Stirring slag scraping machine used for molten aluminum mixing furnace

A technology of mixing furnace and slag removal machine, which is applied in the direction of stirring devices, furnaces, furnace components, etc., can solve the problems of low slag removal efficiency and effect, increased energy consumption, and inability to clean up, so as to improve the slag removal efficiency and effect, The effect of improving the efficiency of slag removal and increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

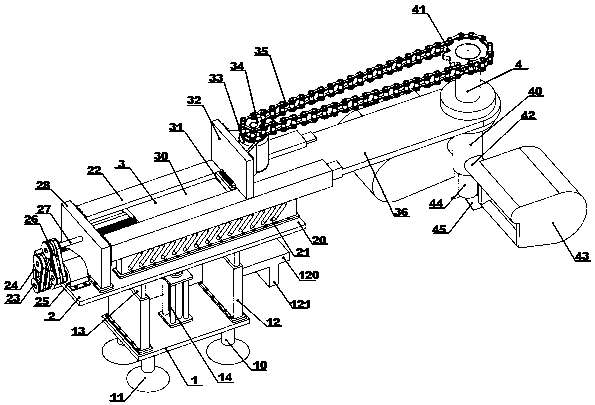

[0021] Such as figure 1 As shown, a stirring and slag removal machine for aluminum liquid mixing furnace includes a base 1, a moving platform 2, a forward extension mechanism 3, and a stirring and slagging mechanism 4. The moving platform 2 is arranged on the base 1, and the extension mechanism 3 is set on the motion platform 2, and the stirring and slag removing mechanism 4 is set on one end of the forward stretching mechanism 3;

[0022] The lower surface of the base 1 is provided with a number of support rods 10, the lower ends of the support rods 10 are provided with a lower support body 11, and the front and rear ends of the upper surface of the base 1 are provided with lifting guide rails 12, and the lifting guide rails 12 is equipped with a lifting plate 13, and the middle part of the upper surface of the base 1 is provided with a lifting cylinder 14;

[0023] Described motion platform 2 comprises motion platform bottom plate 20, and described motion platform bottom pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com