Burning Apparatus and Method for Manufacturing Reduced Iron Using the Same

A technology of combustion equipment and reduced iron, applied in the direction of lighting and heating equipment, maintenance of heating chamber, improvement of process efficiency, etc., can solve the problem of difficult control of combustion furnace temperature and oxygen concentration, difficulty in mass production of reduced iron, metallization of reduced iron Low rate and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

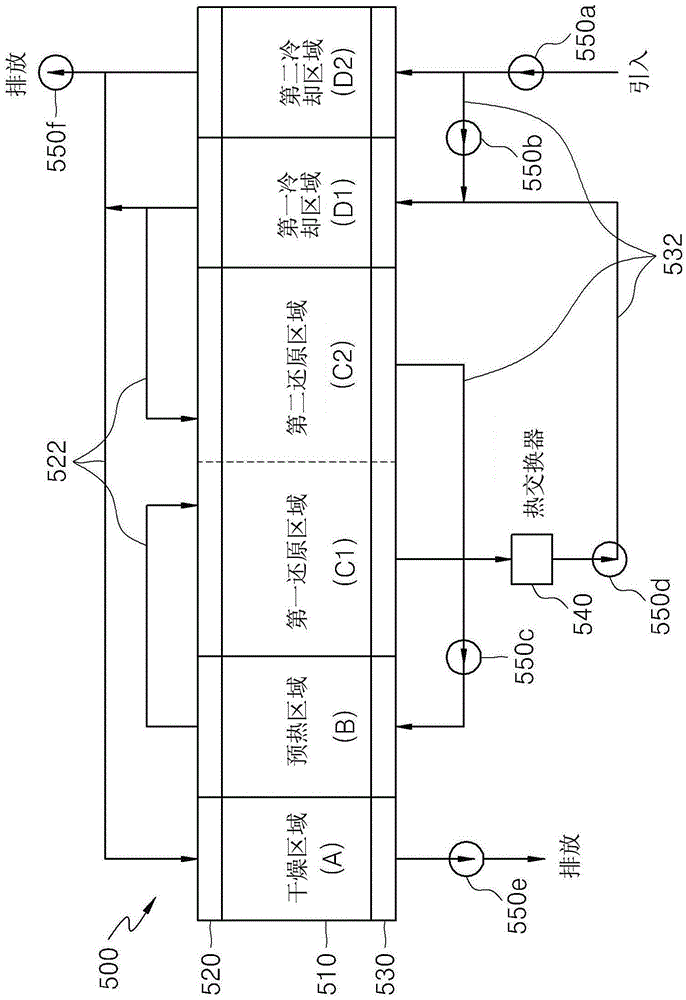

[0062] figure 2 is a block diagram showing the internal structure of the combustion apparatus and the flow of fluid according to the exemplary embodiment.

[0063] refer to figure 2 , the combustion equipment 500 includes: a combustion furnace 510 that defines a path that allows a trolley that accommodates coal blocks to move; an upper passage 520 that is provided in the upper part of the combustion furnace 510 to communicate with the The longitudinal direction is divided into a plurality of regions; the upper connecting pipe 522 is provided in the upper passage 520 to communicate with at least two different regions; the lower passage 530 is provided in the lower part of the combustion furnace 510 to communicate with the combustion furnace 510, and divided into a plurality of regions along the longitudinal direction of the combustion furnace 510; and a lower connection pipe 532 located on the lower passage 530 to communicate at least two different regions.

[0064] The fur...

example 2

[0093] Figure 5 is a schematic diagram showing the structure of a combustion device according to an exemplary embodiment, Image 6 It is a block diagram showing the internal structure of the combustion equipment and the fluid flow according to the movement of the coal block.

[0094] refer to Figure 5 with Image 6 , the combustion equipment 600 includes: a first combustion furnace 610, defining a linear path to heat the coal block, and a trolley accommodating the coal block therein moves from one side to the other side along the linear path; a second combustion furnace 620, defining an annular path to reduce the coal lumps, the annular path being connected to the other side of the first combustion furnace 610, the coal lumps discharged through the other side of the first combustion furnace 610 moving along the annular path; and The cooling area 630 connected to the second combustion furnace 620 defines an annular path to cool the reduced iron, the annular path is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com