Rotary arm milling machine for coal mining roadway

A milling machine and roadway technology, which is applied in the field of coal mining roadway rotary arm milling machines, can solve the problems of high labor intensity, inconvenient operation, and blind spots of sight, so as to reduce potential safety hazards, improve operation efficiency, and high cutting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

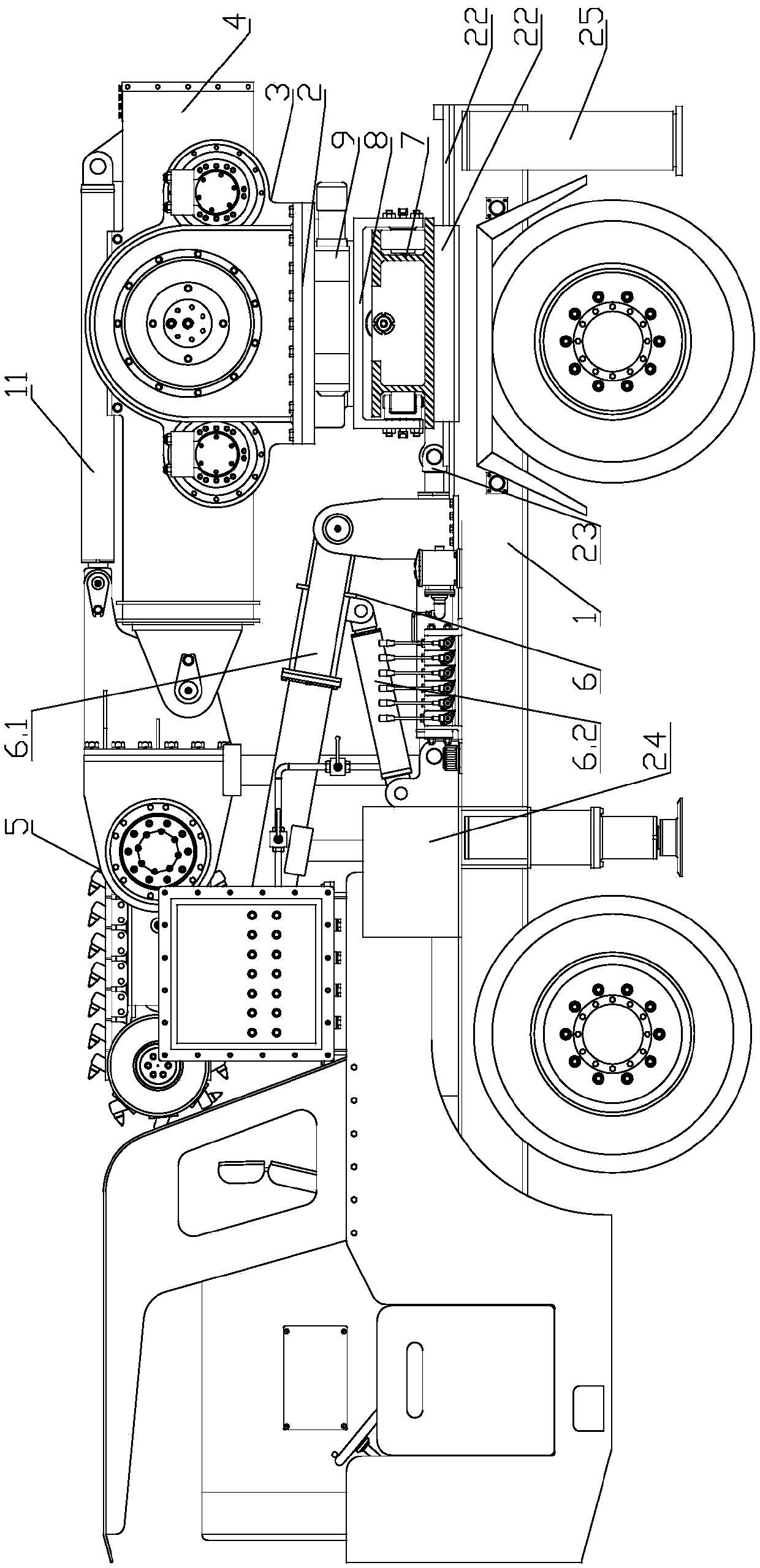

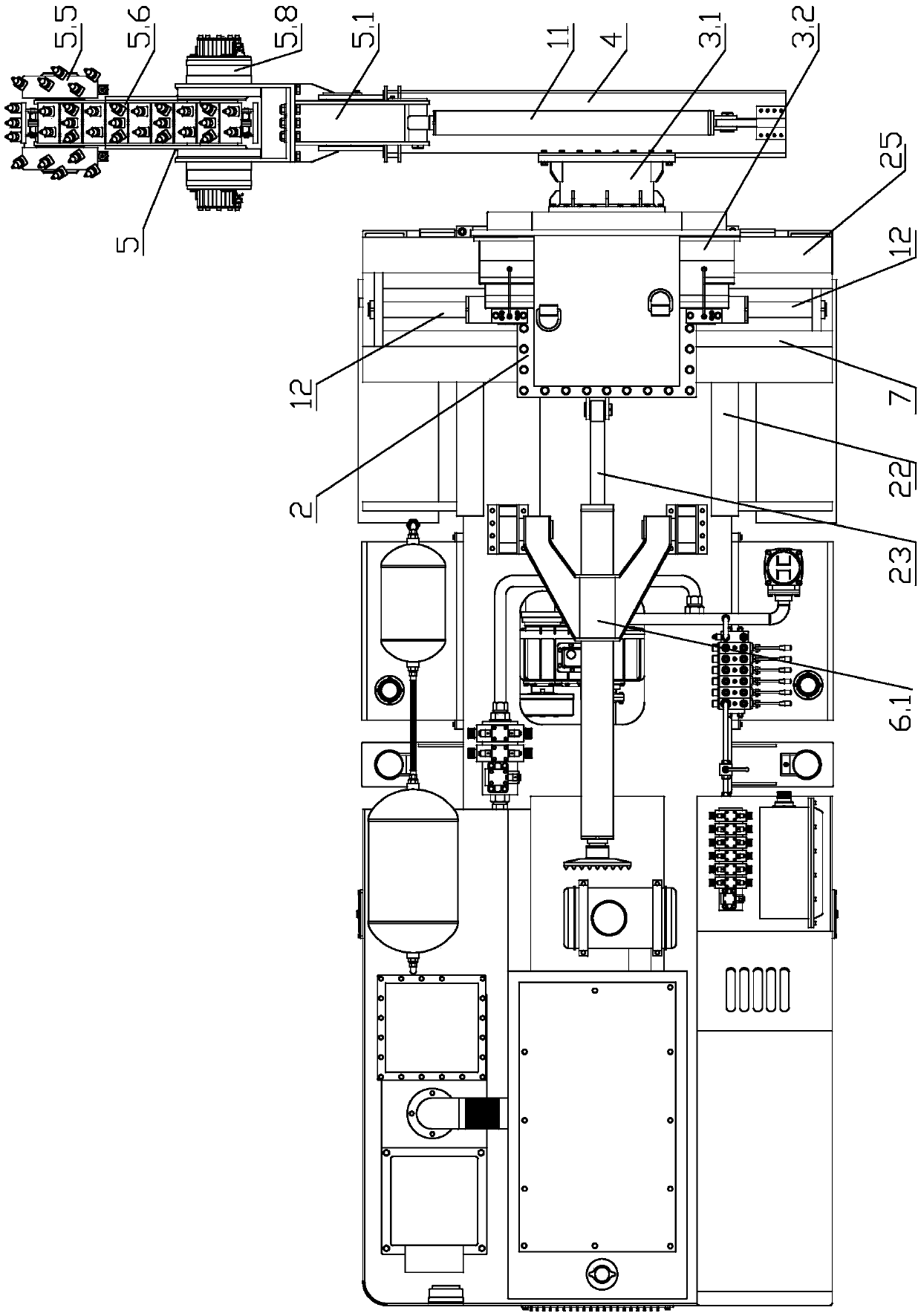

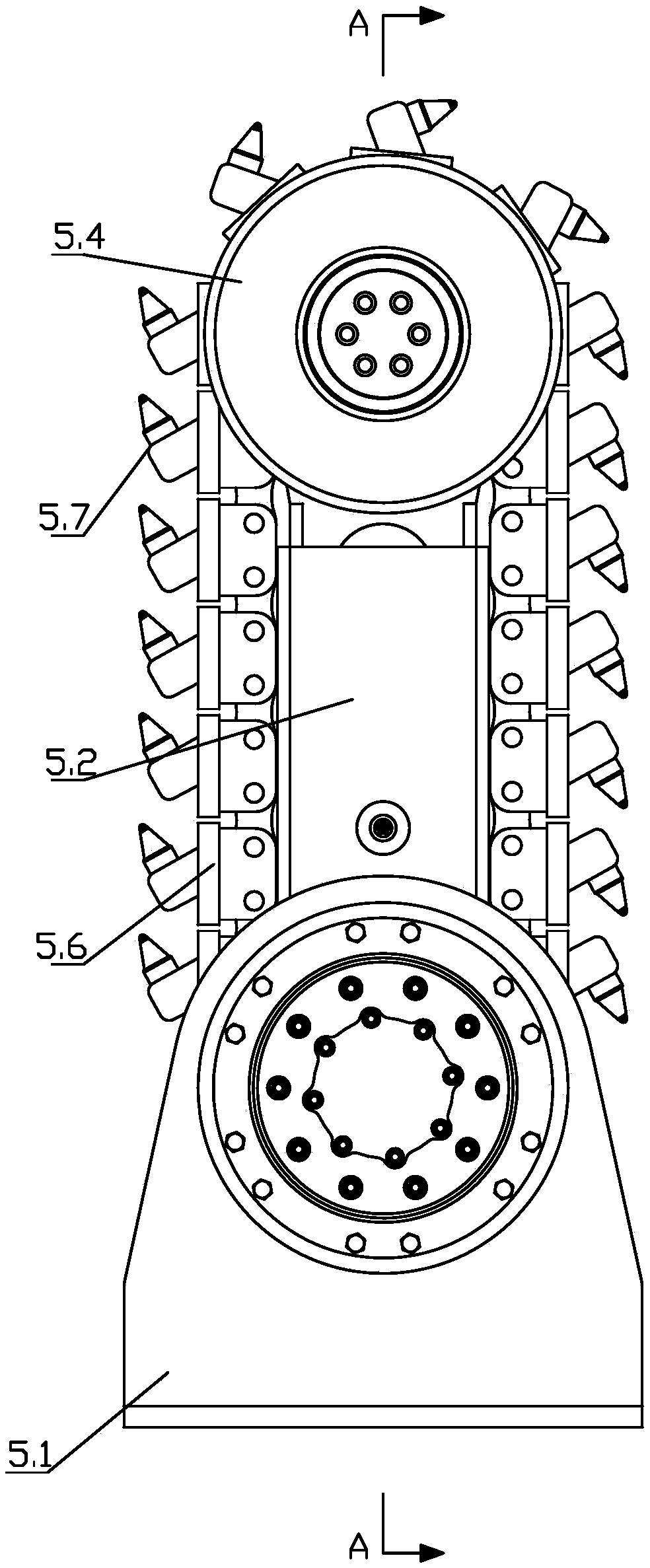

[0029] Such as Figure 1 to Figure 8 as shown,

[0030] A rotary arm milling machine for a coal mining roadway, which includes a traveling chassis 1, a turntable 2, a slewing mechanism 3, a suspension arm 4, and a cutting part 5,

[0031] A roadway support mechanism 6 is arranged in the middle part of the top of the walking chassis 1. The roadway support mechanism 6 includes a top cylinder 6.1 and a lifting cylinder 6.2. The cylinder bottom of the top cylinder 6.1 is hinged with the walking chassis 1. A lift cylinder 6.2 is hinged between the middle part and the walking chassis 1; the top cylinder 6.1 can be controlled to maintain a vertical support state or a downward retraction state through the expansion and contraction of the lift cylinder 6.2;

[0032] Support plate 6.3 is fixed on the telescoping rod top of support cylinder 6.1, and support plate 6.3 can increase support area, makes the support of support cylinder 6.1 and roadway top more stable; More than one outrigge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com