Mounting structure of ceramic liner rotary kiln

A technology of ceramic liner and installation structure, which is used in rotary drum furnaces, furnaces, lighting and heating equipment, etc., can solve the problems of uneven temperature of ceramic liner, affecting product quality, and inconsistent expansion coefficient with metal cylinders, etc. The compaction effect is safe and reliable, the structure is ingenious, and the space occupation is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

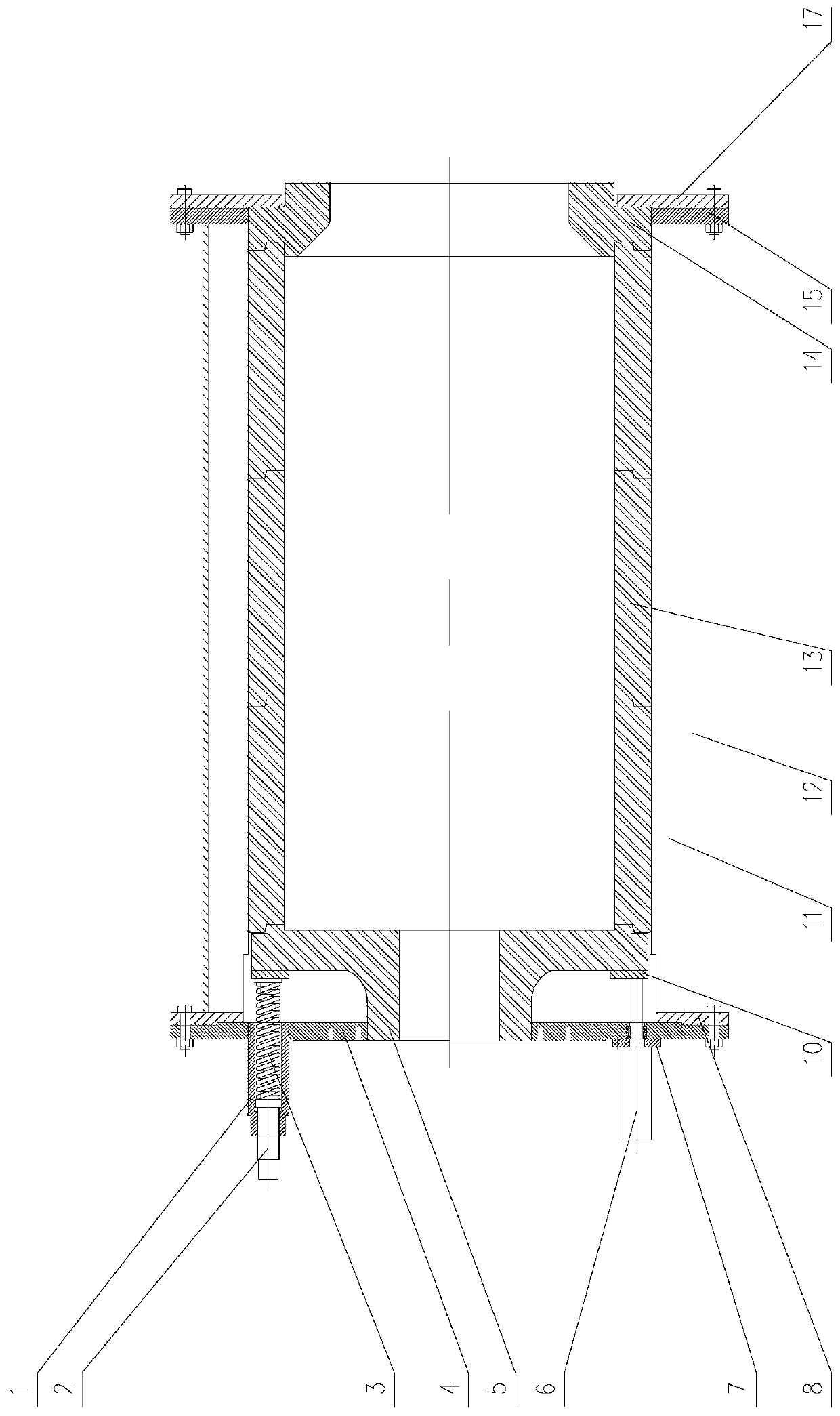

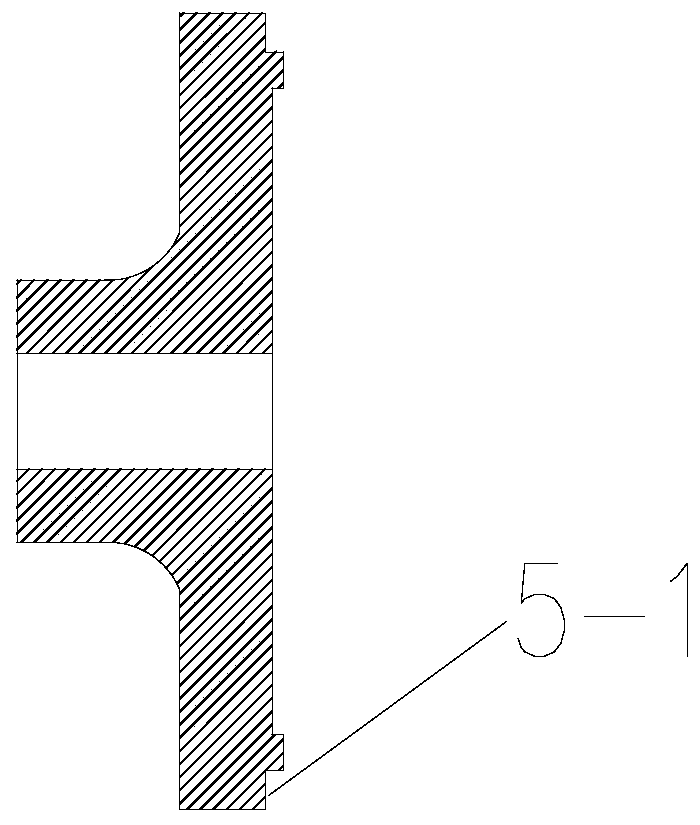

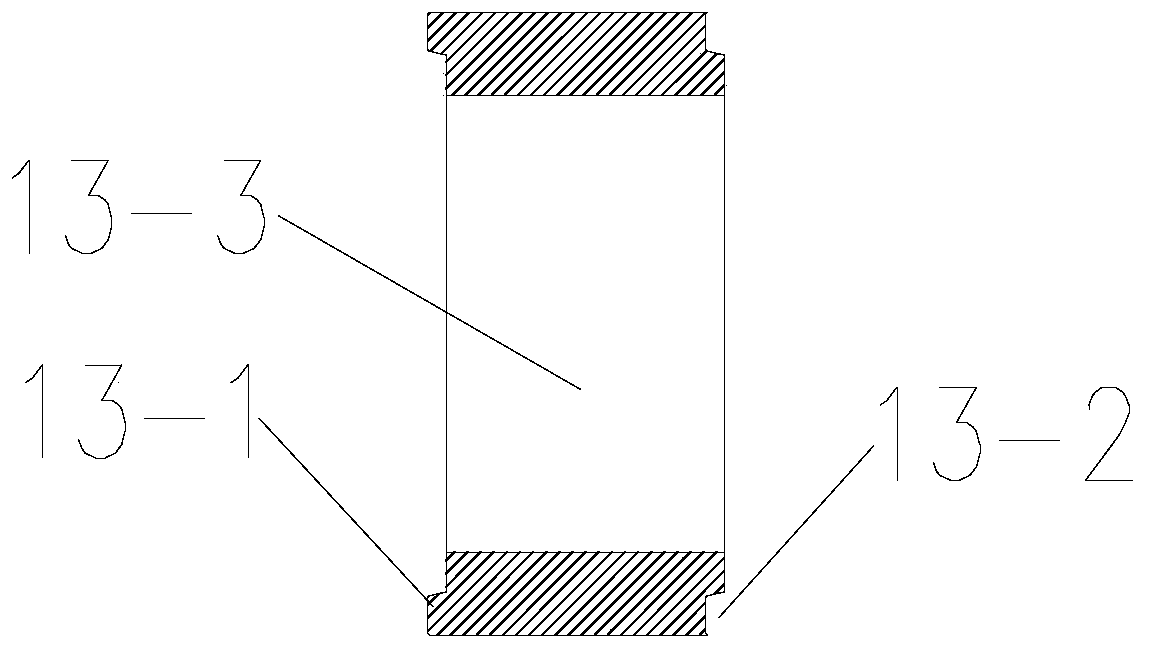

[0020] figure 1 Including high temperature spring mounting bracket 1, high temperature spring compression seat 2, high temperature spring 3, compression installation flange 4, ceramic liner left part 5, right boss 5-1, extrusion cylinder 6, extrusion cylinder installation Plate 7, cylinder left flange 8, ceramic liner protection block 10, insulation layer 11, outer cylinder body 12, ceramic liner middle ring 13, middle ring boss 13-1, middle ring groove 13-2, firing chamber 13 -3. The right part 14 of the ceramic liner, the left groove 14-1, the right flange 15 of the cylinder body, the fixing plate 17 of the ceramic liner, etc.

[0021] like figure 1 As shown, the present invention is a ceramic liner rotary kiln installation structure, including an outer cylinder 12, the outer cylinder 12 is made of metal material, has high strength, redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com