Device for manufacturing bubble bag

A technology of bubble bag and film device, which is applied in the direction of container manufacturing machinery, rigid/semi-rigid container manufacturing, packaging, etc., which can solve the problems of a large amount of material or manpower, unfavorable production efficiency, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

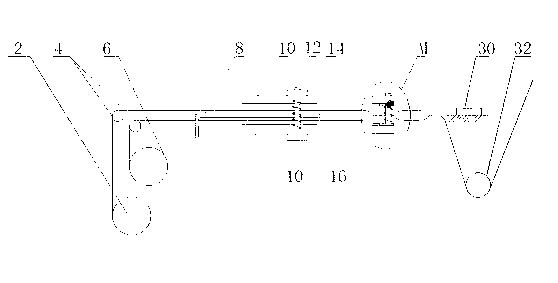

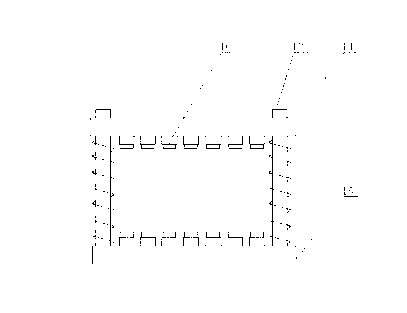

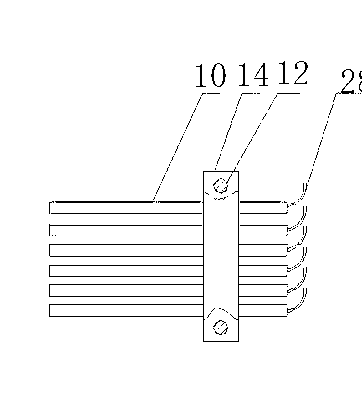

[0032] like figure 1 As shown, the present invention is sequentially connected with an upper film and a lower film release device capable of outputting each other, a lateral edge sealing device including a plurality of horizontally arranged and liftable first heating blocks 10, and an air supply device that can inflate the bubble bag. The device, the longitudinal edge banding device comprising at least one longitudinally arranged and liftable second heating block 18 and at least one longitudinally arranged and liftable incision device. The film release device includes an upper film roller 6 and a lower film roller 2, and a film guide roller 4 is also arranged between the upper film roller 6, the lower film roller 2 and the transverse edge sealing device. The upper film and the lower film output by the film releasing device are sealed laterally through severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com