Clamping plate and method for manufacturing a clamping plate

A technology of pressing plate and structure, which is applied in the direction of manufacturing tools, maintenance and safety accessories, clamping, etc., can solve the problems of mechanical stability of the matrix that damages the pressing plate, weak fixtures, etc., to facilitate the transportation of heat and improve work results , Improve the effect of cooling power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

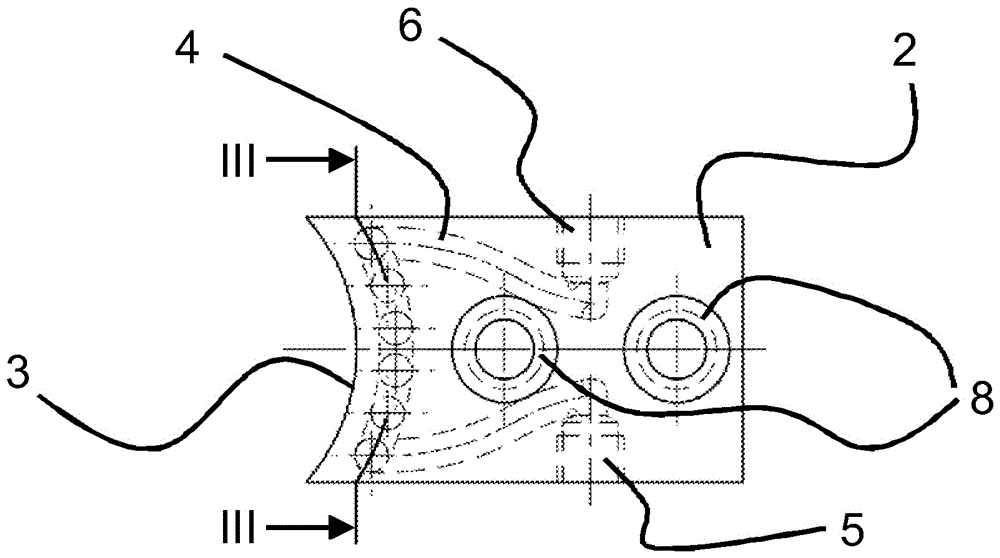

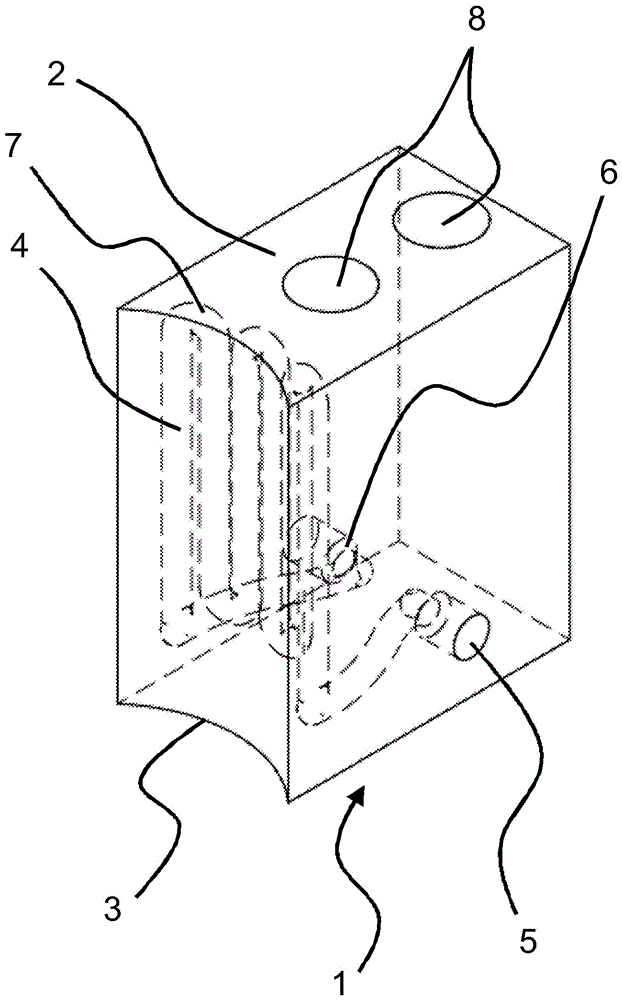

[0030] figure 1 Shown is a pressure plate 1 which is provided for clamping or holding a workpiece. The pressure plate 1 is substantially formed by a base body 2 and has on one side a clamping contour 3 formed in the shape of a circular segment in the exemplary embodiment shown. as in figure 1 As indicated by the dashed lines in the middle, coolant channels 4 are formed in the base body 2 of the pressure plate 1 , which are delimited by a coolant inlet 5 and a coolant outlet 6 . In the exemplary embodiment shown, the coolant channel 4 , which has a plurality of elbow sections 7 , follows the course of the clamping contour 3 in a curved manner. Furthermore, receptacles 8 for receiving fastening means can be seen in the upper side of the base body 2 , with which the pressure plate 1 can be fastened to suitable clamping means.

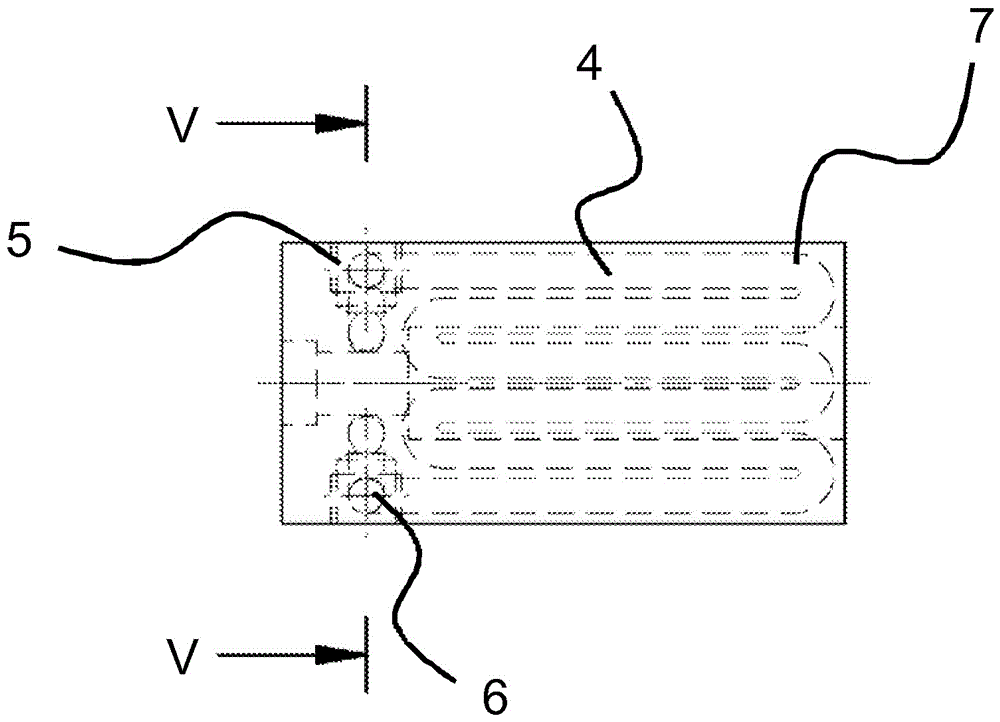

[0031] as in figure 2 As can be seen from the plan view of the pressure plate 1 according to the invention shown in , the shape of the coolant channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com