Sorting system

A sorting system and conveying device technology, applied in sorting and other directions, can solve the problems of one-to-two sorting with few flow directions, unable to meet the cost saving, optimized resource utilization, unable to meet the requirements of multi-flow sorting, etc. The effect of labor intensity and multiple sorting flows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

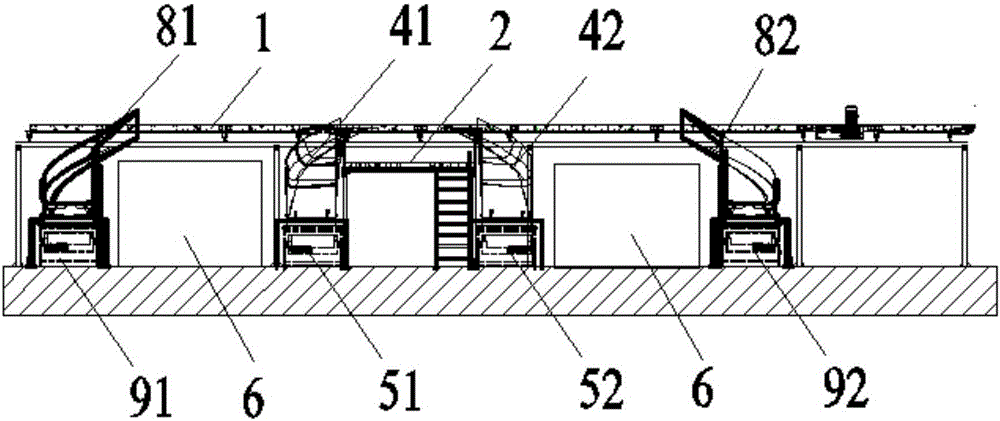

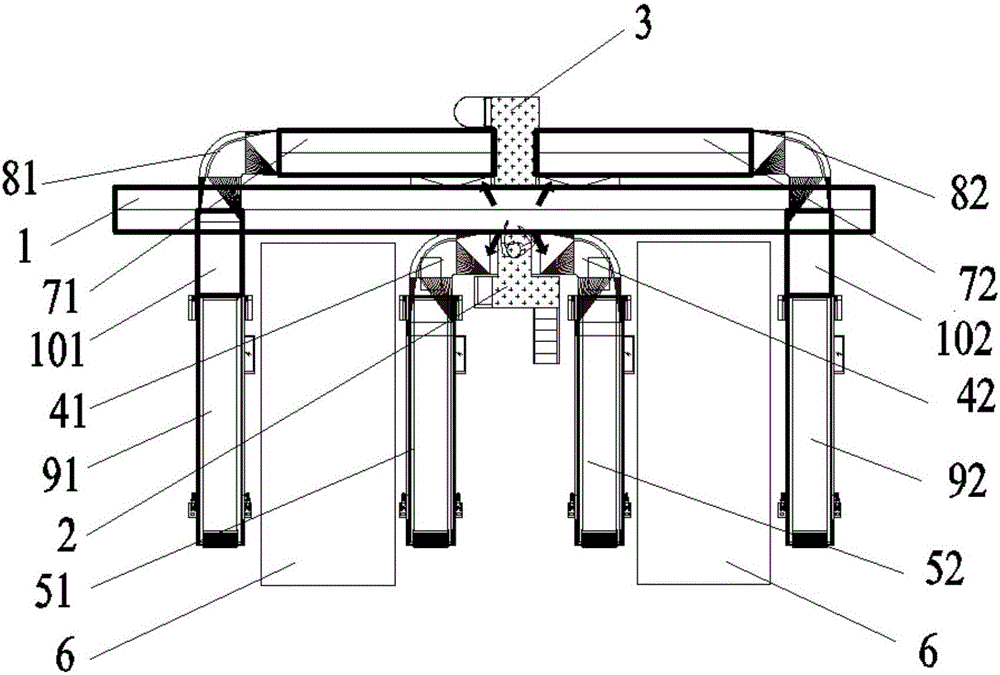

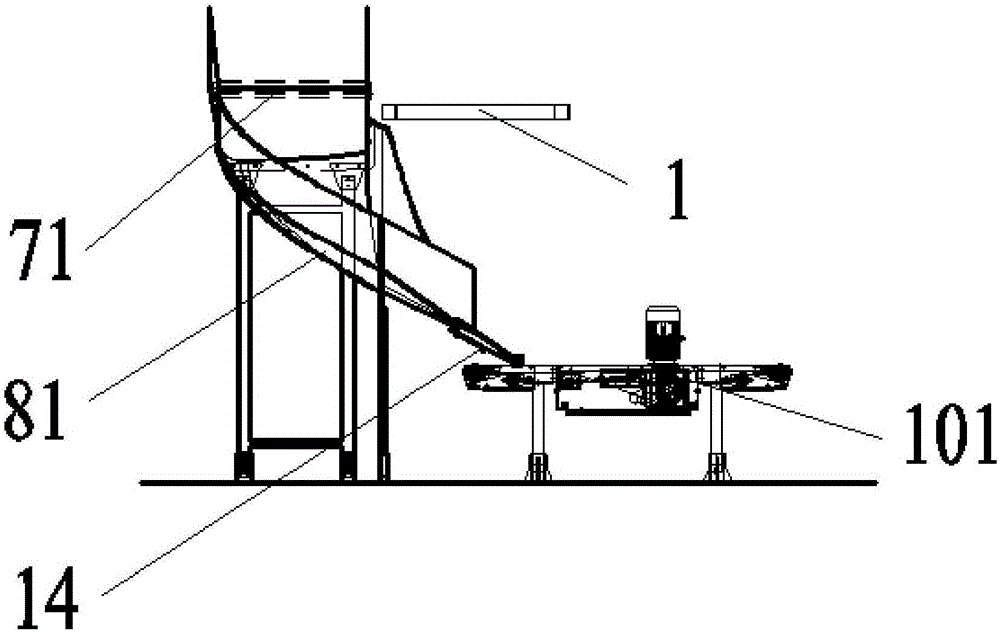

[0034] refer to Figure 1 to Figure 3 , the present embodiment provides a sorting system, including a main express conveying device 1, a main operating platform 2 and an auxiliary operating platform 3;

[0035] The main operation platform 2 is arranged on one side of the main express delivery device 1, and the auxiliary operation platform 3 is arranged on the other side of the main express delivery device 1;

[0036] Both sides of the main operating platform 2 are respectively provided with main sorting chutes or main sorting drums, one side is respectively the main sorting chute or main sorting drum 41, and the other side is the main sorting chute or main sorting drum 41 respectively. The main sorting drum 42, the main sorting chute or the express mail slide-out end of the main sorting drum 41 is provided with a main loading conveyor 51, and the main sorting chute or the express mail slide-out end of the main sorting drum 42 is provided with a main Loading conveying device 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com