High-efficiency waste paper recycling and packaging machine

A high-efficiency, waste paper technology, applied in packaging and other directions, can solve the problems of damage to the bottom of the recycling box, difficult removal of waste paper, and impact on discharge efficiency, so as to reduce waste paper residue, improve packaging efficiency, and improve feeding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

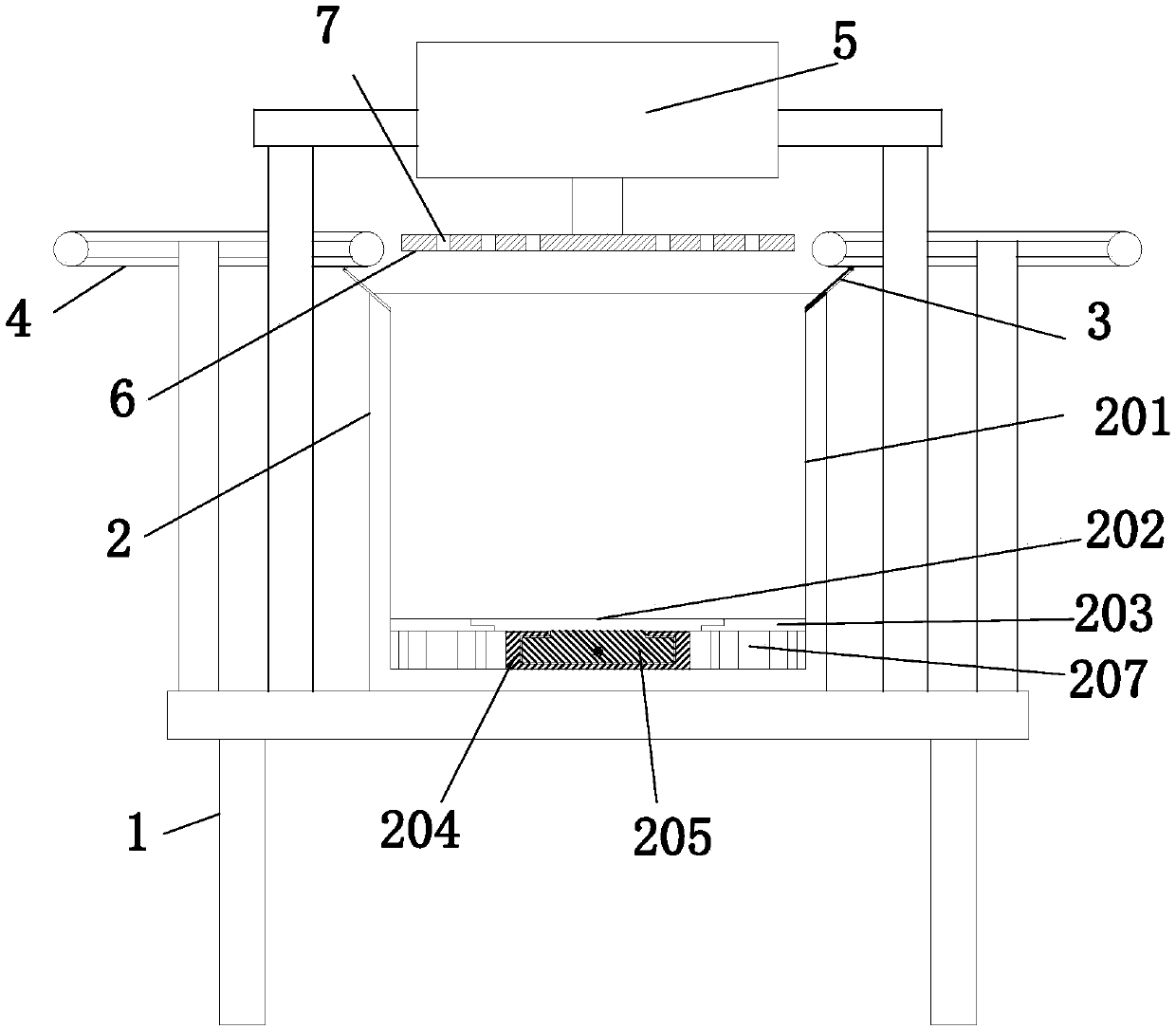

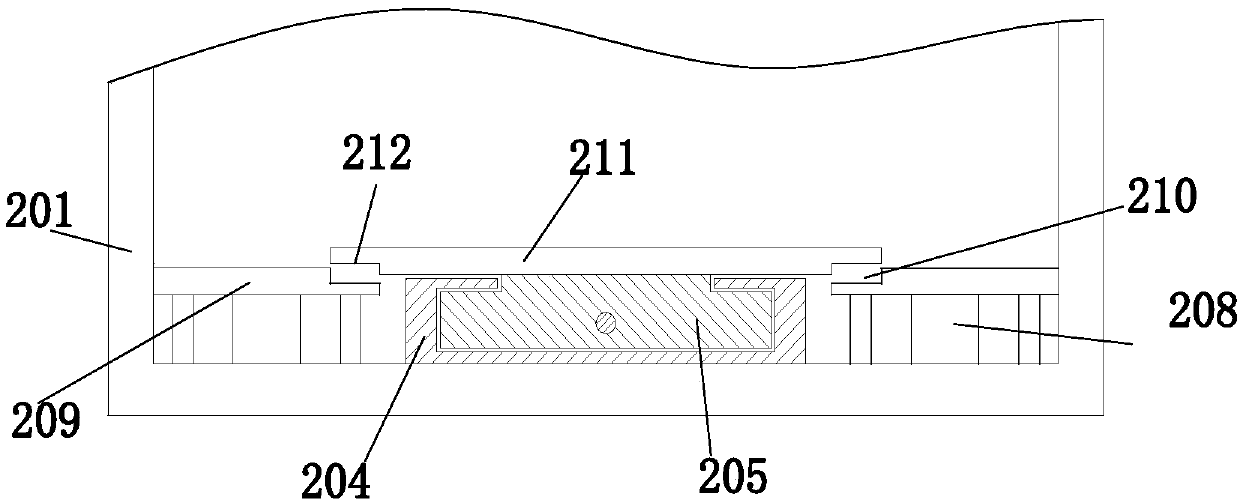

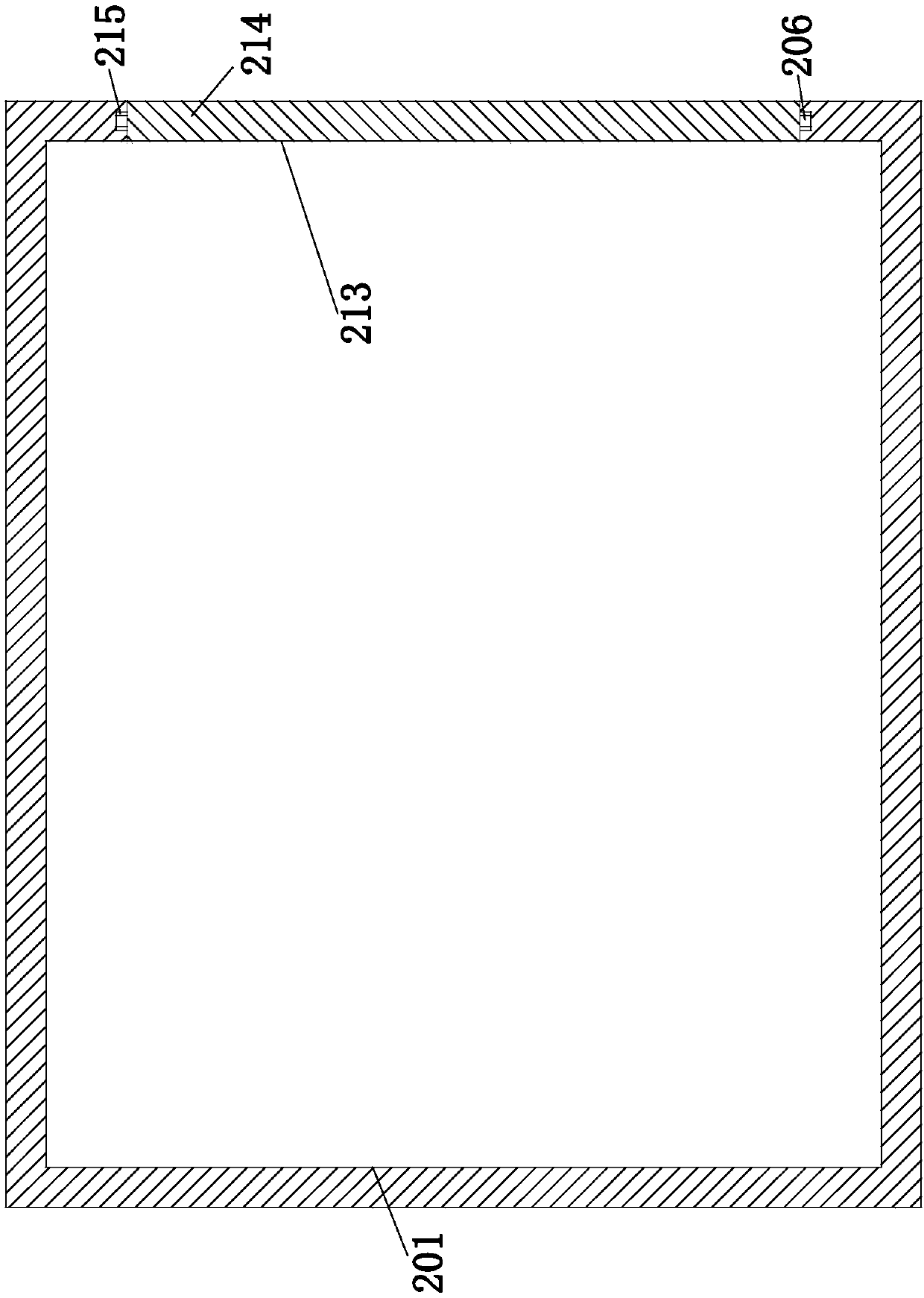

[0018] Example. A high-efficiency waste paper recycling baler is composed of Figure 1 to Figure 4 As shown, it includes a frame 1, a recovery box 2 is arranged above the frame 1, a material guide plate 3 is provided at both ends above the recovery box 2, a waste paper conveying mechanism 4 is arranged above the material guide plate 3, and a waste paper conveying mechanism 4 is arranged above the recovery box 2. The middle part is provided with a hydraulic cylinder 5 fixed on the frame 1, and the output end of the hydraulic cylinder 5 is provided with an extrusion plate 6 corresponding to the recovery box 2; The movable support plate 202 and lifting support plate 203 that block is alternately distributed, the bottom of movable support plate 202 is provided with slide rail 204, and slide rail 204 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com