Harmonious mining method for block-type dip stripes in deep spanned mining areas of steep inclined seam

A mining method and steep inclination technology are applied in the field of coordinated mining of deep cross-mining blocks with segmental inclination strips to achieve the effects of improving the recovery rate and production efficiency, reducing the uneven settlement and deformation of the surface, and slowing the surface deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

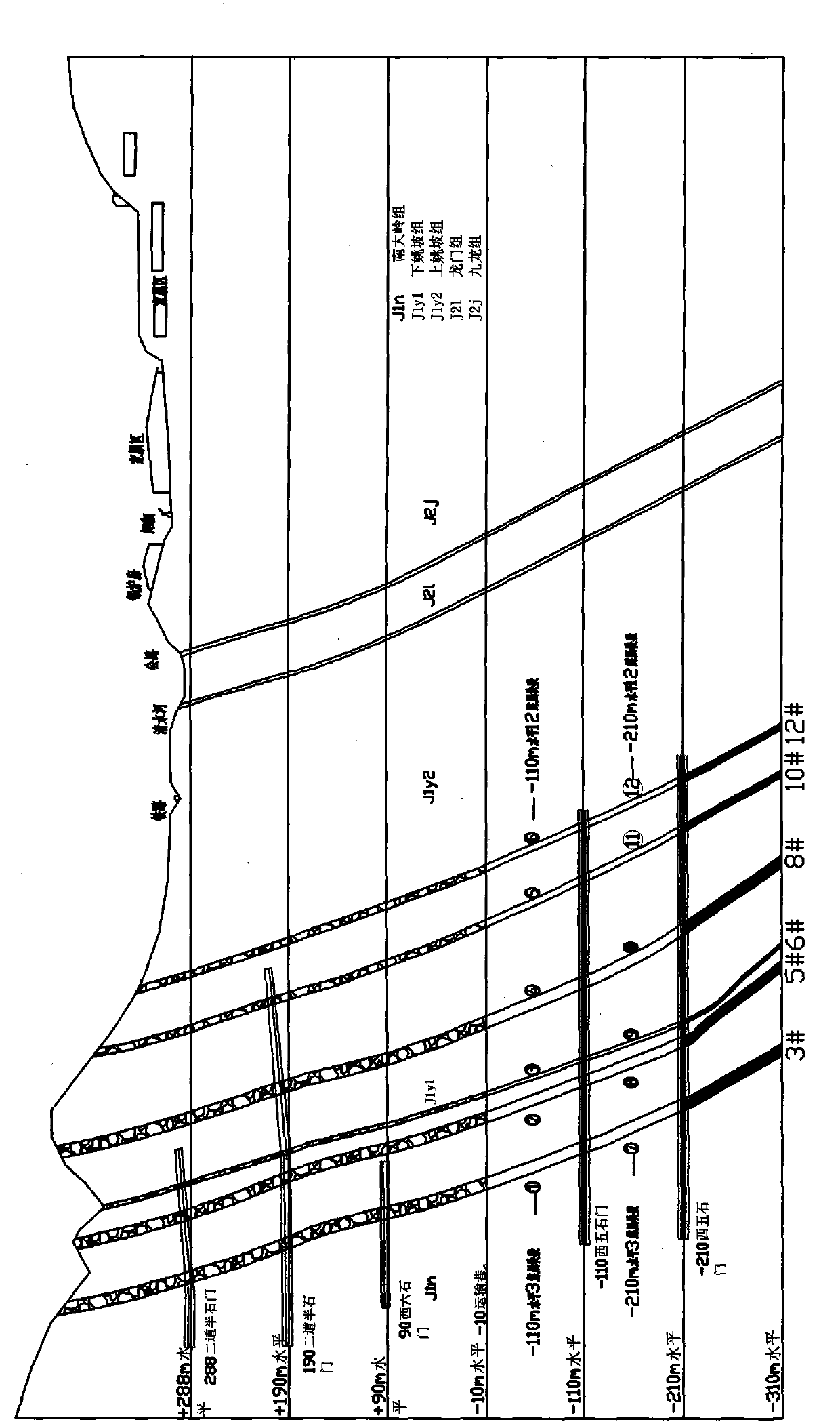

[0052] The mining sequence of coal seam groups is as follows: figure 1 As shown, the steeply inclined coal seam group contains 6 recoverable coal seams, which are 3#, 5#, 6#, 8#, 10# and 12# coal from bottom to top; mining area, the dip section is divided into two mining levels, which are -110m level and -210m level from top to bottom, and the vertical height of each stage is 100m; a total of 12 blocks are mined, from left to right and from top to bottom respectively. These are block 1, block 2, ..., block 12. The mining sequence of the coal seam group is mining the upper level first, and then mining the lower level. The mining sequence of the same mining level is block 1, block 3, block 2, block 4, block 5 and block 6.

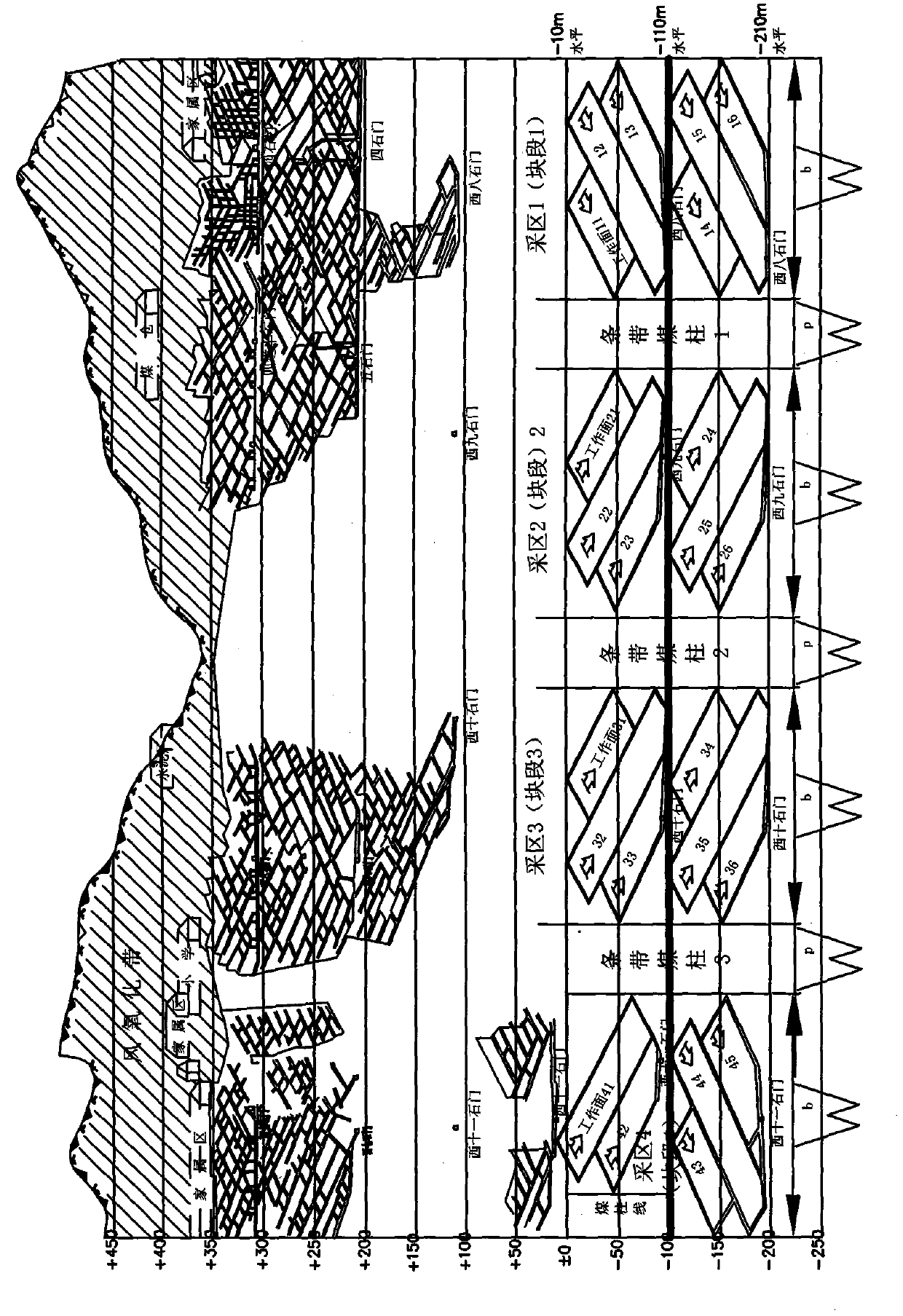

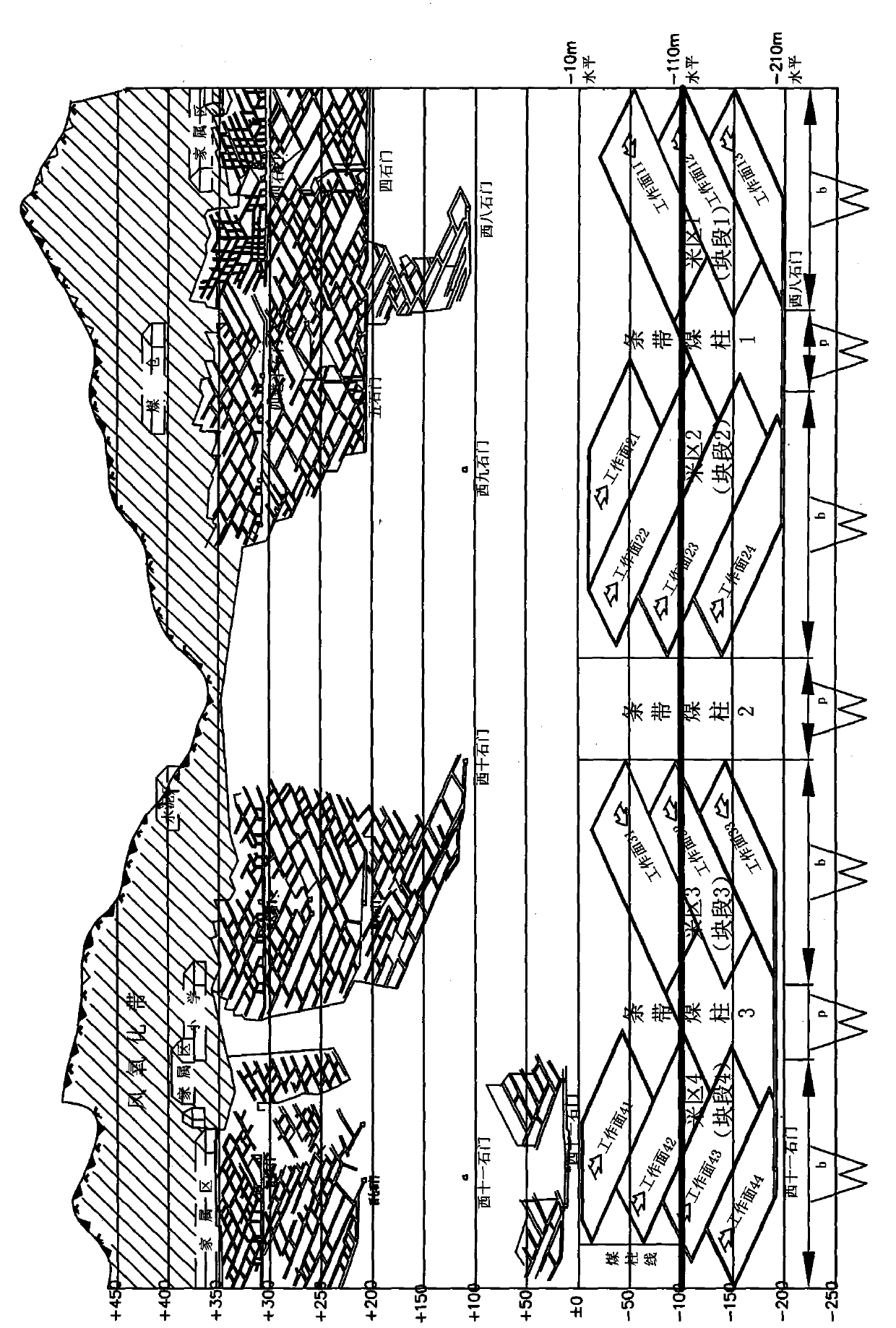

[0053] The mining sequence across mining blocks is as follows: figure 2 As shown, the West 8th to West 11th mining areas of Datai Well are divided into 2 mining levels, which are -110m level and -210m level from top to bottom, and the stage vertical height...

Embodiment 2

[0057] Such as Figures 4a-4g , Figure 5 and Figures 6a-6c As shown, the West 8th to West 11th mining areas at the -210m level of Datai Well are steeply inclined coal seam groups, and there are 7 mineable coal seams, which are slot 11, slot 10, slot N8, slot 6, and slot 5 from top to bottom. Slot, 4 slot, 3 slot. The coal seam strikes NE45°~NE54°, inclines to the northwest, the coal seam inclination angle is 60°~70°, the average is 65°, the average strike length is about 1200m, the mining elevation is -210m~-110m, the mining vertical height is 100m, the mining depth is 460m~560m, the coal seam cumulative The thickness is 10.78m. The mining sequence of the coal seam is multi-coal seam joint mining, that is, the mining of slot 4, N8, and slot 11 in the first stage; the mining of slot 3 and 6 in the second stage; and the mining of slot 5 and 10 in the third stage. There are many faults in the Xishi mining area, and it is impossible to arrange the working face. Here, the pro...

Embodiment 3

[0061] A mine is a group of steeply inclined coal seams, the mining depth of the lower boundary is 600m, the coal seam dip angle is 70°, the mining thickness is 3m, the stage vertical height is 100m, the working face is 250m long, and the coal pillar width is 80m. The overlying rock is medium hard rock. By using the "steeply inclined coal seam mining subsidence prediction analysis system (this prediction analysis is the prior art)" developed by the inventor to simulate calculation. Distribution of surface movement and deformation after mining with coordinated mining method in deep cross-mining area with steeply inclined multi-coal seams. Depend on Figure 7a with 8aIt can be seen that after the mining of mining area 1, mining area 3 and mining area 5, the strip coal pillars in mining area 2, mining area 4 and the mining interval play a good role in blocking the expansion of the goaf and the continuous distribution of stress on both sides, so that The ground surface is in a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com