Vacuum oil injection system for transformer or capacitor

A capacitor and transformer technology, applied in the field of transformer or capacitor vacuum oil injection system, can solve the problems of shortening the service life of chain materials, waste of transformer or capacitor oil, pollution, etc., and achieve the effect of improving safety performance, improving service life and ensuring transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

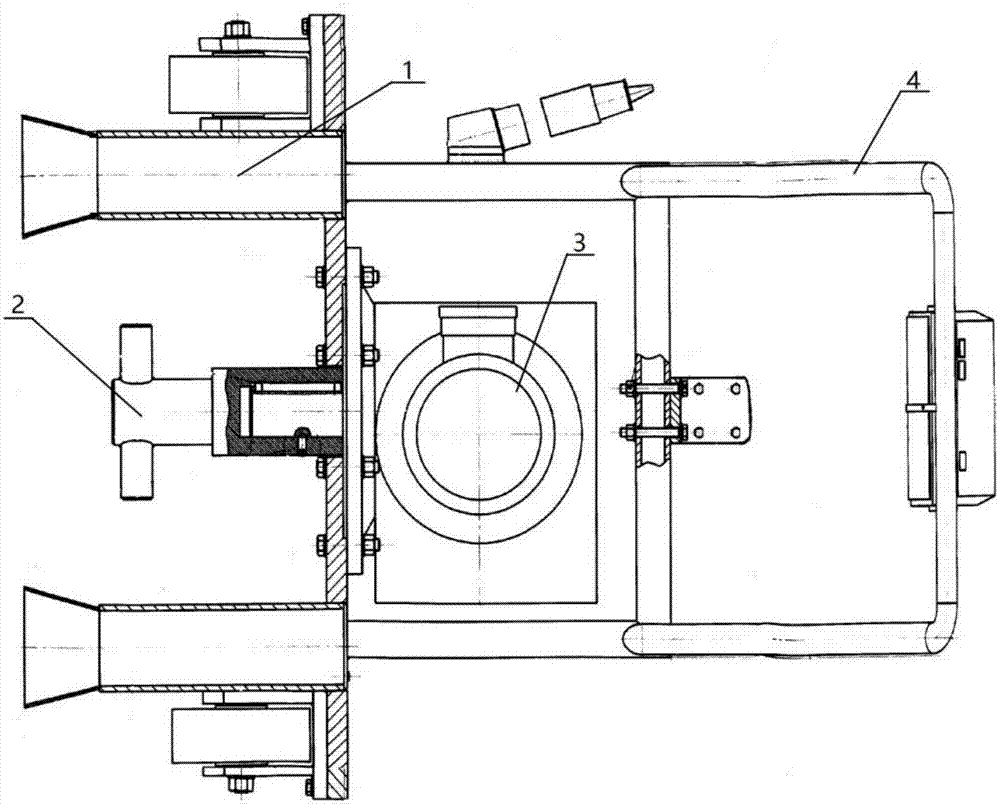

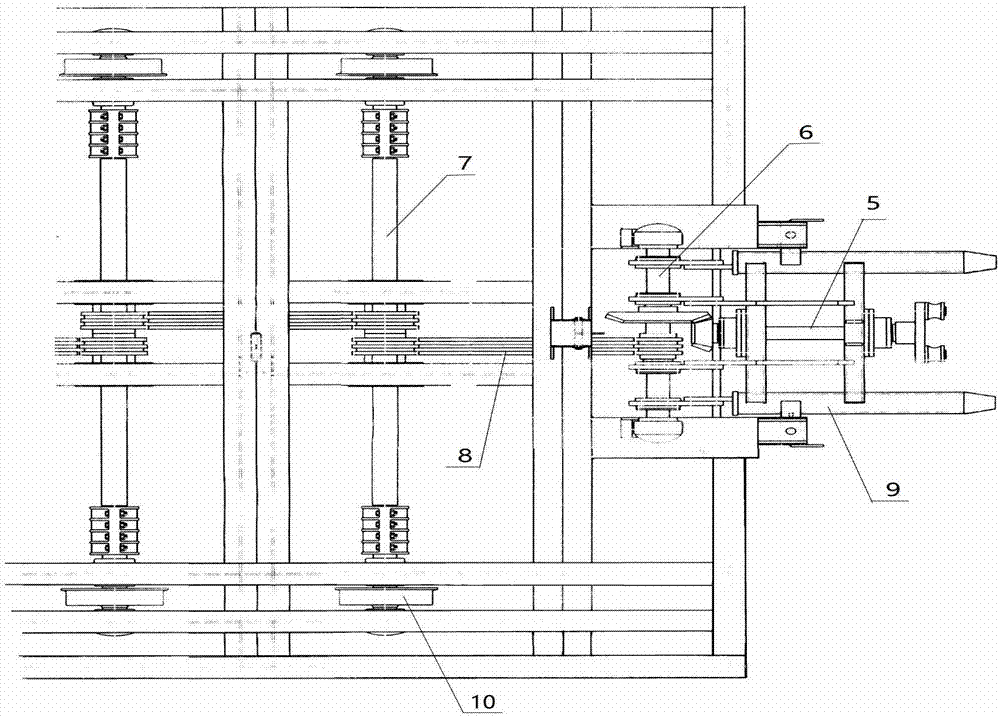

[0038] The vacuum oiling system of the present invention includes a tractor for transporting the transformer or capacitor 5 to be oiled and a vacuum oiling device for oiling the transformer or capacitor 5 to be oiled.

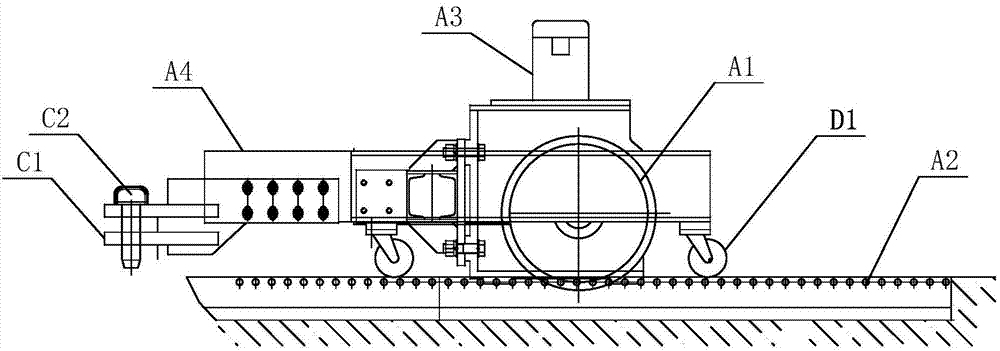

[0039] Wherein the structure of the tractor is as follows image 3 , 4 Shown:

[0040] The tractor includes a headstock A and a car body B that is detachably connected to the headstock A and is used to place the oil-filled transformer or capacitor 5. The headstock A is installed outside the vacuum tank 3 through a transmission sprocket A1. The chain rail A2 meshes to realize the reciprocating movement of the tractor.

[0041] A pair of the chain rails A2 are arranged in parallel on the ground, and the chain rails A2 are correspondingly engaged with the transmission sprockets A1 installed at both ends of the transmission shaft of the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com