Method and equipment for separating, conveying and filling underground coal and gangues

A coal gangue separation and equipment technology, applied in the direction of filling, solid separation, mining equipment, etc., can solve the problems of large floor area, expensive equipment, unsatisfactory treatment effect, etc., achieve small underground space occupation, change the transportation pattern, The effect of avoiding surface subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

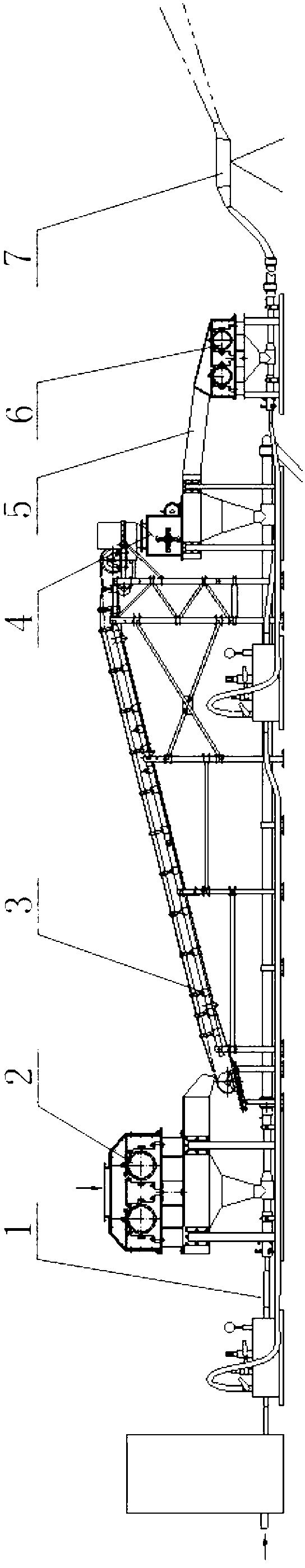

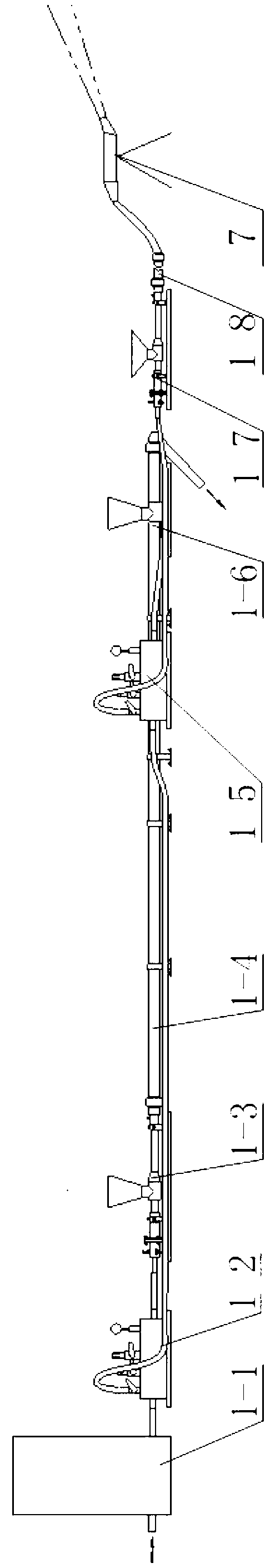

[0017] The present invention will be further explained below in conjunction with the accompanying drawings.

[0018] Such as figure 1 As shown, the underground coal gangue separation, transportation and filling method of the present invention comprises the following steps:

[0019] a. The mined coal and gangue are initially crushed and sorted through the roller crushing and sorting machine 2 in the underground;

[0020] b. Send the coal lumps with a granularity less than 50mm selected by the roller crushing and sorting machine 2 in step a into the pneumatic conveying system 1, and the coal lumps and gangue with a granularity of 50mm or more are carried out through the hammer crushing and sorting machine 4 for the second time. crushing and sorting;

[0021] c. Send the coal lumps with a particle size less than 50mm selected by the hammer crusher and separator 4 in step b into the pneumatic conveying system 1, and combine them with the coal lumps with a particle size of less t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com