Feeding device for outer packages of powder medicine bags

A feeding device and outer packaging technology, which is applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of small weight and volume of acaffeol powder, easily broken packaging bags, time-consuming and labor-intensive, etc., to reduce manual participation, Improve feeding efficiency and facilitate stacking and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

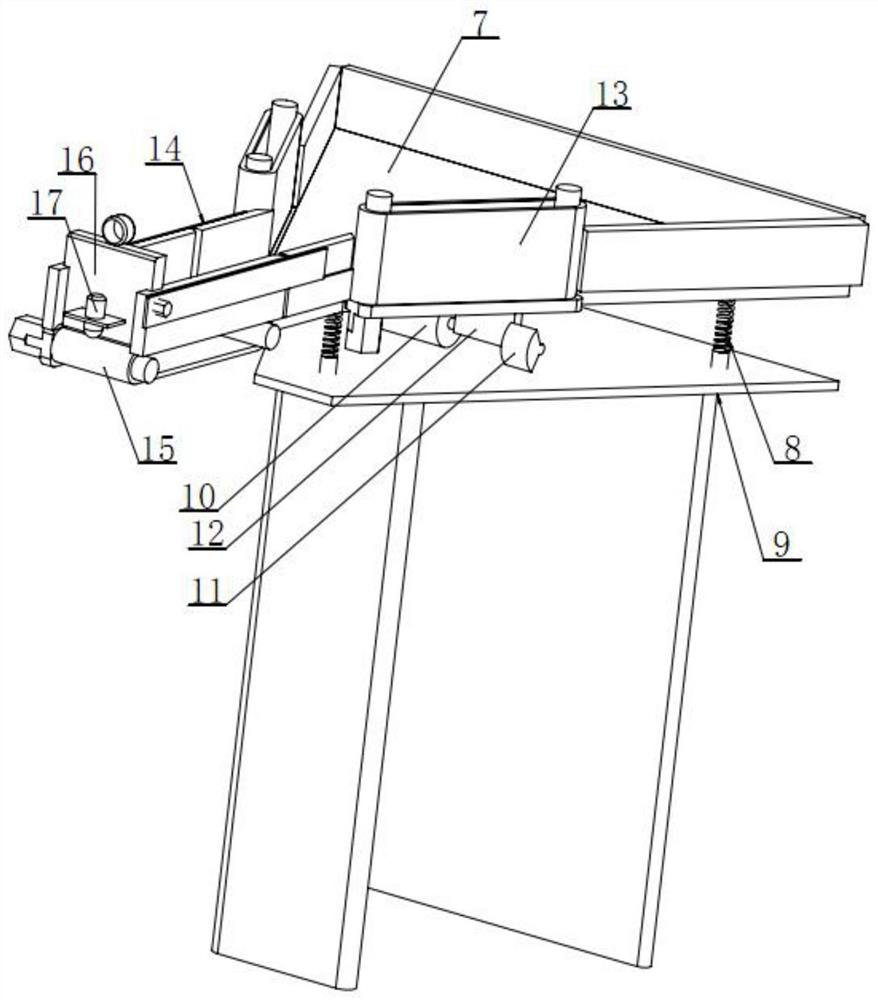

[0024] Embodiment 1: as Figure 1-10 As shown, a feeding device for the outer packaging of powder medicine bags includes a hopper 7, a spring 8 and a vibration drive mechanism. The hopper 7 is a horizontal V-shaped closing structure, and the bottom passes through multiple (4, symmetrical Arranged on both sides) The spring 8 is connected to the feeding frame 9, and the bottom is also equipped with a vibration drive mechanism. The bottom of the hopper 7 is a slope structure of 1-5°, and the feeding frame 9 is installed on the bottom plate. Makes it easier for the medicine bags to start pooling.

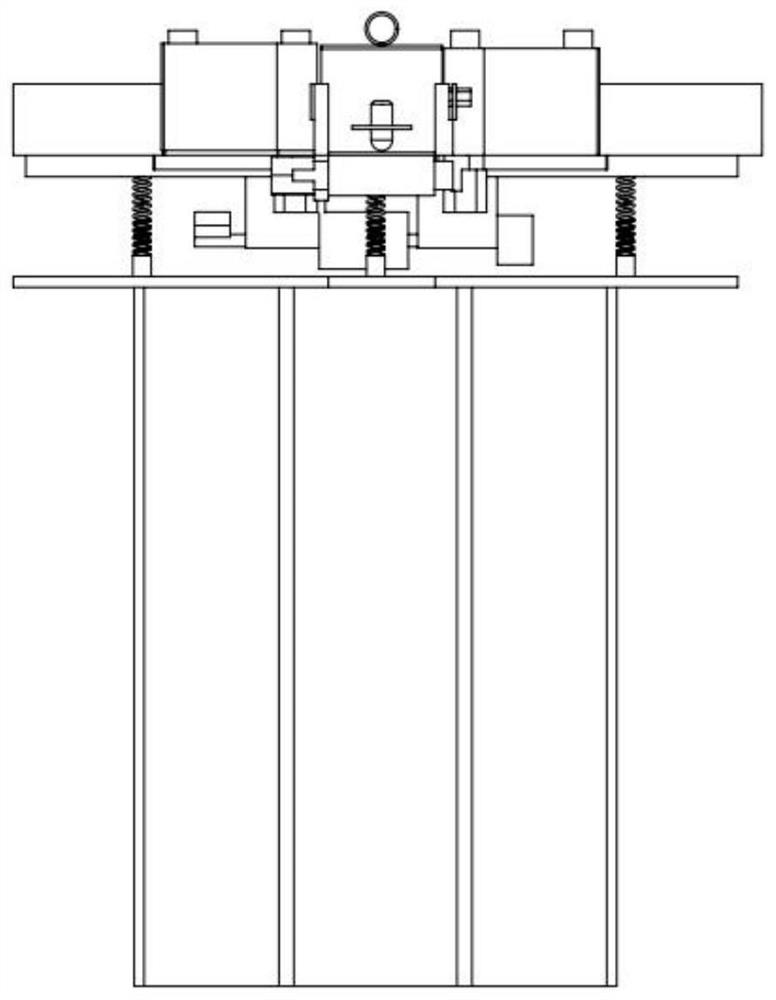

[0025] Preferably, the vibration driving mechanism includes a biaxial drive motor 10 and a sector block 11, the biaxial drive motor 10 is fixedly connected to the bottom of the hopper 7, and two sector blocks 11 are respectively fixedly connected to the two ends of the biaxial drive motor 10, Two fan-shaped blocks 11 are arranged staggered by 90 degrees, and the biaxial rotation of the...

Embodiment 2

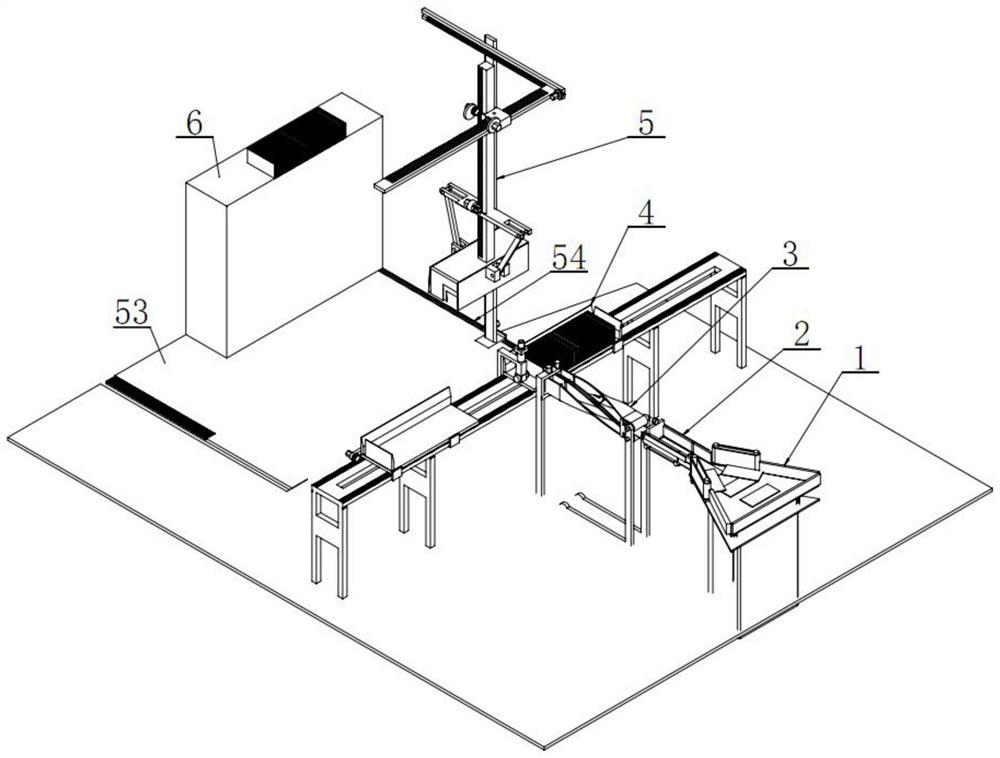

[0028] Embodiment 2: as Figure 1-10 As shown, a device for outer packaging of powder pharmaceutical bags, including a feeding device 1, a sorting device 2, a 90-degree turning device 3, a stacking device 4, and a grabbing device 5, the outlet of the feeding device 1 is equipped with a sorting Device 2, the discharge port of the sorting device 2 is connected to the feed port of the 90-degree turning device 3, the discharge port of the 90-degree turning device 3 is connected to the stacking device 4, and the grabbing device 5 is installed beside the stacking device 4 and can grasp Take the stacked powder bags and move them to the packaging table 6, pour the powder medicine bags filled with powder into the feeding device through the feeding device, and the feeding device pushes them into the sorting device to transport the powder medicine bags one by one to the 90-degree turning device, the 90-degree turning device sends the powder drug bag turned 90 degrees into the stacking de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com