, and the components change.

[0060] The above method is suitable for the production of meta...

Embodiment 2

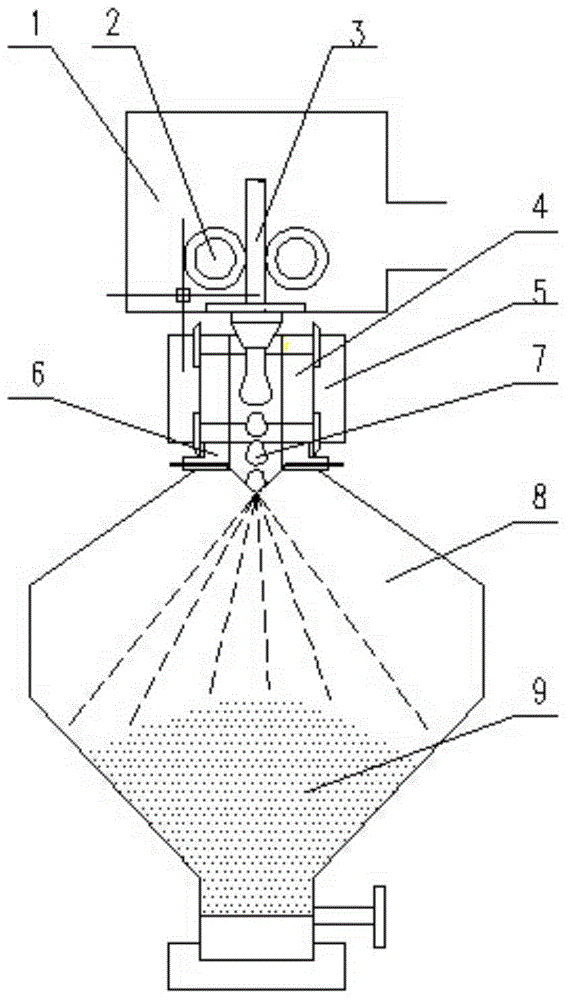

[0064] A metal powder preparation device based on direct resistance heating non-contact smelting, Such as figure 1 shown, including:

[0065] A vacuum chamber 1, the vacuum chamber 1 is provided with an air extraction port and an outlet of the metal rod 3, and the air extraction port is connected to a vacuum extraction device;

[0066] A pair of rollers 2 arranged in the vacuum chamber 1, the axes of the two rollers 2 are parallel, the rotation directions of the two rollers 2 are opposite, and the rotation surface between the two rollers 2 The gap matches the diameter of the metal rod 3; the gap between the rotating surfaces of the two rollers 2 communicates with the outlet of the metal rod 3;

[0067] Both ends are provided with open graphite tubes 4, one end of the graphite tube 4 is connected to the outlet of the metal rod 3, and the other end is connected to the gas atomization nozzle 6 and the powder collector 8 in sequence;

[0068] The exterior of the graphite tube...

Embodiment 3

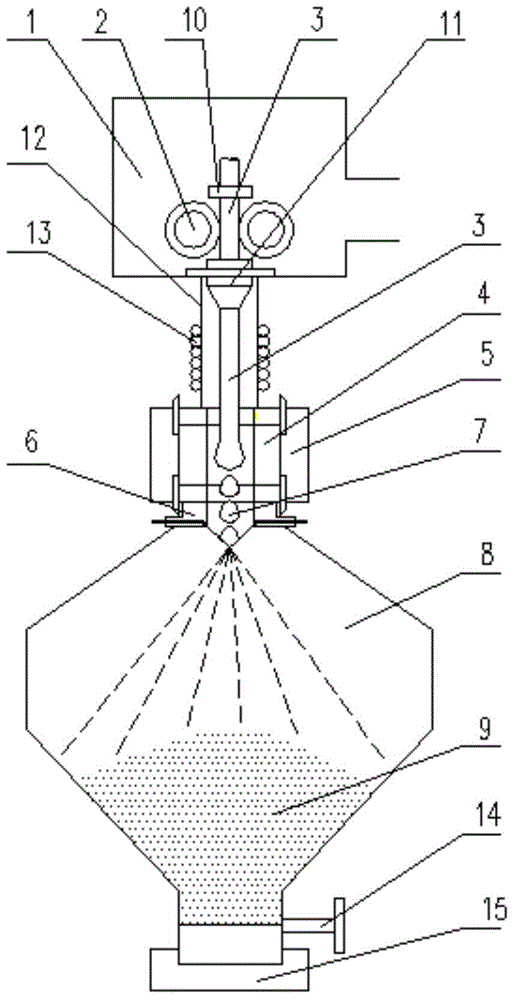

[0075] A metal powder preparation device based on direct resistance heating non-contact melting, such as figure 2 shown, including:

[0076] The vacuum chamber 1 is provided with an air suction port and an outlet of the metal rod 3, and the air suction port is connected with a vacuum suction device.

[0077] The vacuum chamber 1 is provided with a feed guide sleeve 10, a discharge guide sleeve 11 and a pair of rollers 2. The axes of the two rollers 2 are parallel, the rotation directions of the two rollers 2 are opposite, and the rotation surfaces of the two rollers 2 The gap between them matches the diameter of the metal rod 3; the axes of the feed guide sleeve 10, the discharge guide sleeve 11 and the quartz glass tube 12 are collinear; The gap between the material guide sleeve 10, the two rollers 2, the discharge guide sleeve 11 and the outlet of the metal rod 3.

[0078] A quartz glass tube 12 with a coil 13 wound outside, one end of the quartz glass tube 12 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com