Patents

Literature

52results about How to "Realize the separation of man and machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

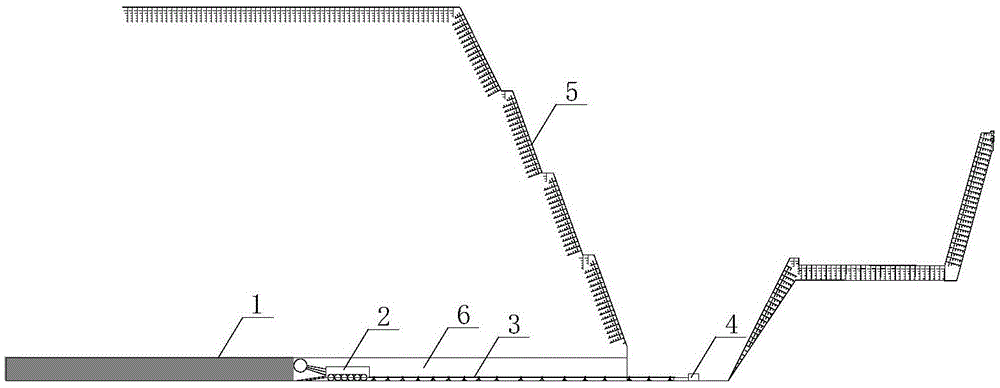

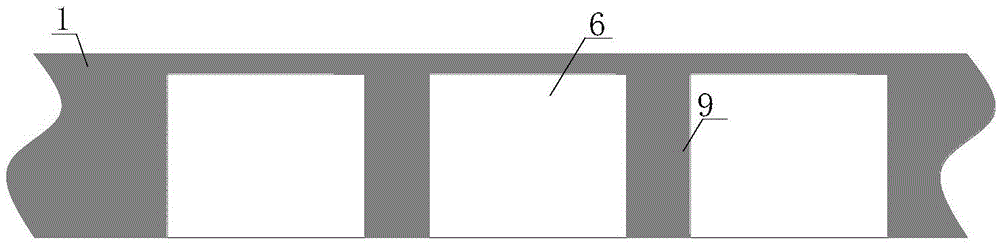

End slope coal bed remote control excavating mining method

InactiveCN104074521AImprove the recovery rate of coal resourcesSimple production processUnderground miningSlitting machinesMining engineeringMan machine

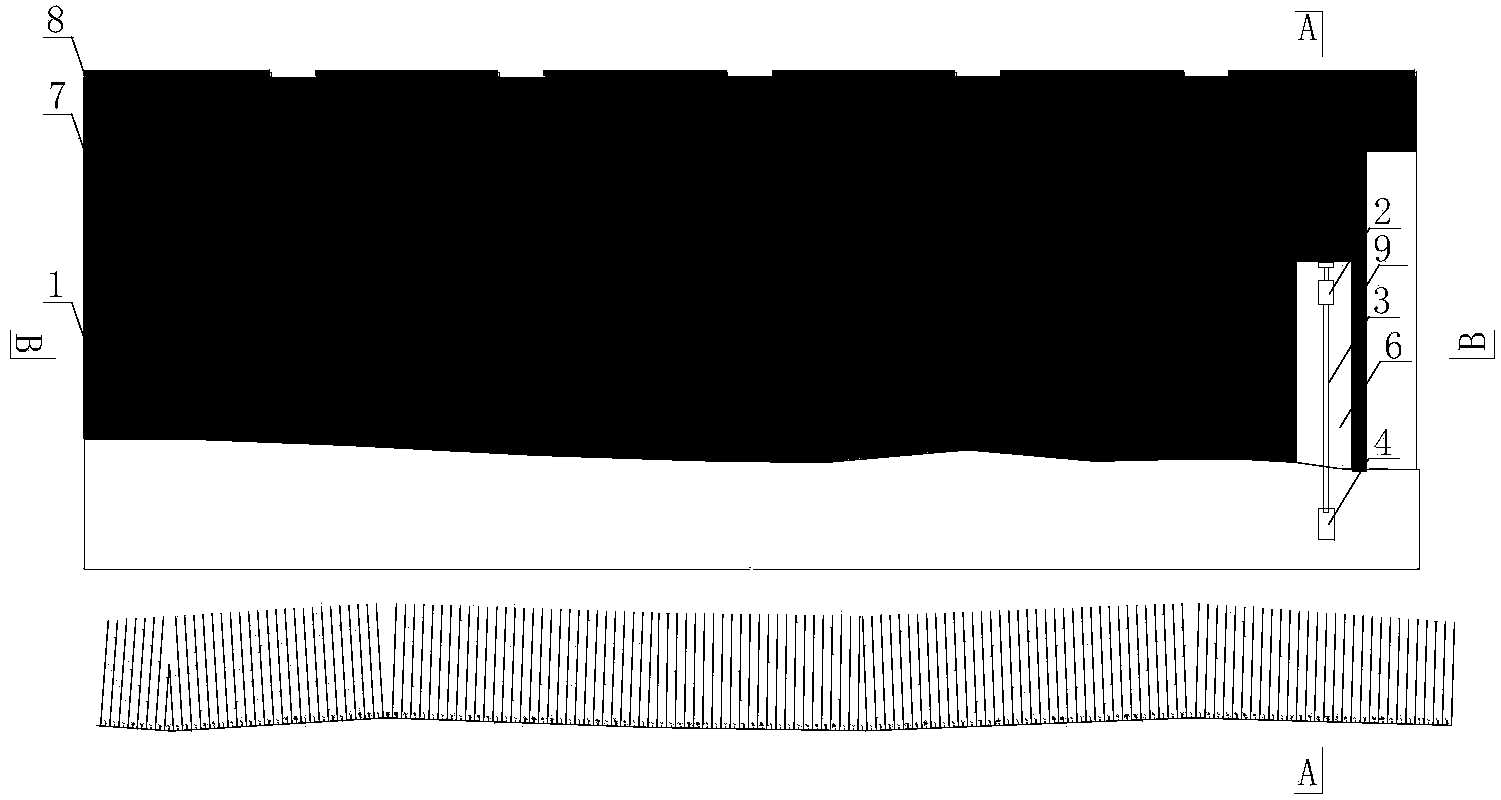

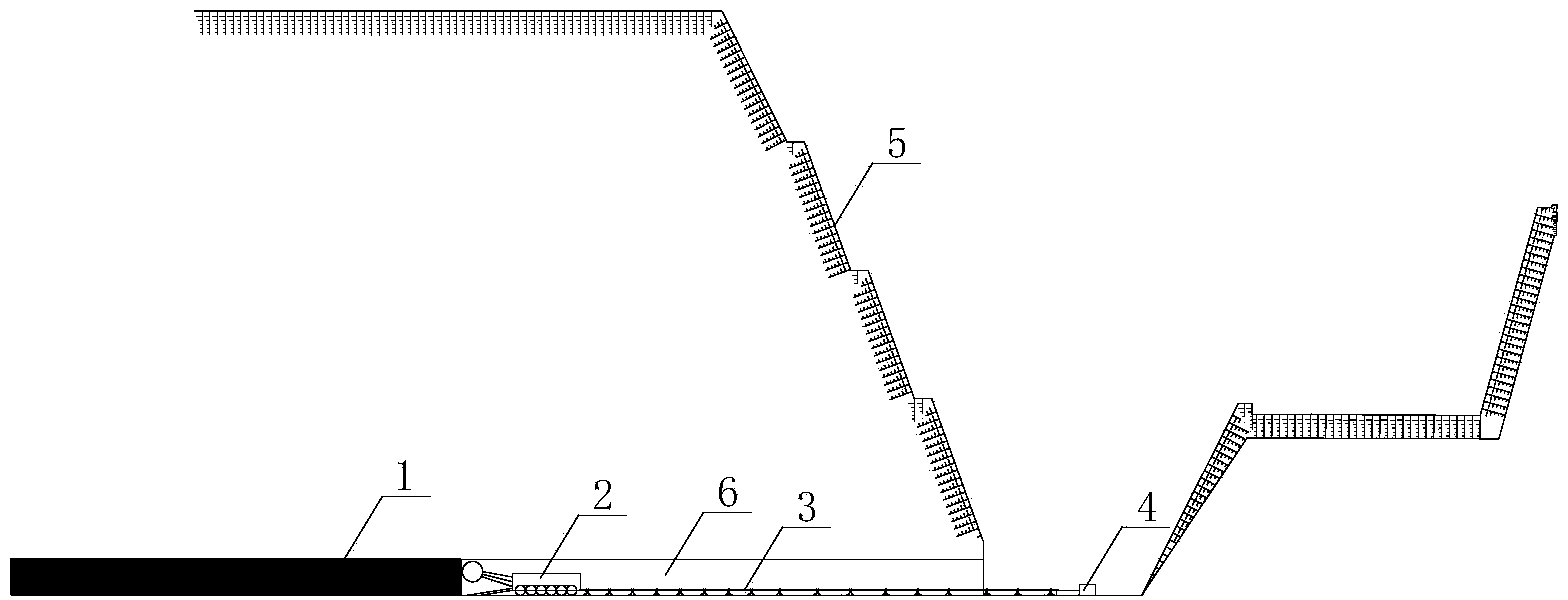

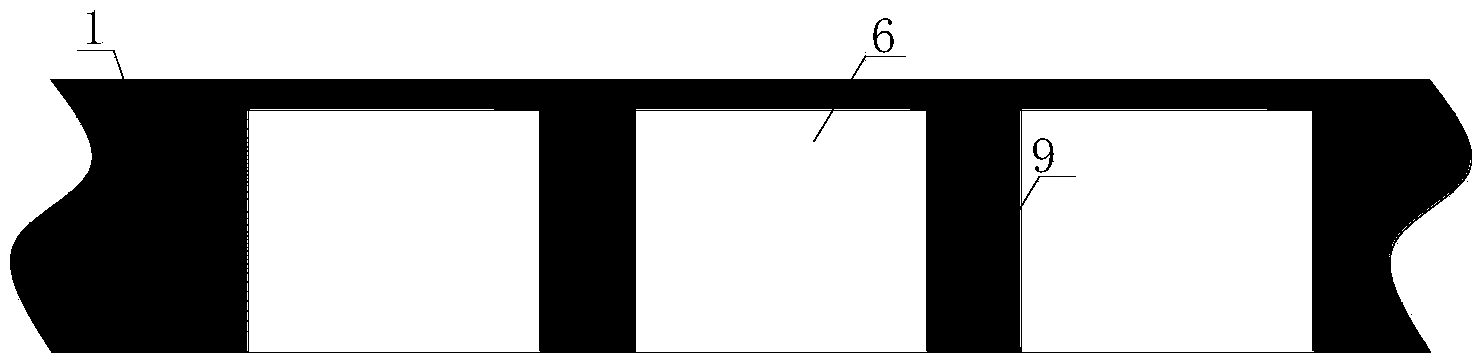

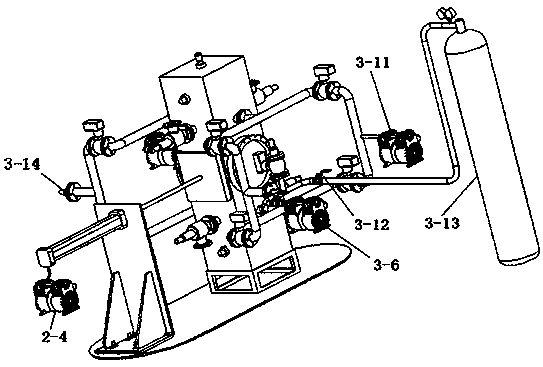

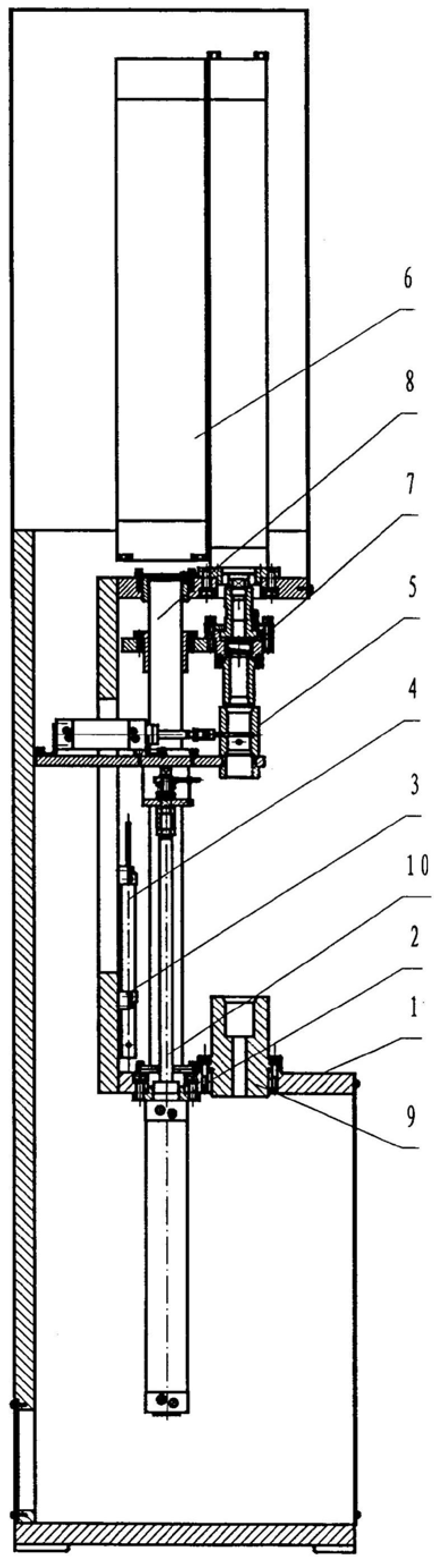

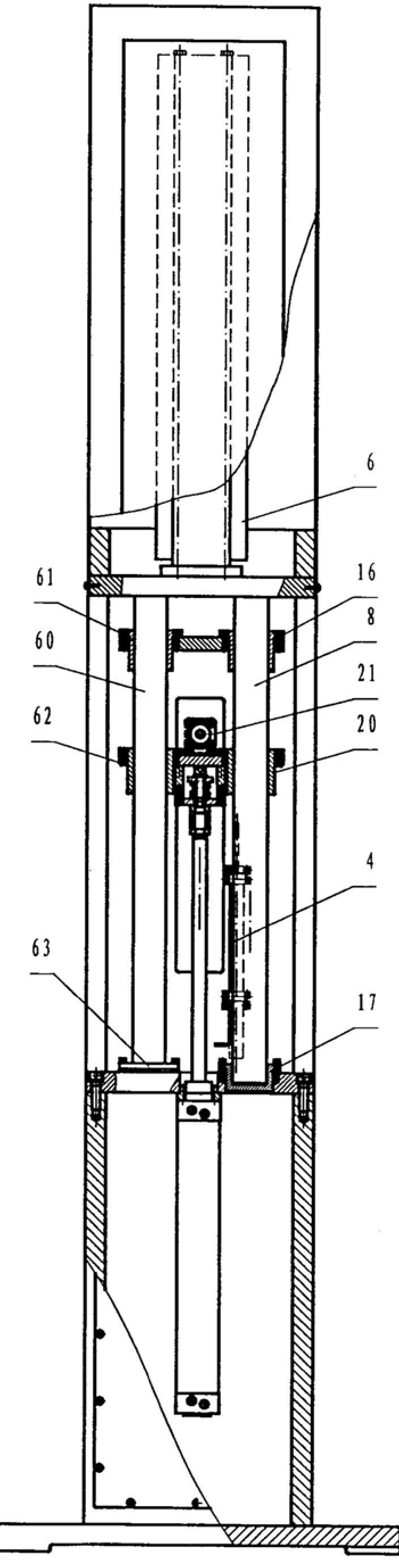

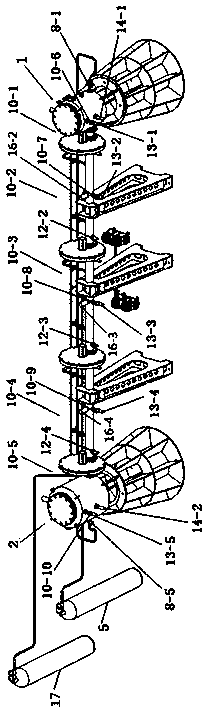

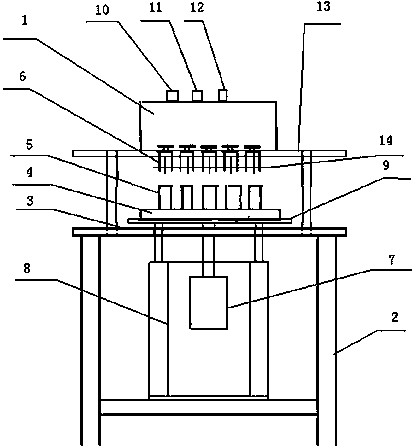

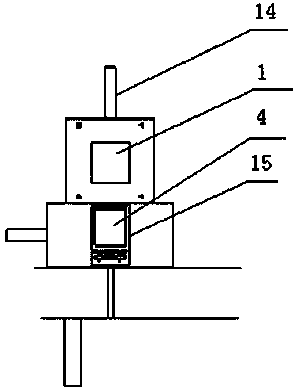

The invention provides an end slope coal bed remote control excavating mining method, which belongs to an end slope residue coal resource extraction method and is used for open pit coal mine end slope and hillside outcrop and shallow surface coal bed mining. A coal mining system adopts a remote control excavating machine system, which comprises an excavating machine and a remote operating and control room, wherein operating and control equipment consists of three parts including a mining flameproof excavating machine electric control box, an excavating machine electric control box and an operating table; the operation function of long-distance wired control is realized; the man-machine separation is realized; and during the coal mining, people operate in a safe operation room. The main mining flow process comprises the steps of cleaning preparation, initial stage mining roadway pit selection, excavating and coal cutting by the excavating machine, coal loading by the excavating machine, belt extending, outward coal conveying by a belt, pile pouring by a loading machine, laneway exiting after coal excavating to a preset position, equipment withdrawing, overhauling, and preparation again for next roadway pit extraction. The end slope coal bed remote control excavating mining method has the characteristics that the coal resource extraction rate improved; the production process is simple, safe and efficient; and the production cost is low, and the like. The safe and efficient mining of open pit coal mine end slope remained coal resources is favorably realized.

Owner:CHINA UNIV OF MINING & TECH

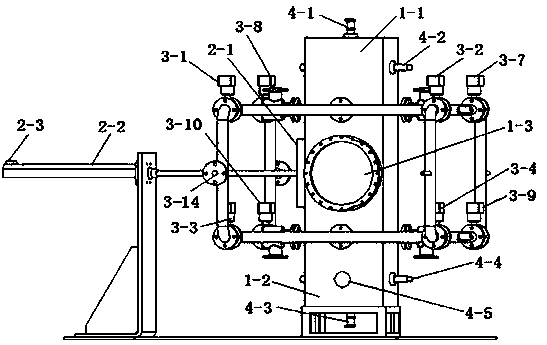

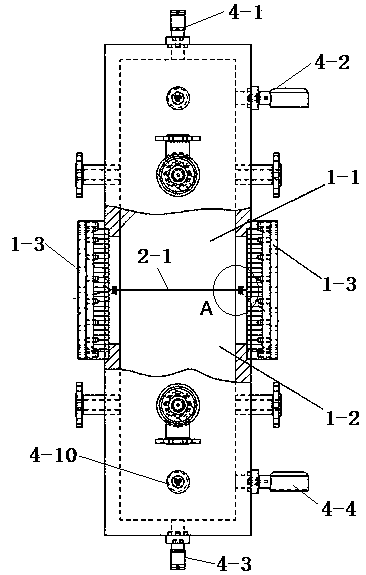

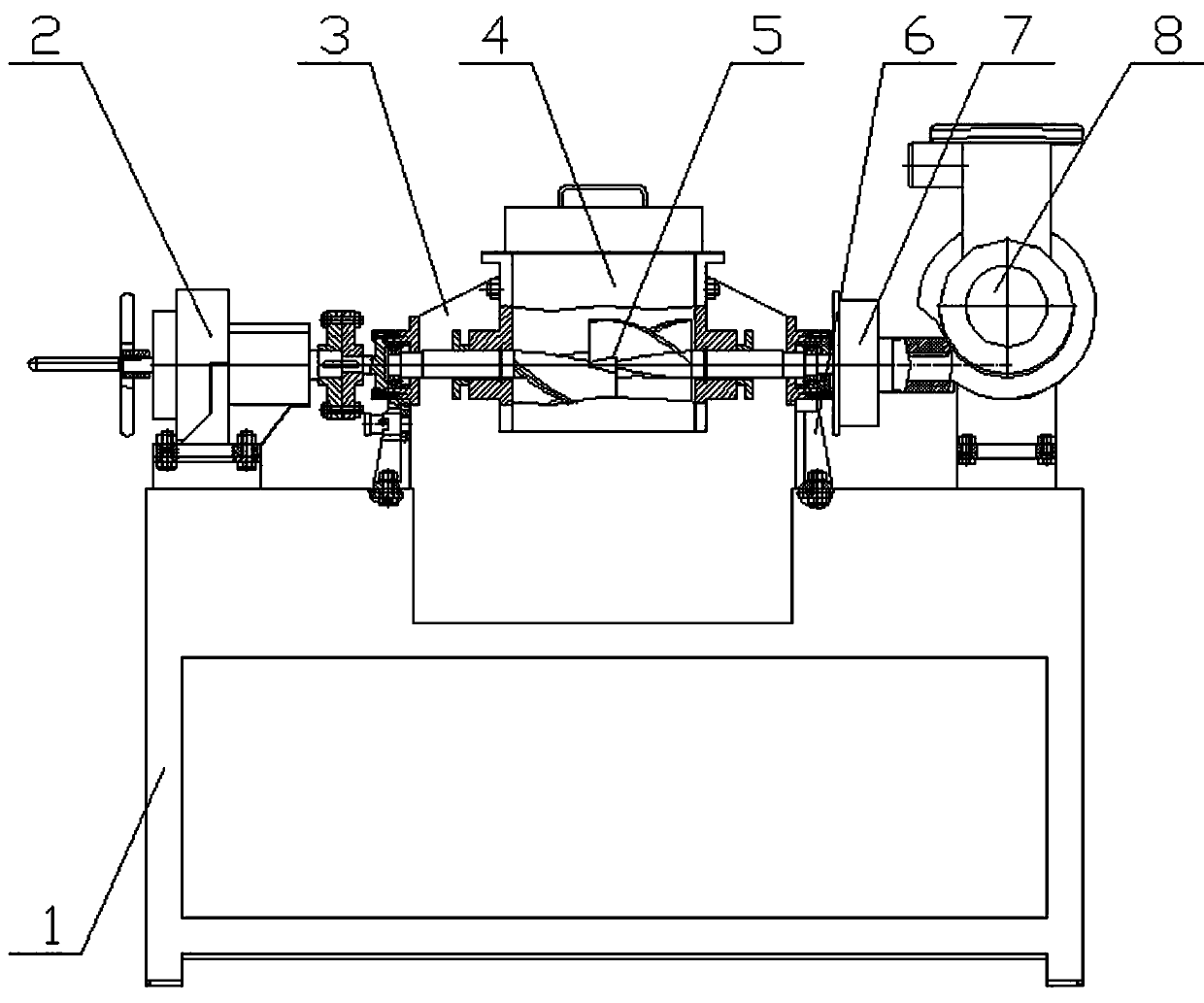

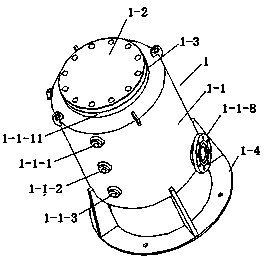

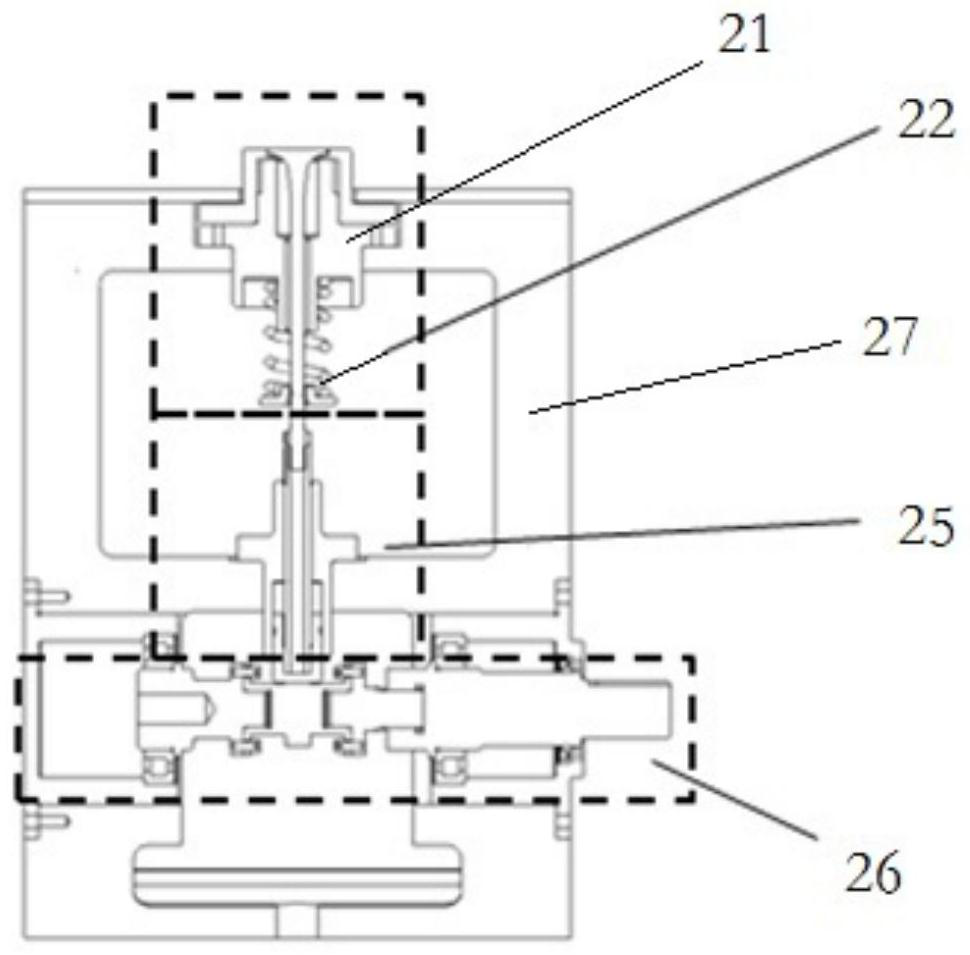

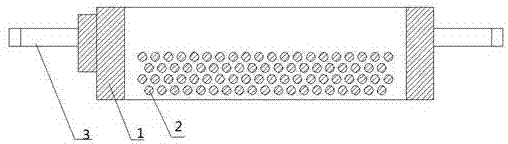

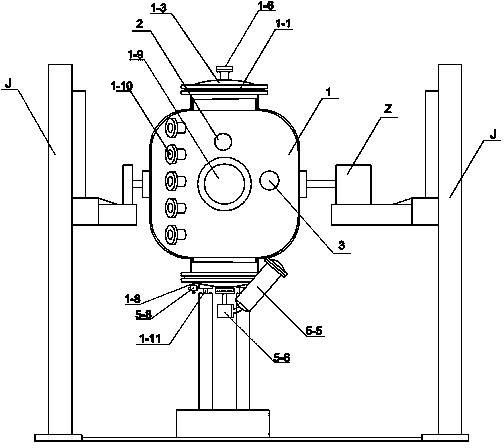

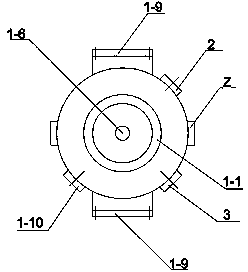

Explosive test device of combustible gas with concentration gradient and using method

ActiveCN108802100AGuaranteed accuracyReduce extrusion deformationMaterial exposibilityCombustible gasPhysical chemistry

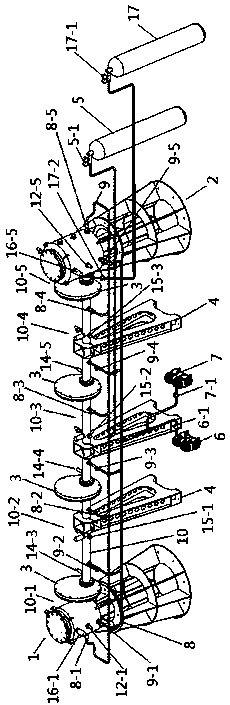

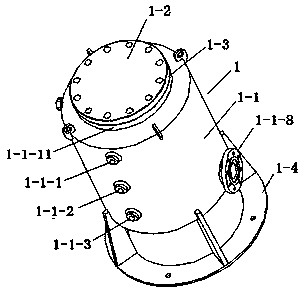

The invention provides an explosive test device of combustible gas with the concentration gradient and a using method. The using method comprises the steps that vacuumizing is conducted till the interior of an explosive reaction container is at the vacuum state; negative pressure is matched with the gradient concentration, specifically, the combustible gas with the different concentrations is allocated in an upper reaction container and a lower reaction container, the pressure balance between the upper reaction container and the lower reaction container is always maintained in the gas injection process by controlling the flux speed electrically; an ignition test is conducted, specifically, an air cylinder is pulled out from a separation plate port, so that the upper reaction container andthe lower reaction container are communicated with each other, meanwhile, the ignition test is started, in the ignition process, a high-speed photography and schlieren measuring system analyzes the parameters such as the maximum explosive pressure, the maximum pressure rise speed, the explosive wave transmission rate, the flow field morphology, the flame evolution and the like to do research on the explosive transmission mechanism of the combustible gas with the concentration gradient and analyzes the evolution dynamics process of explosive. The explosive test device has the effects of being used for doing research on the explosive evolution dynamics process and explosive wave transmission mechanism of the combustible gas with the concentration gradient.

Owner:应急管理部天津消防研究所

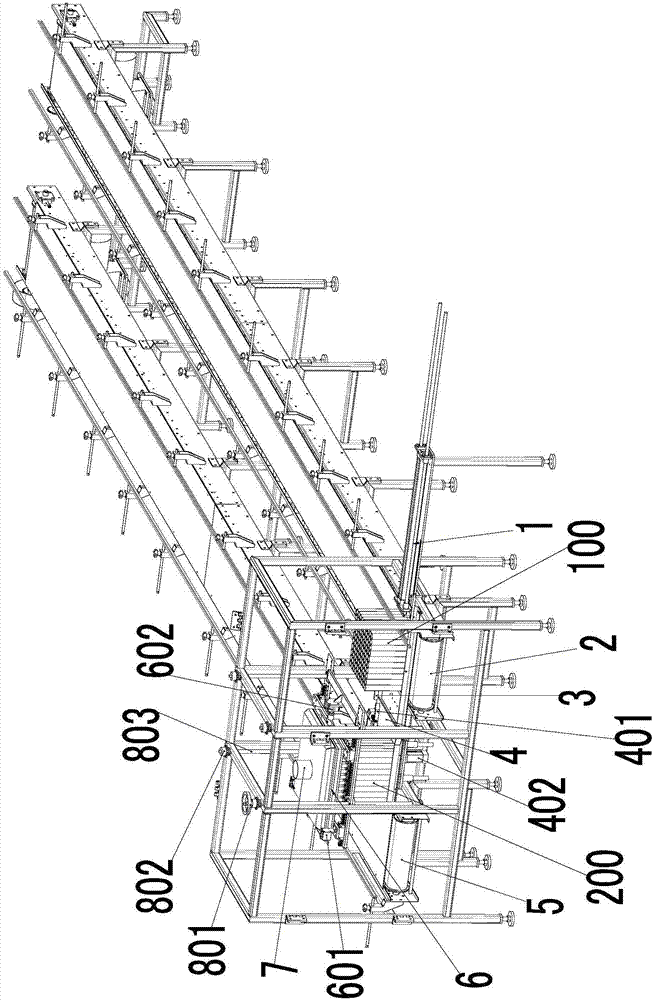

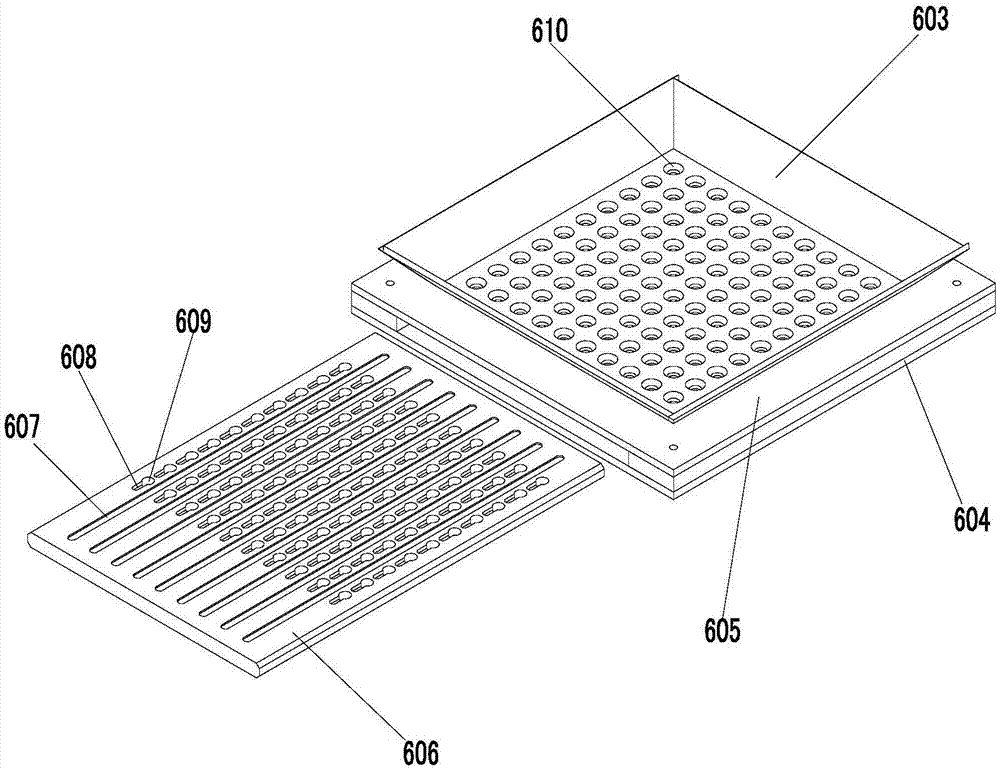

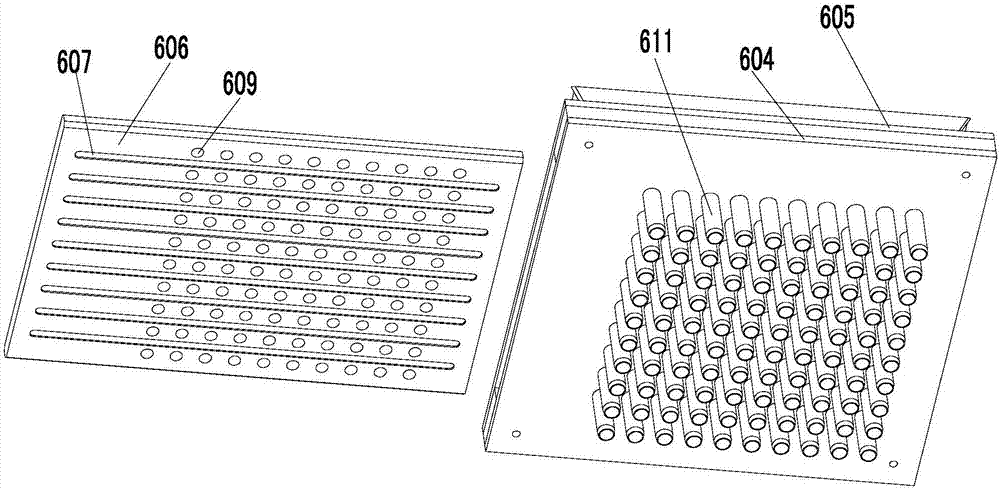

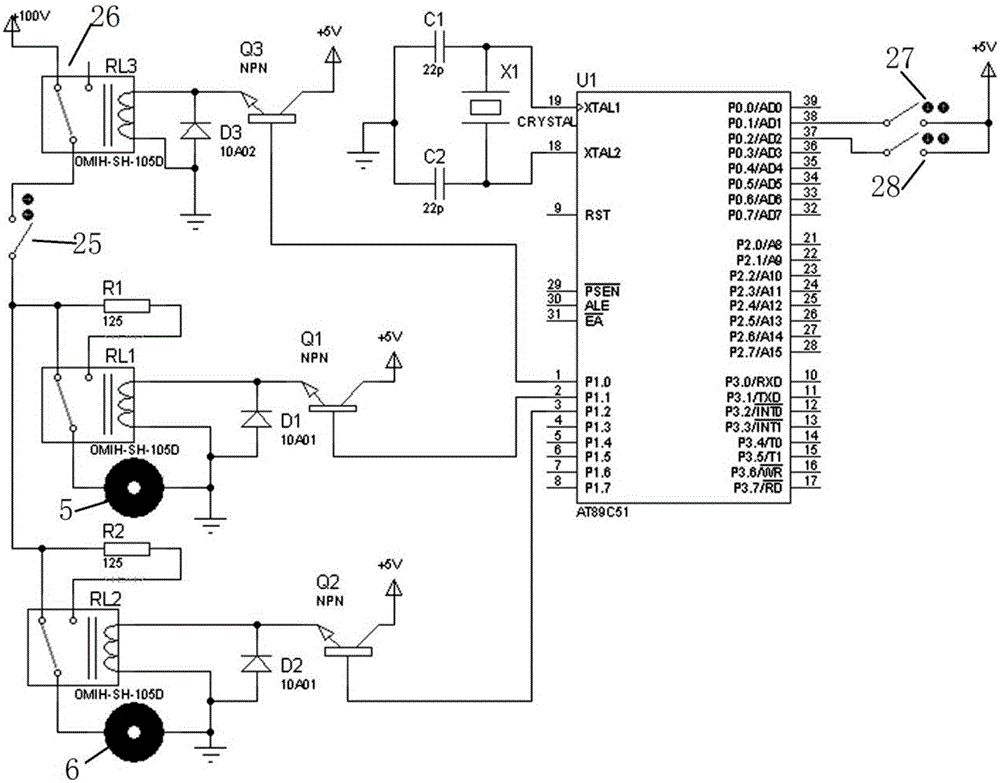

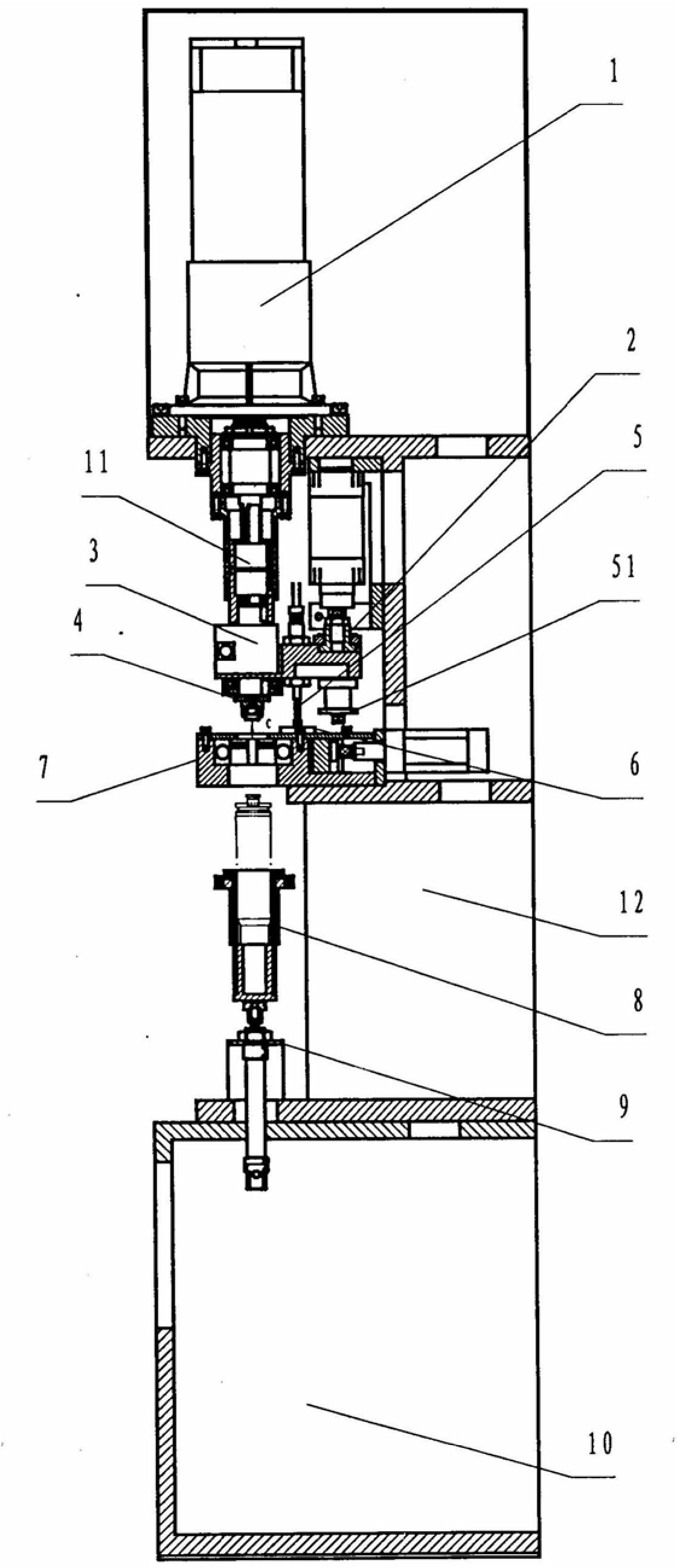

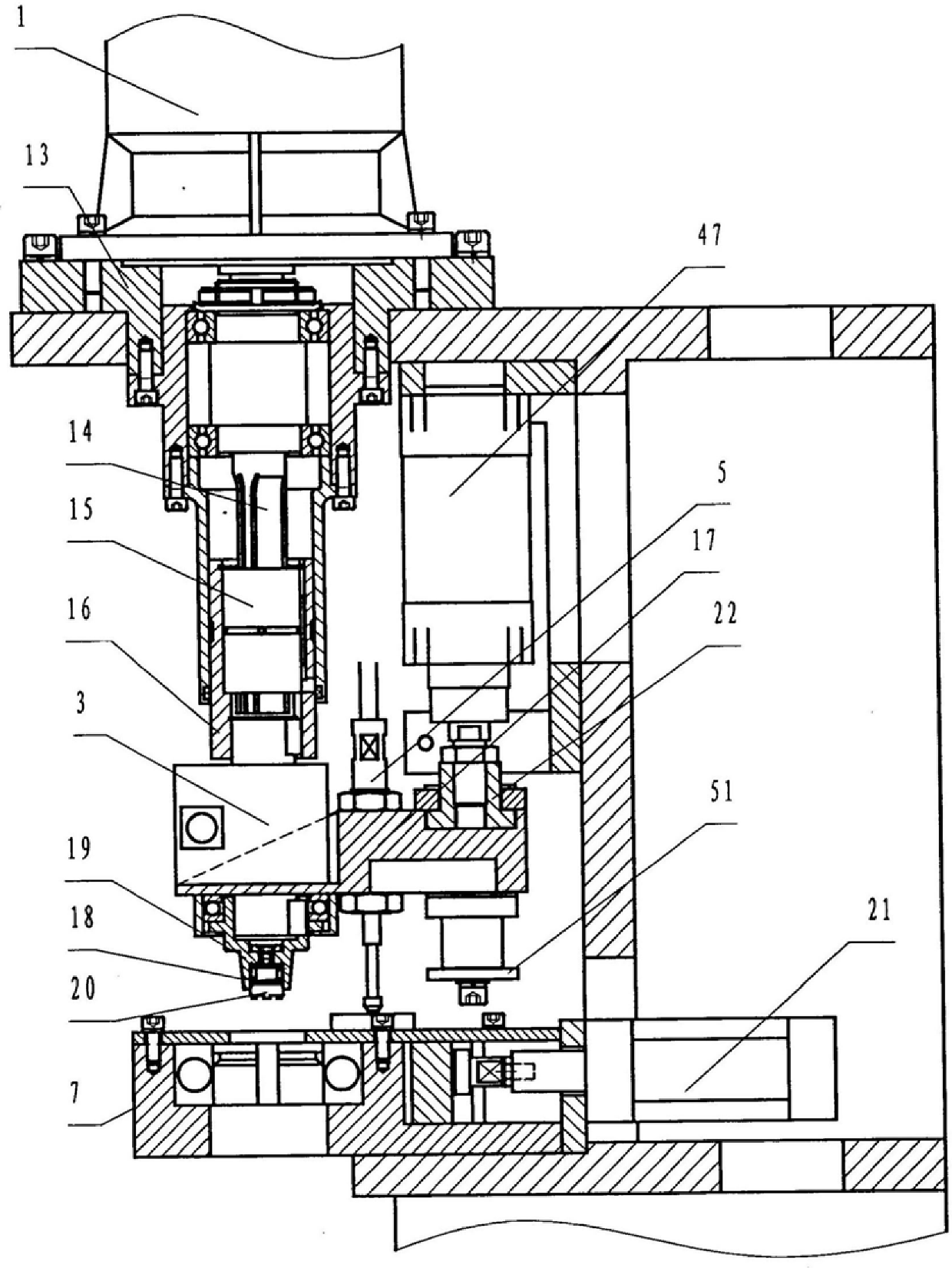

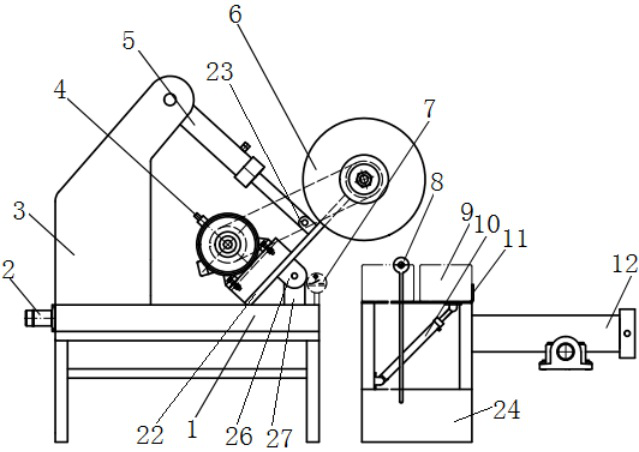

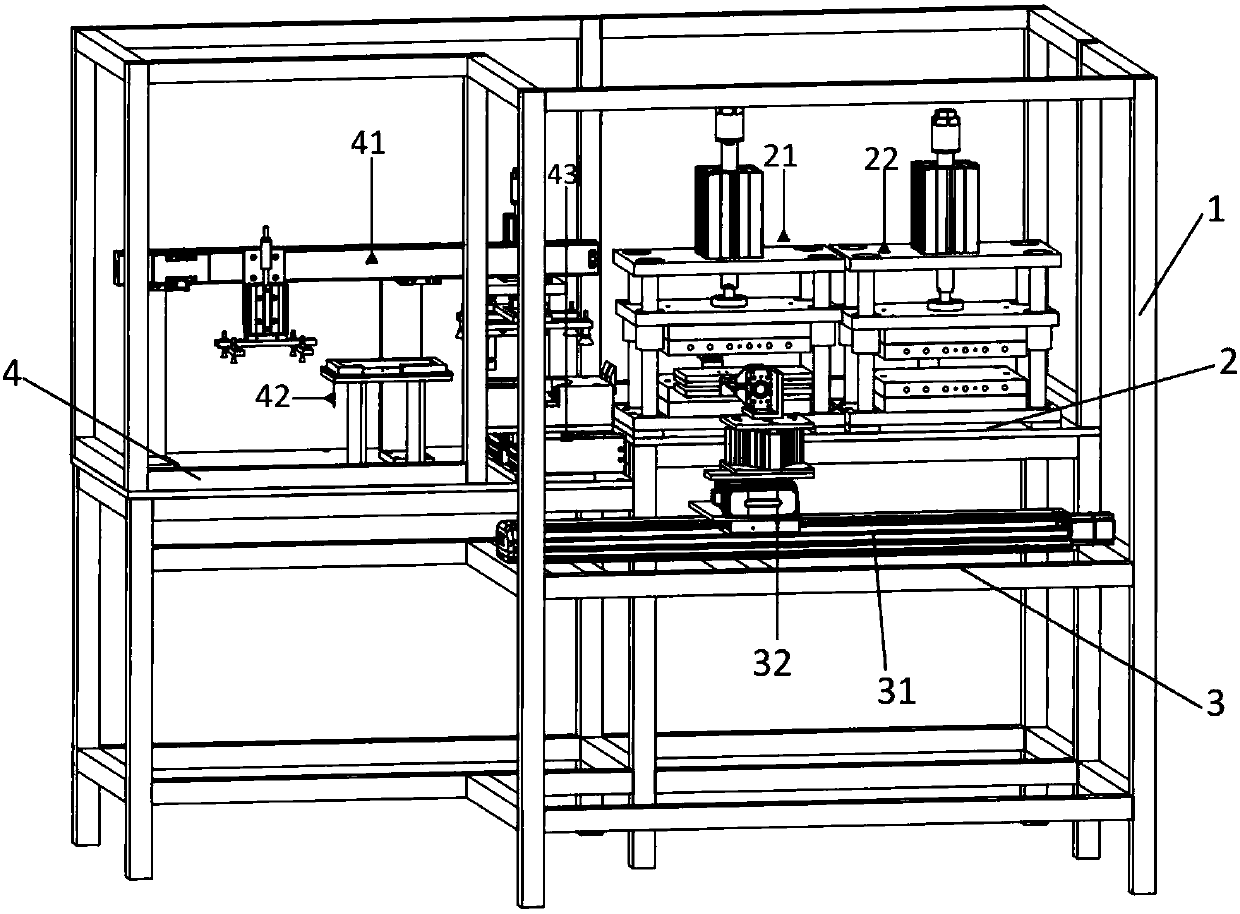

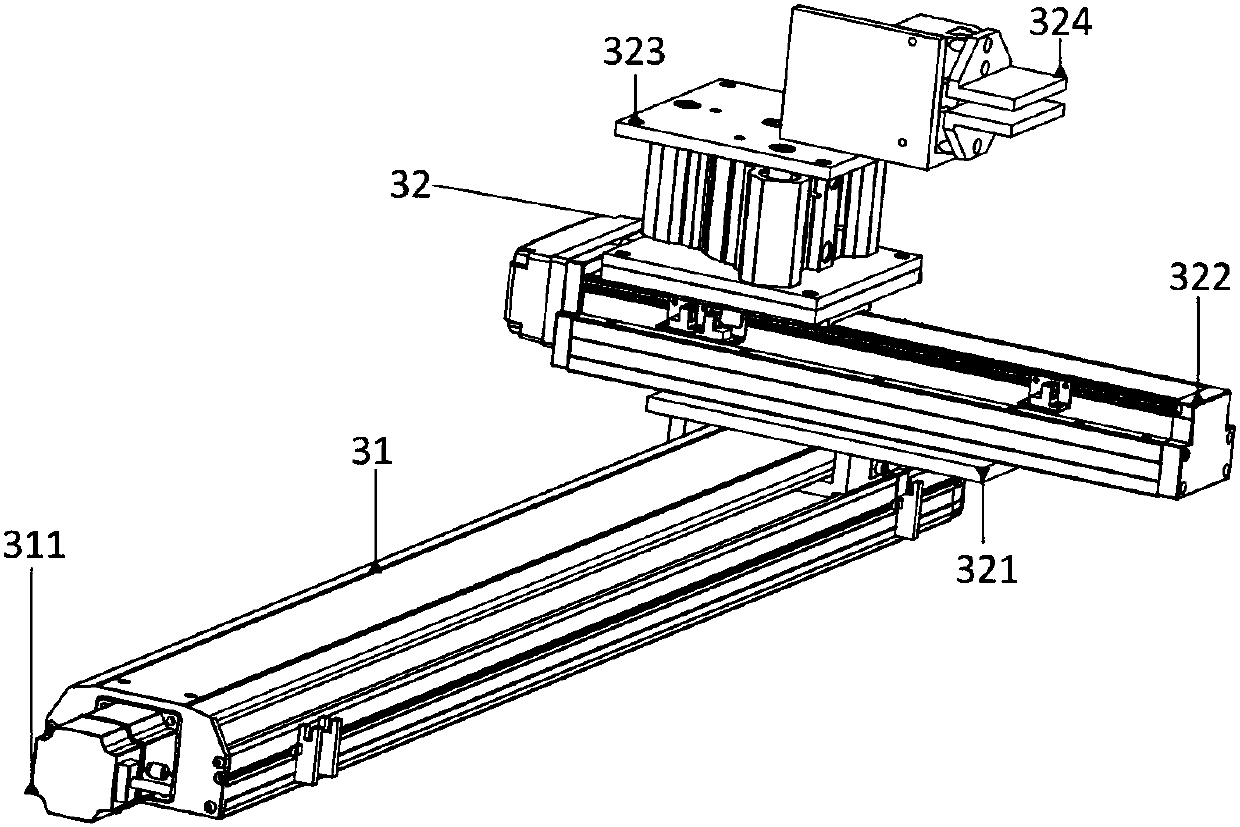

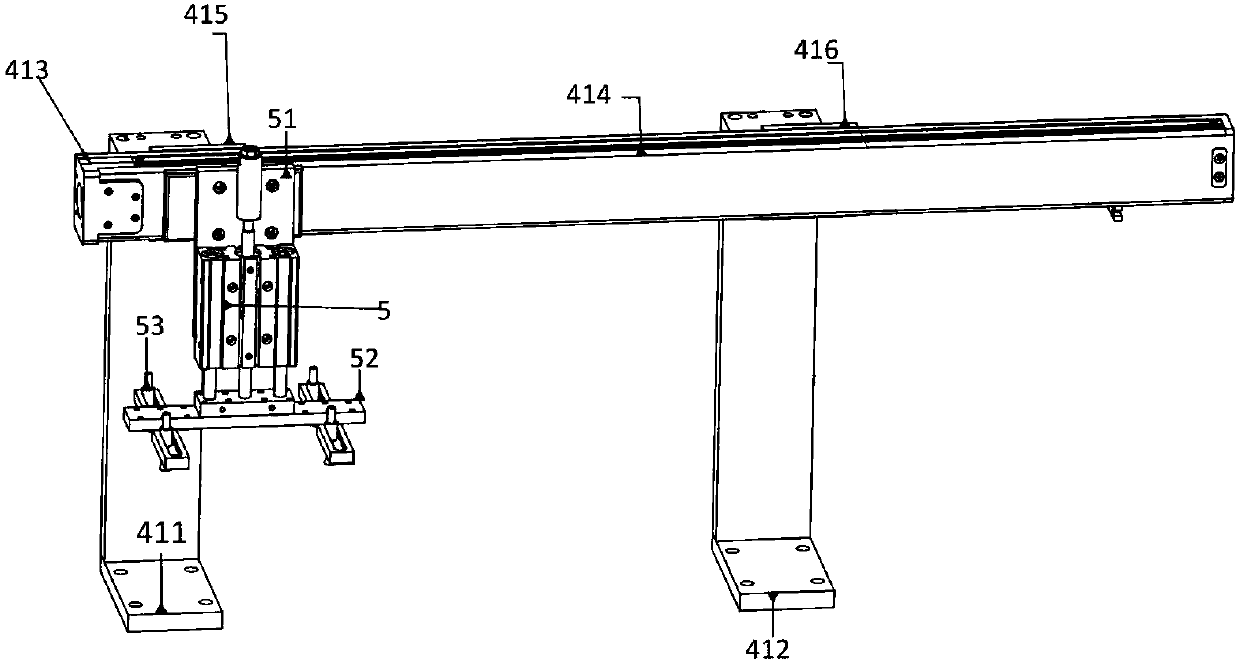

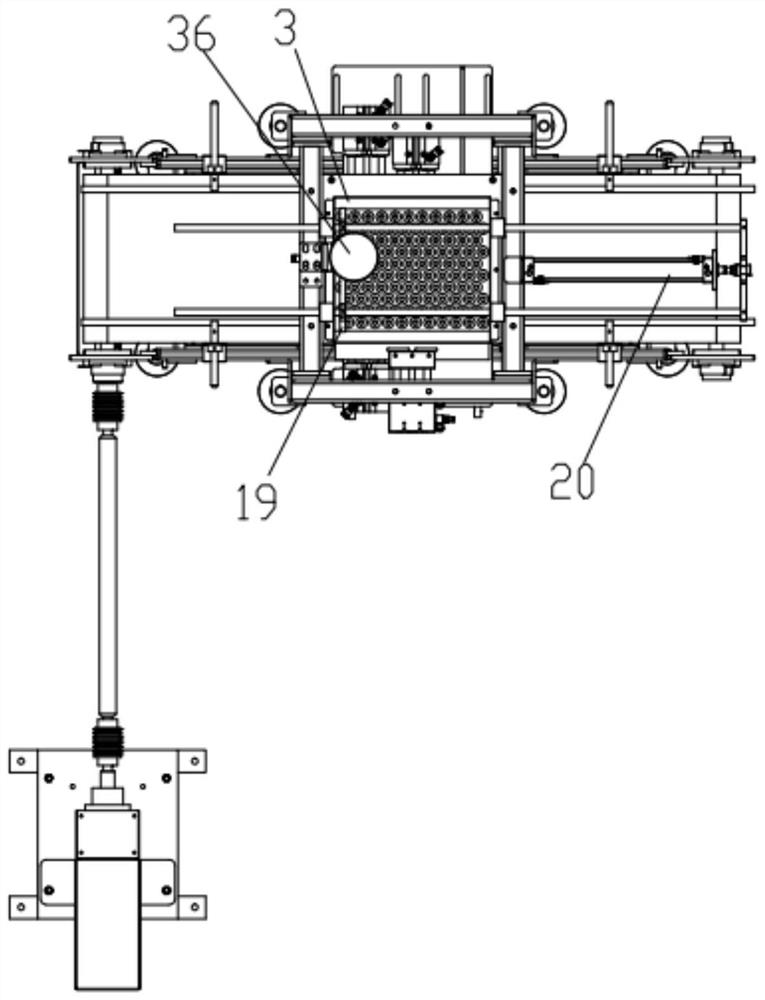

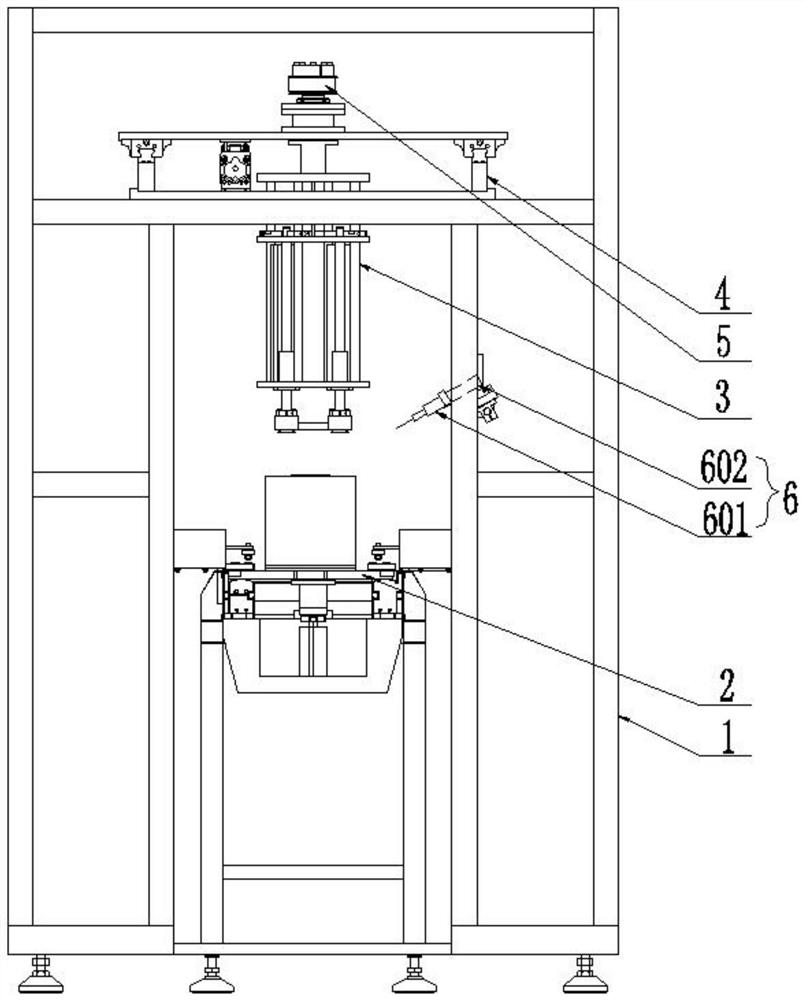

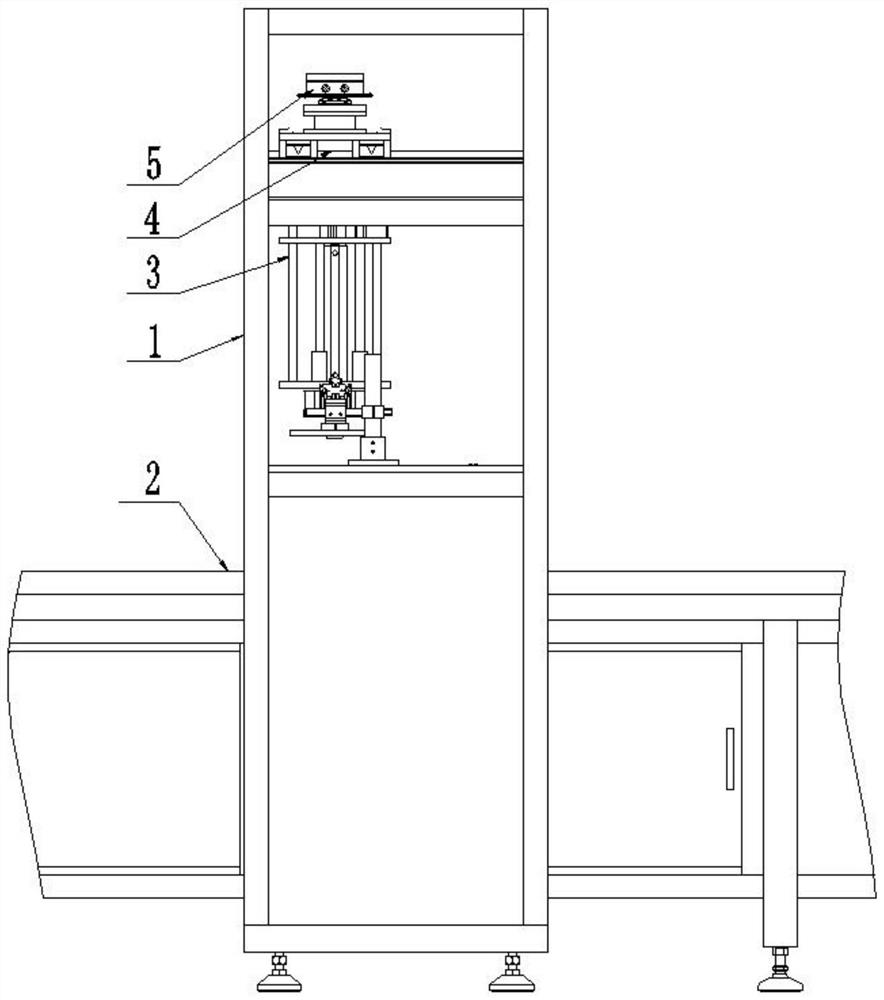

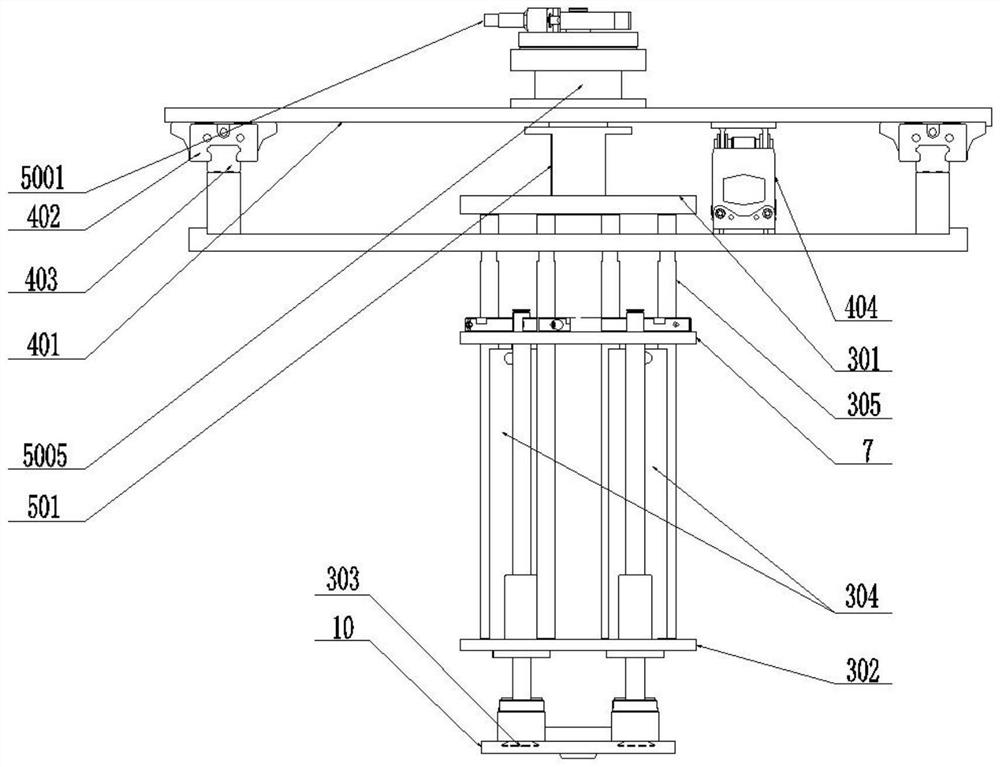

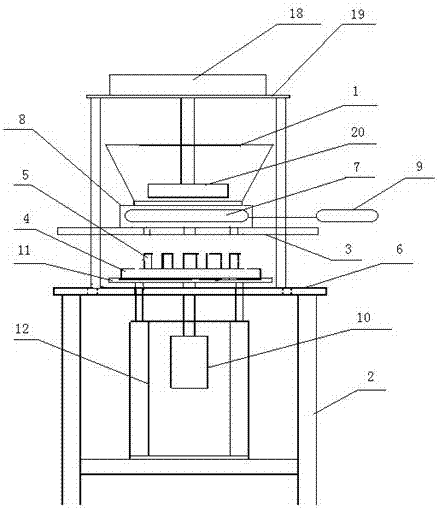

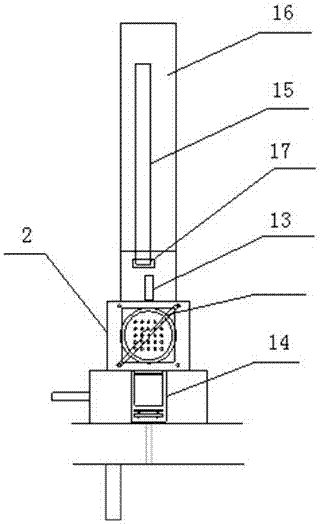

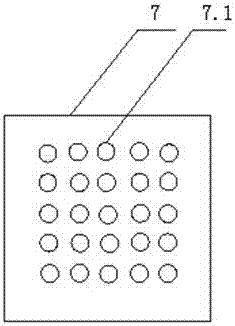

Combined fireworks explosive automatic filling equipment

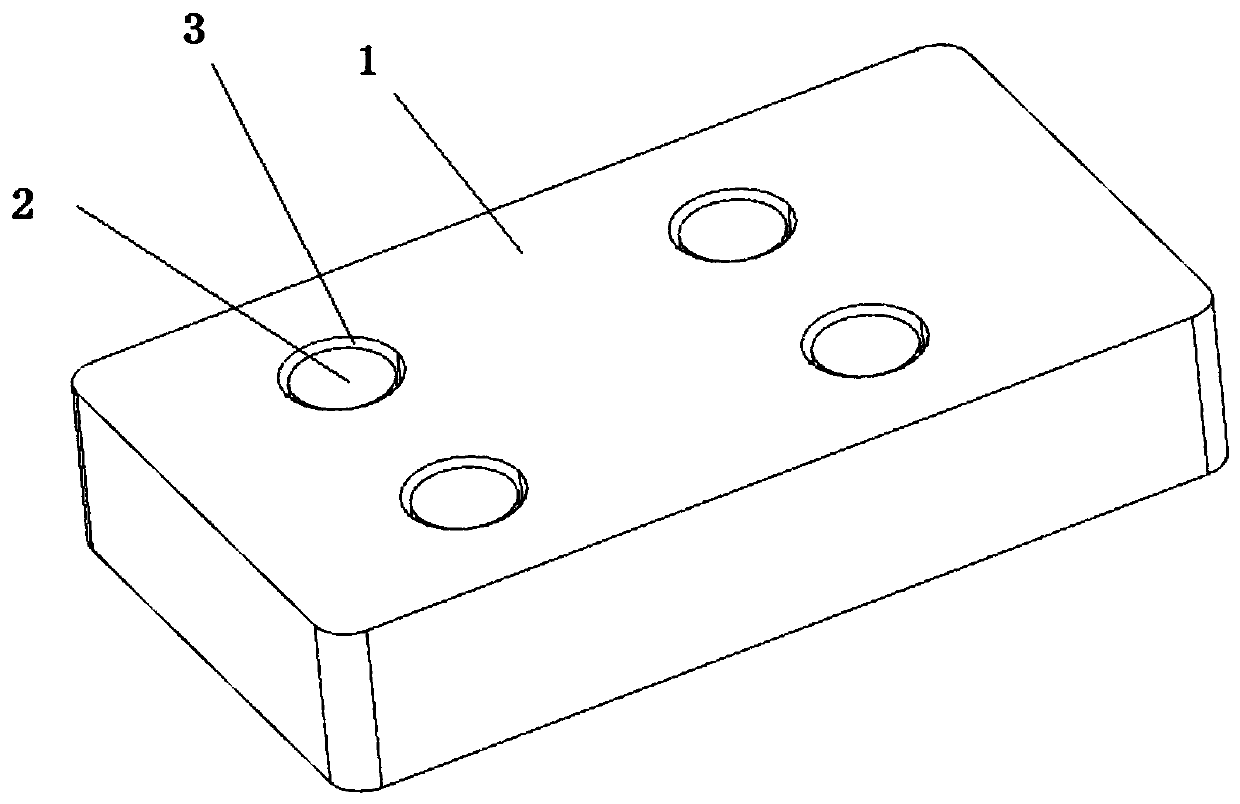

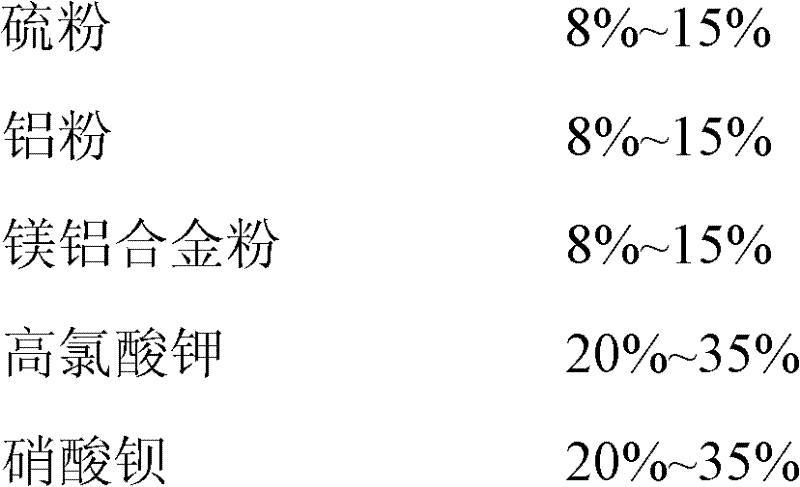

PendingCN107356160AIncrease productivityRealize the separation of man and machineFireworksMan machineFireworks

The invention discloses combined fireworks explosive automatic filling equipment. The equipment is arranged in an explosion-proof workshop; cylinder cakes are output and input by conveying belts, and are automatically and accurately positioned on a filling station to match with a filling mechanism; the filling mechanism comprises upper through holes and lower through holes staggered correspondingly; explosive reception and explosive loading are realized by left-right sliding of a middle slide plate; meanwhile, a redundant explosive temporary storage cavity, a convex bar, an outer ring cavity and the like are arranged on the middle slide plate for guaranteeing safety; and the working reliability is guaranteed through a lifting mechanism and a vibration mechanism. The equipment can automatically finish the explosive loading process under the precondition of truly guaranteeing the safety performance to greatly improve the production efficiency on the basis of reliable work, and realizes man-machine separation and man-explosive separation to prevent personal safety accidents.

Owner:赵光荣

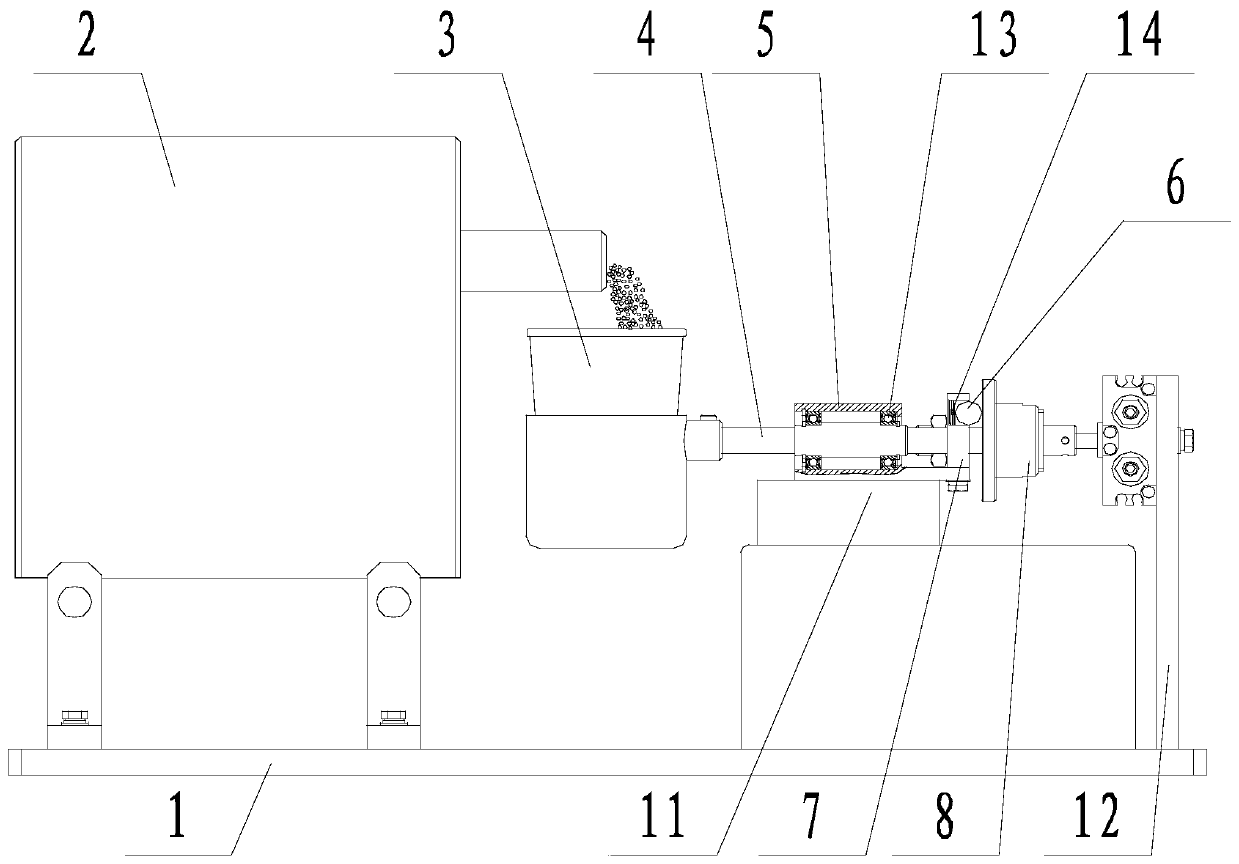

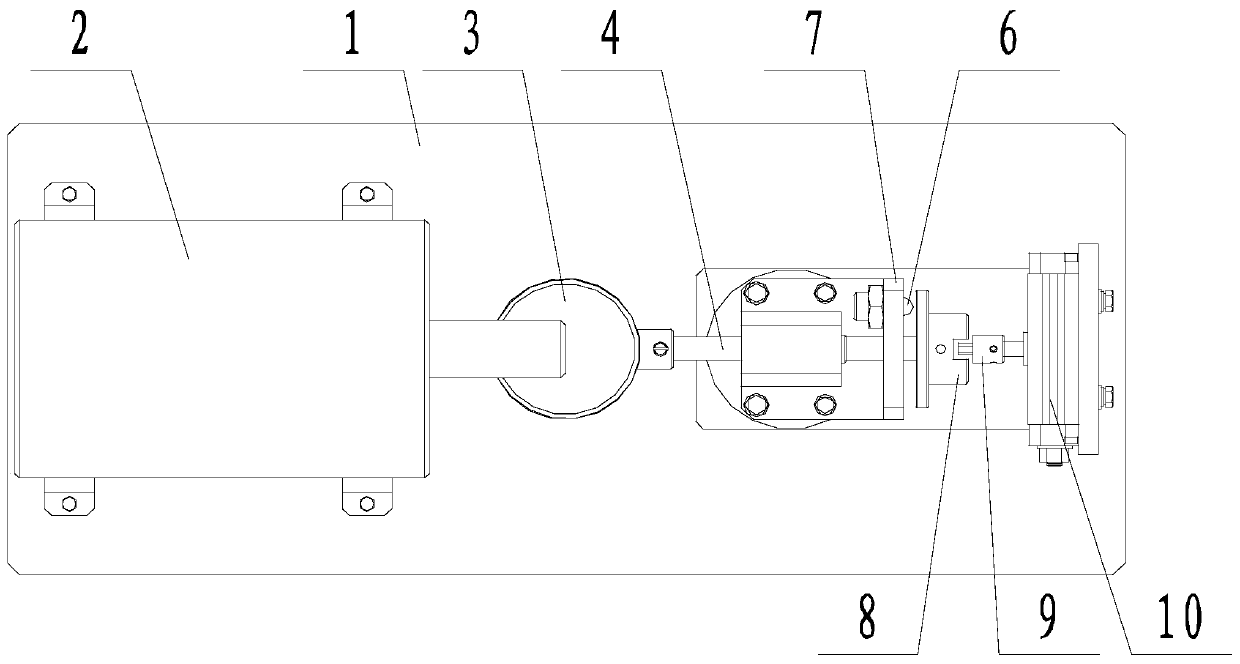

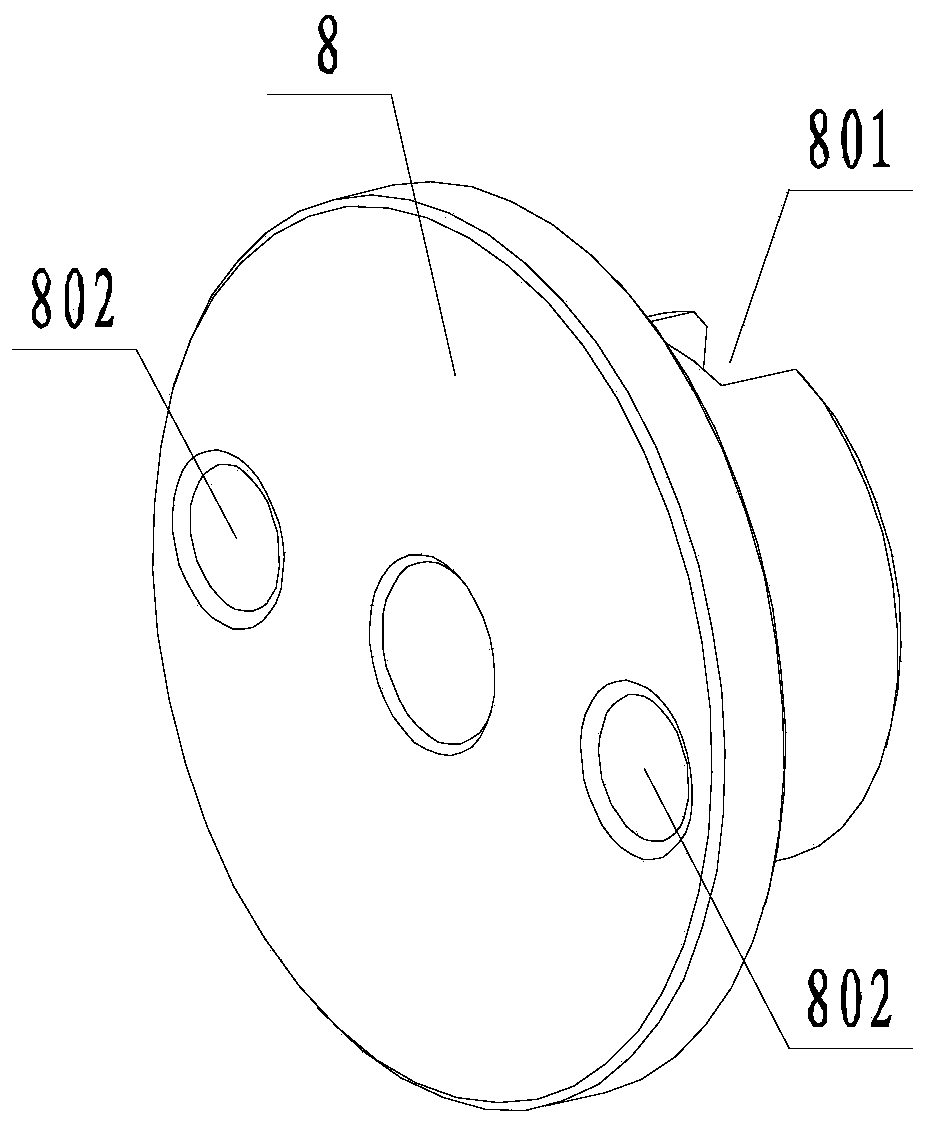

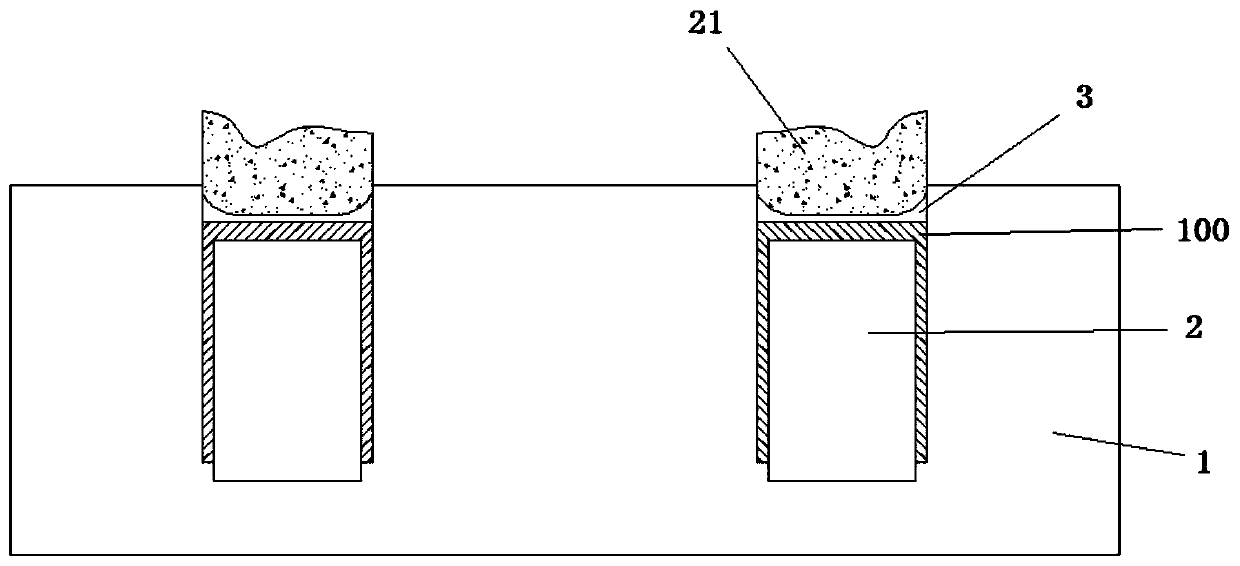

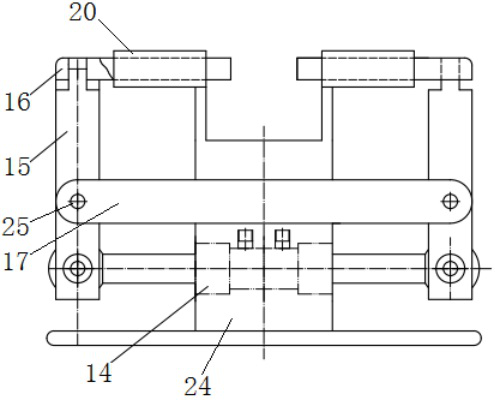

Automatic weighing and pouring device and method for energetic raw material

InactiveCN109752065AEnsure safetySuitable for accurate weighingWeighing apparatus with automatic feed/dischargeDrive shaftMan machine

The invention discloses an automatic weighing and pouring device and method for an energetic raw material. The device comprises a feeding mechanism and a weighing material cup positioned below a discharging hole of the feeding mechanism; the weighing material cup is fixedly connected with a driving shaft; the weighing material cup can rotate along with the driving shaft; one end, far away from theweighing material cup, of the driving shaft is fixedly connected with a shifting fork; the device further comprises a rotating device; the rotating device is used for driving a shifting block to rotate; the shifting fork can rotate along with the shifting block; the device further comprises a weighing sensor; and the weighing sensor is used for monitoring the weight change of the weighing material cup. According to the automatic weighing and pouring device and method for the energetic raw material, the problems of low weighing and pouring efficiency, low automation degree, high potential safety hazard and complex structure of the initiating explosive device and civil explosion industry in the prior art are solved, so that the purposes of improving the automation degree, realizing the man-machine separation and ensuring the personnel safety are achieved.

Owner:CHINA SOUTH IND GRP AUTOMATION RES INST

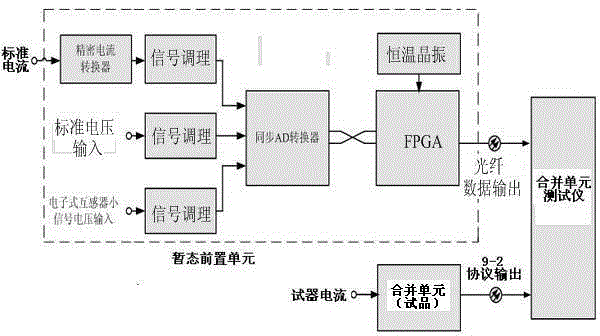

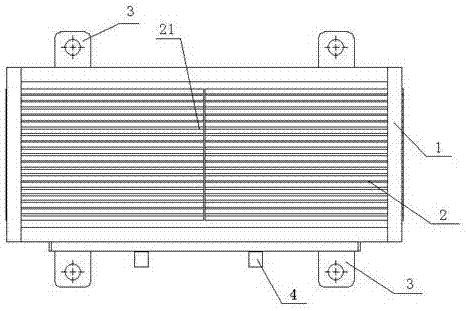

Transient sampling pre-unit for transient testing of electronic transformer and merging unit

InactiveCN104614696AGuaranteed fidelityGood real-time testElectrical measurementsConvertersAnti jamming

The invention provides a transient sampling pre-unit for transient testing of an electronic transformer and a merging unit. The transient sampling pre-unit is composed of a precision current converter, a signal processing circuit, a synchronous AD converter, a constant-temperature crystal oscillator and an FPGA (field-programmable gate array). The signal processing circuit comprises is used for performing signal conditioning on a standard source transient current signal converted by the precision current converter, signal conditioning on the transient low voltage signal of the standard source and signal conditioning on the low voltage signal of an electronic transformer test object; the three signals conditioned are sent into the synchronous AD converter; the synchronous AD converter is connected with the FPGA and outputs signals via an optical fiber serial transmitter. The transient sampling pre-unit has the characteristics of high-speed sampling, high testing precision, good saturation characteristic, good real-time testing property, excellent anti-interference performance, good safety and the like. The transient sampling pre-unit is capable of accurately testing the transient precision of the digital quantity transmitted by the merging unit based on discrete data and providing detection basis for large-area promotion of intelligent substations.

Owner:STATE GRID CORP OF CHINA +1

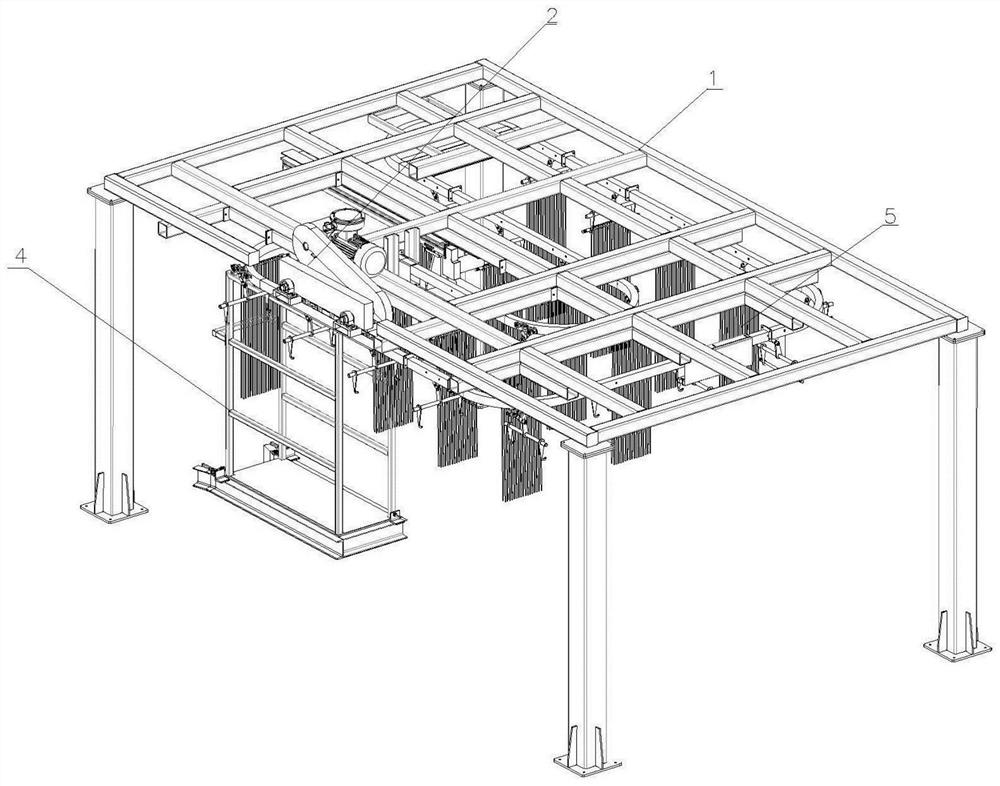

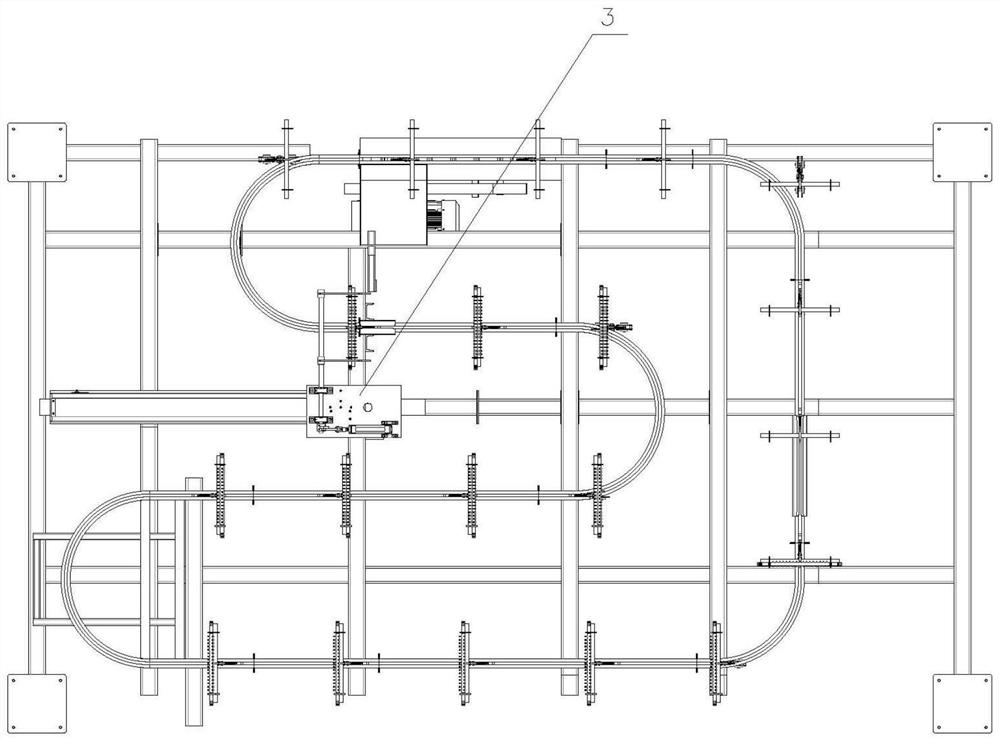

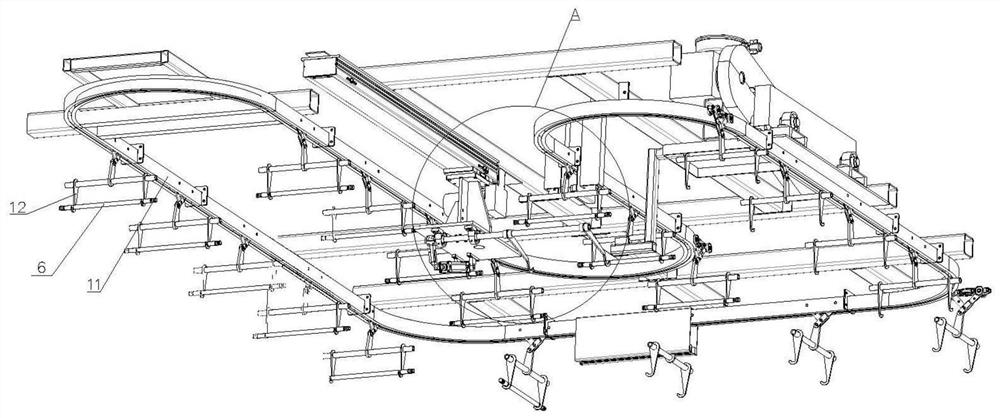

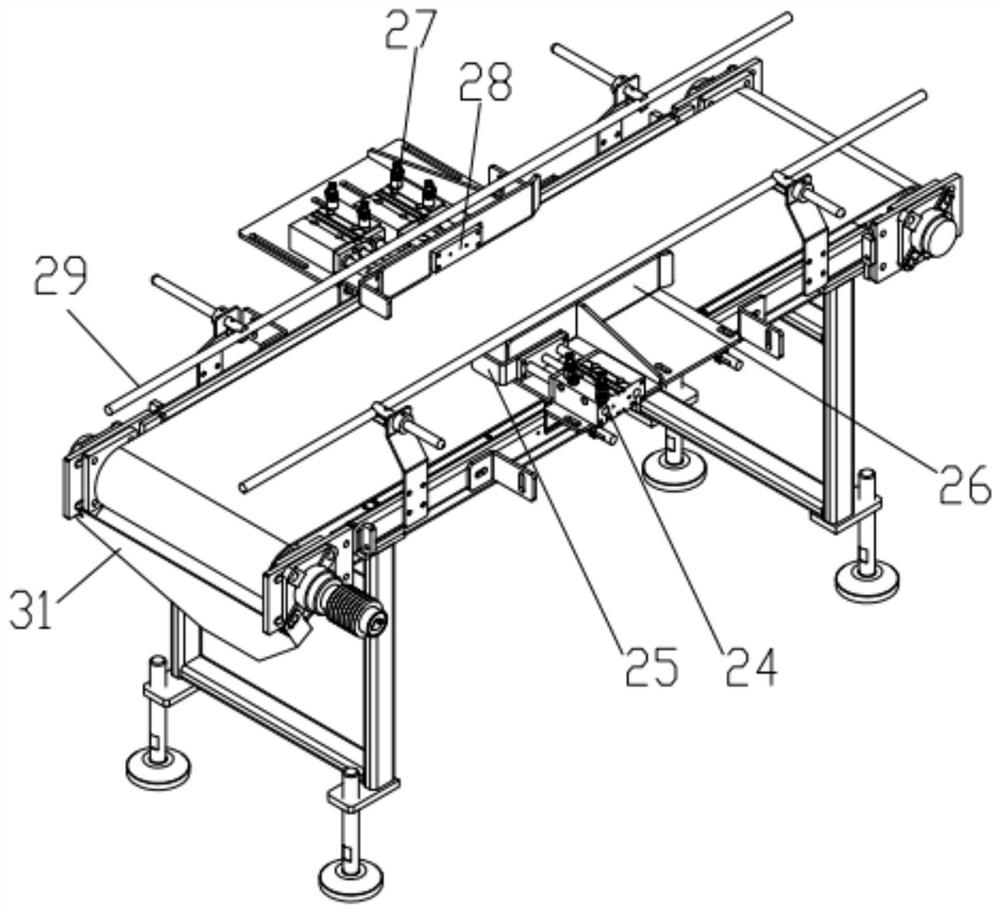

Explosive rod transferring device for hanging explosive strips

ActiveCN111776614AAvoid harmRealize the separation of man and machineConveyorsControl devices for conveyorsMan machineChain link

The invention discloses an explosive rod transferring device for hanging explosive strips. The explosive rod transferring device aims to solve the problems that in the prior art, the explosive rod transferring speed of hanging the explosive strips is low, and the whole production process is influenced; and the solvent in the explosive strip of an initiating explosive device is severely volatilized, so that the harm to a human body is great, and dangerous accidents are easily caused. A closed-loop transfer rail is arranged on a transfer support, a transfer chain is arranged in the transfer rail, a driving assembly drives the transfer chain to operate circularly, the transfer chain drives a plurality of pairs of hooks to operate along with the transfer chain, the stacked explosive rods are unfolded one by one to be distributed on the transfer chain and then placed on a carrying trolley one by one through a discharging assembly, so that mechanical automation is integrally formed, man-machine separation is achieved, harm of the explosive strip solvent volatilization to the human body is avoided, and meanwhile the production speed is increased.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

Explosion-proof fuze tightening machine

The invention belongs to the field of assembly of small-caliber bombs, and in particular relates to a special machine for tightening explosion-proof fuzes used in the assembly of small-caliber bombs. The explosion-proof fuze tightening machine of the present invention includes a full-bomb cup, a full-bomb positioning platform, an automatic pressurizing device, a fuze tightening device, an air circuit system, a control part and control software. The air source, valve, air pipe and the pneumatic actuators of the above mechanical parts form an air circuit system. The control software is set in the controller of the control part, and the controller and the control software control the operation of the above-mentioned mechanical structure. The explosion-proof fuze tightening special machine of the invention can automatically complete the fuze tightening. It solves the screwing depth control when the fuze is tightened, which can ensure the quality of the fuze tightening, improve production efficiency, realize the separation of man and machine, and ensure the safety of production personnel.

Owner:SICHUAN MIANYANG SOUTHWEST AUTOMATION INST

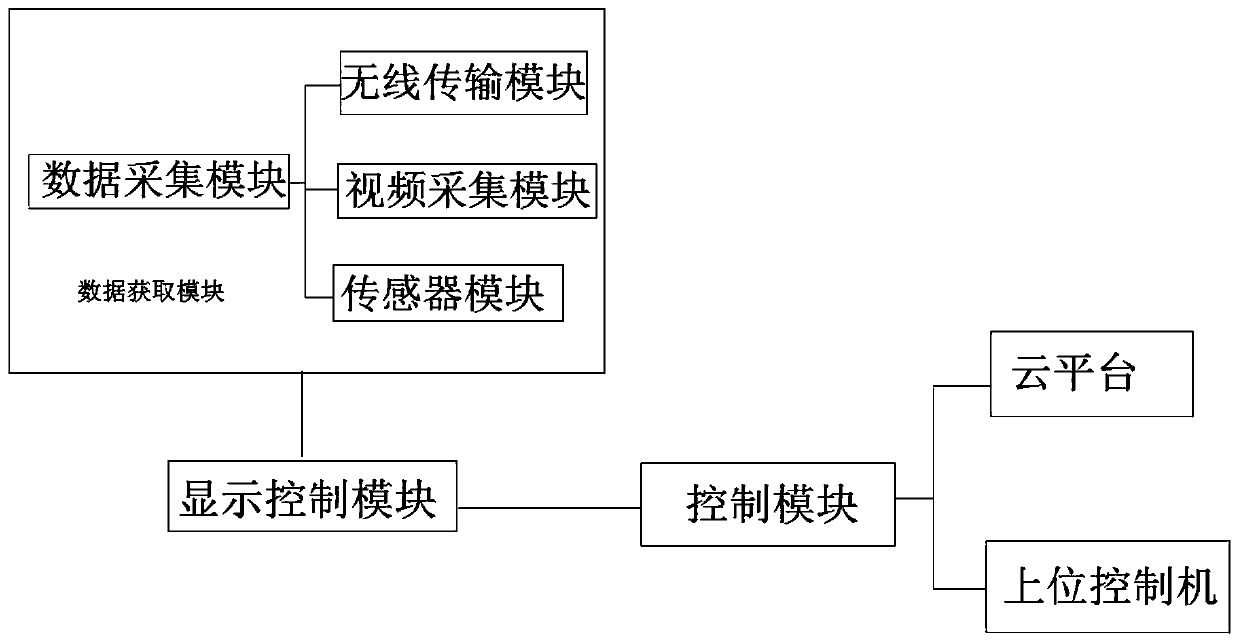

3D printing remote monitoring system based on cloud platform and control method

InactiveCN110948879AImprove printing efficiencyImprove intelligenceAdditive manufacturing apparatusManufacturing data aquisition/processingEnvironmental geologyVideo transmission

The invention discloses a 3D printing remote monitoring system based on a cloud platform. The 3D printing remote monitoring is realized through a remote monitoring system, so that the real-time printing and the real-time monitoring for printing by an upper computer are realized; a video transmission system is used for 3D printer real-time printing monitoring conditions; a sensor technology is usedfor obtaining and storing printing parameters; data is stored and transferred based on the cloud platform; the upper computer is used for realizing direct transmission of the data in the cloud platform to a control module; the control module is used as a control bridge between a 3D printer and the upper computer to realize man-machine separation, so that the printing efficiency is improved, and the intelligence is further improved; and through combination of the cloud platform and the 3D printing technology, the manpower and material resources can be greatly saved.

Owner:BEIFANG UNIV OF NATITIES

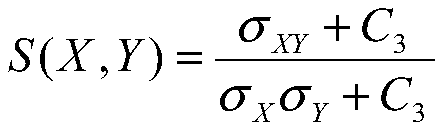

Underground crop digging robot and control method thereof

The present invention discloses an underground crop digging robot and a control method thereof. The robot comprises a travelling mechanism, a soil loosening mechanism, a transmission mechanism, a bagging mechanism and a control system. The travelling mechanism comprises driving wheels and a driven wheel which are arranged at the two ends of a rack respectively, the driving wheels comprise a right driving wheel driven by a first motor and a left driving wheel driven by a second motor, and one ends of the driving wheels are a machine head. The soil loosening mechanism is arranged at the bottom of the rack and comprises a soil digging shovel and a soil loosening shovel, the tail parts of the soil digging shovel and the soil loosening shovel are both connected with the rack, and the transmission mechanism is arranged on the rack. The head of a horizontal conveyor belt is contacted with the tail part of the soil digging shovel, and the tail part is contacted with the bottom of a vertical conveyor belt. The bagging mechanism is arranged at the tail part of the rack and comprises a bag for holding the underground crops. The underground crop digging robot and the control method thereof solve the structural insufficiency of a conventional potato digging machine, highlight the characteristics of the potato digging machine, such as light volume, automatic driving, automatic potato bagging, etc., in the mechanism design, realize the man-machine separation, and avoid the electric shock potential safety hazards of people.

Owner:BEIFANG UNIV OF NATITIES

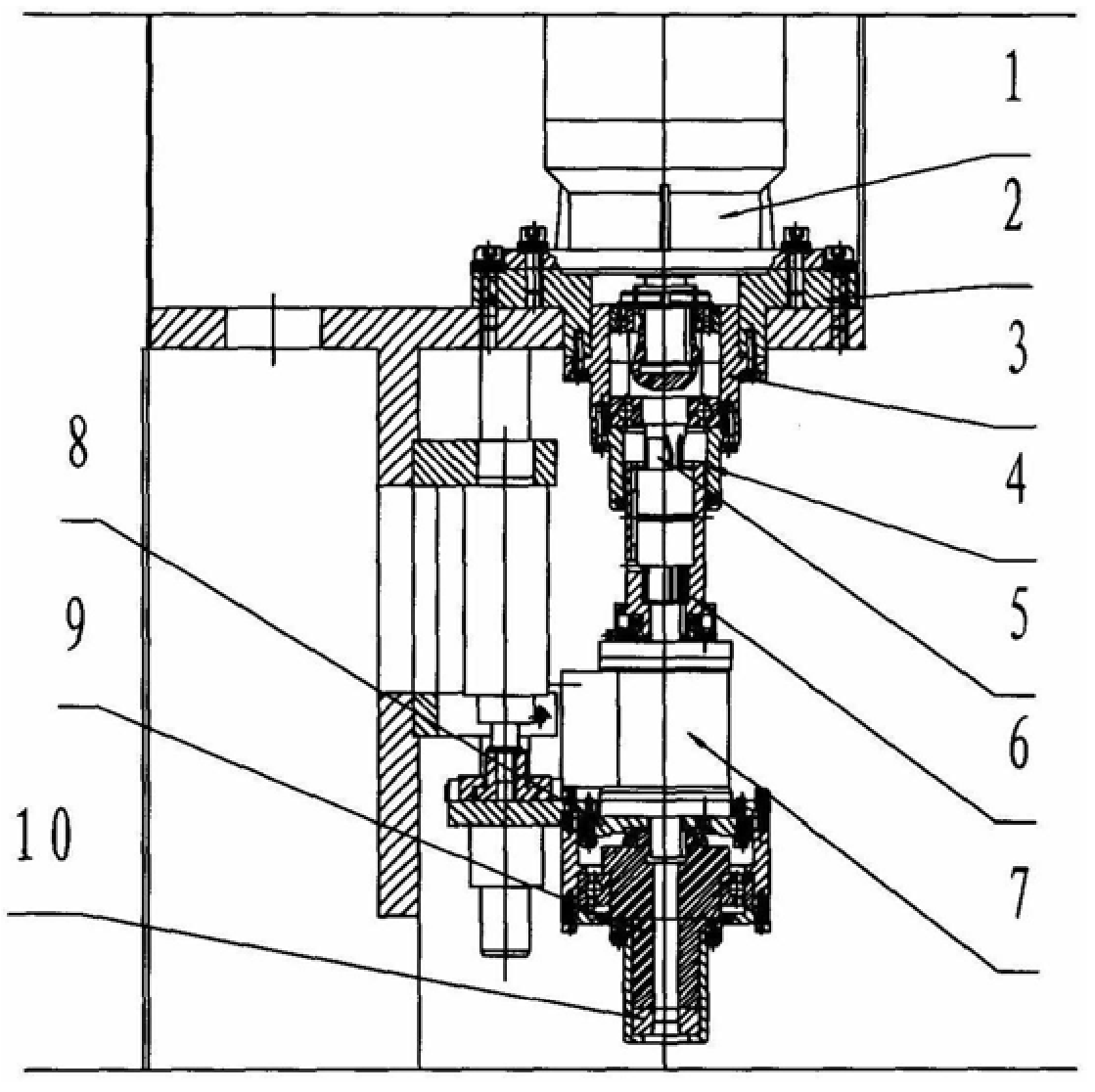

Screw-in electric bottom fire explosion-proof tightening machine

InactiveCN106342168BEnsure safetySolve the pit problemPower driven toolsAmmunition fuzesEngineeringMechanical construction

The invention belongs to the field of assembly of small-caliber bullets, and in particular relates to a screw-in type electric primer explosion-proof screwing machine used in the assembly of small-caliber bullets. A screw-in type electric primer explosion-proof tightening machine of the present invention includes a cartridge cup, a jacking mechanism, a positioning and clamping mechanism, a pit device for automatically pressurizing and searching for a screw-in type electric primer, an air circuit system, a control part and controlling software. The jacking mechanism of the screw-in electric primer explosion-proof screwing machine is installed on the machine base, the cartridge cup is located above the jacking mechanism, and the positioning and clamping mechanism, automatic pressurization and the pit device for finding the screw-in electric primer are located in the cartridge in turn. The top of the cylinder cups are installed on the rack. The air source, valve, air pipe and the pneumatic actuators of the above mechanical parts form an air circuit system. The control software is set in the controller of the control part, and the controller and the control software control the operation of the above-mentioned mechanical structure. The screw-in electric primer explosion-proof tightening machine of the present invention can automatically complete the screwing of the screw-in electric primer, it solves the problem of automatically finding the pit on the screw-in electric primer, and can ensure the precision control of the screw-in electric primer tightening depth , to ensure product quality, realize the separation of man and machine, and ensure the safety of production personnel.

Owner:SICHUAN MIANYANG SOUTHWEST AUTOMATION INST

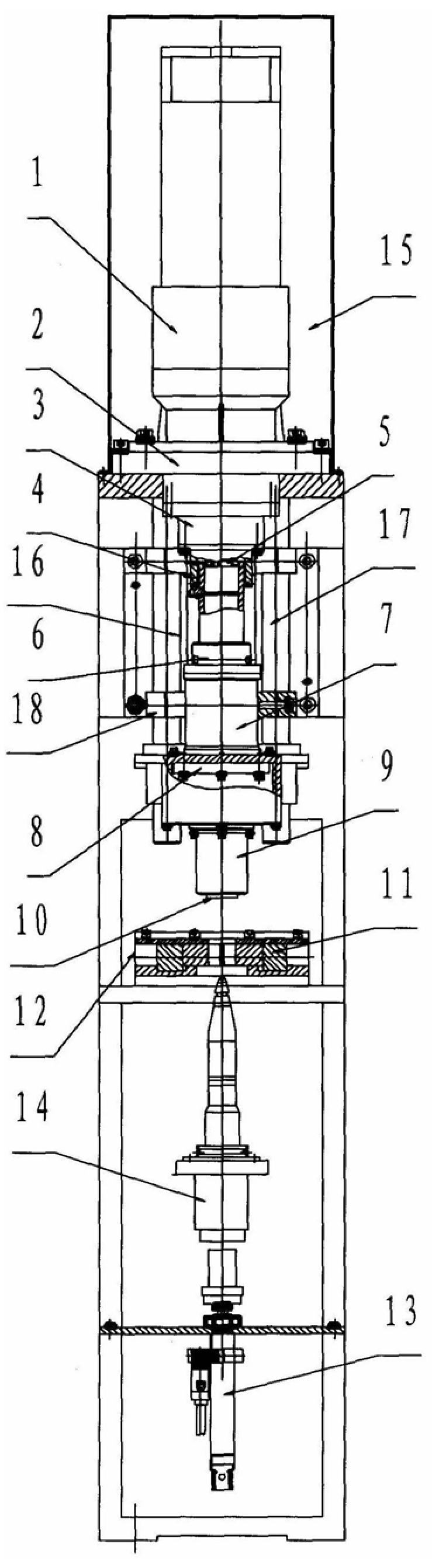

Explosion-proof gas-hydraulic coupling device for projectile and cartridge

InactiveCN106342165BReduce labor intensityRealize the separation of man and machineAmmunition storageFluid-pressure actuatorsMan machineEngineering

The invention belongs to the field of assembly of small-caliber bullets, and in particular relates to an explosion-proof gas-hydraulic combination device for projectiles and cartridges used in the assembly of small-caliber bullets. An explosion-proof gas-hydraulic combination device for projectiles and cartridges of the present invention includes a machine base, a lifting mechanism, a cartridge positioning cup, a pressing mechanism, an air circuit system, a control part and control software. The lifting mechanism of the explosion-proof gas-hydraulic combination device for projectiles and cartridges is located behind the cartridge positioning cup and is fixed on the lower part of the machine base; the pressing mechanism is located above the cartridge positioning cup and is fixed on the upper part of the machine base; the air source, valve 1. The air pipe and the pneumatic components of the above-mentioned mechanical part form an air circuit system; the control software is set in the controller of the controller part, and the controller and control software control the work of the above-mentioned mechanical part. The explosion-proof air-hydraulic combination device for projectile and cartridge can not only automatically complete the loading and unloading, press the projectile and cartridge according to the set pressing depth and pressure, but also realize the separation of man and machine, and reduce the labor of workers Strength, good dynamic performance during the pressing process, after pressing, it can ensure the requirements of the pressing gap and the coaxiality of the whole elastic, and can meet the CIIT4 explosion-proof standard, with good safety performance.

Owner:SICHUAN MIANYANG SOUTHWEST AUTOMATION INST

Experimental method for container pipeline gas explosion experimental device with concentration gradient

InactiveCN109738607AImplement automatic configurationImprove COPFuel testingExperimental methodsCombustible gas

The invention relates to an experimental method of a container pipeline gas explosion experimental device with a concentration gradient. The method comprises the following steps: starting a vacuum pump to make first to fifth gas concentration limited spaces vacuum; setting a gradient concentration under negative pressure, configuring combustible gases of different concentrations in the five gas concentration limited spaces, or configuring combustible gases of different concentrations in the first to fourth gas concentration limited spaces while configuring an inert gas in the fifth gas concentration limited space; and carrying out an ignition experiment, enabling an upper computer to control four sealing devices at the same time to communicate the five gas concentration limited spaces, sending an ignition instruction to an ignition device, sensing the pressure change with a PCB pressure sensor, detecting a flame signal with a flame detector, and transmitting monitoring data to the upper computer for analysis and processing. The configuration of the combustible gases with different combination concentrations and the configuration of combustible gases with different combination concentrations and the inert gas can be realized, so as to study the explosion propagation mechanism and explosion evolution dynamics process of combustible gases with concentration gradients.

Owner:应急管理部天津消防研究所

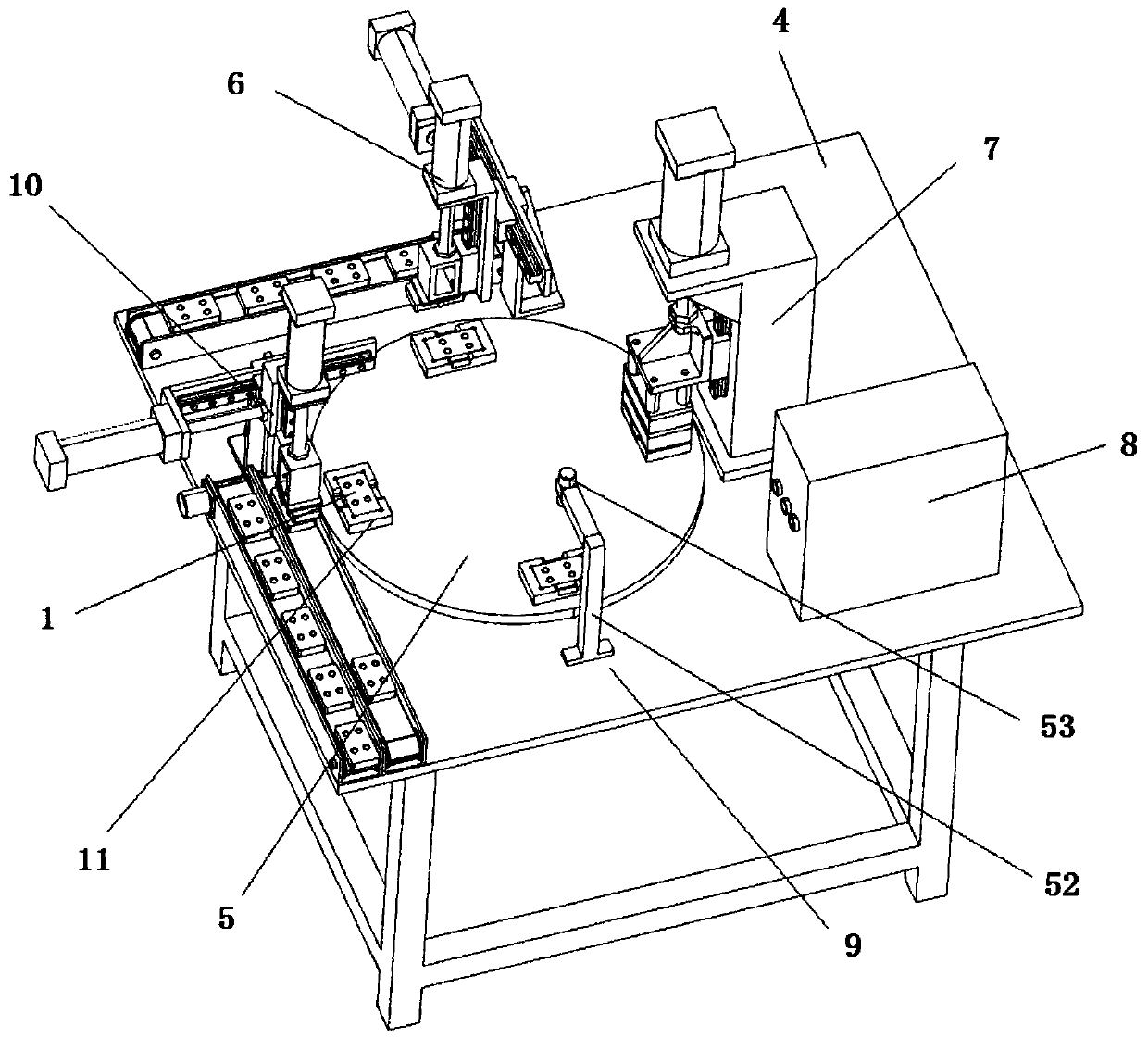

Full-automatic welding device of magnetic inductor

PendingCN111361162ARealize automatic feeding processRealize automatic weldingSortingControl engineeringInductor

The invention relates to a full-automatic welding device of a magnetic inductor. The full-automatic welding device comprises a rack, wherein a rotary positioning disc, an automatic feeding mechanism,an automatic welding mechanism, a workbin control mechanism, an automatic detecting mechanism and an automatic discharging mechanism are arranged on the rack; the automatic feeding mechanism, the automatic welding mechanism, the automatic detecting mechanism and the automatic discharging mechanism are sequentially arranged around the rotary positioning disc; and workpiece positioning clamps in one-to-one correspondence with the automatic feeding mechanism, the automatic welding mechanism, the automatic detecting mechanism and the automatic discharging mechanism are arranged on the rotary positioning disc. The workpiece positioning clamps on the rotary positioning disc as processing stations to be in one-to-one correspondence with the automatic feeding mechanism, the automatic welding mechanism, the automatic detecting mechanism and the automatic discharging mechanism are utilized, so that the full-automatic welding device realizes unified and continuous operation of automatic feeding,automatic welding, automatic detection and automatic discharging, realizes replacement of manual operation through full automation, and greatly improves the assembling efficiency.

Owner:HUIZHOU JIAHONGCHANG MAGNET PROD

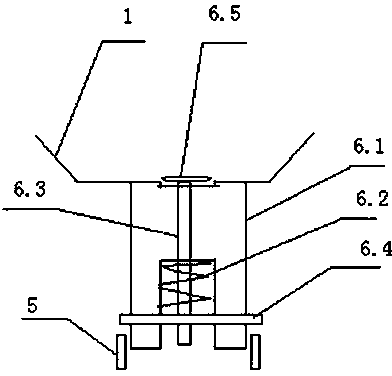

Wet mixing machine capable of facilitating material clearing for chemicals

InactiveCN110449063AEasy to cleanImprove uniformityRotary stirring mixersTransportation and packagingEngineering

The invention discloses a wet mixing machine capable of facilitating material clearing for chemicals. The machine comprises a working platform, a material mixing pot is arranged above the upper side of the working platform through a frame, the material mixing pot is connected with the working platform through a rotary supporting mechanism, and the material mixing pot is connected with a rotating device for controlling rotation of the material mixing pot; and the interior of the material mixing pot is provided with a stirring device, the stirring device is connected with a power device, the power device is located outside the material mixing pot, and the connection place of the stirring device and the power device is located on the rotary central axis of the material mixing pot. According to the machine provided by the invention, the material mixing pot and the stirring device are arranged, so that mixing of the chemicals is realized; the rotating device is arranged, so that turning ofthe material mixing pot for material clearing is realized; an open-close pot bottom of the material mixing pot is designed, so that timely clearing of the material mixing pot is facilitated, and the difficult problems that an original machine uses great labor to pour materials and materials are difficult to clear are solved; mixing of the chemicals can be automatically completed by controlling a motor, and the uniformity of the mixed chemicals is high; and separation of human and machine is realized in the whole wet mixing process, safety of workers is ensured, and the efficiency of mixing thechemicals is improved.

Owner:河南中南工业有限责任公司

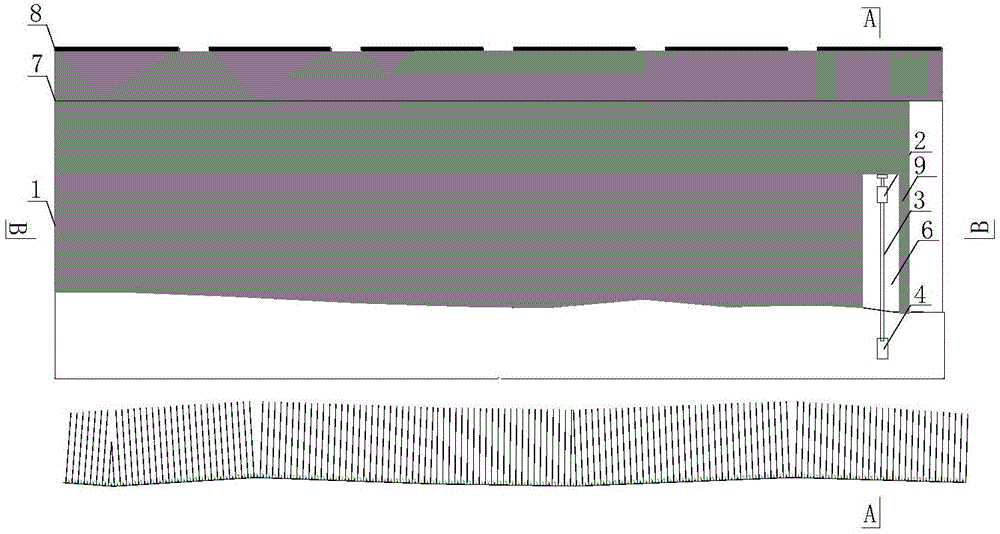

Method for sealing inner cylinder of composite firework with sealing agent and inner cylinder sealing agent machine

InactiveCN103507301AImprove securityHigh degree of automationPaper/cardboard wound articlesFireworksWorking environmentFireworks

The invention relates to the technical field of firework production equipment, and discloses a method for sealing inner cylinder of composite firework with a sealing agent and an inner cylinder sealing agent machine. The inner cylinder sealing agent machine comprises a template in-and-out operating mechanism, a lower position upper ejecting mechanism, and an automatic sealing agent filling device, wherein the template in-and-out operating mechanism for feeding an inner cylinder template in a sealing agent filling start station is arranged on one side of a frame sealing agent application start position, the lower position upper ejecting mechanism for lifting the inner core template is arranged in the center of the frame sealing agent application start position, and the automatic sealing agent filling device arranged at the bottom of a sealing agent pressure container comprises a plurality of sealing agent injecting nozzles, each of which corresponds to an inner core rack pipe lifted to the sealing agent filling position. Due to improvement and development of traditional firework production process, the invention has the characteristics of high safety, less occupied space, high degree of automation, less labor consumption, high efficiency, and good production working environment, and achieves fundamental shift of the development of firework production industry.

Owner:HENAN LINXIAO SCI & TECH DEV

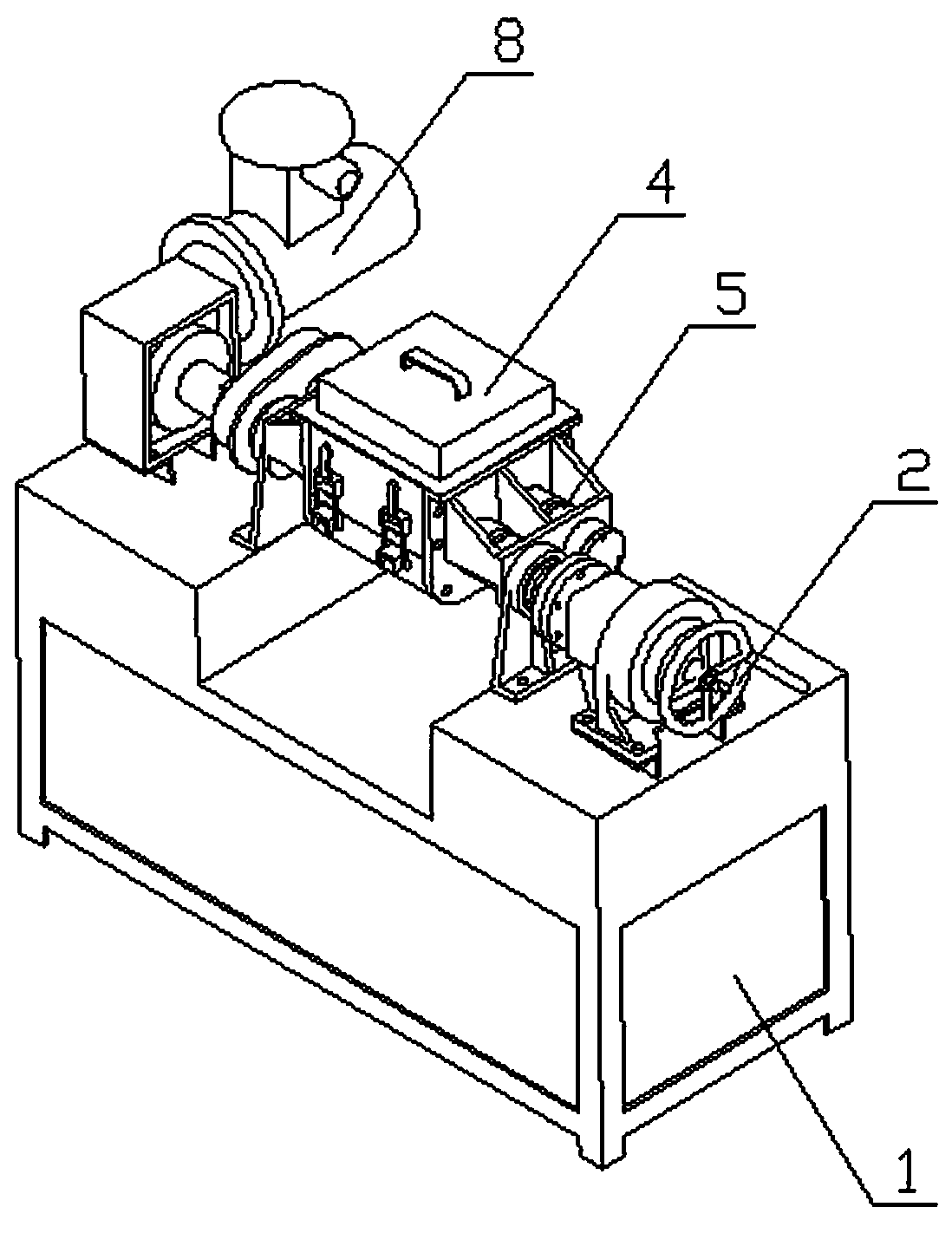

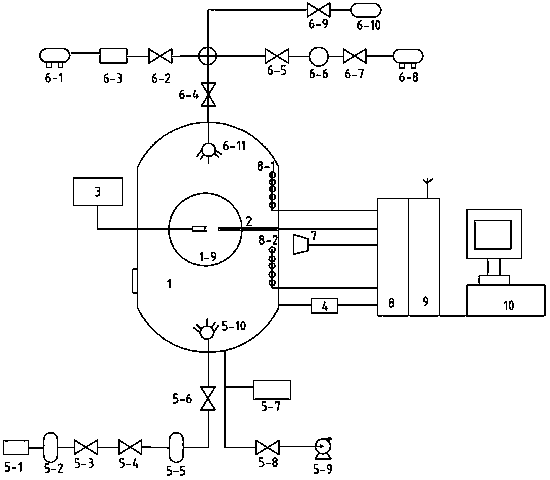

Container pipeline gas explosion experiment device with concentration gradient and use method

InactiveCN109738608AImplement automatic configurationRealize the separation of man and machineFuel testingCombustible gasConcentration gradient

The invention relates to a container pipeline gas explosion experiment device with a concentration gradient and a use method. A vacuum pump is started until a first gas concentration restriction space, a second gas concentration restriction space, a third gas concentration restriction space, a fourth gas concentration restriction space and a fifth gas concentration restriction space are under a vacuum state; gradient concentration is subjected to negative pressure proportioning, and combustible gases of different concentrations are proportioned in five gas concentration restriction spaces; anignition experiment is carried out, an upper computer simultaneously controls four sealing devices to simultaneously link the five gas concentration restriction spaces, an ignition instruction is emitted to an ignition device, a PCB (Printed Circuit Board) pressure sensor induces pressure changes, a flame detector detects a flame signal, and monitoring data are transmitted to the upper computer tobe analyzed and processed. By use of the device and the method, the ignition at different positions and the configuration function of combustible gases of different combined concentrations can be realized, so that the explosion transmission mechanism and the explosion evolution dynamic process of the combustible gases with different concentration gradients under different working conditions can be researched.

Owner:应急管理部天津消防研究所

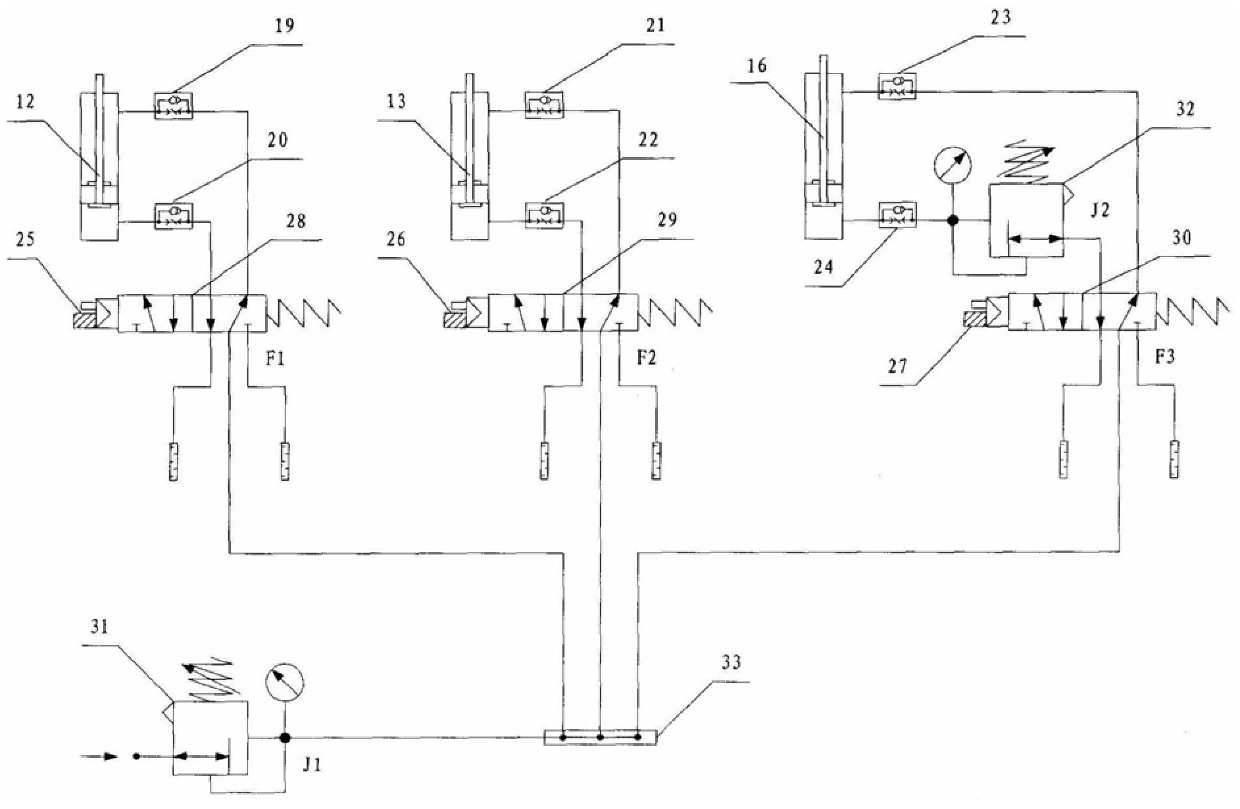

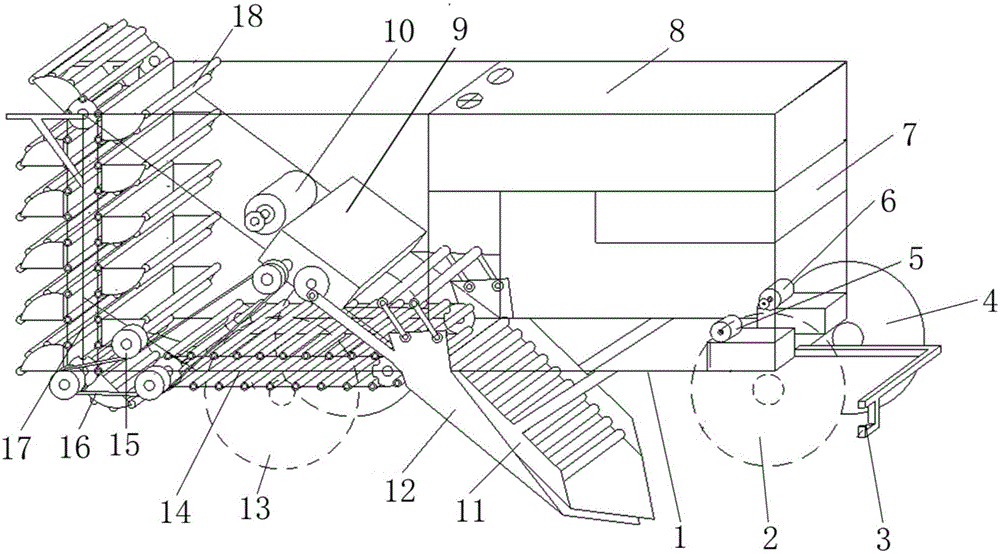

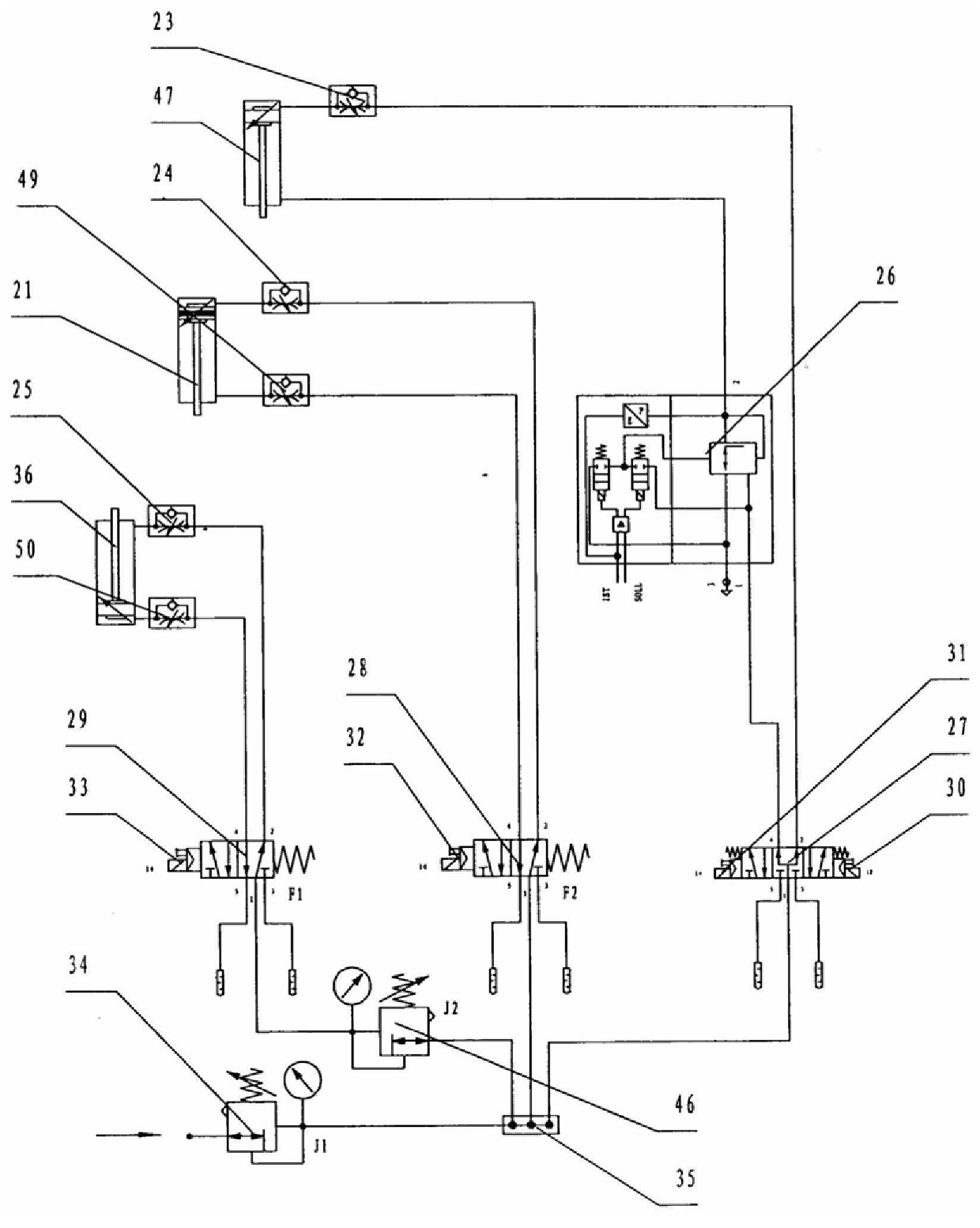

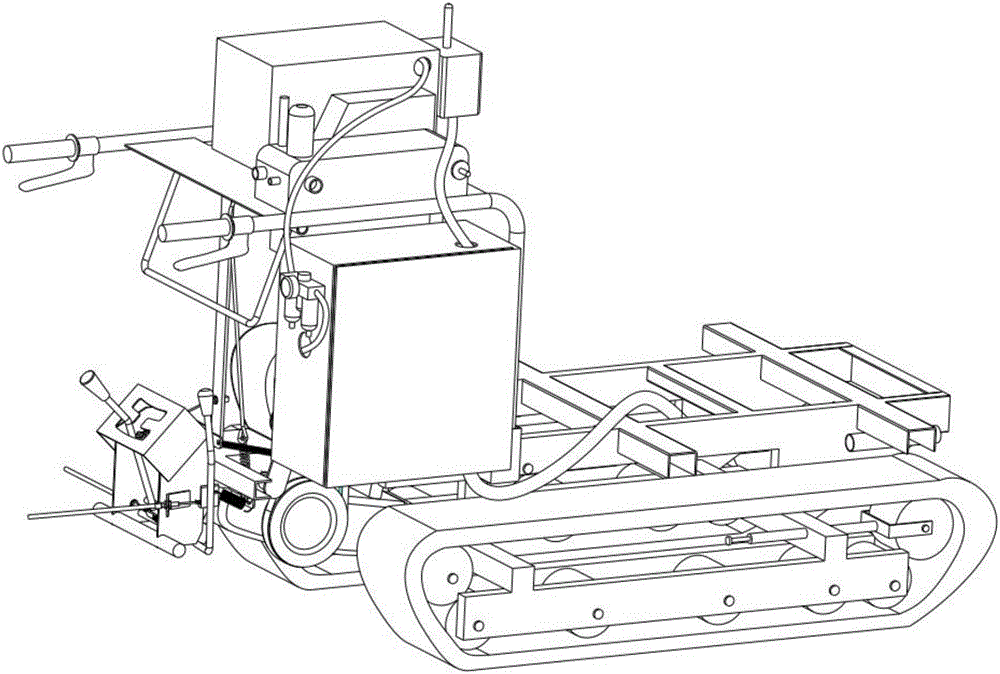

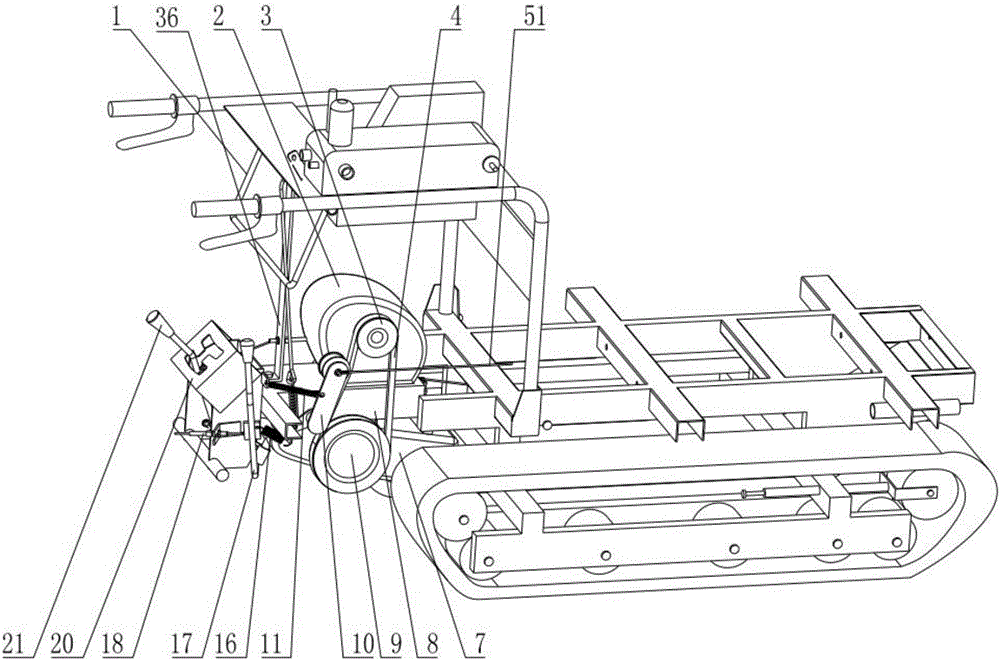

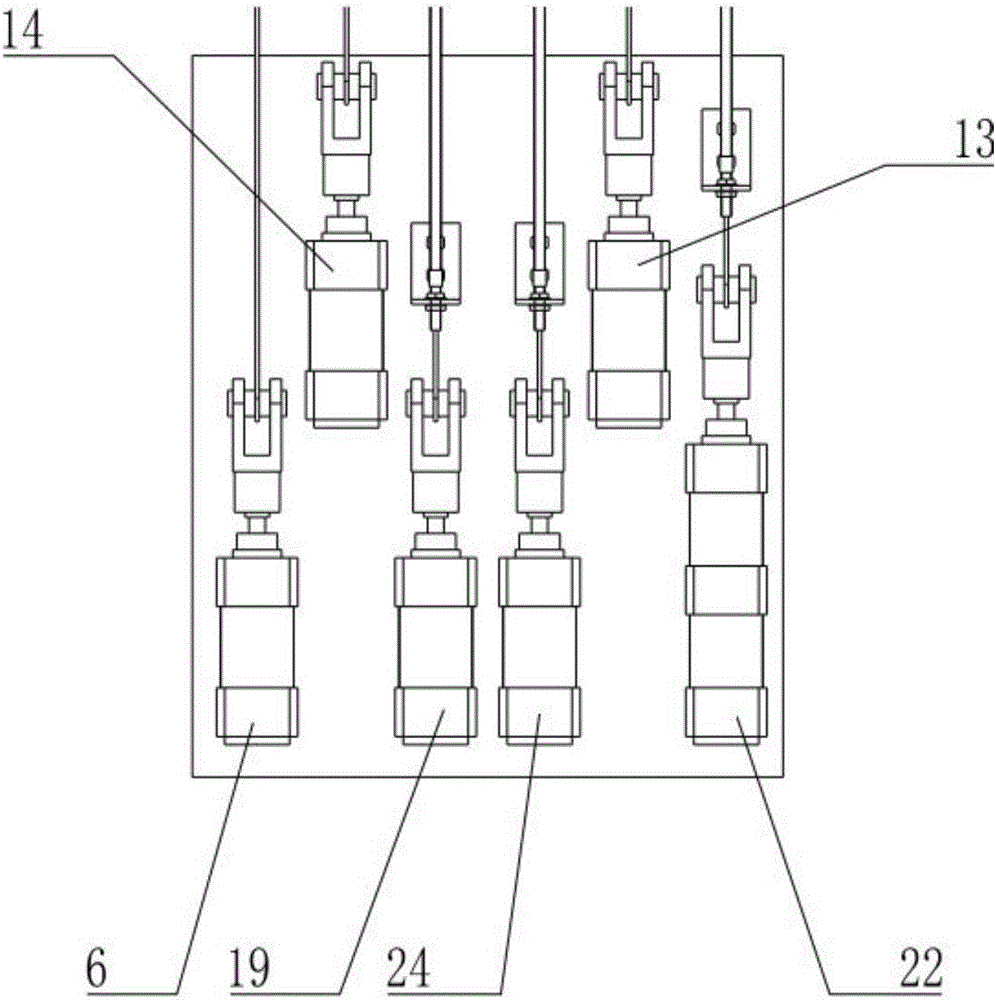

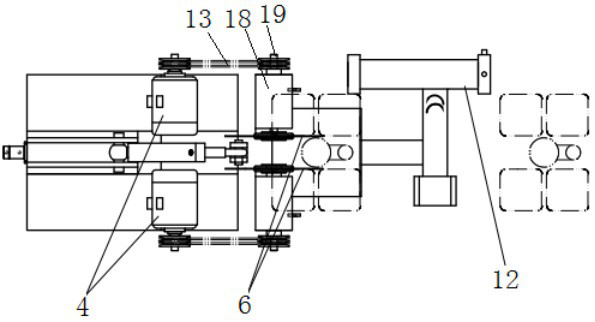

Self-propelled caterpillar band chassis vehicle remote control system and control method

InactiveCN106585742AEasy and stable operationEase of manual interventionEndless track vehiclesClutchPressure controller

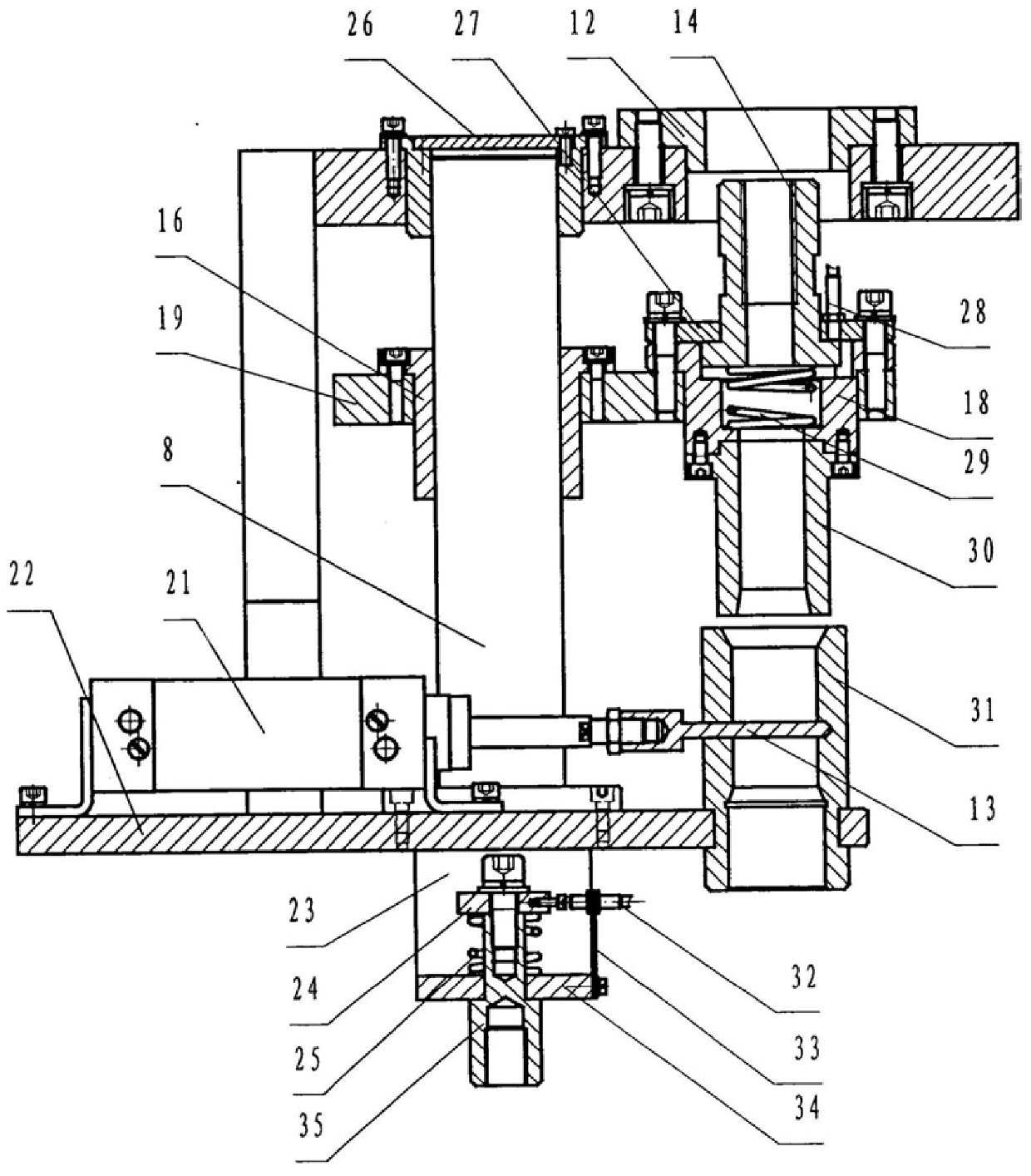

The invention belongs to the field of intelligent agricultural equipment and provides a self-propelled caterpillar band chassis vehicle remote control system which is used for remotely controlling a self-propelled caterpillar band chassis vehicle. The system comprises an execution unit, a pneumatic unit and a control unit. The execution unit comprises a left turning air cylinder (14), a right turning air cylinder (13), a clutch air cylinder (6), a high and low gear shifting air cylinder (19), a transverse multi-gear shifting air cylinder (22) and a longitudinal multi-gear shifting air cylinder (24). The pneumatic unit comprises an air pump (26), a one-way valve (27), an air storage tank (28), a pneumatic three-piece unit (29), a pressure controller (30), an overflow valve (31), a hand slide valve (32), a compensated flow control valve (33), an electromagnetic valve (34) and a position sensor (35). The control unit comprises a signal receiving device, a signal transmitting device and a programmable logic controller. The remote control system is quite suitable for working under the conditions of the limited working space, the complex road condition and the severe environment, man-machine separation is achieved, and working safety is guaranteed.

Owner:CHINA AGRI UNIV

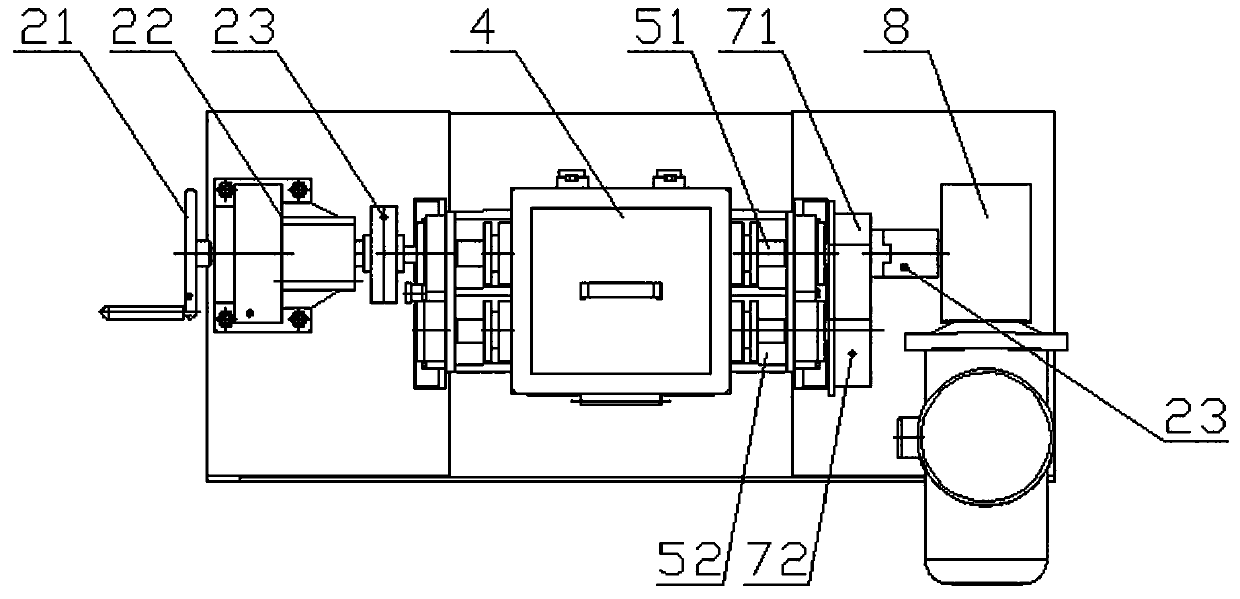

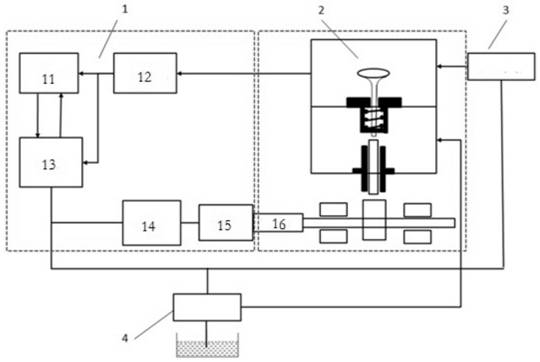

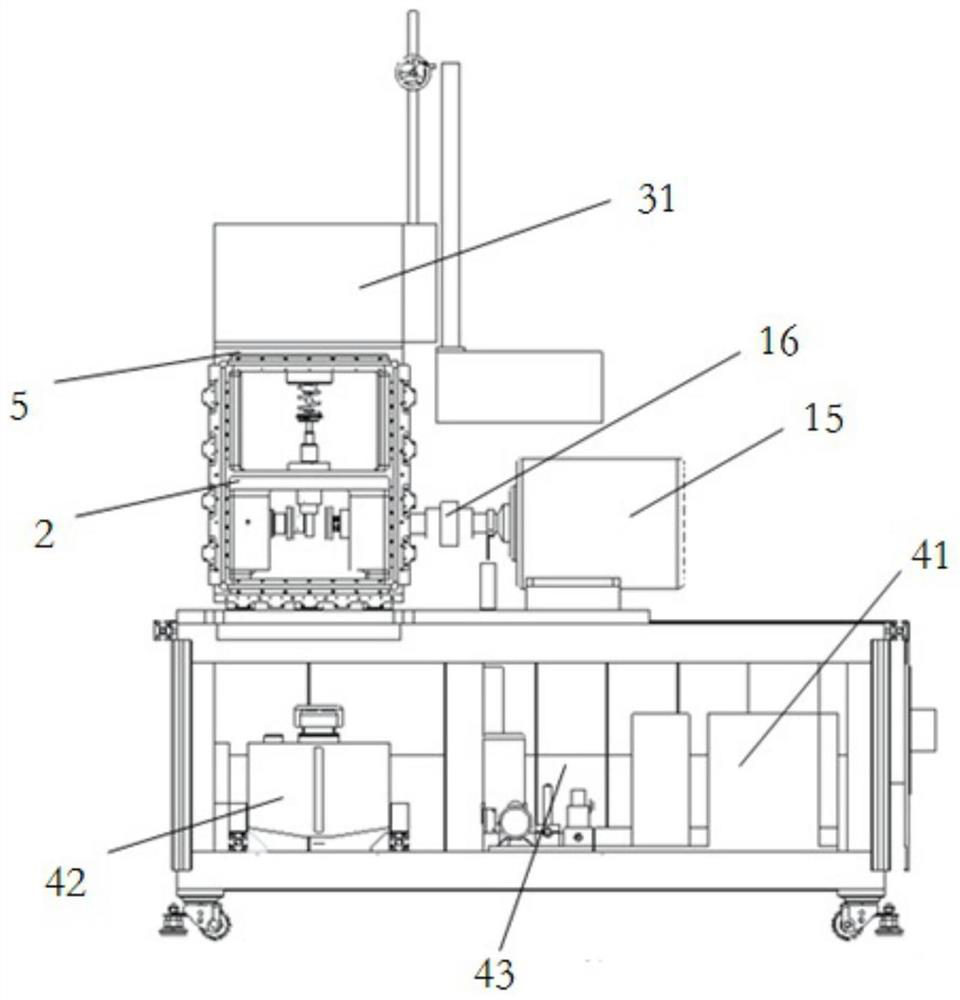

Enhanced wear test system with valve-valve seat ring

PendingCN112782017AIncrease seating forceIncrease preloadInvestigating abrasion/wear resistanceMatching testWorking temperature

The invention provides an enhanced wear test system with a valve-valve seat ring. The enhanced wear test system comprises a control system, a mechanical system, a heating system and a lubricating system. Compared with the prior art, the enhanced wear test system has the following advantages that the wear test system integrates a heating system, a lubricating system, a mechanical system and a control system, and mechanical load and thermal load can be simulated and loaded at the same time. An inverted valve-valve seat ring structure is adopted, the spring is strengthened, and the spring pre-tightening force and the spring rigidity are increased, so that the valve seating force is increased, the one-time abrasion test period is shortened to 7-10 hours, and the multi-scheme valve-seat ring matching test efficiency is greatly improved. A PLC is adopted to remotely control starting and stopping of the test bench, data acquisition and online monitoring of the operation state, man-machine separation is achieved, and the safety and reliability of the test process are improved. The resistance furnace capable of accurately controlling the heating temperature simulates a valve-seat ring working temperature field, so that a tested piece is in a high-temperature state in the whole test process.

Owner:CHINA NORTH ENGINE INST TIANJIN

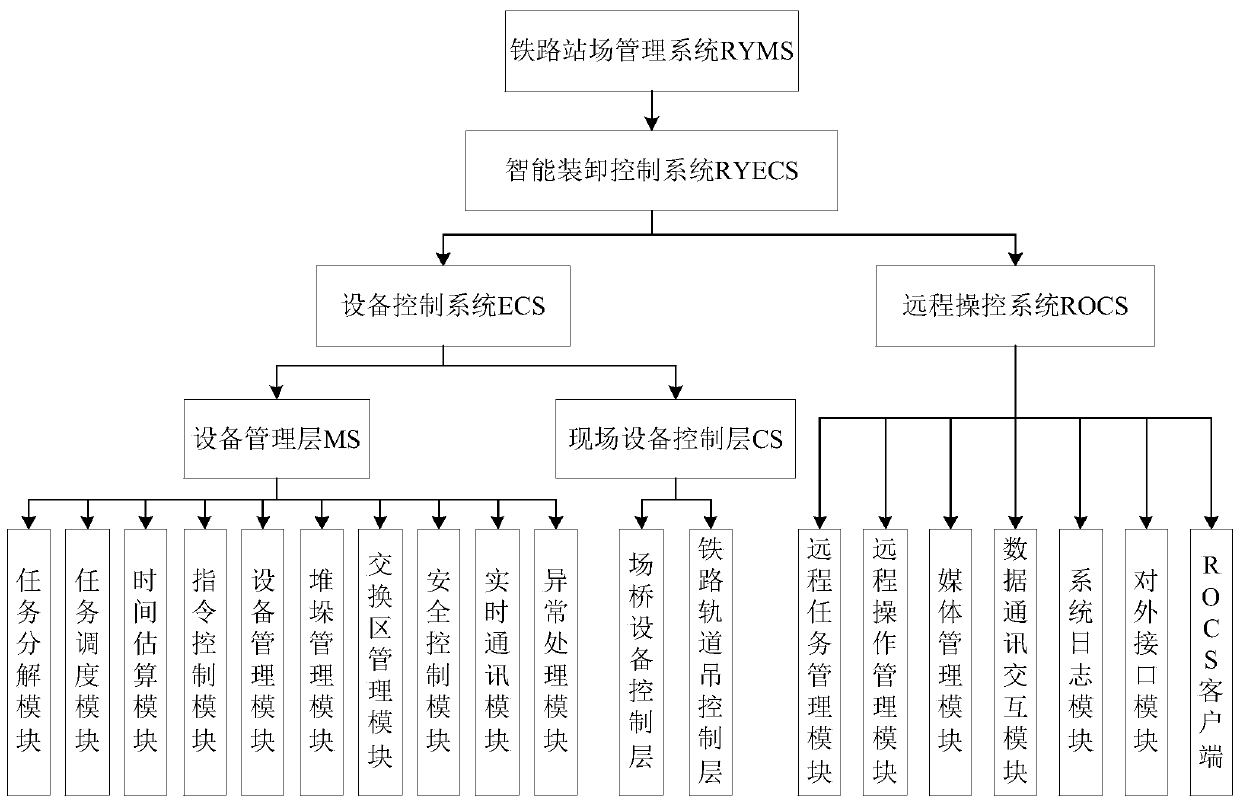

Railway yard container intelligent loading and unloading control system

InactiveCN110844790AReal-time interactionReal-time organic interactionLoad-engaging elementsControl systemRemote control

The invention discloses a railway yard container intelligent loading and unloading control system. The intelligent loading and unloading control system (RYECS) is responsible for receiving instructions from a railway yard management system (RYMS), automatically planning an operation route of mechanical equipment and controlling operation of the equipment, commanding the equipment to complete operation, meanwhile, feeding back operation states and results of relevant operation tasks to the railway yard management system (RYMS), the railway yard management system (RYMS) specifically comprises anequipment control system (ECS) and a remote control system (ROCS), the equipment control system (ECS) is used for controlling automatic loading and unloading equipment level events and processes, andthe remote control system (ROCS) is used for allowing technicians to monitor an operation state of an entire yard, and capable of controlling yard machines manually. The disclosed control system canimprove the safe reliability and the quality of service of railway yard operation, the loading and unloading efficiency of a railway yard is improved, the labor intensity and the operation risk of operating personnel of the railway yard are lowered, and intelligent development and upgrading of the railway yard are promoted.

Owner:OCEAN UNIV OF CHINA +1

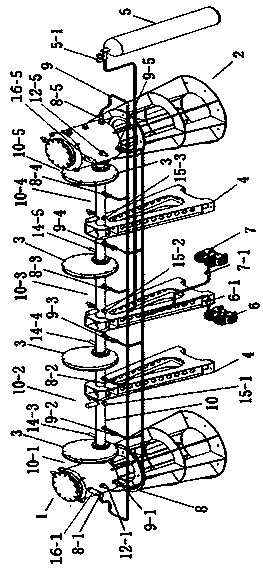

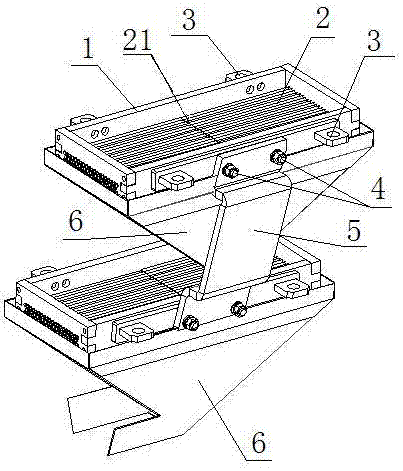

Vibration distribution and guide type gunpowder mixer

PendingCN107270777AFor the purpose of mixingRealize the separation of man and machineExplosive working-up apparatusFireworksFiberCarbon fibers

The invention relates to a vibration distribution and guide type gunpowder mixer comprising frames, gunpowder mixing rods, connection plates and vibrators. The number of the frames ranges from 2 to 10. The frames are connected through the connection plates. The gunpowder mixing rods are cylindrical rods made of carbon fiber materials and are arrayed in the frames on multiple layers. A gap exists between every two adjacent gunpowder mixing rods. When gunpowder is conveyed into the frames, under the pneumatic effect, the gunpowder is distributed downwards towards the two sides from the gunpowder mixing rods, and therefore the aim of mixing is achieved. The carbon fiber roller type multilayer arraying in the frames and pneumatic gunpowder mixing are adopted, manual work is replaced with machines, man-machine separation and man-gunpowder separation are achieved, and safety, high efficiency and the good gunpowder mixing quality are integrated; and potential safety hazards are eliminated, and the problems that static electricity is quite likely to be generated when gunpowder mixing is conducted through an existing mesh screen and the static electricity is accumulated because the static electricity cannot be released are solved. The vibration distribution and guide type gunpowder mixer is simple in structure, high in practicability, convenient to operate, low in labor intensity, high in efficiency, capable of saving time and labor, uniform in gunpowder mixing, safe and reliable.

Owner:刘伟平

Casting double-end cutting device

PendingCN112404583AHigh degree of automationImprove securityMetal sawing devicesMaintainance and safety accessoriesMan machineStructural engineering

The invention discloses a casting double-end cutting device. The casting double-end cutting device comprises a cutting device body and a control box used for complete machine control; the cutting device body is composed of a cutting unit and a self-centering clamping mechanism; the self-centering clamping mechanism is arranged at the front side of the cutting unit in an overturning manner througha 180-degree rack type overturning oil cylinder; and the cutting unit comprises a cutting workbench frame, a supporting arm installed on the cutting workbench frame in a sliding manner and a cutting mechanism movably connected with the supporting arm through a cutting machine ascending and descending oil cylinder. According to the casting double-end cutting device, man-machine separation can be achieved, the safety of an operator is greatly improved, the labor intensity of workers is reduced, and a large amount of manpower, material resources and cost are saved.

Owner:殷凯

Experiment device and experiment method for gas cloud combustion, explosion simulation and inerting, inhibition

ActiveCN102879416BRealize the separation of man and machineEasy to installMaterial exposibilityData acquisitionEngineering

The invention relates to the technical field of fire hazard safety, and especially relates to an experiment device and an experiment method for gas cloud combustion, explosion simulation and inerting, inhibition. The device comprises an experiment test system composed of an explosion experiment container tank, a flame and explosion pressure radial propagation detection device, an ignition device, a generated gas sampling analyzer, and a high-speed schlieren and data acquisition, a sample introduction system, a combustion explosion inerting inhibition system, and a control system composed of wireless synchronous control and computer remote monitoring, and is a multifunctional comprehensive experiment platform device. The invention realizes 180-degree rotation of the tank, data synchronous acquisition, gas distribution and sample introduction with precise proportions, synchronous and delayed multimode ignition and inhibition system ejection; wireless and wired data transmission is adopted for control; man-machine separation of the tank and the controlling person is realized; safety and reliability of data transmission are guaranteed; combustion or explosion and inerting and inhibition experiments of various experiment samples such as gas cloud, dust, oil mist, and the like can be carried out when the tank is in a vertical or horizontal state.

Owner:吉林市宏源科学仪器有限公司

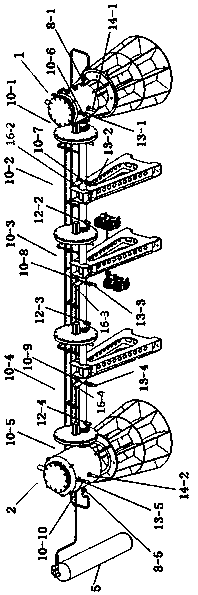

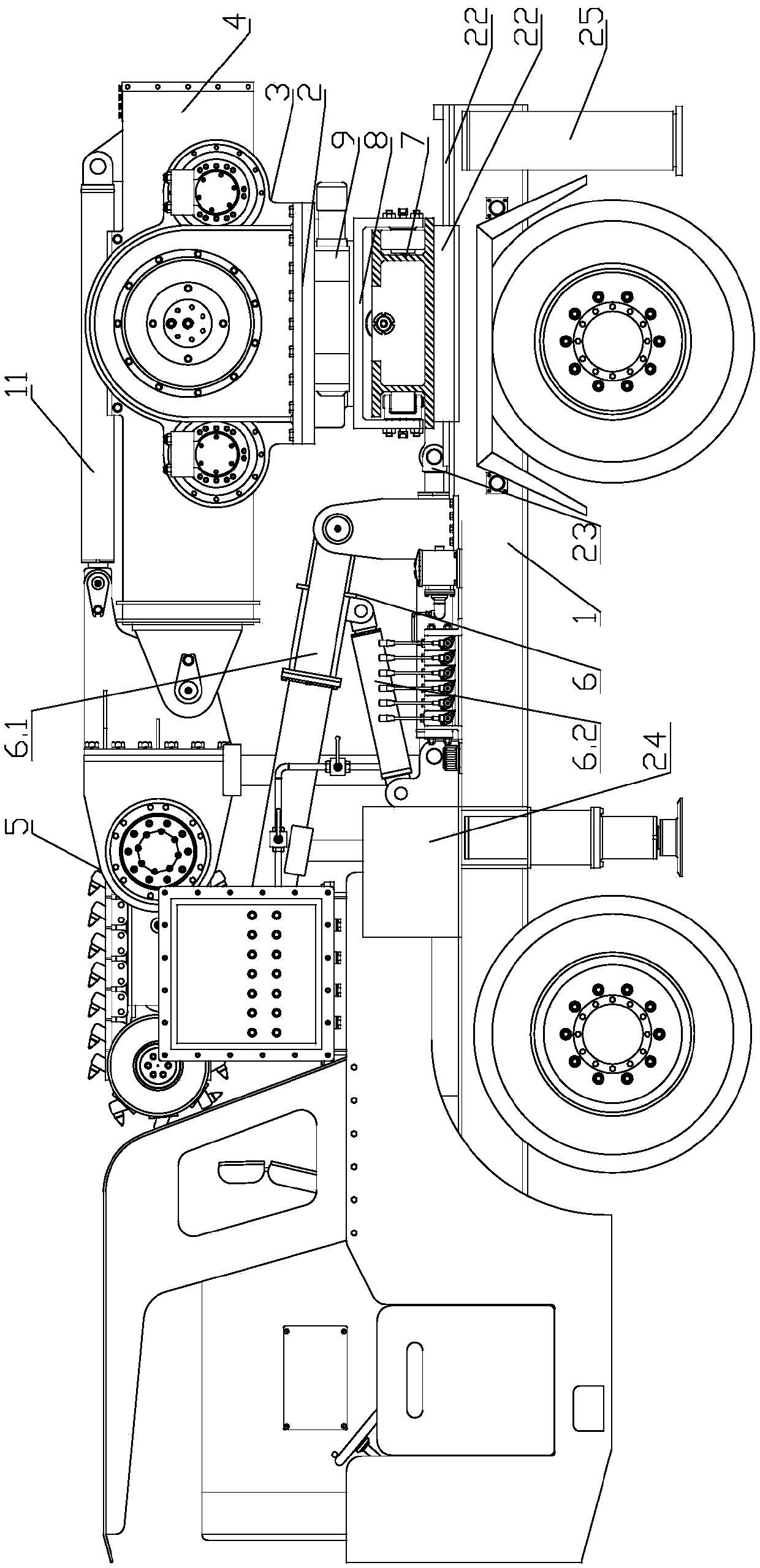

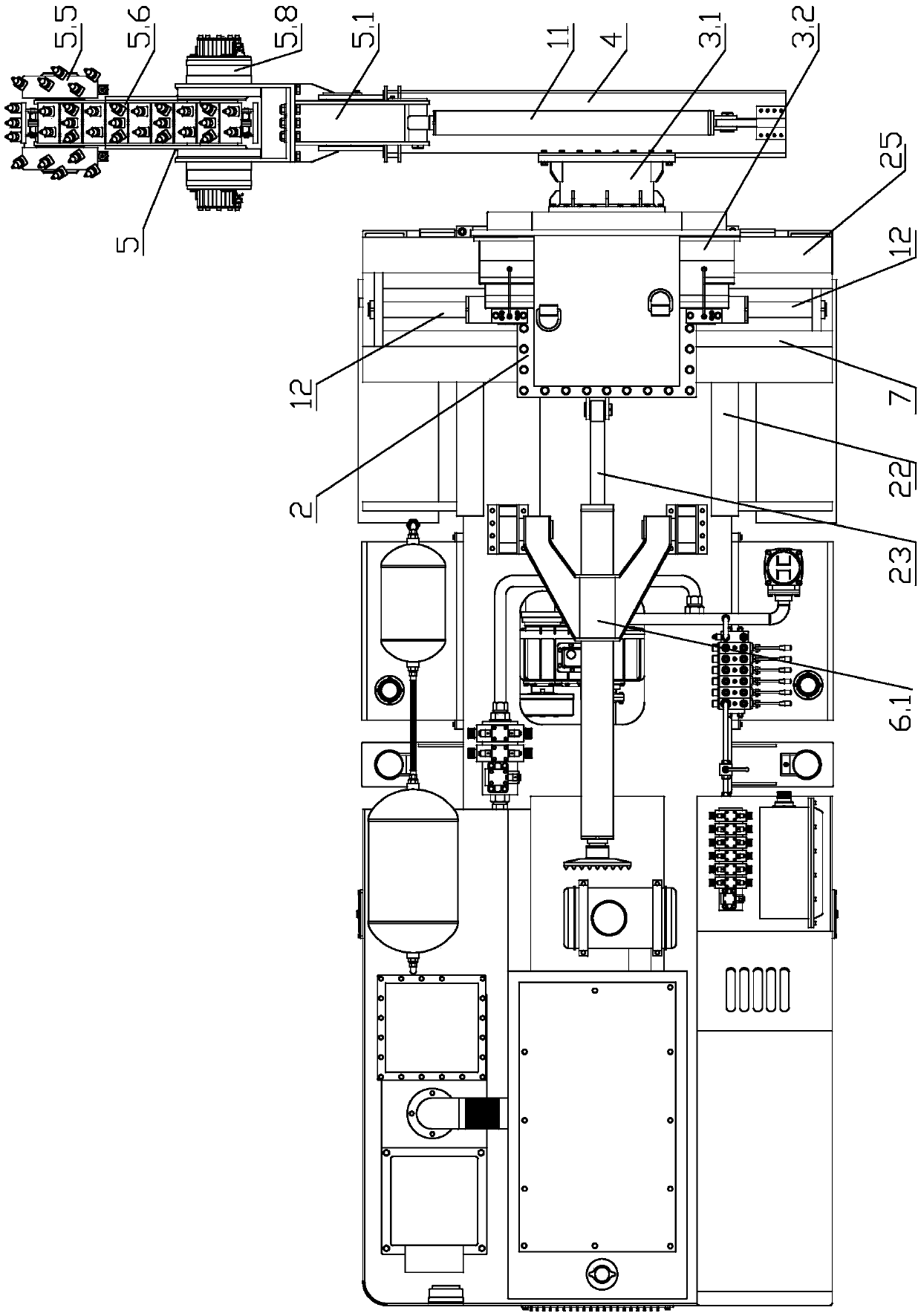

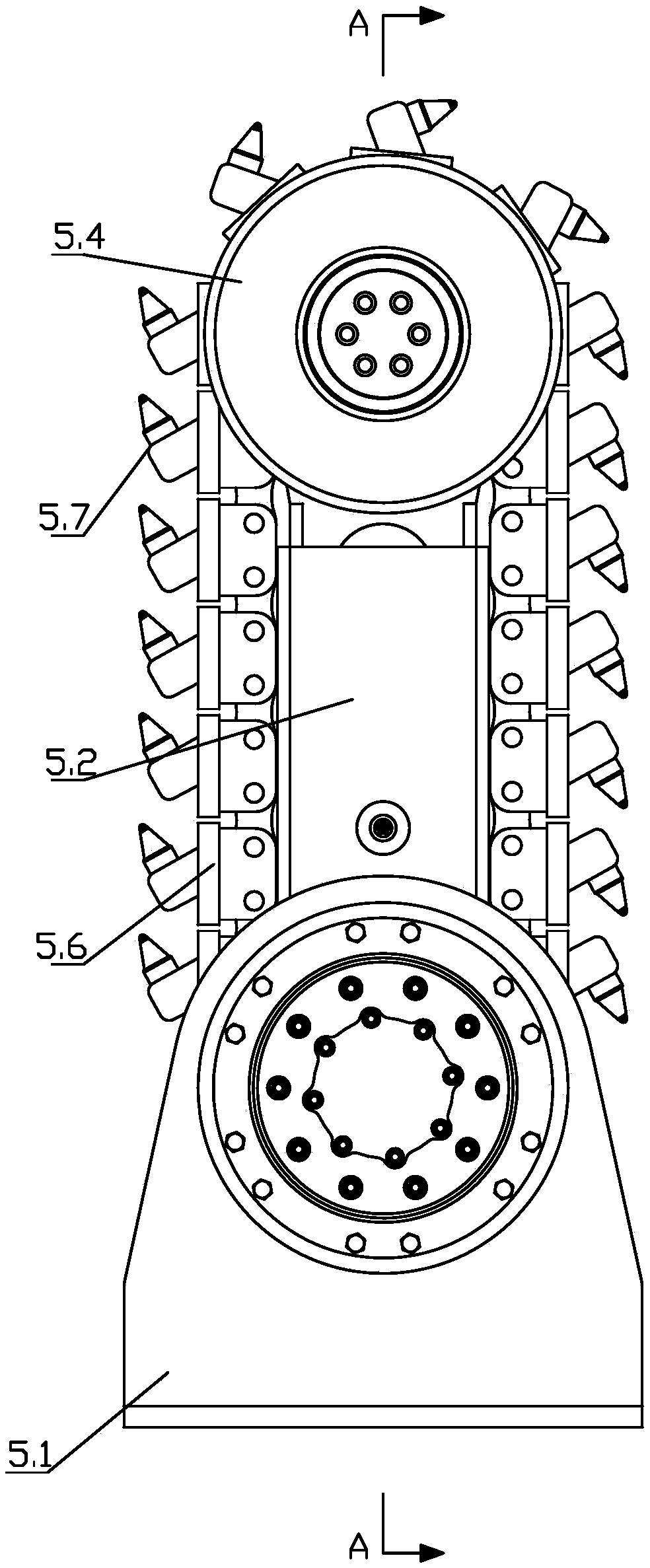

Rotary arm milling machine for coal mining roadway

PendingCN110043255AImprove visibilityRealize the separation of man and machineDriving meansPropulsionVisibilityRemote control

The invention discloses a rotary arm milling machine for a coal mining roadway. The rotary arm milling machine includes a walking chassis, a rotating table, a rotation mechanism, a suspension arm anda cutting part. The rotary arm milling machine has the advantages that 1, remote control can be achieved through a remote controller to achieve man-machine separation, the visibility of a cutting surface during work is good, no dead area exists, and the operation is facilitated; 2, through a sliding cylinder of a sliding rail and a sliding cylinder of the rotary table, the movement of the suspension arm and the cutting part on a sliding saddle in the front and rear directions and the left and right directions can be controlled, the distance is adjusted without moving a vehicle, and the operation efficiency is improved; 3, personnel can operate remotely, and the potential safety hazards are reduced; 4, the whole cutting part can penetrate into an operation surface, no cutting dead angle exists, and the rotary arm milling machine is suitable for slotting engineering work; and 5, an intermediate base material can be cut off by using cutting teeth on a cover plate chain, the cutting part does not need to swing from side to side, equipment is not prone to being damaged, the cutting efficiency is high, cutting teeth are arranged on the cover plate chain of the cutting part and a cuttingroller, the cutting part can penetrate directly into the cutting surface, the cutting depth can be formed in one time, and the cross section is smooth.

Owner:鄂尔多斯市智博机械制造有限责任公司

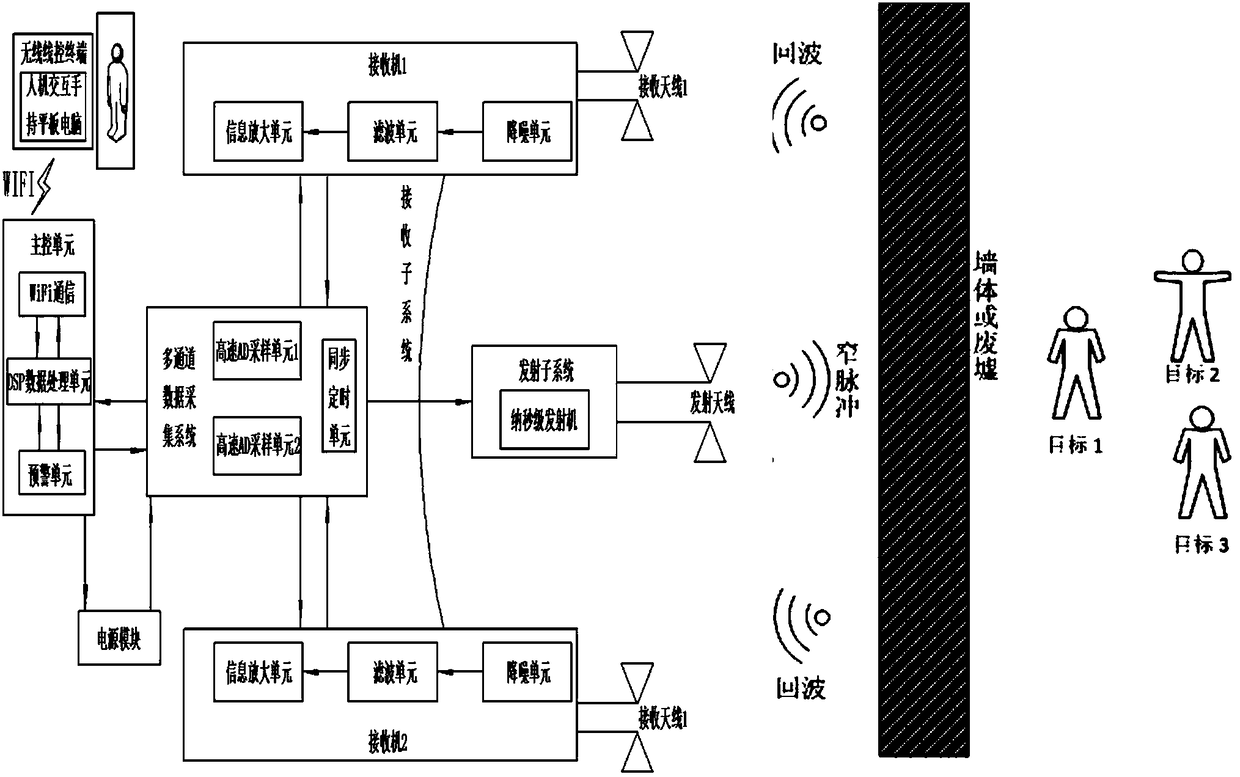

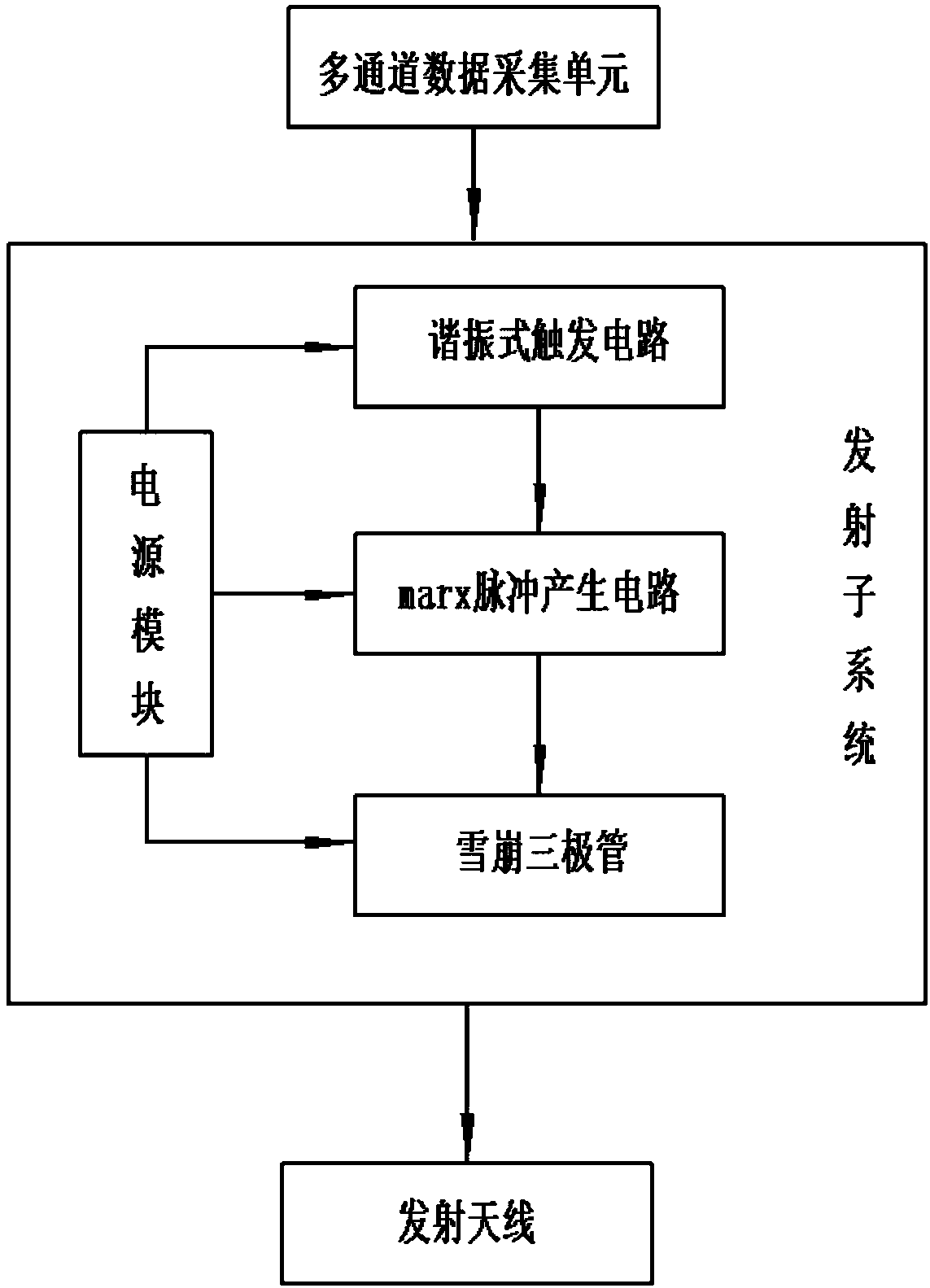

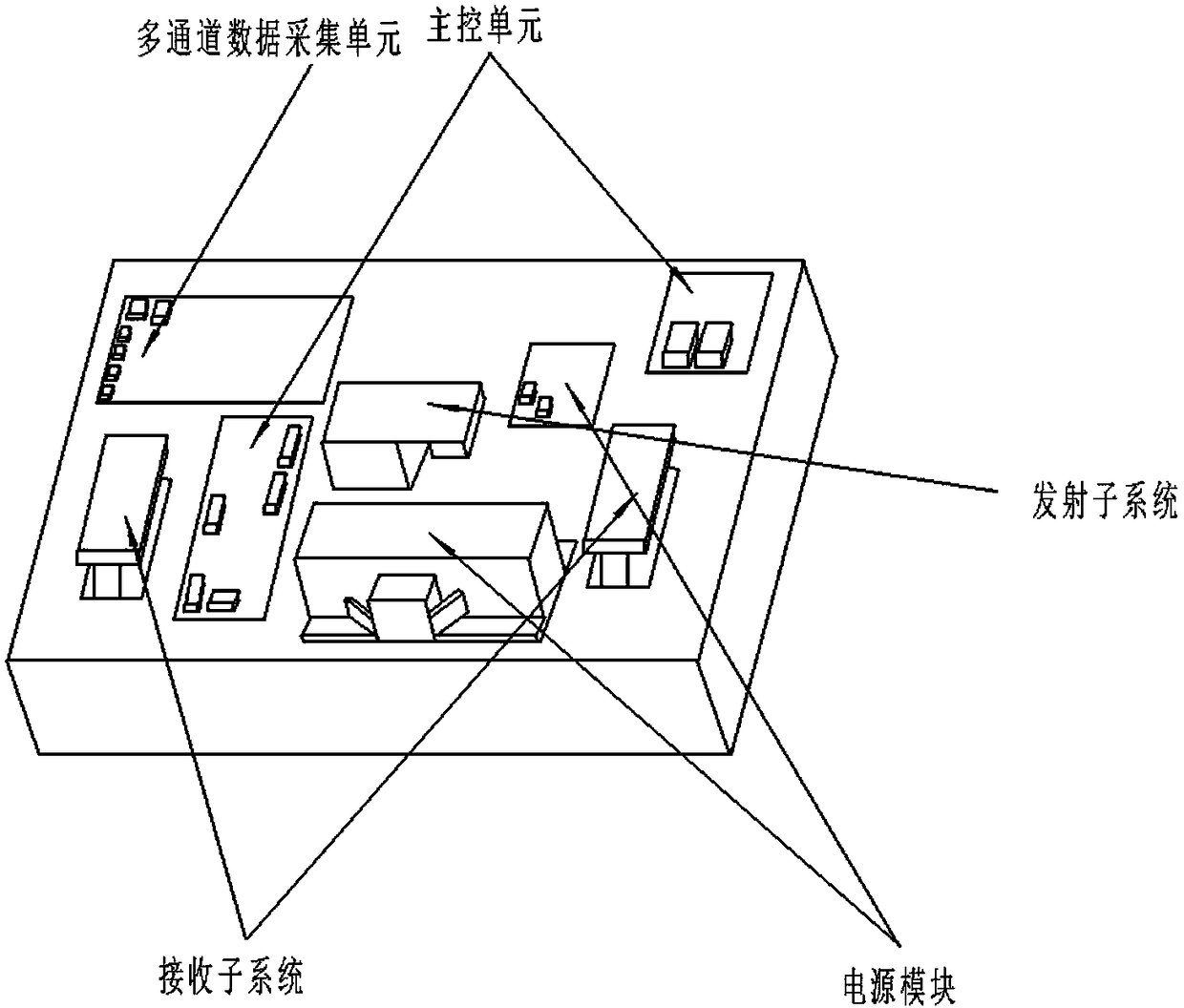

3D radar life detecting and positioning device with high resolution and high penetrability

ActiveCN108490435AStable synchronous superpositionImprove stabilityTransmission systemsRadio wave reradiation/reflectionCollection systemData acquisition

The invention discloses a 3D radar life detecting and positioning device with high resolution and high penetrability. The device comprises an emission subsystem, a reception subsystem, a multichanneldata collection system, a master control unit, a wireless display control terminal and a power supply module; the nanosecond level high-amplitude pulse emission subsystem is composed of a marx pulse generation circuit, three avalanche triodes and a resonant trigger circuit; echoes are received by the reception subsystem, processed by a noise reduction unit, a filtering unit and a signal amplification unit, and sent to the multichannel data collection system for sampling, a sampling result is input and output to the master control unit in which a Linux system is operated by a DSP data processing module and a WiFi communication in parallel, and bidirectional data communication of the wireless display control terminal is realized by 2.4GWiFi. Thus, the device can realize 3D life detection andpositioning, pulses are prevented from distortion, 3D simulated images are clearer, and received weak signals are stronger.

Owner:湖南正申科技有限公司

Automatic thermal protruding device for printed circuit board

PendingCN107750092AReduce the frequency of testing productsRealize the separation of man and machinePrinted circuit manufactureManipulatorPrinted circuit board

The invention provides an automatic thermal protruding device for a printed circuit board. The device comprises a device framework, and a group including a punch press platform, a carrying system platform and a loading and unloading platform and arranged on the device framework. The punch press platform is provided with a punch press. The punch press is provided with an upper mold loading plate. Alead screw is arranged on the carrying system platform and is provided with a carrying mechanism. The carrying mechanism includes a carrying Z-axis slide rail equipped with a mechanical arm corresponding to the upper mold loading plate. The loading and unloading platform is provided with a lead screw rack. The lead screw rack is provided with a loading and unloading mechanism and a mold opening and closing cover mechanism. The loading and unloading platform is also provided with a material tray corresponding to the loading and unloading mechanism. The automatic thermal protruding device improves the production efficiency of the product, reduces labor cost, eliminates the influence of the operators on the product quality, and enables the product to smoothly pass the reliability test of high temperature and high humidity.

Owner:SHANGHAI BOLE ELECTRONICS CO LTD

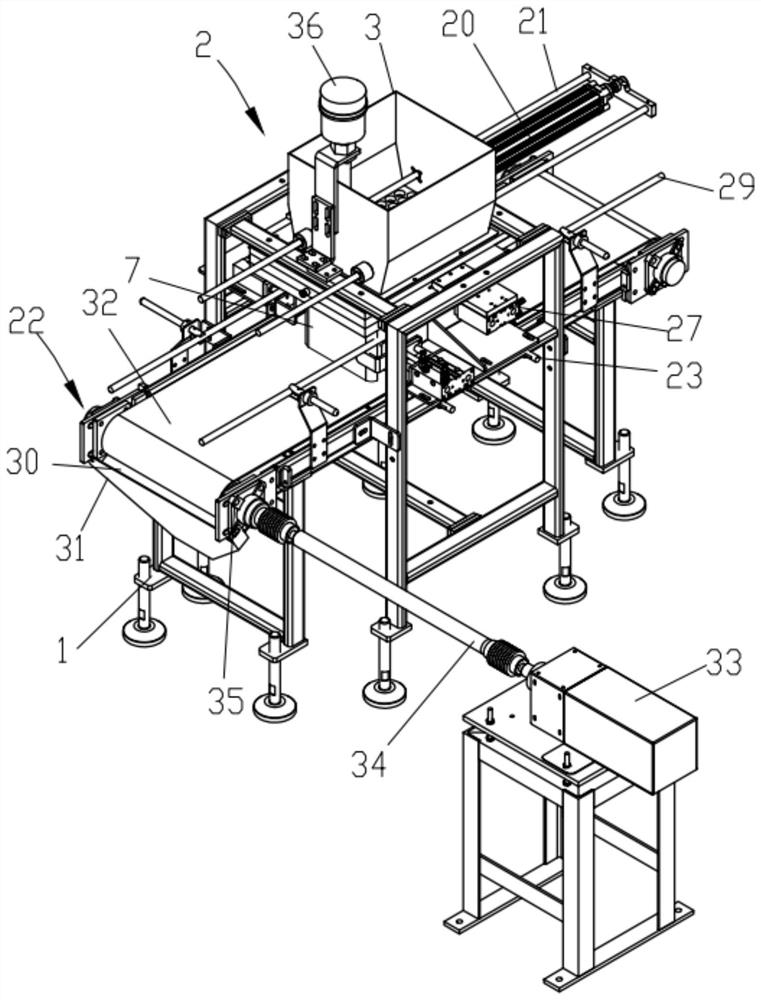

Firework propellant powder filling machine

The invention discloses a firework propellant powder filling machine. The firework propellant powder filling machine comprises a machine frame, a quantification device and a conveying device, whereinthe quantification device and the conveying device are mounted on the machine frame. The quantification device comprises a hopper, a panel, a quantification plate and a base plate, wherein the panel,the quantification plate and the base plate are mounted from top to bottom in a stacked mode, the panel is mounted on the lower side of an outlet in the bottom of the hopper, a base plate through holecorresponding to a filling hole in a firework cylinder on the conveying device is formed in the base plate, a quantification hole corresponding to the base plate through hole is formed in the quantification plate, a panel through hole corresponding to the quantification hole is formed in the panel, and the quantification plate is slidably connected between the panel and the base plate to alternately communicate the base plate through hole with the panel through hole. According to the firework propellant powder filling machine, full-automatic filling is adopted, so that the filling efficiencyis high, labor can be greatly saved, high labor intensity is eliminated, and meanwhile, stable and good product quality can be guaranteed.

Owner:浏阳市华冠出口花炮集团有限公司

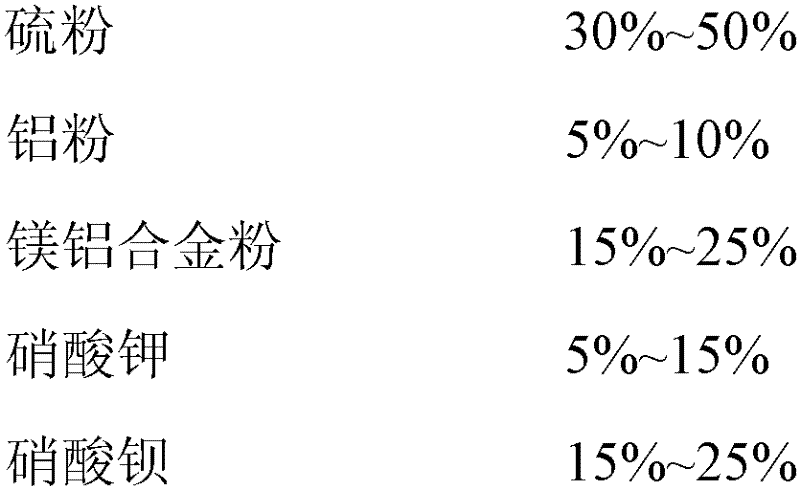

Method for preparing firework composition by boiling granulation process

InactiveCN102219625AImprove discharge performanceRealize the separation of man and machineExplosivesFirecrackerPrill

The invention relates to a method for preparing a firework composition by a boiling granulation process, and belongs to the technical field of fireworks and firecrackers. The method comprises: putting raw materials weighed according to a firework composition proportion into a closed container, mixing well the raw materials through a gas flow with a speed of 1 to 2 m / s, atomizing a binder solution, injecting the atomized binder solution into the closed container, processing the atomized binder solution and the raw materials into a granular composition through a gas flow with a speed rate of 1 to 2 m / s and a temperature of room temperature to 60 DEG C, and drying the granular composition to obtain firework composition products. Through adopting a boiling granulation process, the method realizes a man-machine separation and can produce firework composition products with the advantages of uniform particles, good flowability and no dust. Firework and firecracker products produced from the firework composition prepared by the method have a stable burning performance.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Automatic gluing device

ActiveCN110404733BHigh degree of automationIncrease productivityLiquid surface applicatorsCoatingsMan machineEngineering

The invention discloses an automatic gluing device, which comprises a frame, a transmission line arranged in the frame, a translation mechanism arranged on the frame, a rotation mechanism arranged on the translation mechanism, a grasping mechanism connected with the rotation mechanism and The gluing mechanism set on the frame, the translation mechanism can slide on the frame, the grasping mechanism and the rotation mechanism can slide on the frame synchronously with the translation mechanism, and the rotation mechanism can control the rotation of the grasping mechanism, and then drive the cover Rotate, the gluing mechanism can spray glue to the cylinder cover. During the rotation of the cylinder cover, the gluing mechanism can automatically and evenly apply glue on the outside of the cylinder cover. The translation mechanism drives the rotation mechanism and the grabbing mechanism to move synchronously on the machine. The cylinder cover is moved to the top of the cartridge for assembly. The invention has the advantages of simple structure, convenient operation, high degree of automation, and improved production efficiency; it completely realizes the separation of man and machine, and reduces potential safety hazards.

Owner:中国兵器装备集团自动化研究所有限公司

A kind of automatic drug charging method and drug charging machine for combined fireworks production

InactiveCN103512436BImprove securityHigh degree of automationFireworksProcess developmentBiochemical engineering

Owner:HENAN LINXIAO SCI & TECH DEV

A kind of remote control excavation mining method of end-assisted coal seam

InactiveCN104074521BSafe miningSafe and Efficient MiningUnderground miningSlitting machinesOutcropElectric control

The invention provides an end slope coal bed remote control excavating mining method, which belongs to an end slope residue coal resource extraction method and is used for open pit coal mine end slope and hillside outcrop and shallow surface coal bed mining. A coal mining system adopts a remote control excavating machine system, which comprises an excavating machine and a remote operating and control room, wherein operating and control equipment consists of three parts including a mining flameproof excavating machine electric control box, an excavating machine electric control box and an operating table; the operation function of long-distance wired control is realized; the man-machine separation is realized; and during the coal mining, people operate in a safe operation room. The main mining flow process comprises the steps of cleaning preparation, initial stage mining roadway pit selection, excavating and coal cutting by the excavating machine, coal loading by the excavating machine, belt extending, outward coal conveying by a belt, pile pouring by a loading machine, laneway exiting after coal excavating to a preset position, equipment withdrawing, overhauling, and preparation again for next roadway pit extraction. The end slope coal bed remote control excavating mining method has the characteristics that the coal resource extraction rate improved; the production process is simple, safe and efficient; and the production cost is low, and the like. The safe and efficient mining of open pit coal mine end slope remained coal resources is favorably realized.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com