Briquette clamp for cylindrical briquettes

A technology of cylindrical blanks and blanks, applied in the directions of manipulators, presses, manufacturing tools, etc., can solve the problems of unfavorable direct reduced iron mechanization, automation and large-scale production, uneven quality of direct reduced iron, inconsistent uniformity, etc. problem, to achieve the effect of simple structure, convenient operation and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

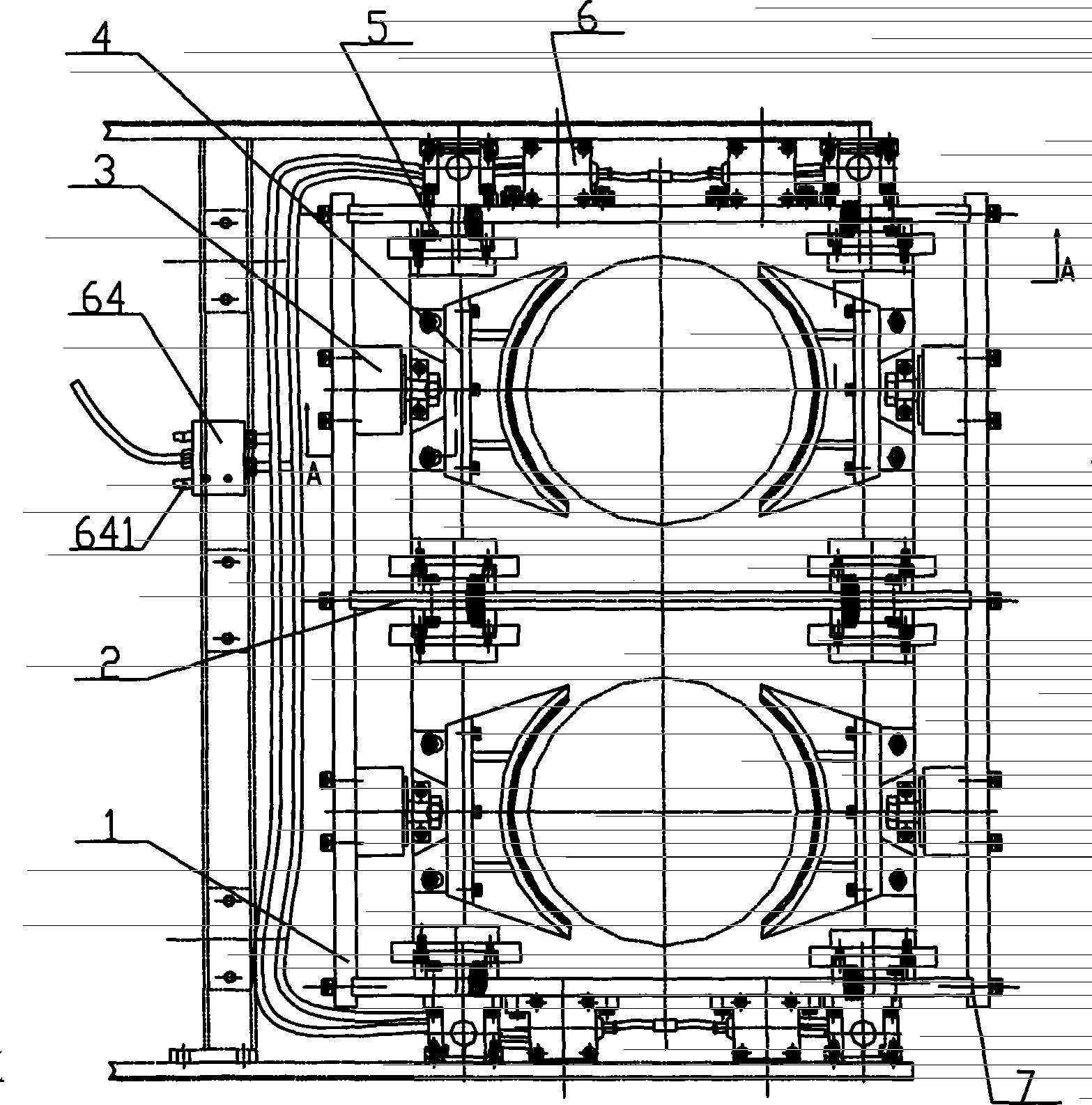

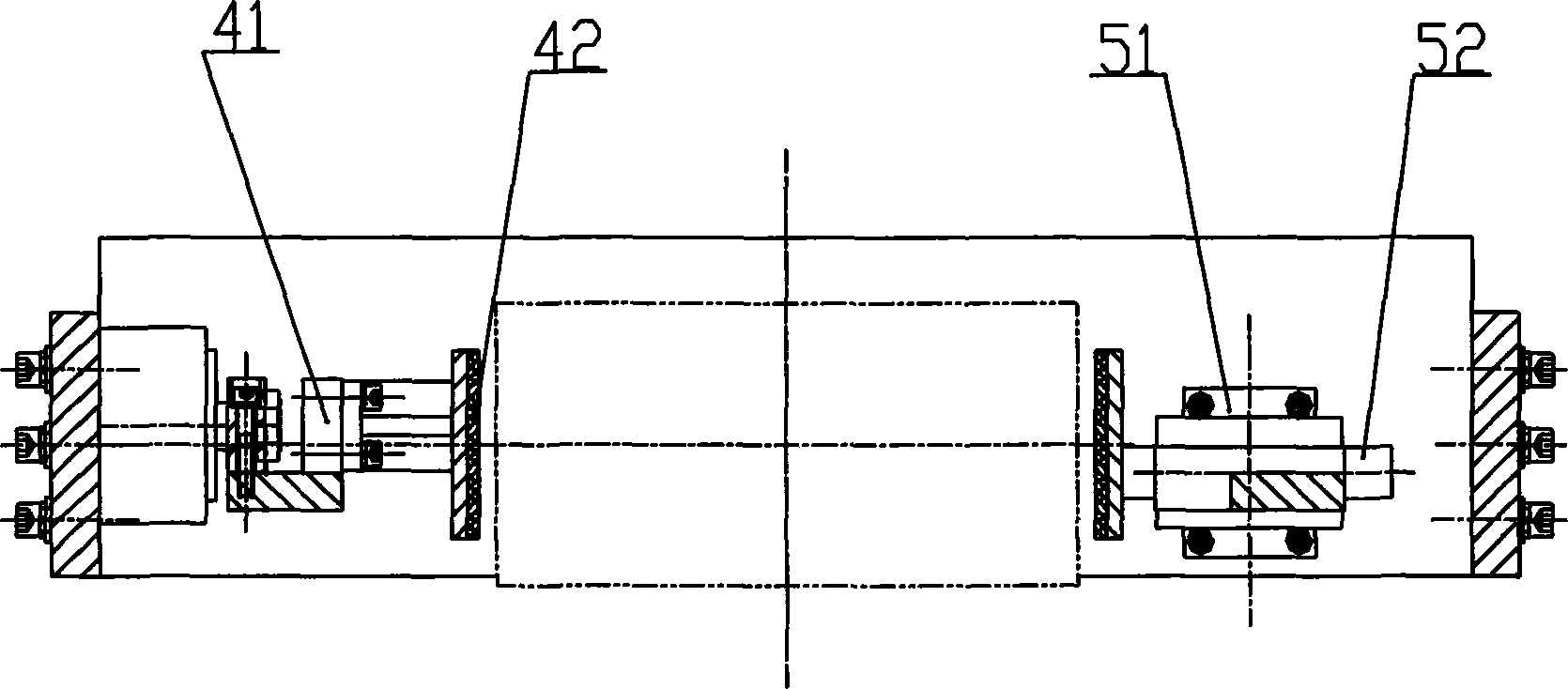

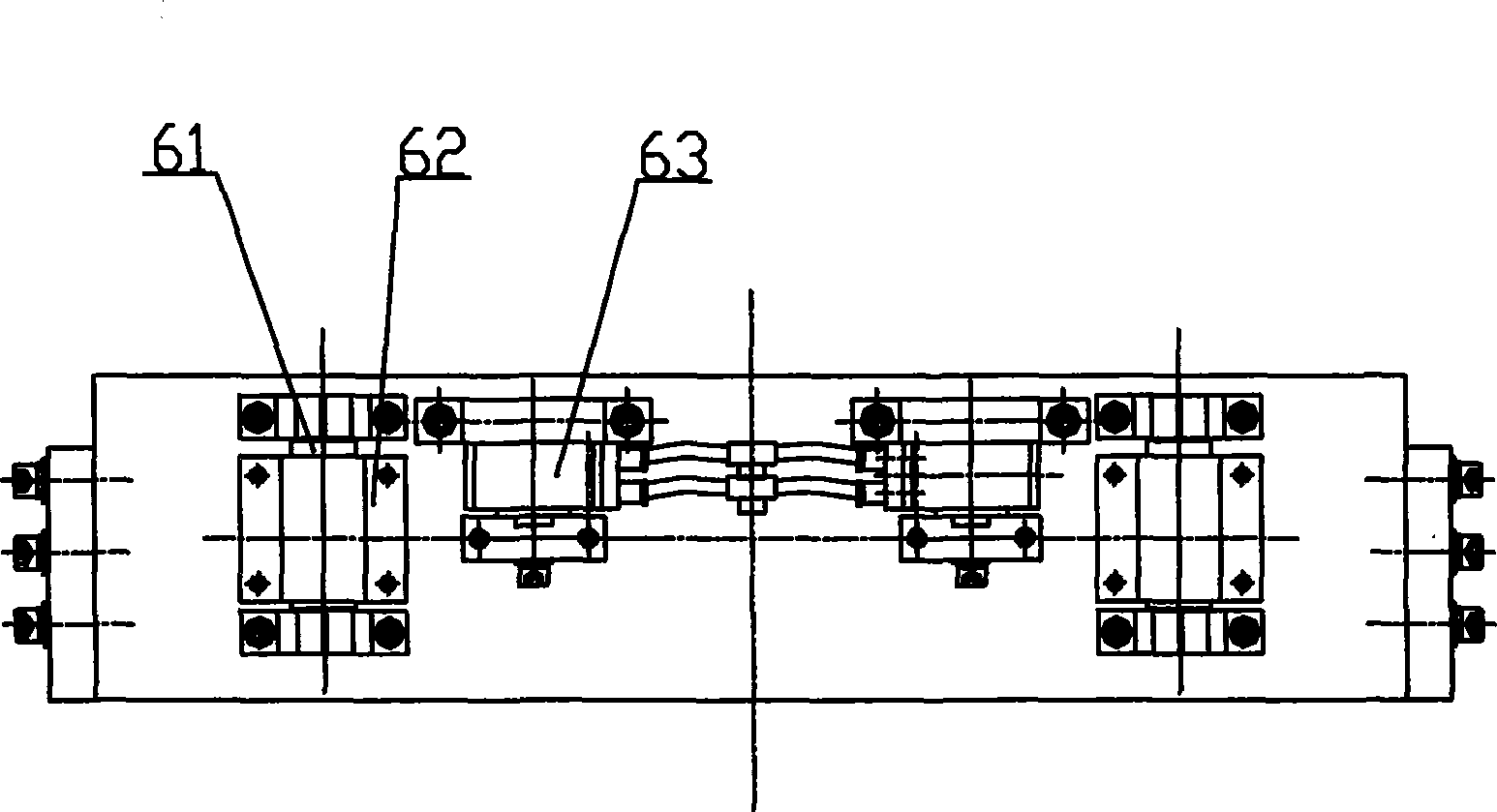

[0020] refer to figure 1 with figure 2 , a blank holder for a cylindrical billet, comprising two positioning plates (1) and a plurality of support plates (2), the plurality of support plates (2) are vertically fixed and installed with the two positioning plates (1) according to a certain distance , combined into a clamping frame (7), which is characterized in that: it also includes a driving device (3), a clamping hand (4), a guiding device (5) and a lifting mechanism (6), and the clamping hands (4) are distributed in pairs, The driving device (3) and the guiding device (5) are respectively connected with the clamping blank frame (7), and the lifting mechanism (6) is installed on the support plate (2) outside the clamping blank frame (7). Gripper (4) comprises clamping bracket (41) and clamping surface (42), and clamping surface (42) has the arcuate surface that adapts to cylindrical blank external shape, and clamping surface (42) is a kind of Elastic and wear-resistant rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com