Logistics turnover box

A turnover box and logistics technology, applied in the field of logistics, can solve the problems of manual removal of transshipment objects and inconvenient logistics turnover, and achieve the effects of improving convenience, reducing labor intensity, and reducing box pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

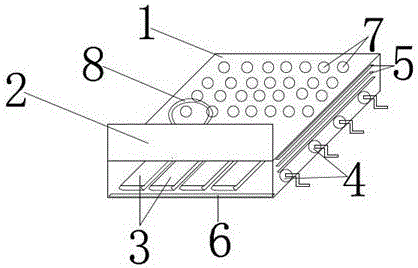

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] Such as figure 1 Shown: a logistics turnover box, including a box body 1, the side of the box body 1 is a push-pull box door 2; the bottom surface of the box body 1 is provided with a conveyor belt 3, the conveyor belt 3 includes a conveyor belt 306, a driving Assembly and driven assembly, the active assembly includes a drive shaft 302, a drive gear 301301 installed on the drive shaft 302 and bearings 305 installed at both ends of the drive shaft 302, the driven assembly includes a driven shaft 304, installed on the slave The driven gear 303 on the driving shaft 304 and the bearings 305 installed at both ends of the driven shaft 304; the driving gear 301 is connected to the hand crank 4 outside the casing 1 through the driving shaft 302; the length of the conveyor belt 3 is less than the The length of the bottom of the box 1; the surface where the hand crank 4 ...

Embodiment 2

[0036] The present invention is especially suitable for the conveyance of heavy and bulky articles.

[0037] For items with large single volume and heavy weight, logistics turnover boxes of corresponding specifications can be used. The conveyor belt 3 is one.

[0038] A logistics turnover box, including a box body 1, the side of the box body 1 is a push-pull box door 2; the bottom surface of the box body 1 is provided with a conveyor belt 3, and the conveyor belt 3 includes a conveyor belt 306, active components and slaves. Driven assembly, described active assembly comprises driving shaft 302, the driving gear 301301 that is installed on the driving shaft 302 and the bearing 305 that is installed at the two ends of driving shaft 302, and described driven assembly comprises driven shaft 304, is installed on driven shaft 304 The driven gear 303 on the top and the bearings 305 installed at both ends of the driven shaft 304; the driving gear 301 is connected to the hand crank 4 ...

Embodiment 3

[0046] The invention is especially suitable for conveying articles with small weight and small volume.

[0047] For items with small volume and light weight, logistics turnover boxes of corresponding specifications can be used. The conveyor belts 3 are multiple in parallel.

[0048] A logistics turnover box, including a box body 1, the side of the box body 1 is a push-pull box door 2; the bottom surface of the box body 1 is provided with a conveyor belt 3, and the conveyor belt 3 includes a conveyor belt 306, active components and slaves. Driven assembly, described active assembly comprises driving shaft 302, the driving gear 301301 that is installed on the driving shaft 302 and the bearing 305 that is installed at the two ends of driving shaft 302, and described driven assembly comprises driven shaft 304, is installed on driven shaft 304 The driven gear 303 on the top and the bearings 305 installed at both ends of the driven shaft 304; the driving gear 301 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com