Dust production simulation experiment device for heading machine cutting head and experiment method thereof

A technology of simulation experiment and simulation device, which is applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc., to achieve the effect of simple adjustment, simple overall structure and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

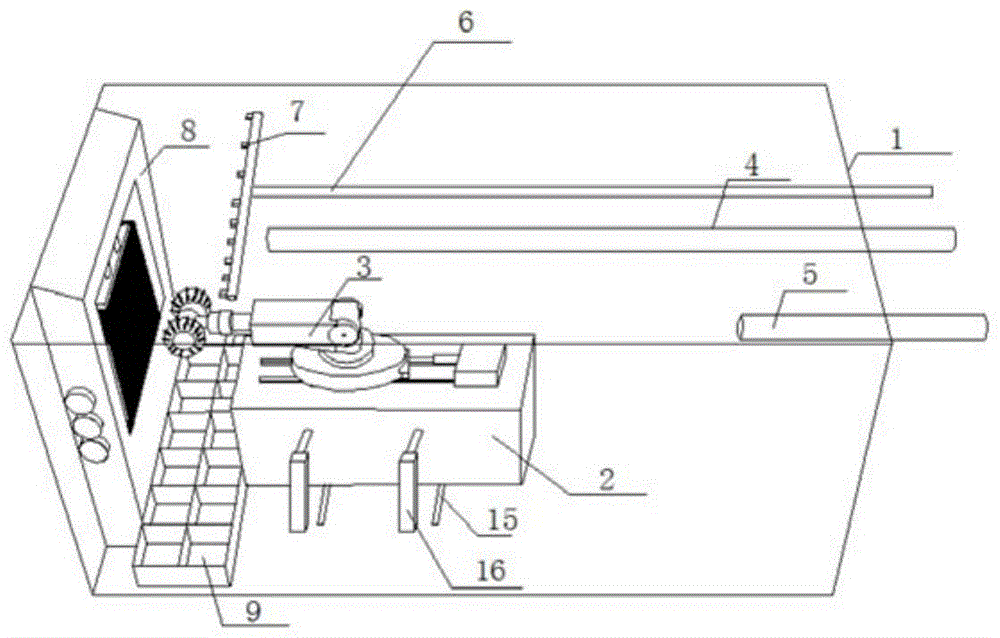

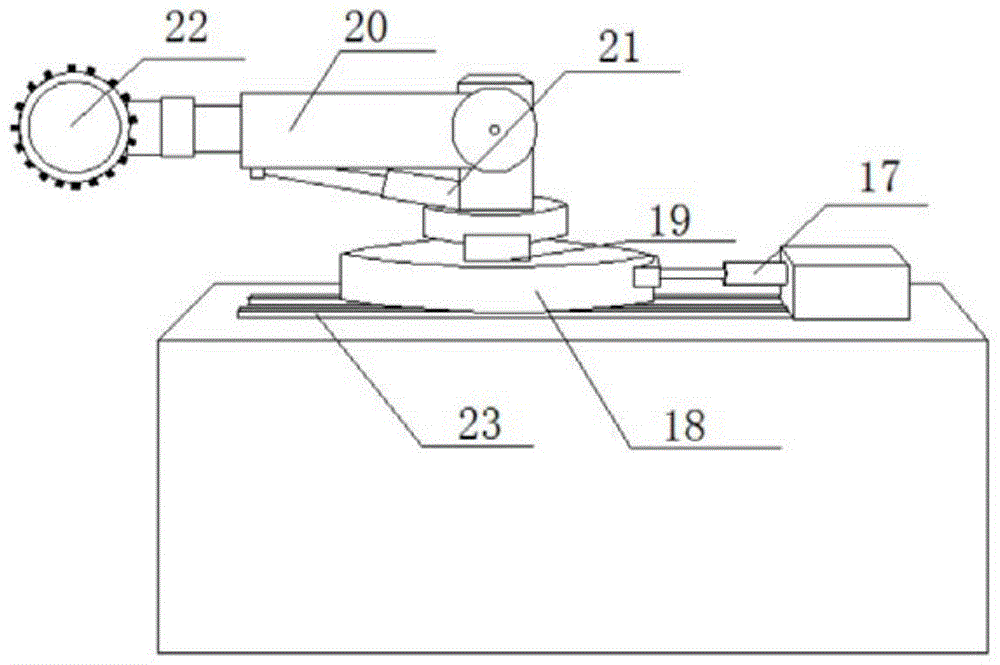

[0071] Such as Figure 1 to Figure 3 As shown, the roadheader cutting head dust production simulation experimental device of the present invention comprises a plexiglass cover 1, a roadheader simulation device mounting table 2, a roadheader simulation device 3, a compressed air duct 4, an exhaust air duct 5, a pushing Rod 6, measuring instrument 7, coal setting platform 8 and sample receiving box 9; where:

[0072] Above-mentioned plexiglass cover 1 comprises a frame in the shape of a cuboid, and the six faces of the frame are respectively closed and sealed by six plexiglass plates, forming a box structure in which the outside is in the shape of a cuboid and the inside is a cavity;

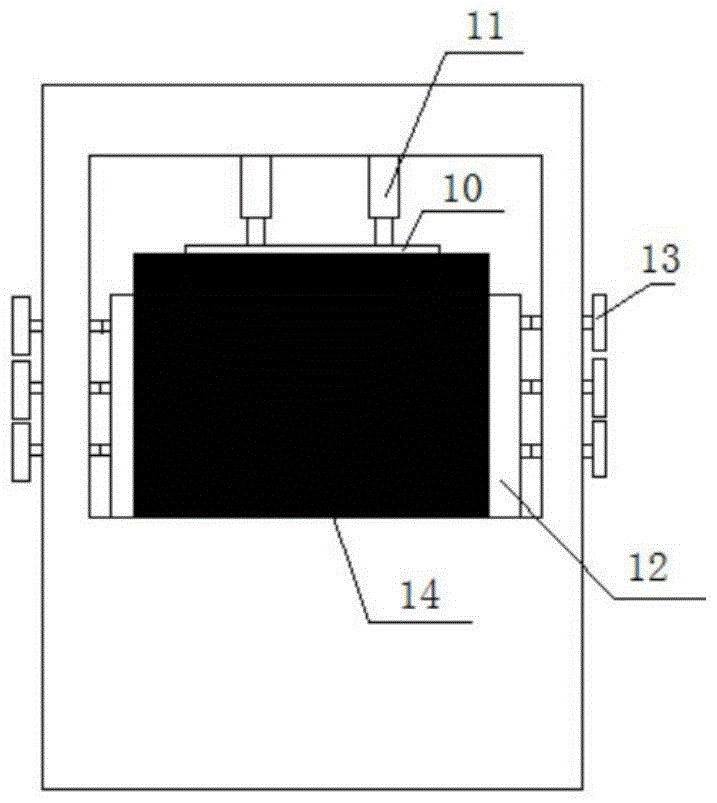

[0073] On the left wall surface of the above-mentioned plexiglass cover 1 inside, a coal platform 8 is arranged, and the coal platform is an inverted U-shaped cofferdam, and a number of screw holes are respectively arranged on the two side wall surfaces of the cofferdam; A stress applying device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com