Lithium battery cell matching device

A technology of lithium batteries and batteries, which is applied in the field of automation, can solve problems such as the inability to achieve absolute consistency in size and capacity, and the large fluctuation range of module length and capacity, so as to reduce manpower consumption and prevent collisions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

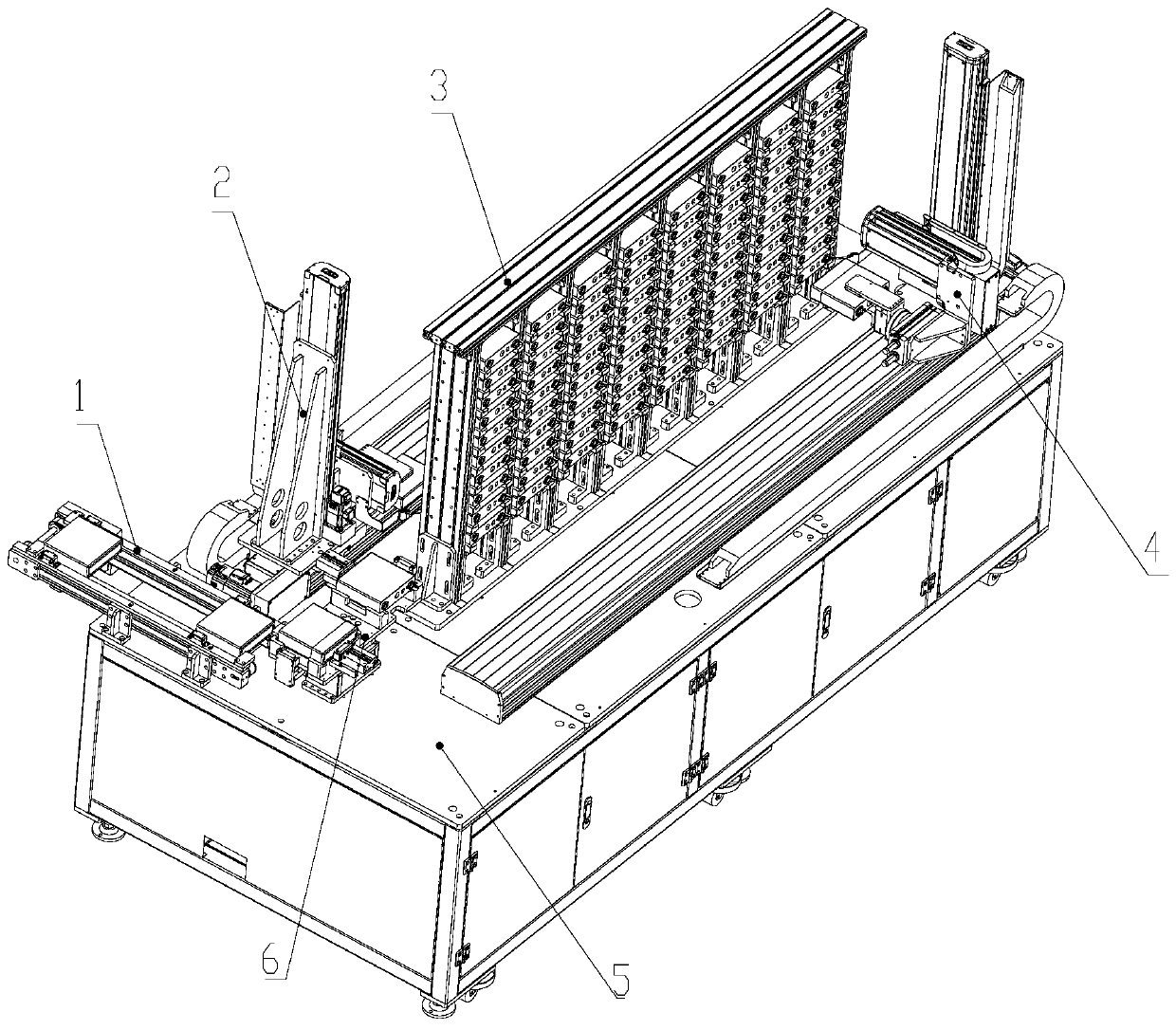

[0025] Example: such as figure 1 As shown, a lithium battery cell assembly equipment includes a workbench 5, on which a cache rack 3 for placing the battery cells is arranged, and on both sides of the buffer rack 3 are respectively provided storage and take-out racks for transporting the battery cells. The material mechanism 2 and the out-of-warehouse reclaiming mechanism 4 are provided with a transfer platform 6 on one side of the in-store and reclaimer mechanism 2, and an abnormal output line 1 is provided on the side of the transfer table 6.

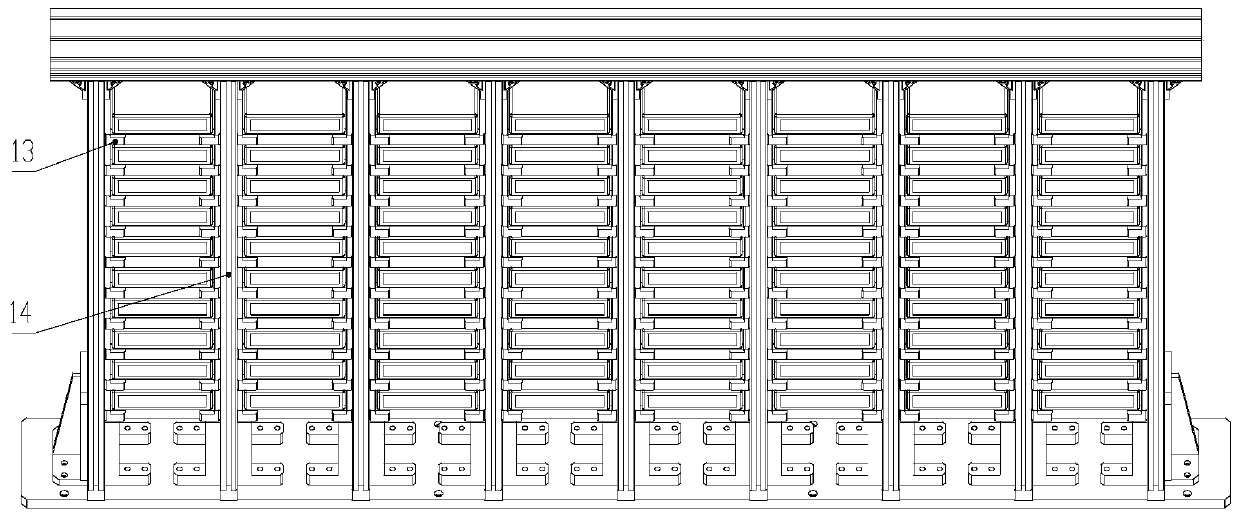

[0026] Cache shelf 3: such as image 3 As shown, it includes a first aluminum profile frame 14, and the first aluminum profile frame 14 is provided with a first cell fixture 13 for storing batteries; the middle part of the first aluminum profile frame 14 is a vertically uniformly arranged support, The first cell fixtures 13 arranged evenly up and down are arranged between the two supports.

[0027] The buffer rack 3 is a station for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com